Patents

Literature

42results about How to "Blow drying effect is good" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

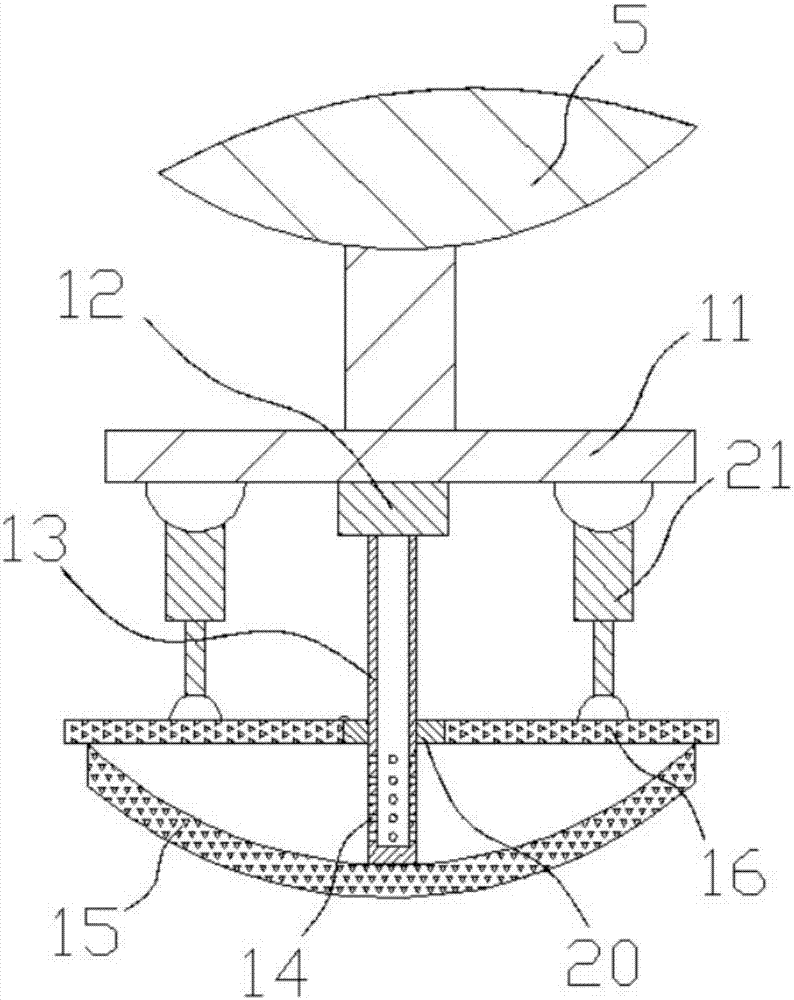

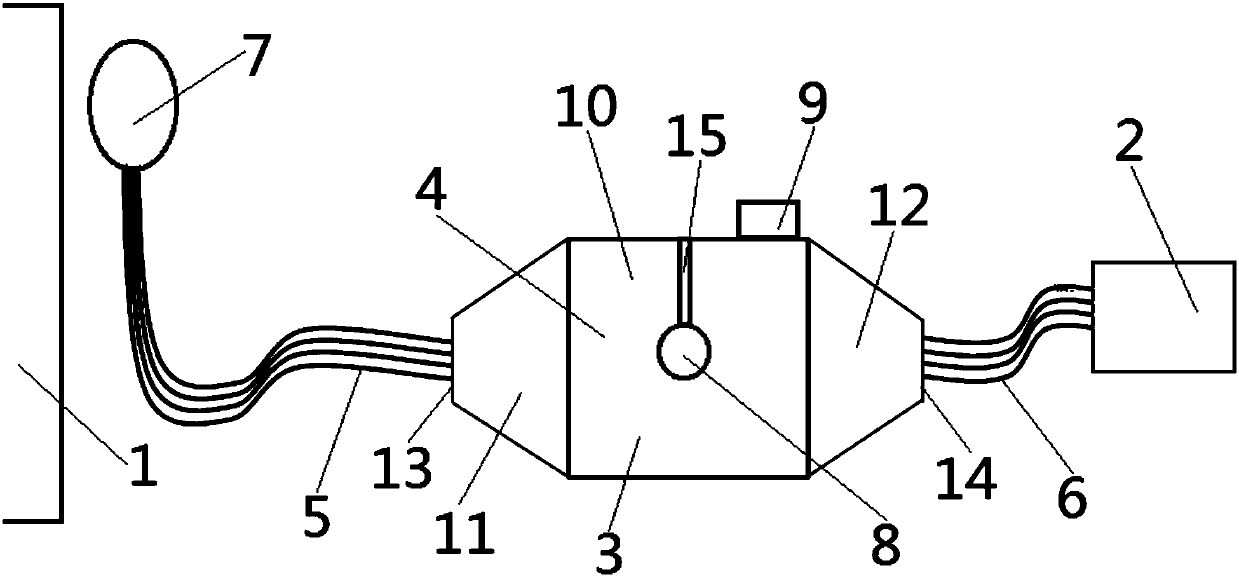

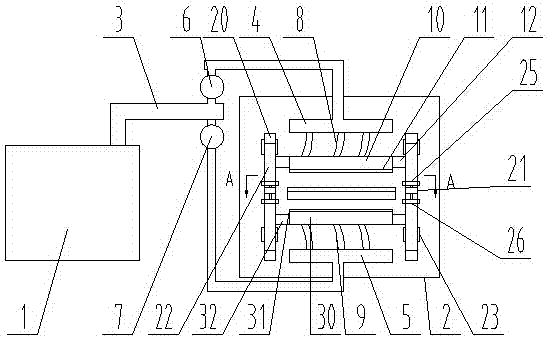

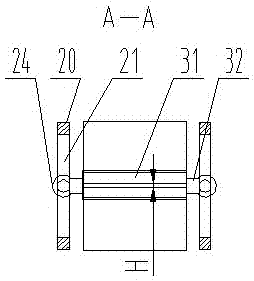

Electromagnetic wire drying device

ActiveCN102760540AEffectively blow offReasonable structureCable/conductor manufactureCopper wireAcute angle

The invention discloses an electromagnetic wire drying device which comprises a fan, an air inlet pipe, a blowing mechanism and a support. The electromagnetic wire drying device is characterized in that the blowing mechanism comprises a shell, a partition is arranged in the shell, the shell is divided into an air outlet cavity positioned at the center and an air inlet cavity positioned outside the center by the partition, the air inlet pipe is communicated with the air inlet cavity, the front center and the rear center of the air outlet cavity are respectively provided with a through hole, electromagnetic wires pass through the through holes, at least one slit-shaped air hole is arranged on the partition or between the partition and the shell, the air holes are opposite to the movement direction of the electromagnetic wires, and an acute angle is formed between each air hole and the corresponding electromagnetic wire. The electromagnetic wire drying device solves the problems that an existing copper wire drying device is provided with overlarge blow holes, air speed cannot be effectively increased, and further blowing effects are affected. The electromagnetic wire drying device has the advantages of reasonable structure and fine drying effects.

Owner:NEWONDER SPECIAL ELECTRIC

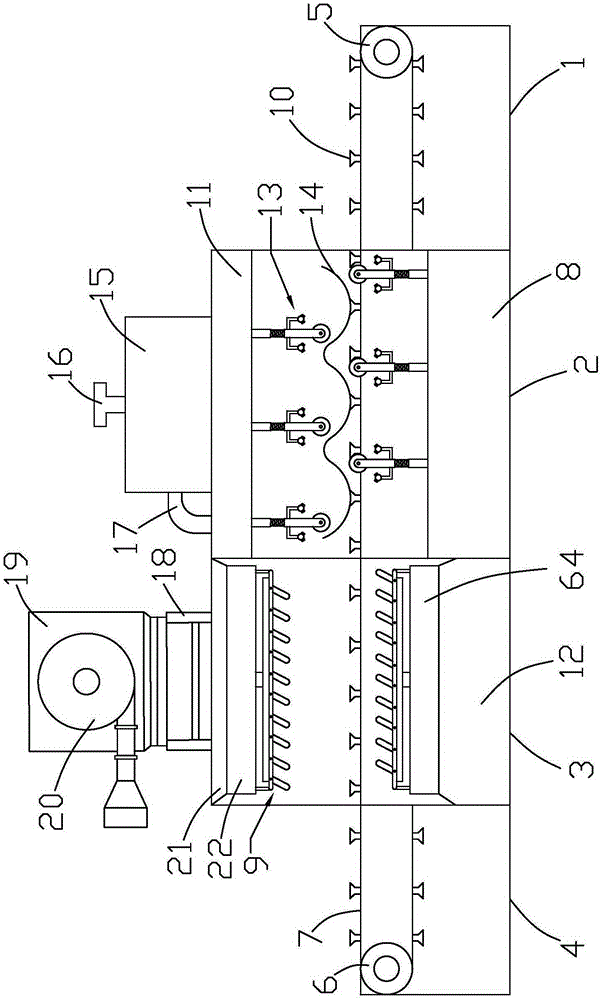

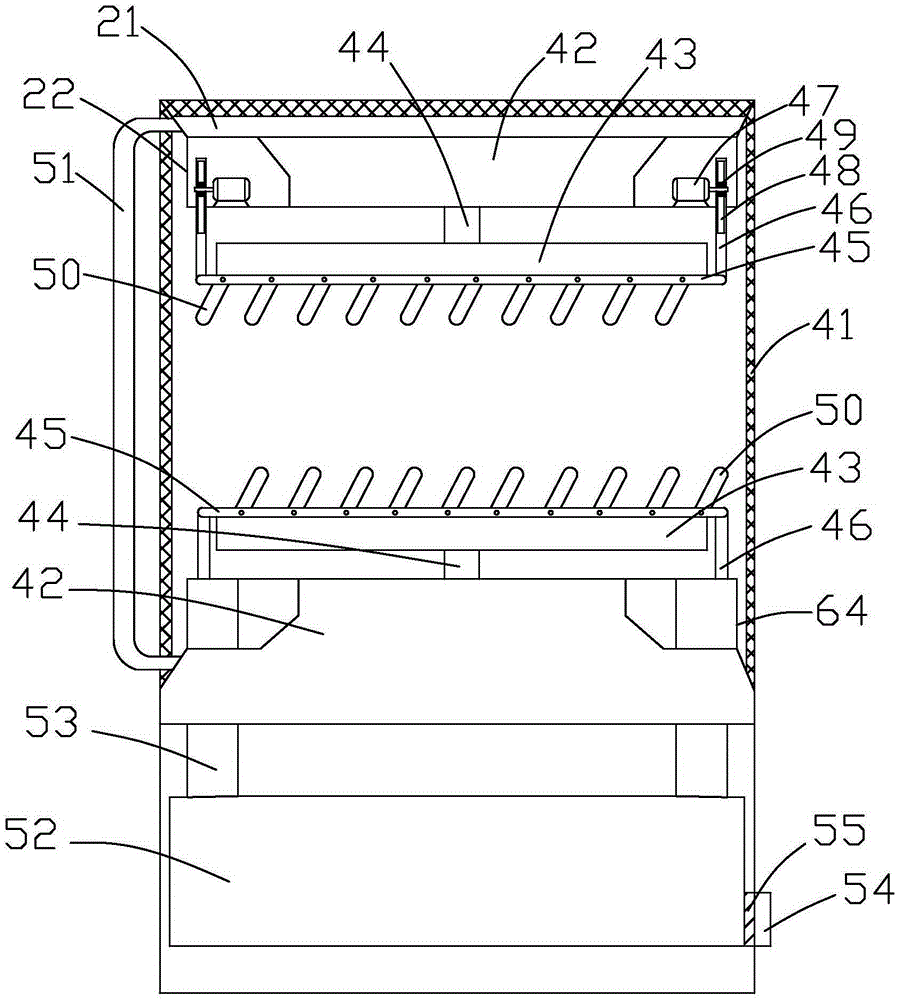

Curved glass cleaning machine

The invention discloses a curved glass cleaning machine. The curved glass cleaning machine comprises a charging tank, a cleaning tank, a drying tank and a discharging tank, wherein a driving wheel is arranged on the charging tank, and a driven wheel is arranged on the discharging tank; the driving wheel passes through the cleaning tank and the drying tank through a conveying belt and is connected with the driven wheel; elastic adsorption heads are uniformly arranged on the conveying belt; a first base and a suspension beam are arranged in the cleaning tank; a cleaning device is arranged in the suspension beam; a top plate is arranged on the top surface of the drying tank, and a second base is arranged on the bottom surface of the drying tank; a first air supply tank is arranged on the bottom surface of the top plate, and a second air supply tank is arranged on the top surface of the second base; a pressurization cavity is formed inside the first air supply tank; a pressurization cavity and a flow guide pipe are arranged in the second air supply tank; blowing mechanisms are arranged at the bottom of the first air supply tank and the top of the second air supply tank respectively. The curved glass cleaning machine is simple in structure and high in practicality, the requirements for cleaning and drying of both plane glass and curved glass can be met, the machine is convenient and flexible to use, and the production cost is reduced.

