Efficient cutting equipment for automotive cables

A technology for automotive cables and cutting equipment, which is applied in the direction of cutting/dividing cable equipment, cable installation, and cable installation devices, and can solve problems such as low cutting efficiency, unsatisfactory cutting effect, and inability to cut multiple cables. Achieve the effect of improving cutting efficiency and saving working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

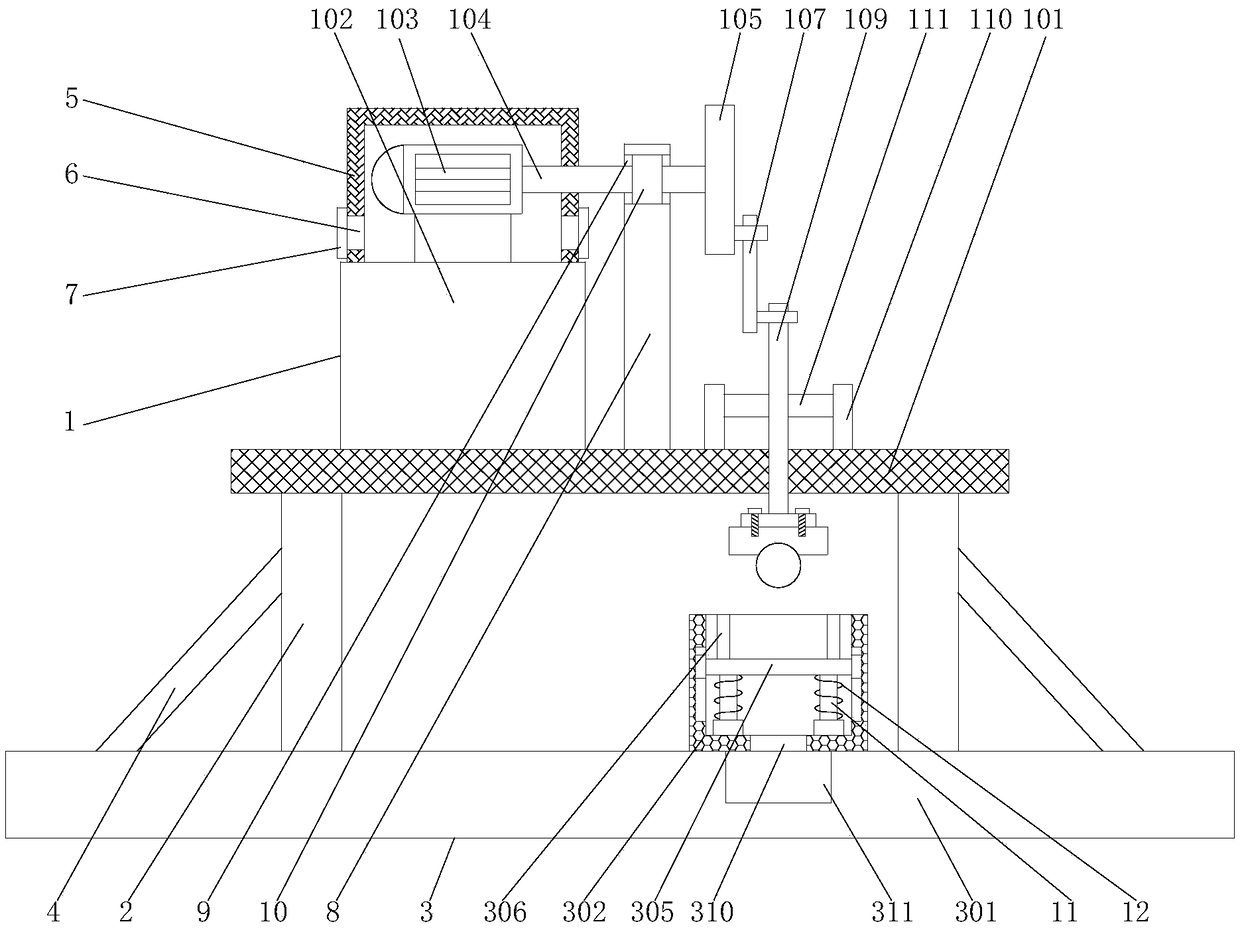

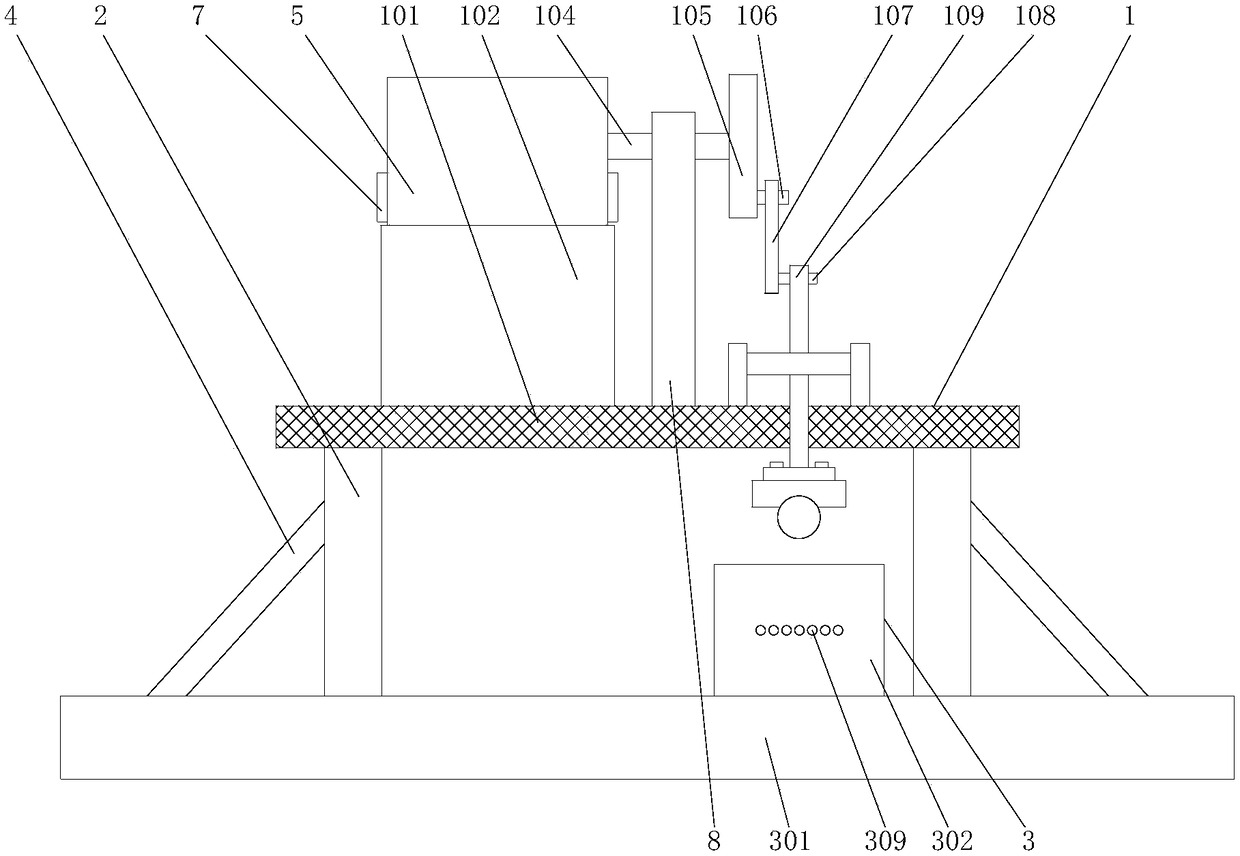

[0025] The invention provides a cutting device 1 and a limiting device 3 of a high-efficiency cutting device for automotive cables. The cutting device 1 is arranged on the top of the leg 2, and the limiting device 3 is arranged on the bottom of the leg 2. According to the needs of the work, due to different The automobile cable radii and materials of the parts are different, and the fixing block 112 and the mounting block 113 are separated from each other by rotating the fixing bolt 114, and then according to actual work needs, the cutting blades 115 of different sizes and materials are replaced to avoid the cutting blade 115 being unable to Car cables are effectively cut, resulting in reduced cutting efficiency, and because the cutting blade 115 is in the cutting state and used for a long time, the cutting blade 115 will be worn or broken, so it is convenient to replace the cutting blade 115 and facilitate the maintenance of the equipment.

