Annular hot air blow-drying equipment for welding cables

A technology for welding cables and rings, which is applied in the manufacture of cables/conductors, circuits, electrical components, etc., can solve the problems of not easy to remove moisture and unsatisfactory effects, and achieves improved drying effect, improved drying effect, and strong practicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

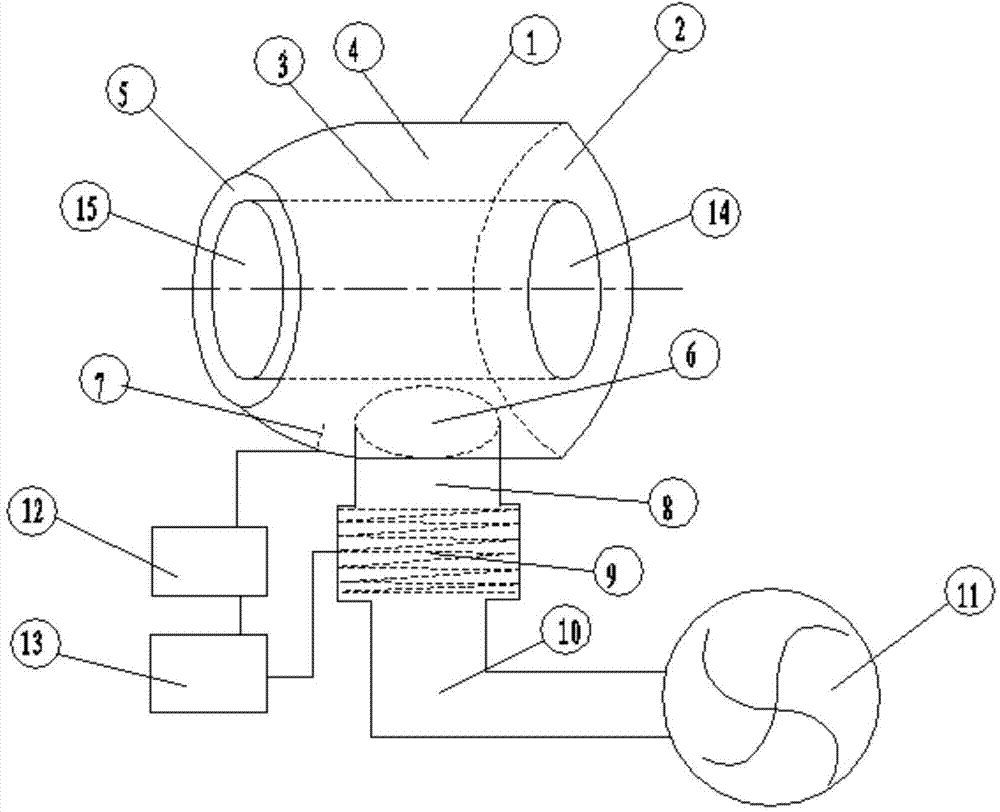

[0017] Ring-shaped hot air drying equipment for welding cables, including the inner tube 3 and the shell 1, the inner tube and the shell are placed horizontally, the shell is coaxially sleeved on the outside of the inner tube, and the inner tube is on the right side The connection between the inlet 14 of the cable and the right end surface of the housing is connected by a mounting plate to form a closed end surface 2, and there is a gap between the outer wall of the inner tube passing through the line and the inner wall of the housing to form an air cavity 4, and the outlet line on the left side of the inner tube passing through the line A blowing port 5 is formed between the port 15 and the left end surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com