Owner:SHENGZHOU HUANDING GLASS TECH CO LTD

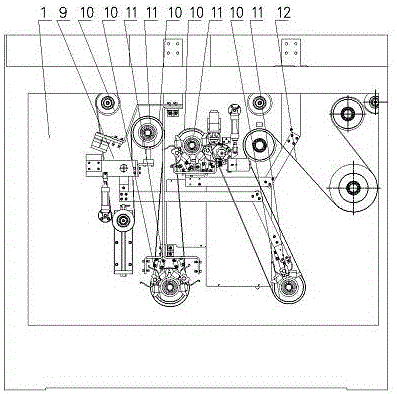

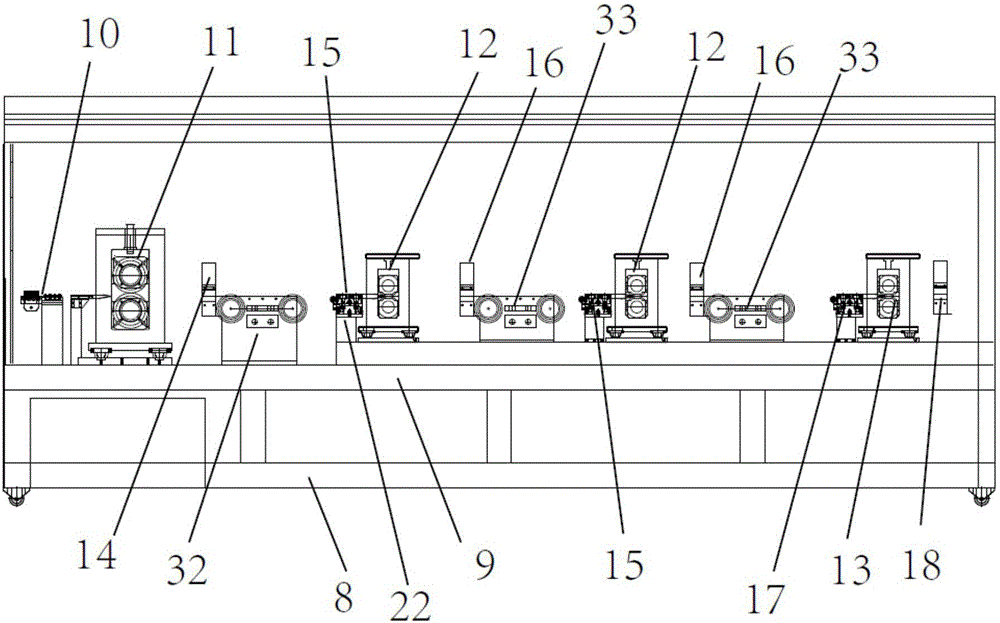

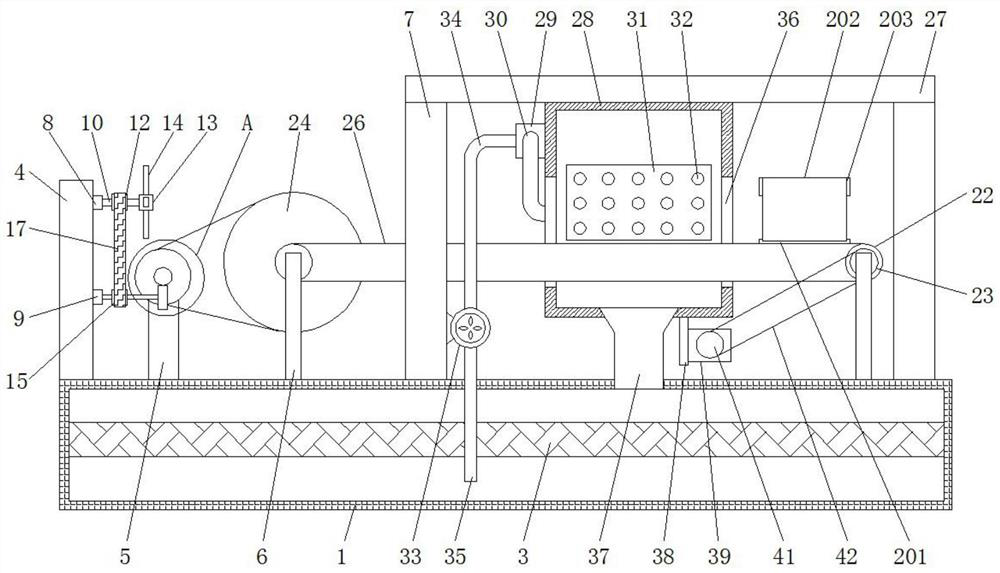

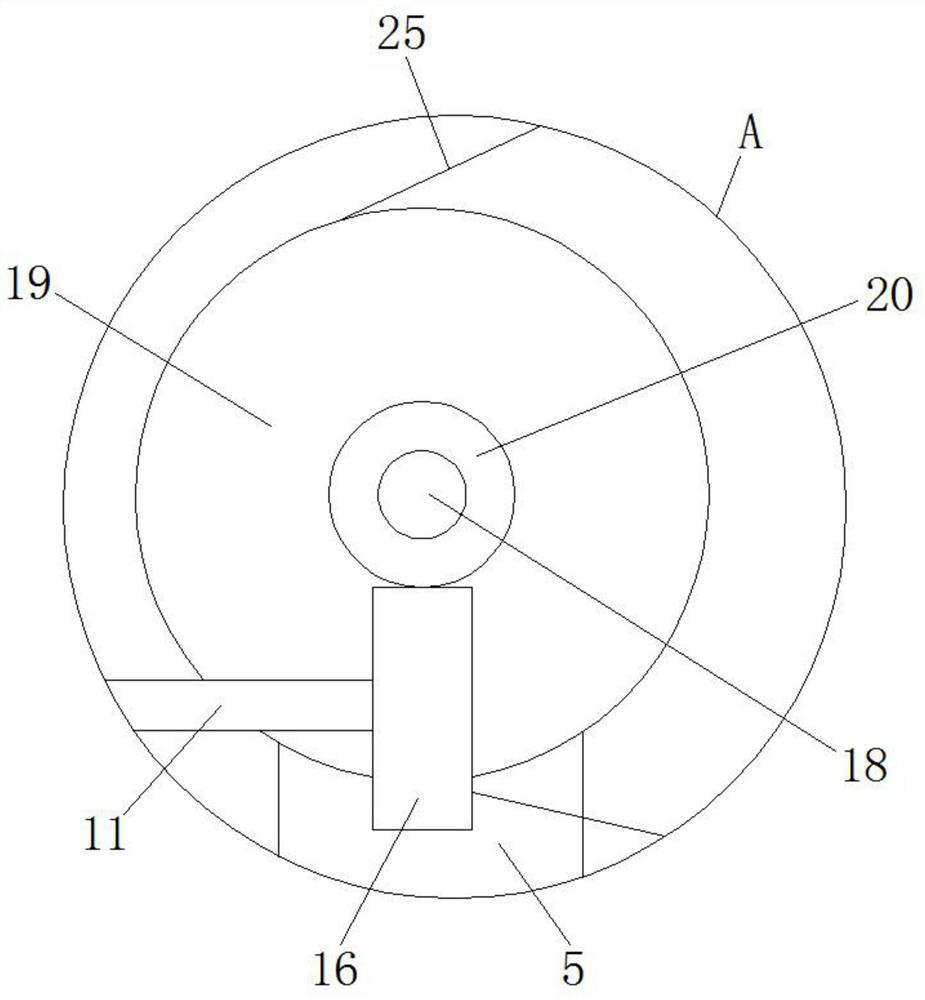

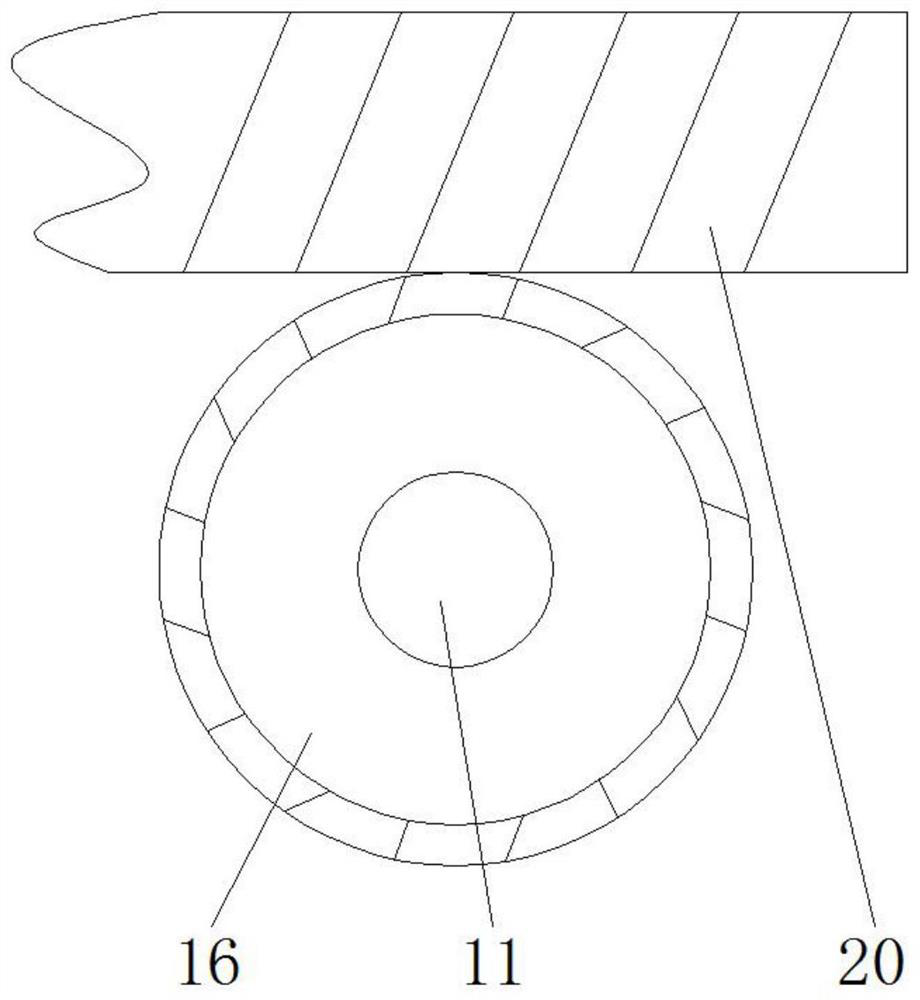

High speed multi-head annealing machine

The present invention discloses a high speed multi-head annealing machine, which comprises a rack, an annealing section positive electrode guide wheel, an annealing section negative electrode guide wheel, an annealing section output guide wheel and a preheating section guide wheel, wherein the annealing section positive electrode guide wheel, the annealing section negative electrode guide wheel, the annealing section output guide wheel and the preheating section guide wheel are rotatablely supported on the rack, the annealing section positive electrode guide wheel, the annealing section negative electrode guide wheel, the annealing section output guide wheel and the preheating section guide wheel are electrically connected to an annealing electricity transmission device having a sectioning and switching function, the annealing section positive electrode guide wheel, the annealing section negative electrode guide wheel, the annealing section output guide wheel, the preheating section guide wheel and a drive device form transmission connection, and an annealing drying device integrating functions of protection, cooling and drying is arranged on the rack, and is positioned at the wire path between the annealing section positive electrode guide wheel and the annealing section output guide wheel. According to the present invention, the high speed multi-head annealing machine has characteristics of high annealing treatment efficiency, compact structure, high wire quality, and strong process adaptability.