Embodiment 2

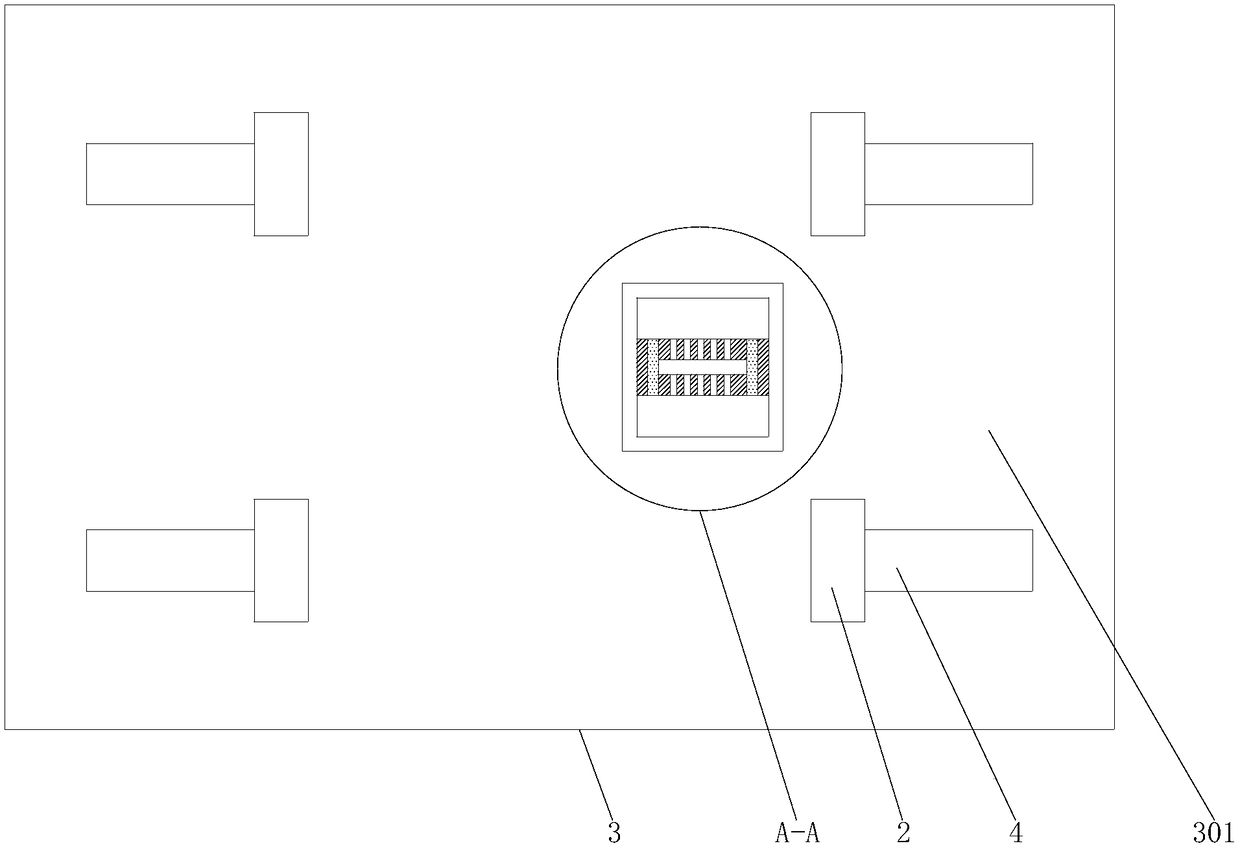

[0027] The cutting motor 103 drives the turntable to rotate through the cutting shaft 104, the turntable 105 drives the rotating rod 107 through the first rotating shaft 106, and the rotating rod 107 drives the cutting rod 109 to rotate through the second rotating shaft 108. The position limit makes the cutting rod 109 reciprocate up and down, and puts a plurality of automobile cables into the housing 302 through the limit groove 309. Since the limit groove 309 and the fixing groove 308 are mutually adapted, the automobile cables are put into place. Into the fixing groove 308, the automobile cable is limited by the fixing groove 308, protruding from the opposite side of the limiting groove 309, when the cutting rod 109 drives the cutting blade 115 to move downward, the cutting blade 115 penetrates into the housing 302 Among them, the cutting blade 115 passes through the cutting groove 307, the first through groove 310 and the second through groove 311 in turn to cut off the aut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com