Owner:JIANGSU HONTA MACHINERY

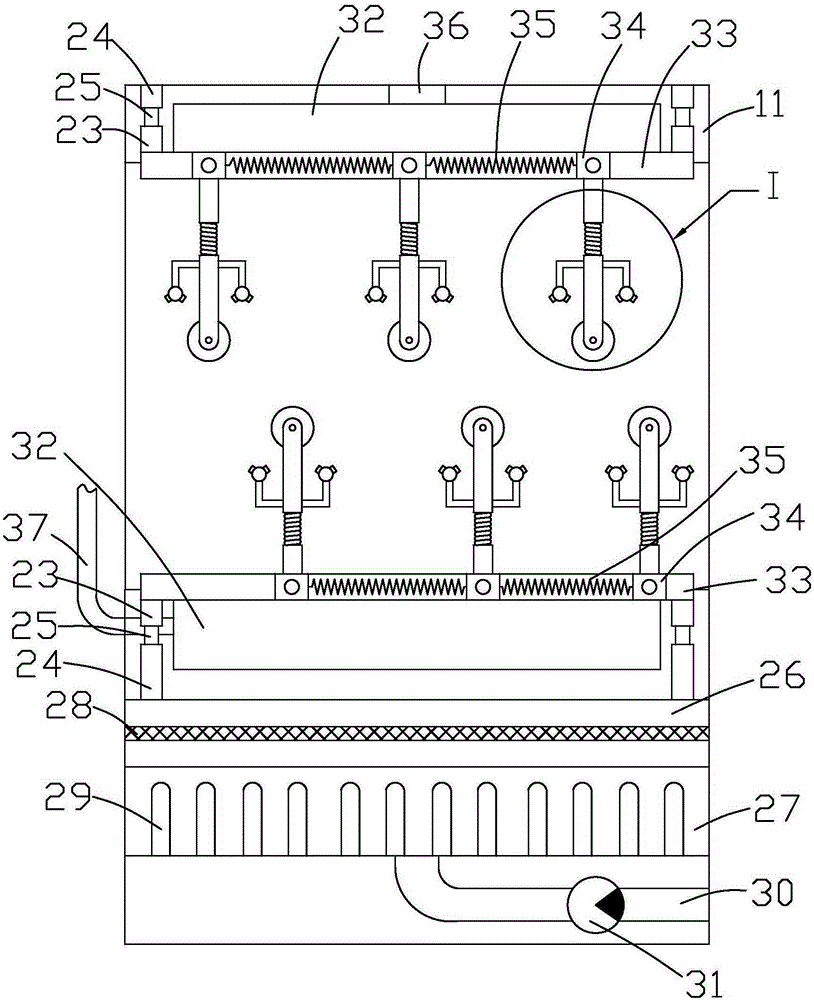

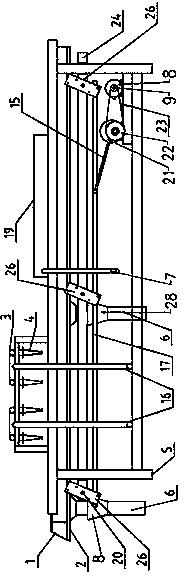

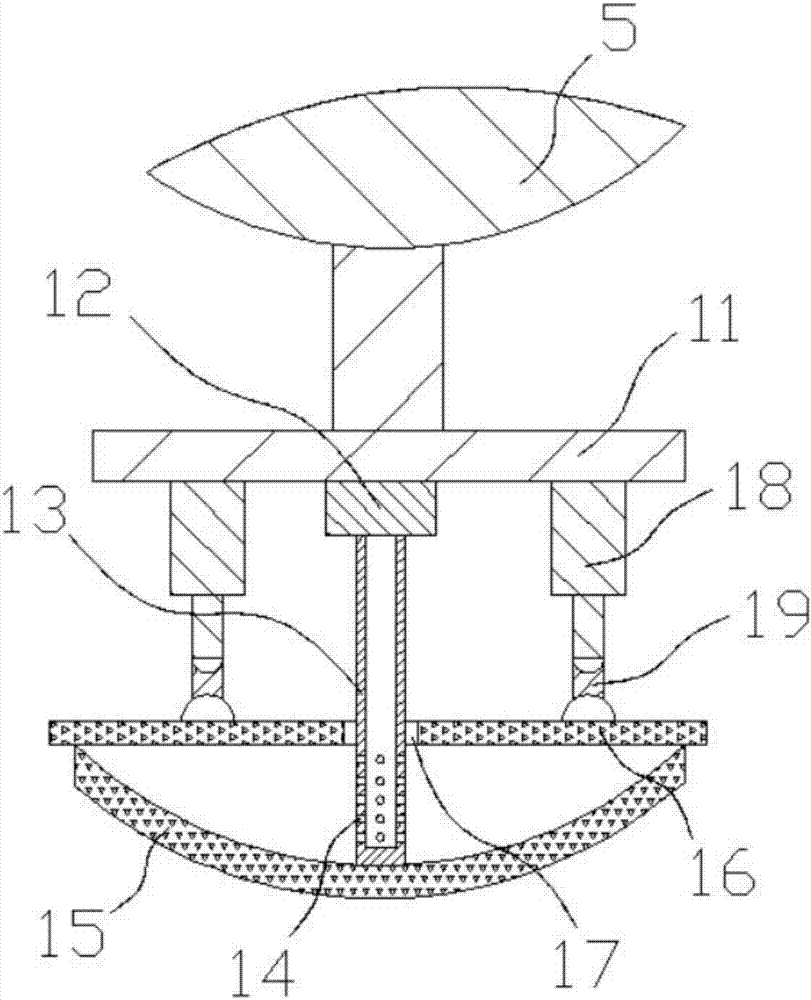

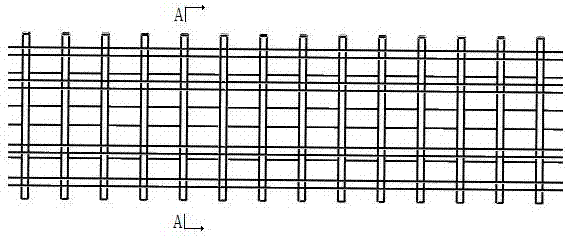

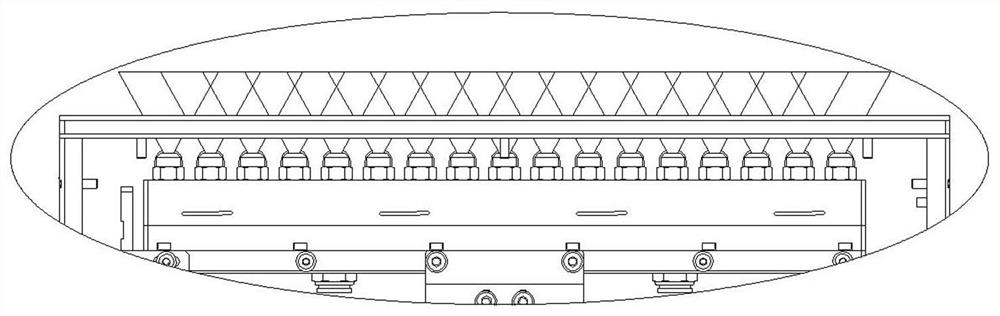

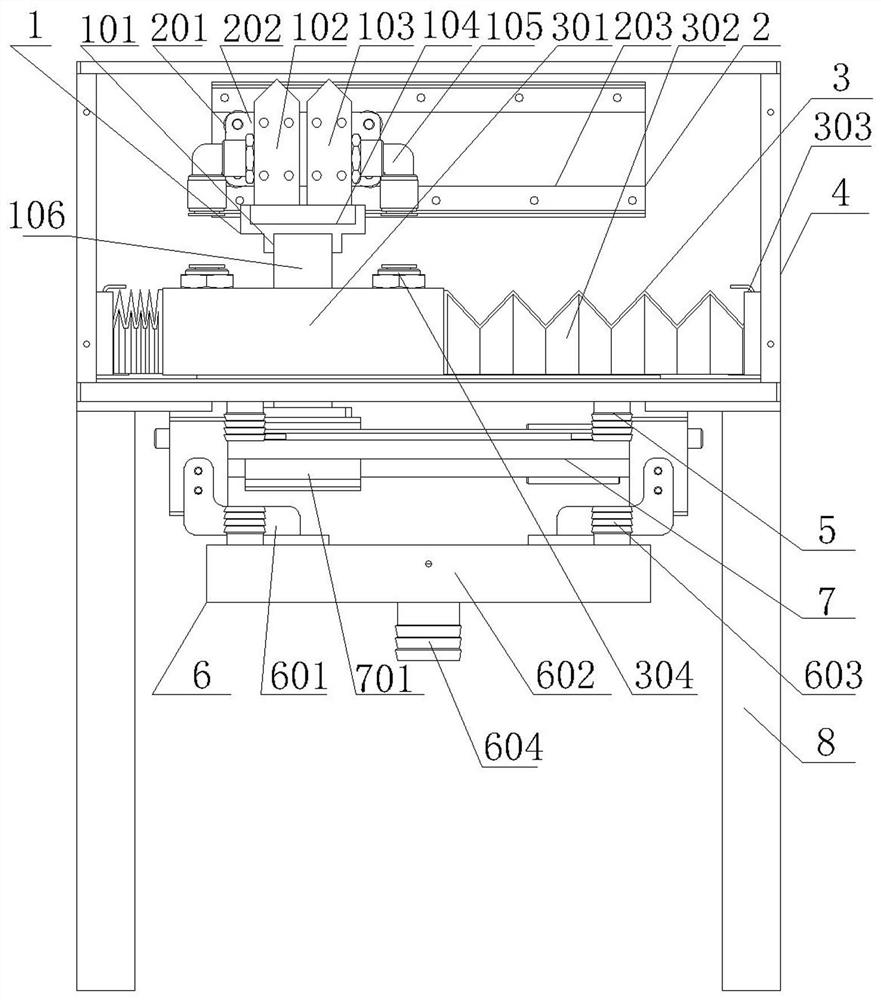

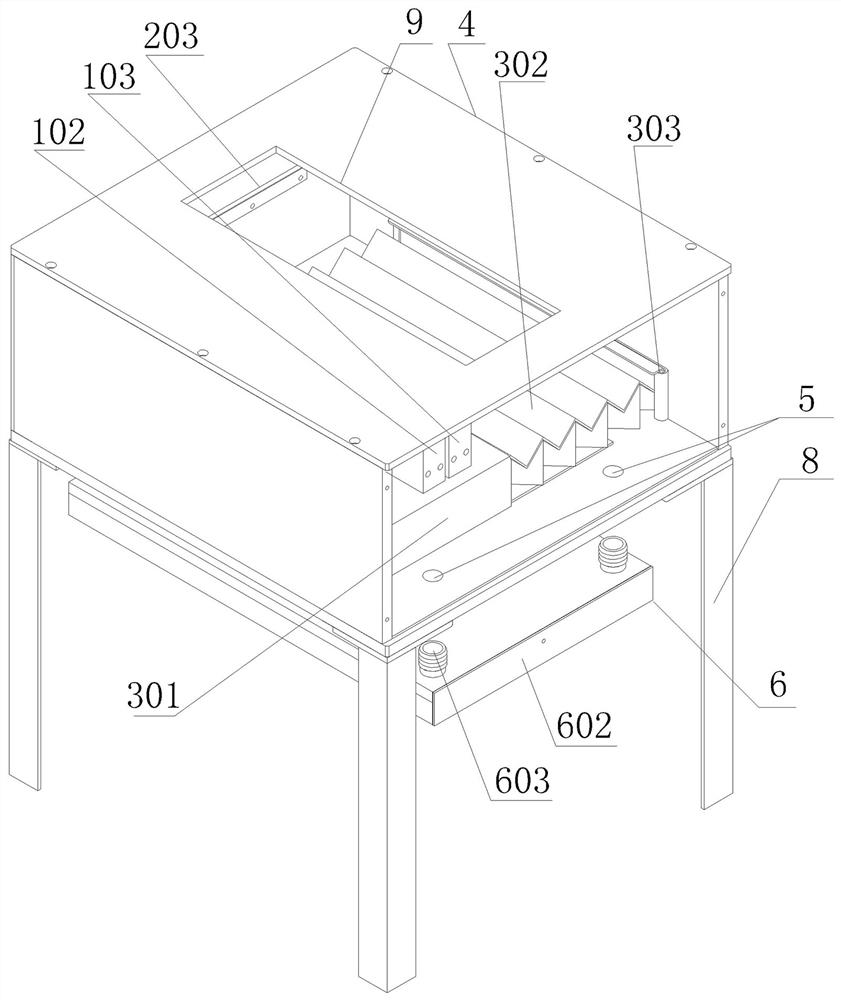

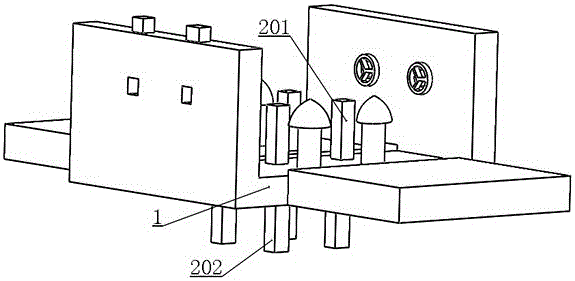

Cistanche tubulosa vibration washing and drying machine and washing and drying method

ActiveCN103750514ACleans and dries wellSimple structureFood treatmentProduct processingEcological environment

The invention belongs to the field of Chinese medicine product processing, and particularly relates to a Cistanche tubulosa vibration washing and drying machine and washing and drying method. Cistanche tubulosa has low ecological environmental requirements on planting and has broad developing prospect. Currently, more than 3 million mu Cistanche tubulosa are plant artificially in Hotan region, processed products enter international market; since the Cistanche tubulosa grows in sand, sand and earth are cling to the fleshy surface excavated from the sand, expected sand removal requirements cannot be achieved by the traditional washing method, and the existing device has no timely drying mechanism. The Cistanche tubulosa vibration washing and drying machine comprises a frame and a screen frame, a vibrating device, a high pressure spraying device and a high pressure blowing device which are all arranged on the frame. The screen frame is arranged on the middle-upper portion of the frame and is linked with the vibrating device through a vibrating swing arm plate. The high pressure spraying device is arranged on the upper-right portion of the frame, and the high pressure blowing device is arranged on the upper-left portion of the frame. By the method of spraying and blowing, the purposes of washing and drying can be acquired once, usage is safe, and energy consumption is saved.

Owner:和田天力沙生药物开发有限责任公司

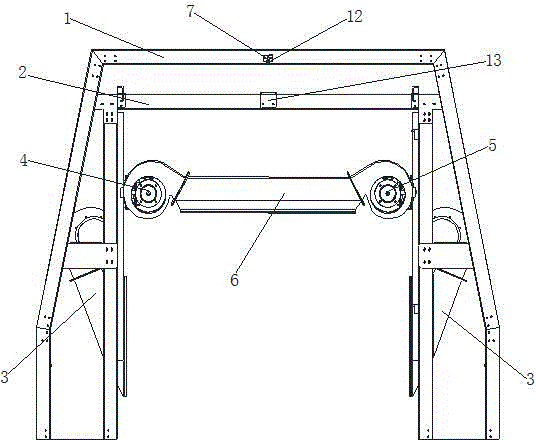

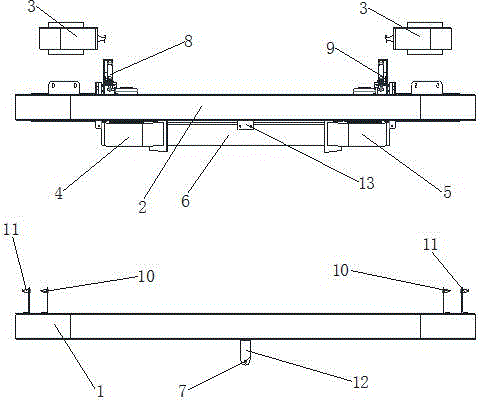

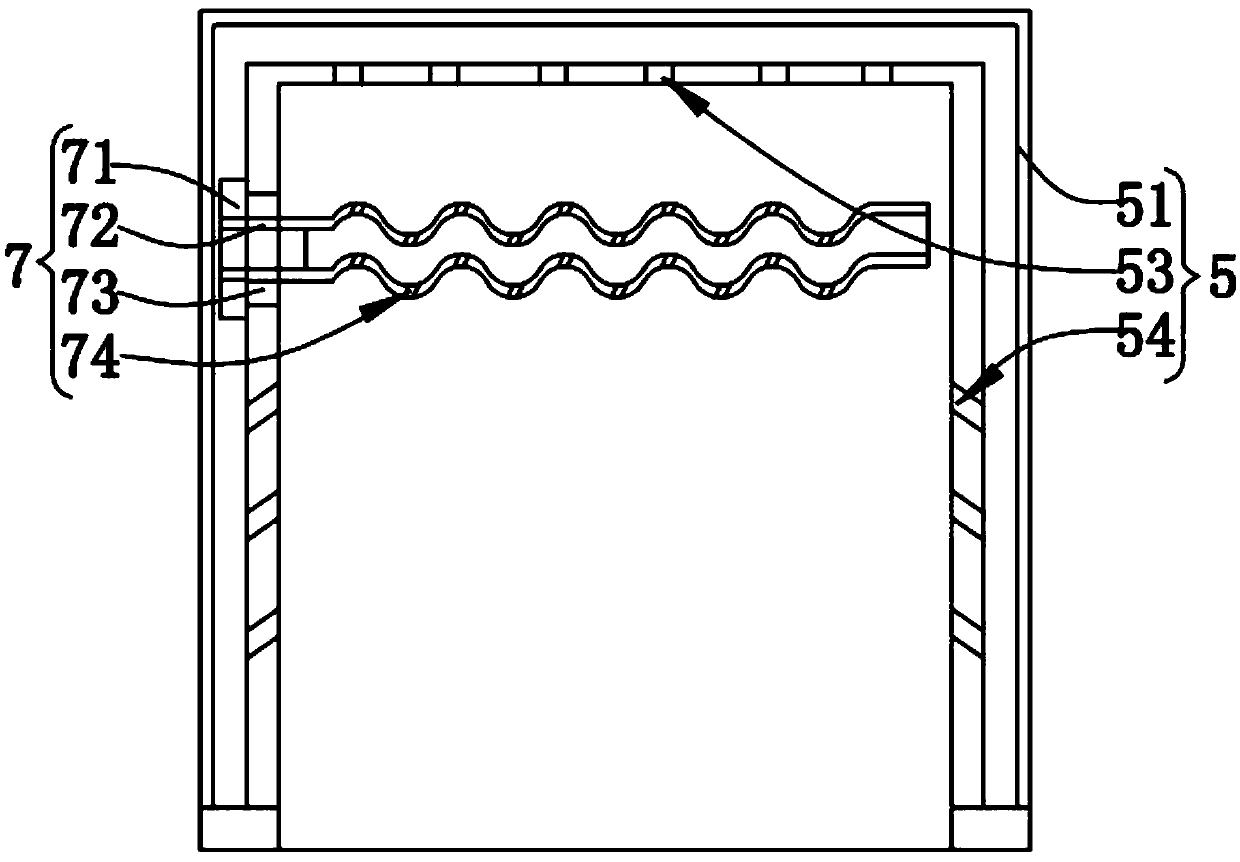

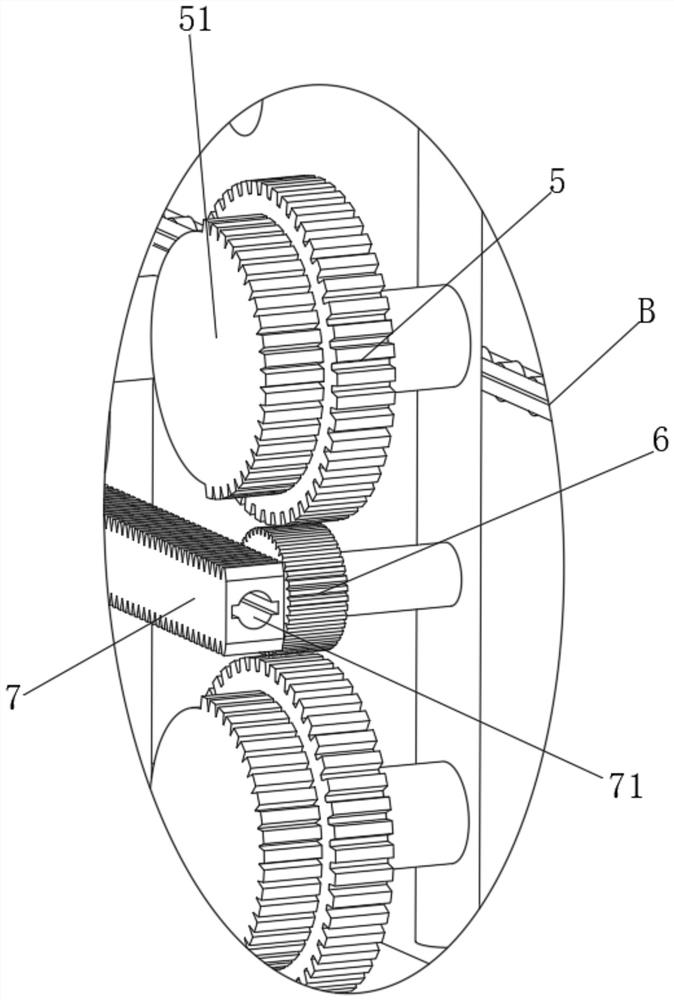

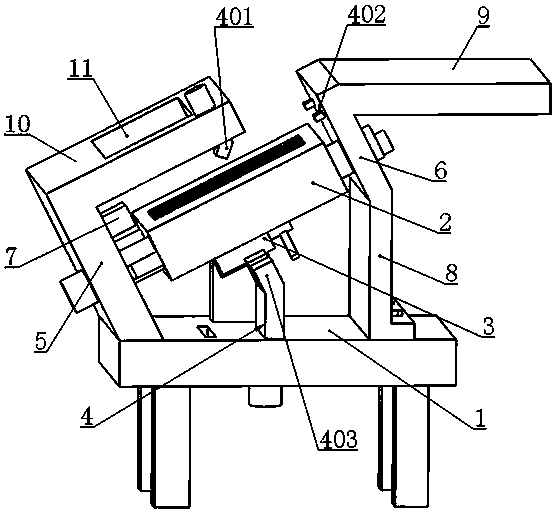

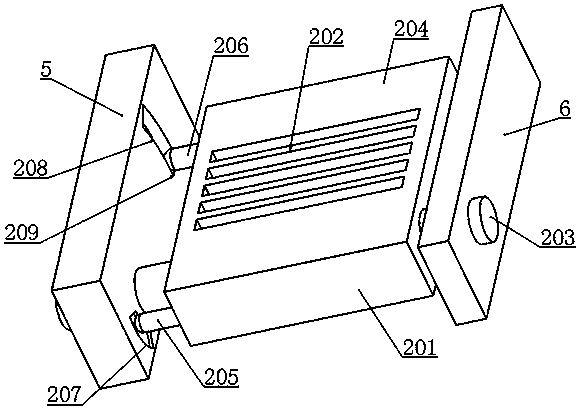

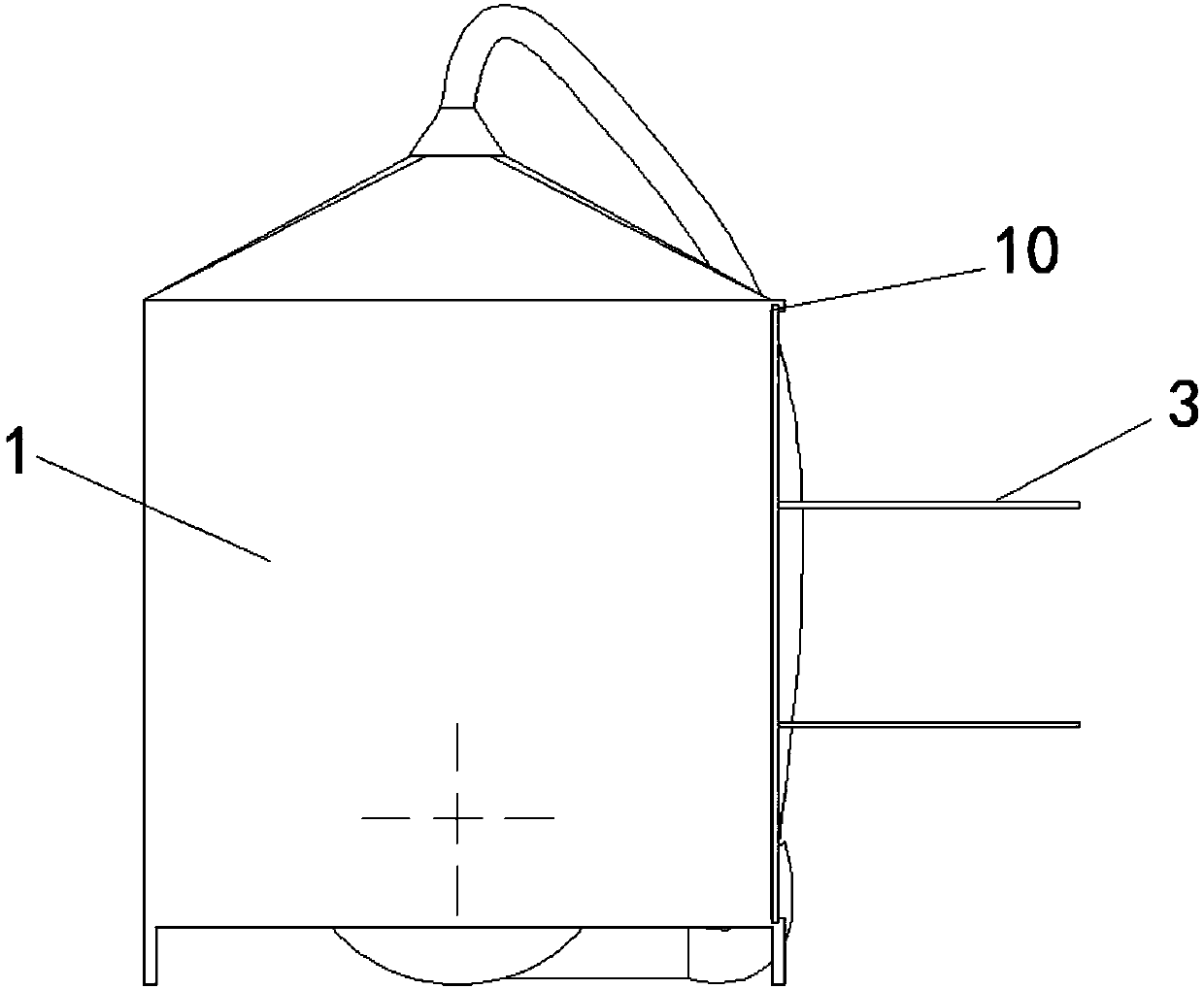

Drying system of automatic car washing machine

InactiveCN106274827ABlow drying effect is goodAvoid Rigid ImpactCleaning apparatus for vehicle exteriorsAgricultural engineeringBody surface

The invention discloses a drying system of an automatic car washing machine. The drying system comprises a first gantry, a second gantry, a top blowing assembly, side blowing assemblies and a control board. The top blowing assembly comprises a first top draught fan set, a second top draught fan set, a top draught fan wind tunnel, a distance measuring sensor and a servo motor; the first top draught fan set is connected with a first top draught fan swinging mechanism, the second top draught fan set is connected with a second top draught fan swinging mechanism, the wind outlets of the first top draught fan set and the second top draught fan set communicate to the left wind inlet and the right wind inlet of the top draught fan wind tunnel, and the wind outlets of the top draught fan wind tunnel follow the shape of the car and have a fixed distance relative to the car body surface; and the servo motor, the distance measuring sensor, the side blowing assemblies and draught fan startup optoelectronic switches arranged on the first gantry are connected with the control board. According to the drying system of the automatic car washing machine, the drying effect is good, the rigid impact, vibration and noise when the top blowing machine assembly is lifted can be avoided, and the service life of electric-mechanical components is favorably prolonged.

Owner:NANJING LYTON AUTOMATION EQUIP CO LTD

Automatic rinsing mechanism used for white tea processing

InactiveCN107952736AAchieve water cleaning effectTo achieve the throwing effectPre-extraction tea treatmentDrying gas arrangementsGourdVertical plane

The invention relates to an automatic rinsing mechanism used for white tea processing. The mechanism comprises a lower rack and an upper rack, the lower rack is provided with a water containing device, the upper rack is provided with a rinsing rotating shaft and a rinsing stepping motor which are matched and are arranged in the front and back horizontal direction, the rinsing rotating shaft is sleeved with a rinsing rotating disc, charging devices are evenly arranged on the rinsing rotating disc, when the charging devices are located on the lowest portion of the rinsing rotating disc, the charging devices are cooperated with the water containing device, each charging device comprises a charging rotating base which is connected with the rinsing rotating disc, the charging rotating bases areconnected with opened charging net gourd ladles through charging connection pipes in the radial direction, openings of the charging net gourd ladles are matched with charging net covers, and the charging net covers are connected with net cover opening and closing devices arranged on the charging rotating bases. The rinsing rotating shaft and the rinsing rotating disc drive the charging devices torotate in the vertical plane, rinsing cleaning effect of tea leaf raw material can be continuously and automatically achieved, the rinsing time can be controlled, rapid rotation is achieved to achieve water throwing out effect, and the rinsing effect is improved.

Owner:DONGGUAN UNIV OF TECH

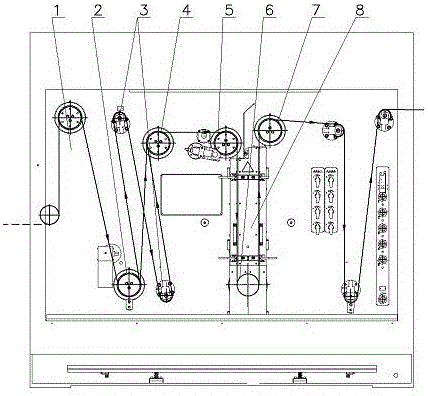

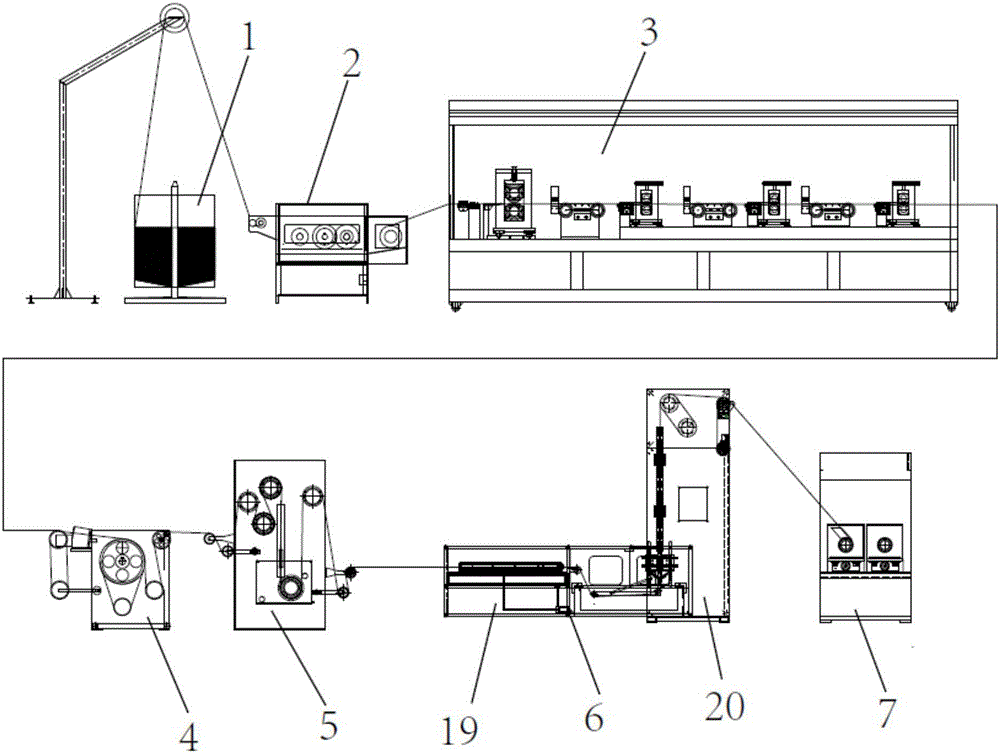

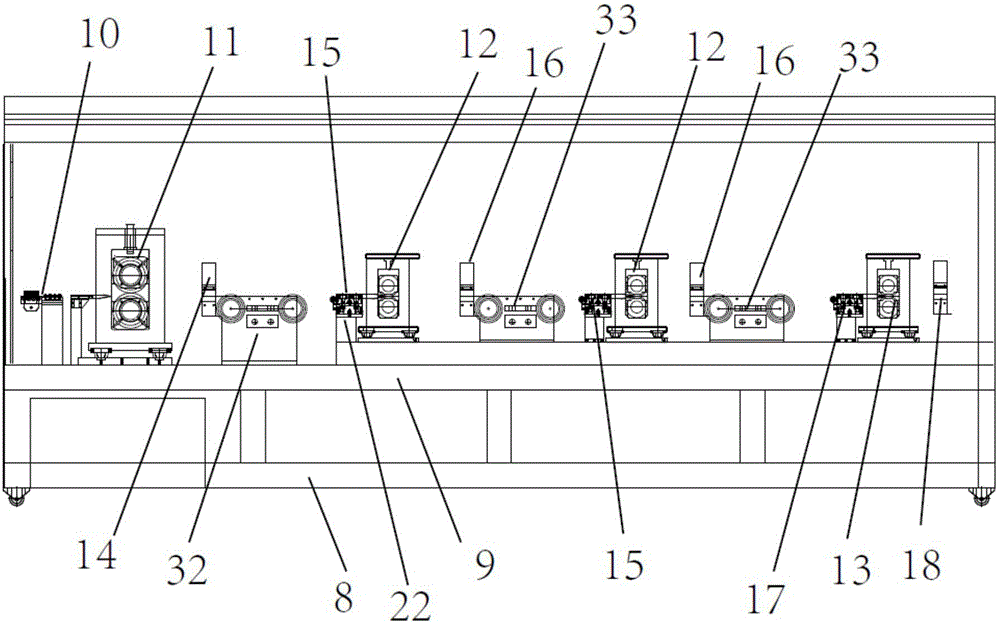

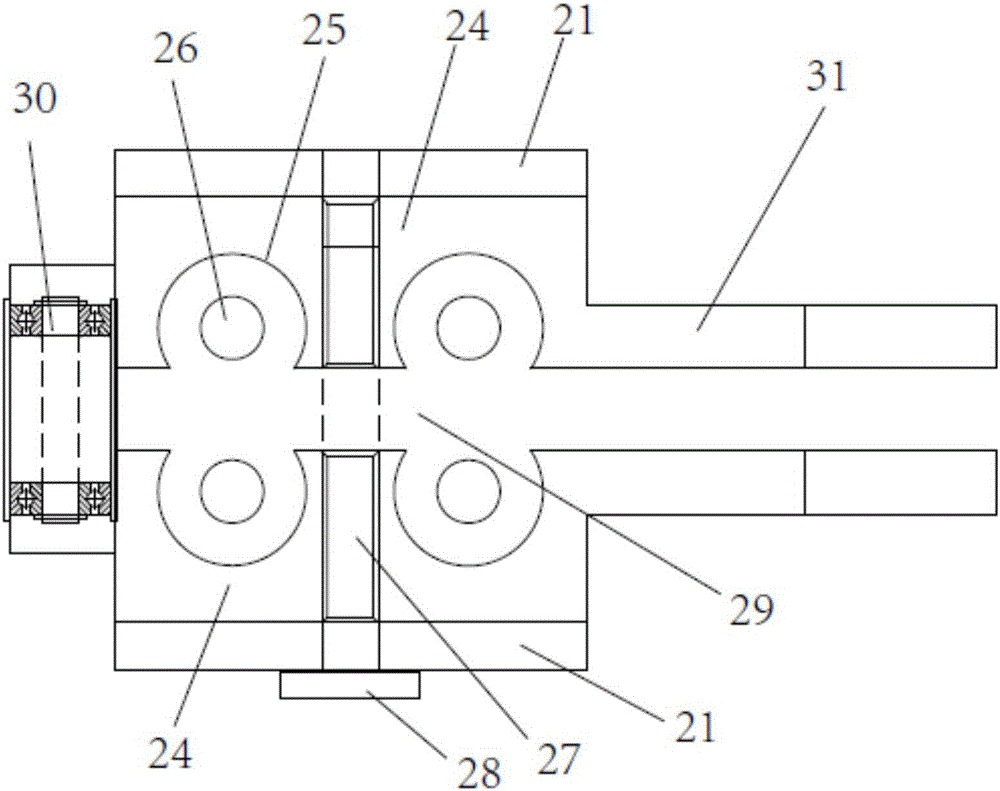

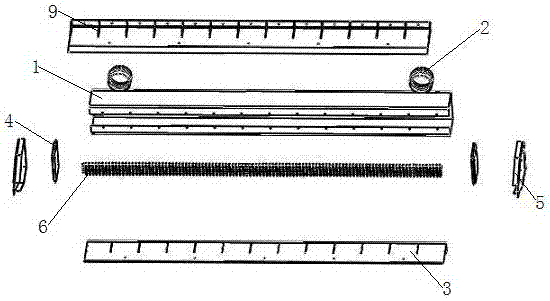

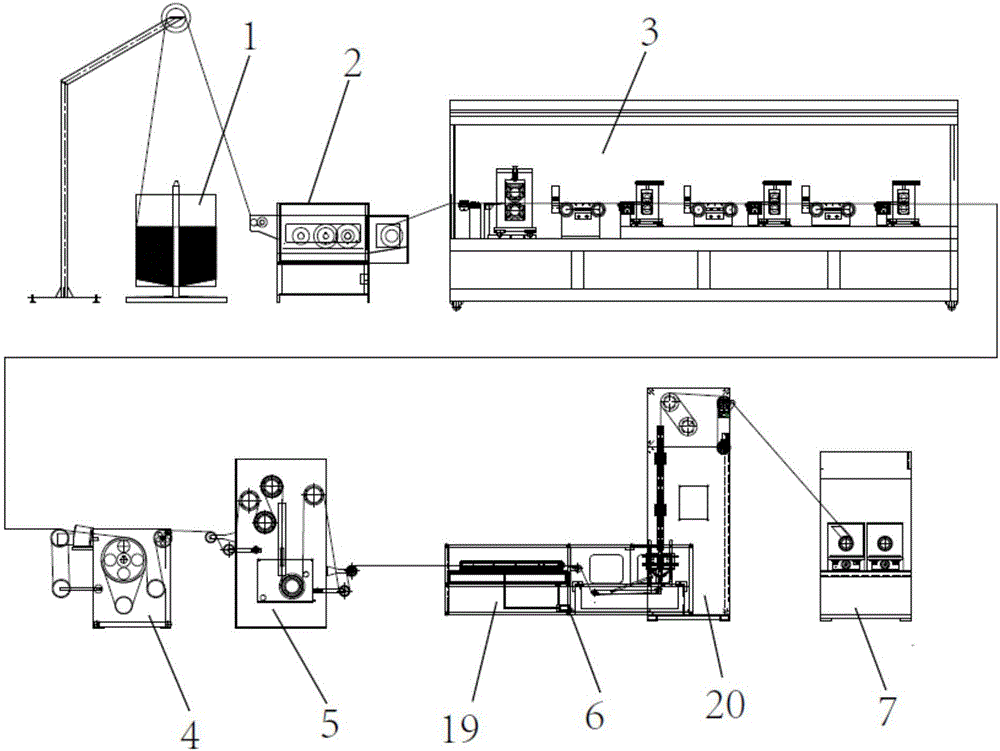

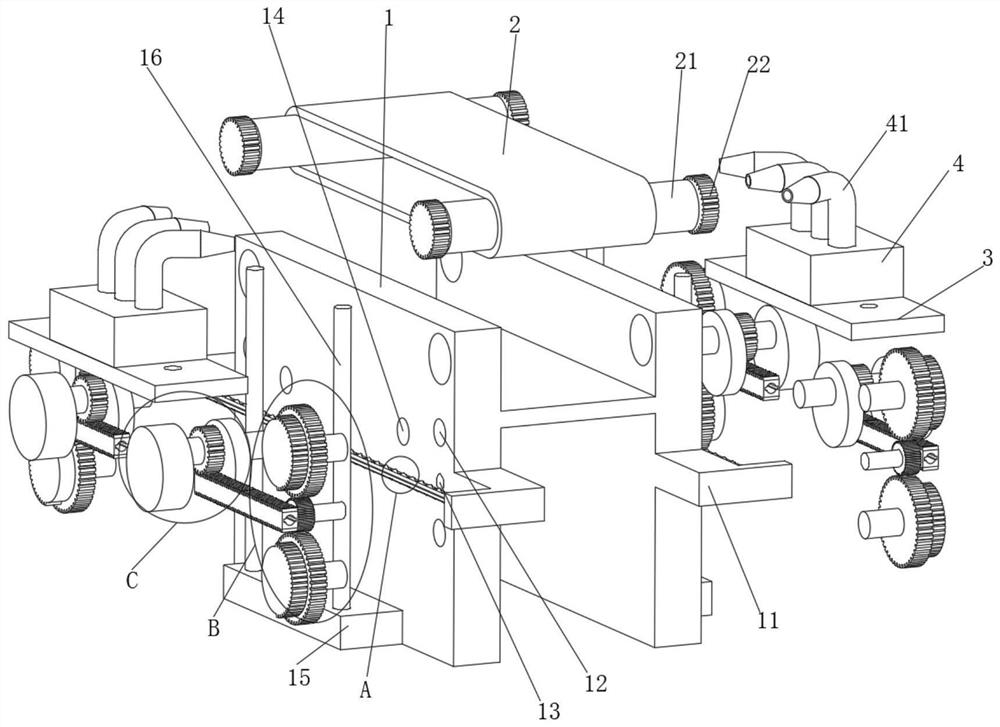

Calendaring production line for busbars

ActiveCN106180253AStable thicknessGuaranteed rolling qualityExtrusion cleaning devicesProduction lineBusbar

The invention discloses a calendaring production line for busbars. The calendaring production line comprises a pay-off rack, a wire drawing machine, a calendaring machine, a traction machine, an annealing device, a tin coating machine and a take-up machine, wherein the pay-off rack, the wire drawing machine, the calendaring machine, the traction machine, the annealing device, the tin coating machine and the take-up machine are sequentially arranged in the wire conveying direction. The calendaring machine comprises a machine frame. An operation platform is arranged on the machine frame. A wire straightening machine, a roughing mill, a forming mill and a finishing mill are sequentially arranged on the operation platform in the wire conveying direction. A wire inlet guiding nozzle is arranged on the wire inlet side of the roughing mill. A first diameter measuring gauge is arranged on the wire outlet side of the roughing mill. A first edge trimming machine is arranged on the wire inlet side of the forming mill. A second diameter measuring gauge is arranged on the wire outlet side of the forming mill. A second edge trimming machine is arranged on the wire inlet side of the finishing mill. A third diameter measuring gauge is arranged on the wire outlet side of the finishing mill. The tin coating machine comprises a cleaning part and a tin feeding part. According to the calendaring production line, the production speed is high, and the production quality is high.

Owner:JIANGSU YOUZHA MACHINE CO LTD

Conductive glass cleaning device and method

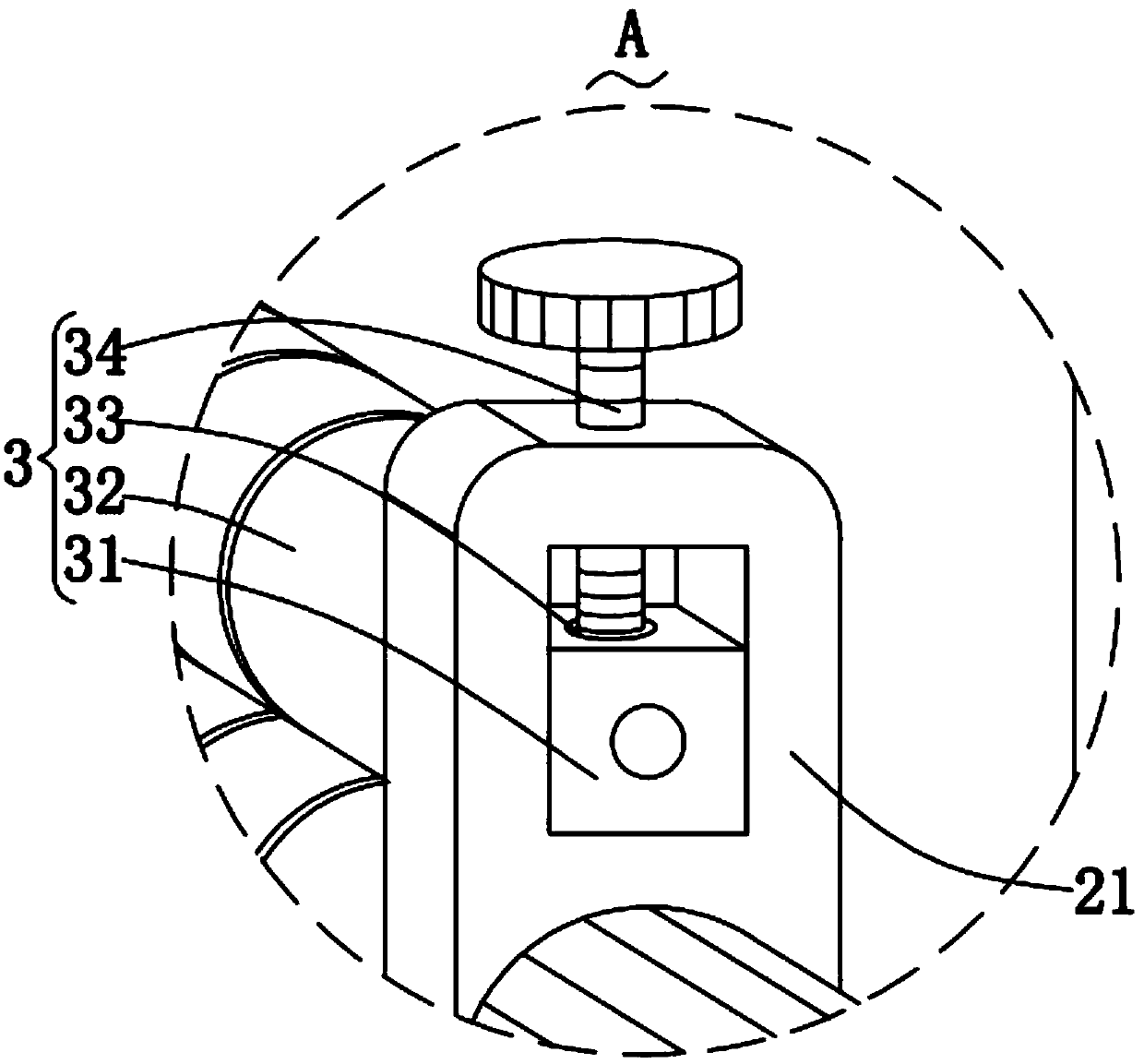

PendingCN107838109ASimple structureImprove drying efficiencyDrying gas arrangementsFlexible article cleaningEngineeringCommunicating cavity

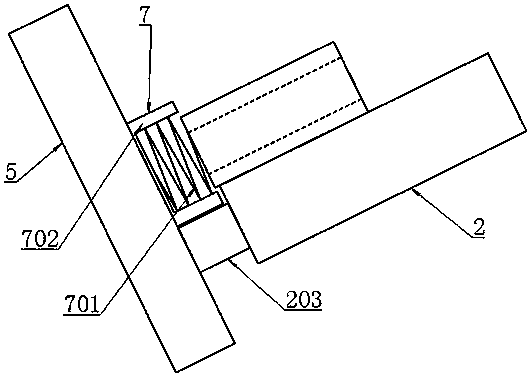

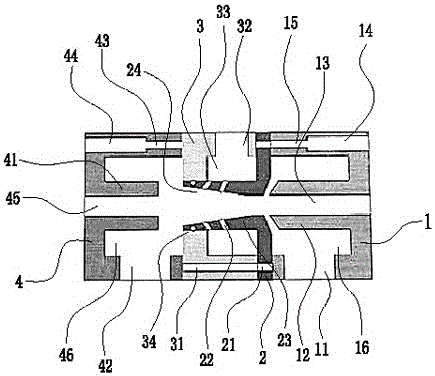

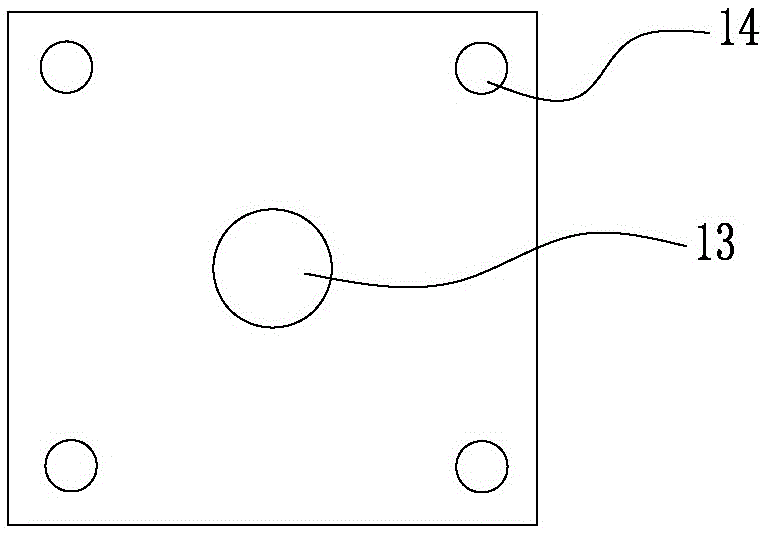

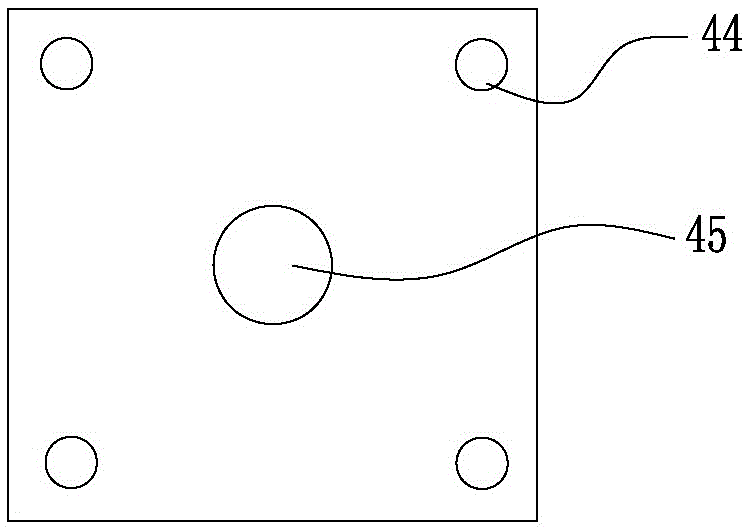

The invention provides a conductive glass cleaning device which is applied to the technical field of conductive glass treatment and further relates to a conductive glass cleaning method. An air bag (3) is arranged between a washing component (1) and an air knife drying component (2) of the conductive glass cleaning deice, one end of a compressed air inlet pipe (5) of the air bag (3) communicates with a pressure air pump (7), and the other end of the compressed air inlet pipe (5) communicates with one end of a cavity (4). The other end of the cavity (4) communicates with one end of a compressedair outlet pipe (6), the other end of the compressed air outlet pipe (6) communicates with the air knife drying component (2), and a heating component (8) is further arranged in the cavity (4). According to the conductive glass cleaning device and method, a glass substrate can be cleaned conveniently and fast, water left after the glass substrate is cleaned can be blown dry fast, and it is ensured that the film coating quality achieved after cleaning is effectively improved.

Owner:WUHU TOKEN SCI

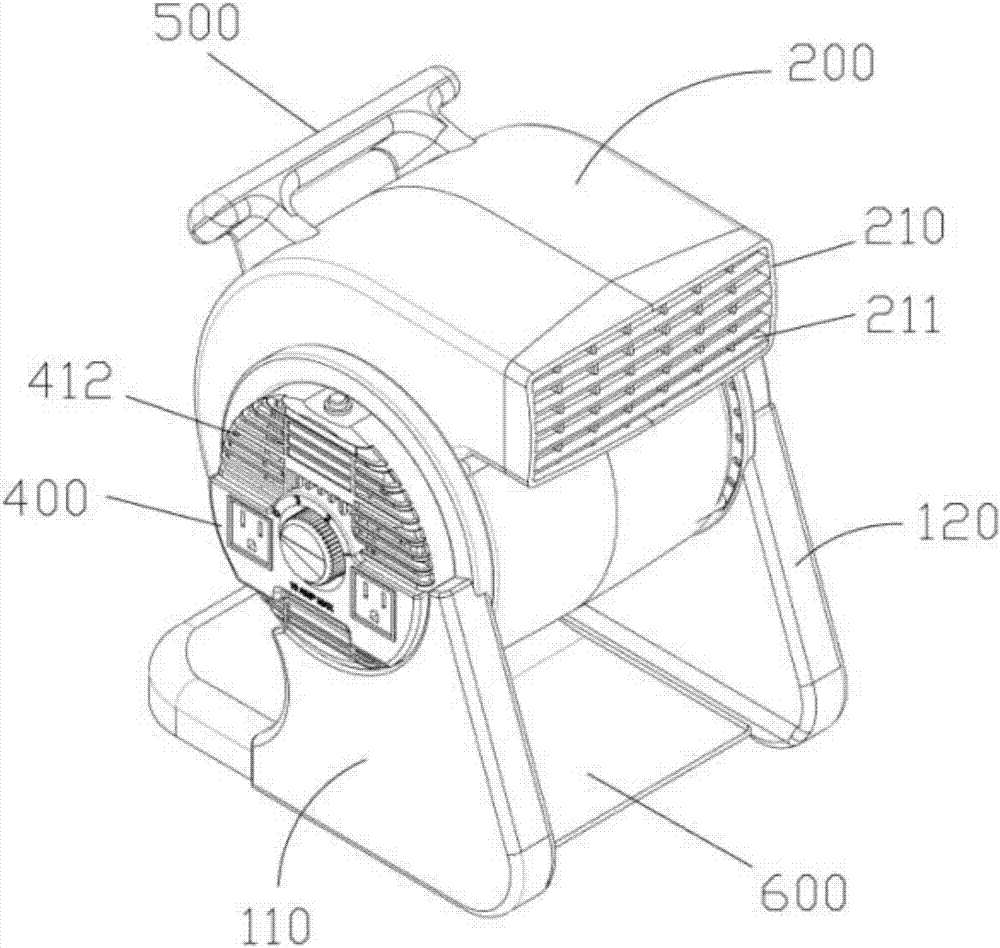

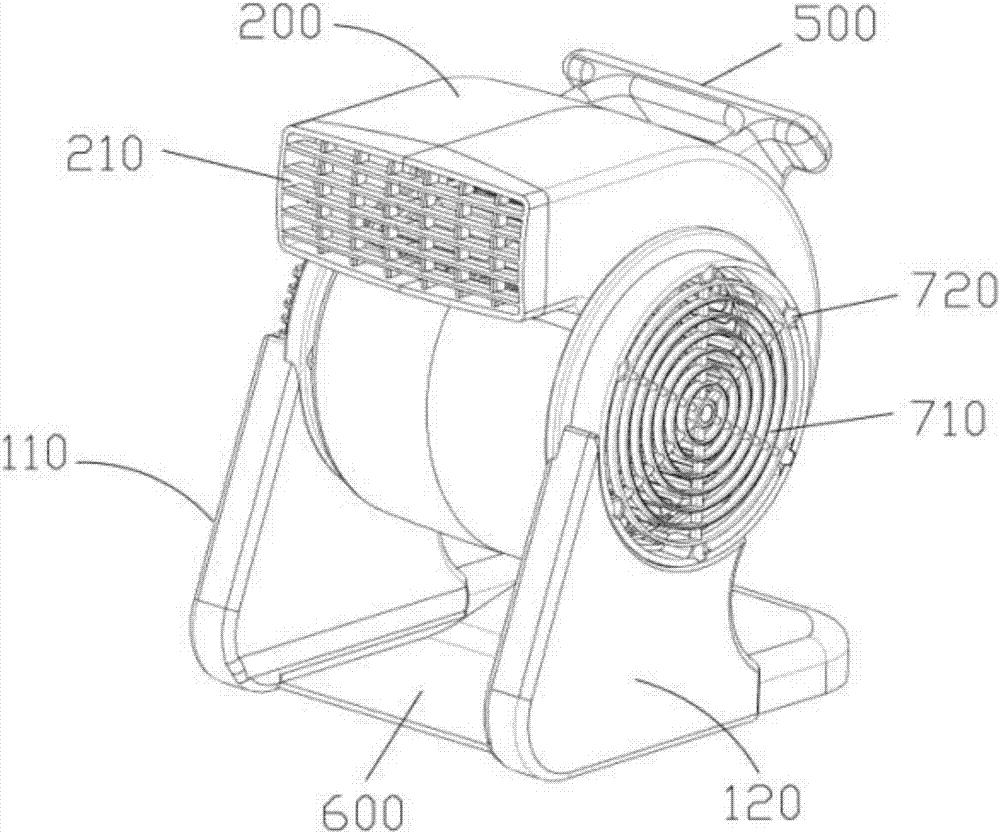

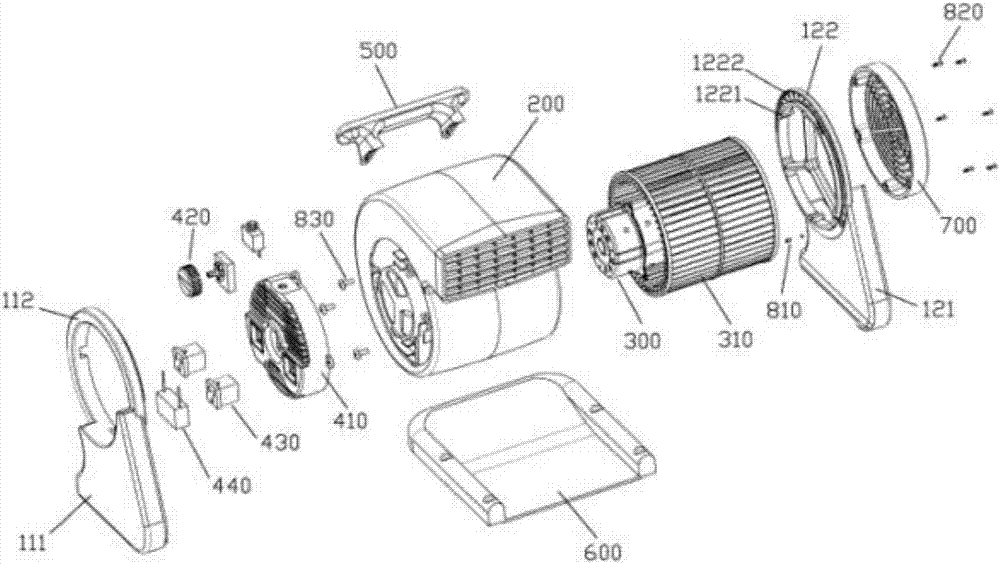

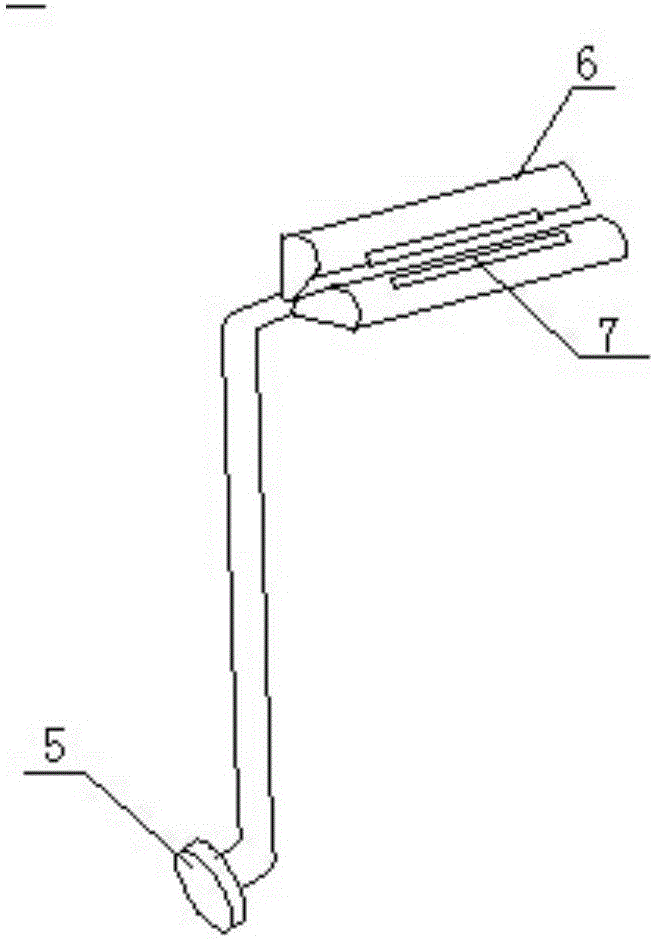

Floor blowing machine

The invention relates to a floor blowing machine. The floor blowing machine comprises two side walls, an air guiding barrel, a handle, a motor, a wind wheel and a control assembly. The two side walls are oppositely arranged in parallel. The air guiding barrel is rotatably arranged between the two side walls. The handle is installed on the air guiding barrel. The motor and the wind wheel are both installed in the air guiding barrel. The control assembly is arranged on the side wall on the side close to the motor, and the position where the control assembly and the corresponding side wall are installed is located on the inner side of the corresponding side wall; and the control assembly is electrically connected with the motor. The air-out angle can be adjusted through rotation of the air guiding barrel, better blowing and drying effects are achieved, and the floor blowing machine is compact in overall structure and attractive and durable.

Owner:JIANGMEN KEYE ELECTRICAL & MECHANICAL MFG CO LTD

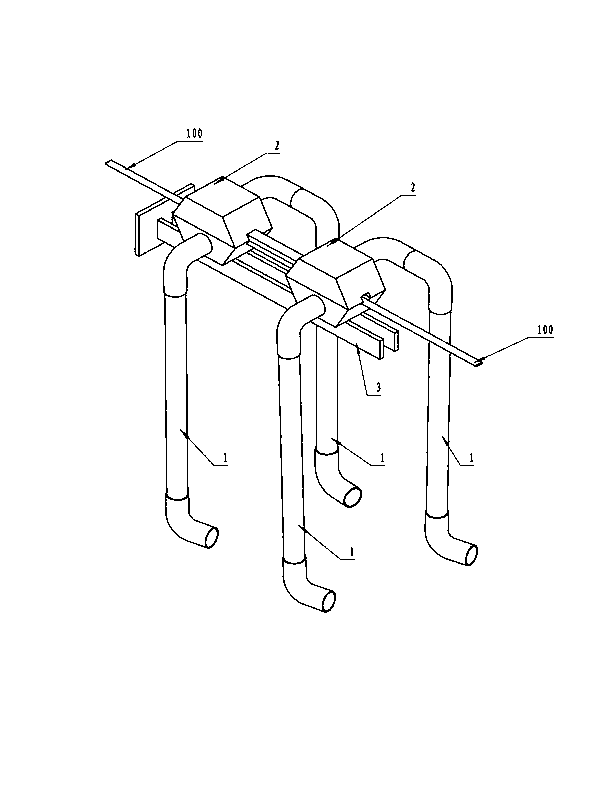

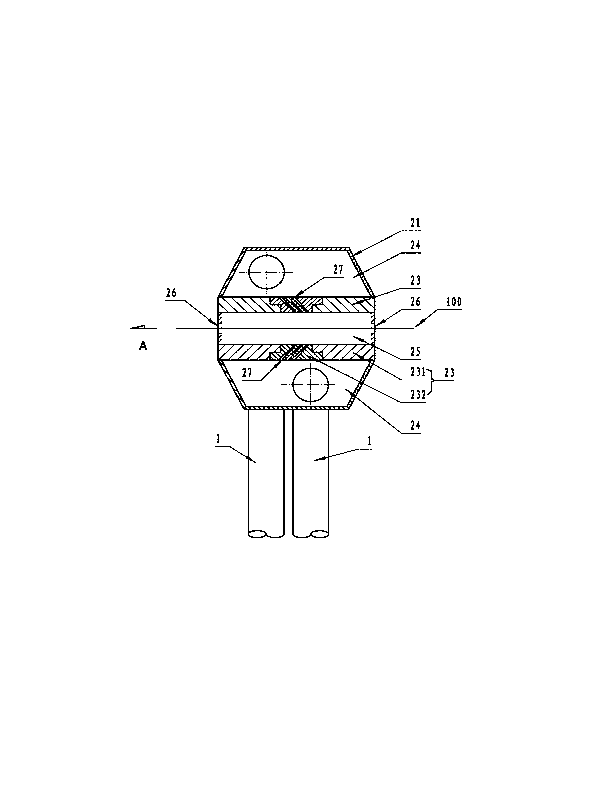

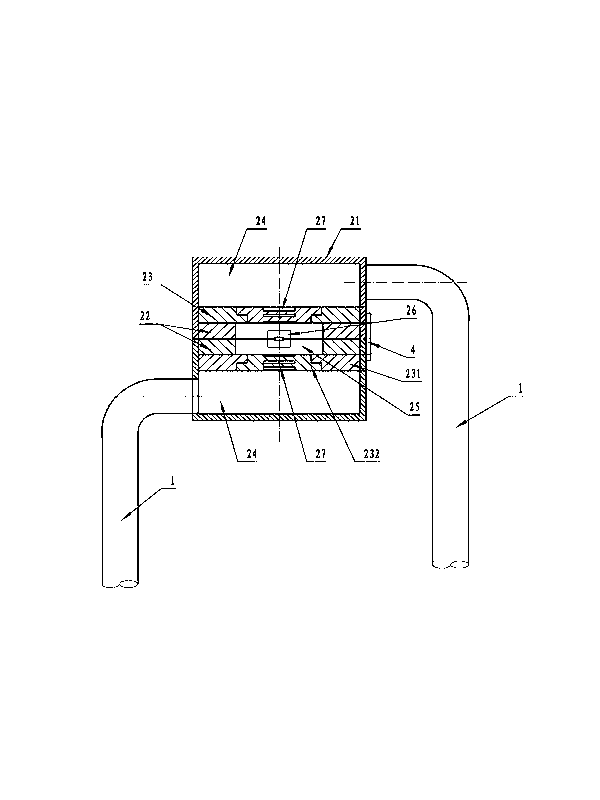

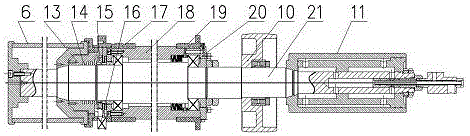

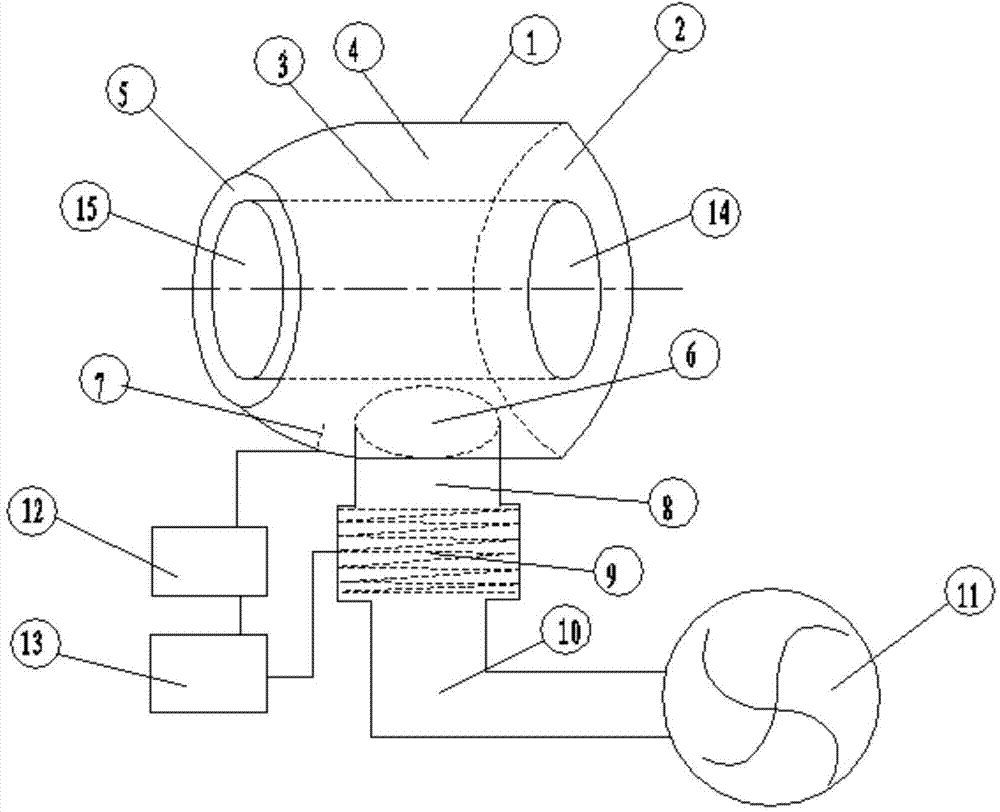

Annular hot air blow-drying equipment for welding cables

InactiveCN103594209AImprove drying effectControl speedCable/conductor manufactureControl engineeringTurbine

The invention relates to annular hot air blow-drying equipment for welding cables. The annular hot air blow-drying equipment comprises a cable passing inner pipe and a shell. The cable passing inner pipe and the shell are both horizontally arranged, and the shell is coaxially mounted on the outer side of the cable passing inner pipe in a sleeved mode; a cable inlet in the right side of the cable passing inner pipe and the right end face of the shell are connected through a mounting plate to form a closed end face; an air cavity is formed by a gap between the outer wall of the cable passing inner pipe and the inner wall of the shell; an air blowing port is formed between a cable outlet in the left side of the cable passing inner pipe and the left end face of the shell; a heating pipe is installed on the lower portion of the shell, the front end of the heating pipe extends into the air cavity, a heating unit is installed in the heating pipe, and the rear end of the heating pipe is connected with a turbine fan. The annular hot air blow-drying equipment for the welding cables is ingenious in design, reasonable in structure and high in practicability. Furthermore, when the equipment is used, the blow-drying effect can be improved, blow-drying efficiency is enhanced, and convenience is brought to the next step of processing the welding cables.

Owner:TIANJIN KEBO ELECTRIC POWER TECH DEV

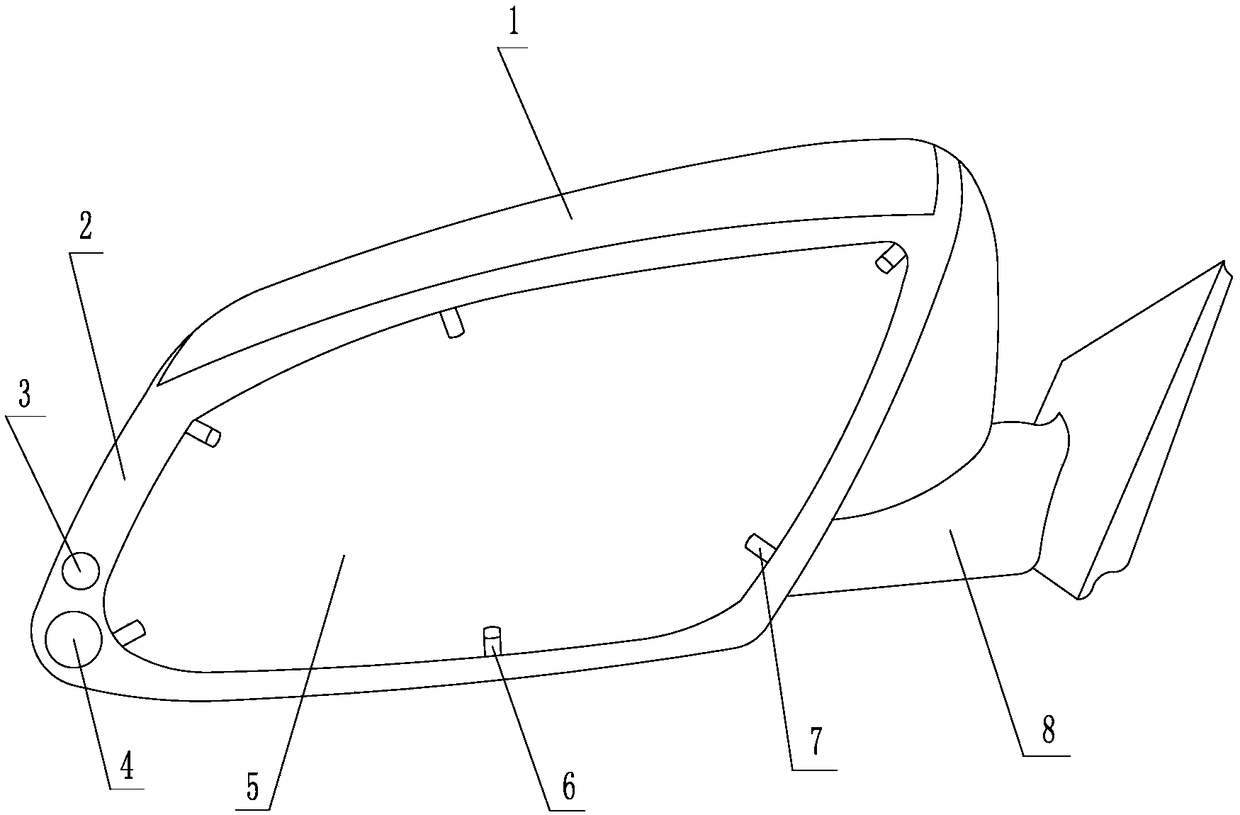

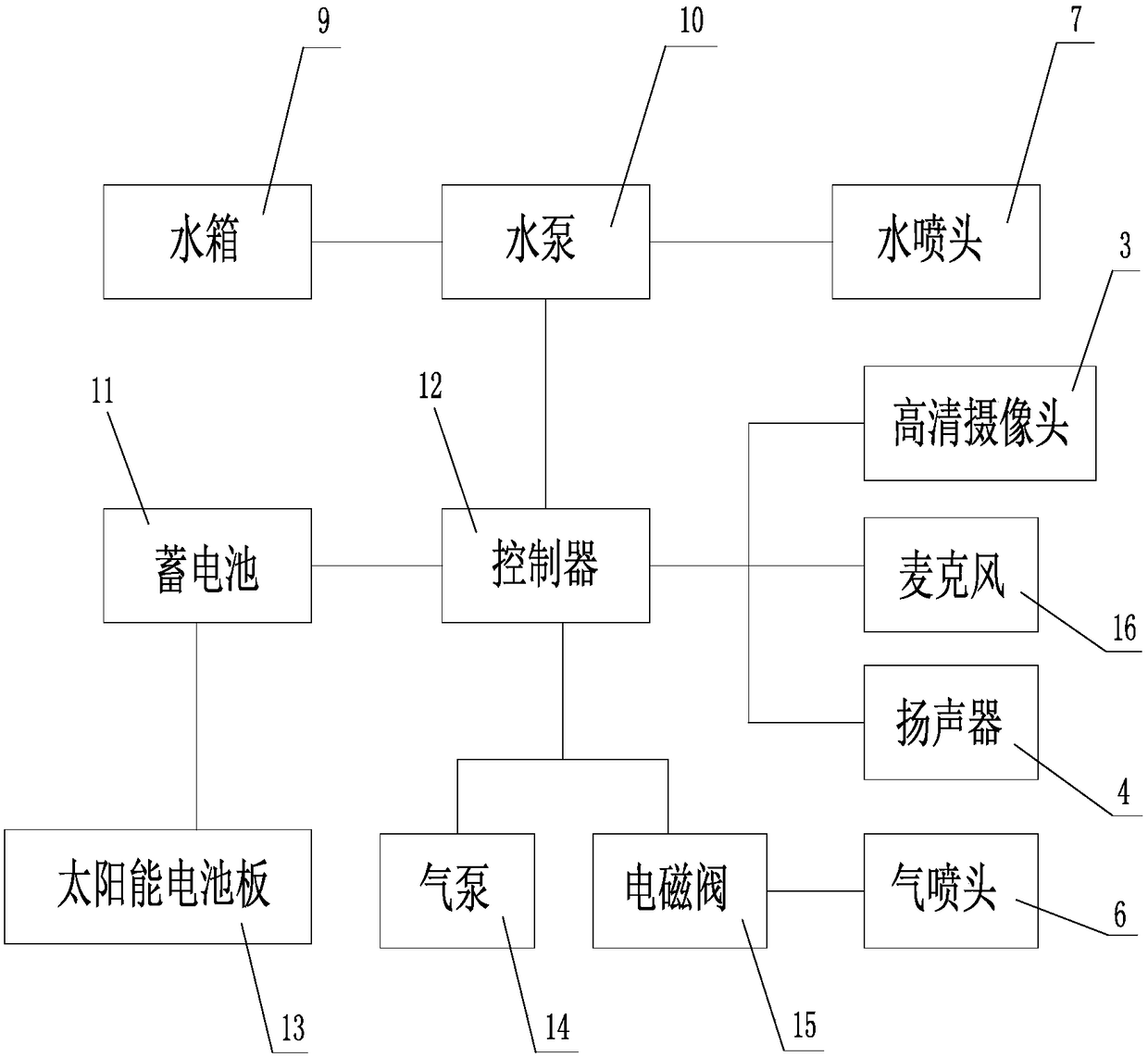

Carbon fiber automobile rearview mirror

InactiveCN108327635ACorrosion resistanceHigh strengthVehicle cleaningElectric/fluid circuitFiberElectricity

A carbon fiber automobile rearview mirror comprises a rearview mirror shell, a mirror face and a connecting rod used for installing the rearview mirror shell on an automobile body and further comprises a water tank, a water pump, water nozzles, an air pump, air nozzles, electromagnetic valves and a controller. The mirror face is arranged on the rearview mirror shell. The water tank, the water pump, the air pump and the electromagnetic valves are installed below an automobile engine hood. The controller is installed on a driving table in an automobile. The multiple water nozzles and the multiple air nozzles are provided, installed on the rearview mirror shell and alternately distributed along the circumference of the mirror face. The air nozzles are connected with an air outlet of the air pump through air pipes in a communicating mode. The electromagnetic valves are arranged on the air pipes. The water pump is located in the water tank. The water nozzles are connected with a water outlet of the water pump through water pipes in a communicating mode. The water pump, the air pump and the electromagnetic valves are all electrically connected with the controller. The rearview mirror shell is made of a carbon fiber material. Te mirror face can be washed and quickly blow-dried by a driver according to the requirements of the driver, so that traveling safety is effectively guaranteed.

Owner:朱玲

Rubber tire hot film air drying compression roller device

The invention relates to the field of rubber tire hot film production and processing devices, in particular to a rubber tire hot film air drying compression roller device. The device comprises a base,a feeding structure, an adjusting structure, a guide structure, an air inlet structure, a discharging structure and a hanging structure; the interior of a fixing sleeve is connected to three internalhollow hanging rods which are in a triangular structure in a rotating mode through a second bearing, each of the three hanging rods is of a continuous S-shaped structure, so that the contact area between the hanging rods and the rubber tire hot film can be effectively reduced, and thus a better blow-drying effect is achieved; a plurality of air holes which are in 45-degree included angles with the fixing sleeve are formed in each hanging rod, so that when the rubber tire hot film is in contact with the hanging rods, the air holes cannot be influenced to blow air to the rubber tire hot film; and a plurality of blades are distributed on the outer part of each hanging rod in an annular array mode, the blades can slightly rotate when airflow enters an air channel, then the hanging rods are driven to rotate, further, the rubber tire hot film on the hanging rods can vibrate, and therefore a better drying effect is achieved.

Owner:嘉兴华竹电子有限公司

Car washer air-drying device

The invention discloses a car-washer air-drying device which comprises an air knife and a connecting device. The connecting device is connected with the end of the air knife which comprises an air knife box, air knife connectors, an air knife blade, air knife fixing blocks, air knife end caps and an air guide device. The upper portion of the air knife box is connected with the air knife connectors, and the lower portion of the air knife box is connected with the air knife blade. One ends of the air knife fixing blocks are connected with the air knife box, and the other ends of the air knife fixing blocks are connected with the air knife end caps. The air guide device is connected with the air knife box. The car washer air-drying device is simple in structure, reasonable in design and convenient to operate, and the air-drying device is high in outlet air speed, capable of effectively forming an air-knife-shaped air beam, uniform in blowing, good in blow-drying effect, low in energy consumption, suitable for being selectively assembled on various car washers and capable of being used for cleaning and blow-drying of various vehicle models.

Owner:ZHEJIANG INST OF COMM +1

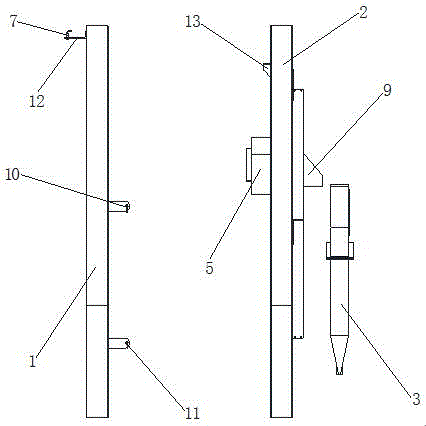

Thermal air blowing mechanism of cold end glass washer of float glass production line

ActiveCN105444552AReasonable structural designSave energyDrying gas arrangementsProduction lineHigh pressure

The invention discloses a thermal air blowing mechanism of a cold end glass washer of a float glass production line. The thermal air blowing mechanism comprises an annealing furnace (1) and the glass washer (2). The feeding end of the glass washer (2) is connected with the glass discharging end of the annealing furnace (1) through a conveyor. The thermal air blowing mechanism further comprises a thermal air blowing mechanism body. The thermal air blowing mechanism body comprises a main thermal air pipe (3), an upper thermal air branch pipe (4), a lower thermal air branch pipe (5), an upper high-pressure fan (6), a lower high-pressure fan (7), a set of upper flexible pipes (8), a set of lower flexible pipes (9), a set of air knife supporting and limiting devices, an upper air knife assembly and a lower air knife assembly. The thermal air blowing mechanism has the advantages that the structural design is reasonable; afterheat of the hot end annealing furnace of the float glass production line is fully used, energy resources are greatly saved, and thermal air knifes are designed to be adjustable, so that the blow-dry effect is better and good practical value is achieved.

Owner:FUYAO GRP TONGLIAO CO LTD

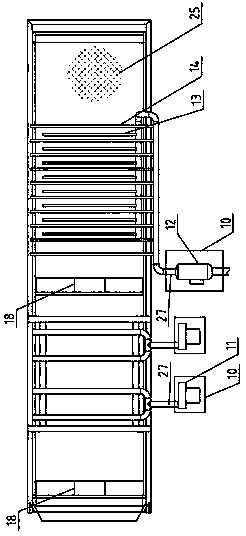

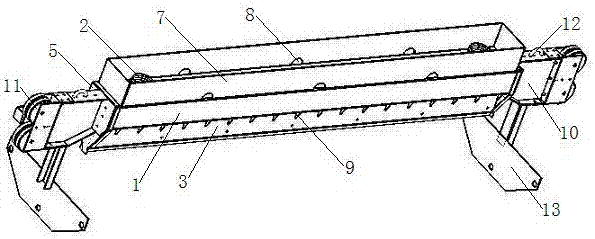

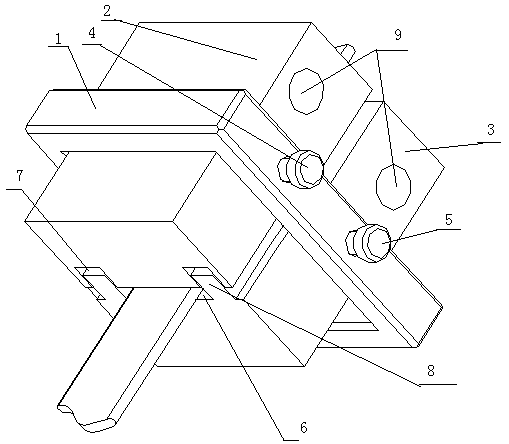

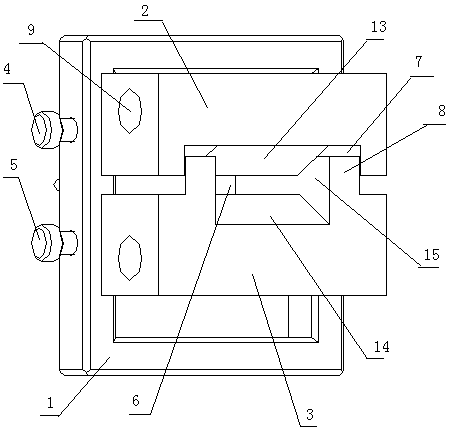

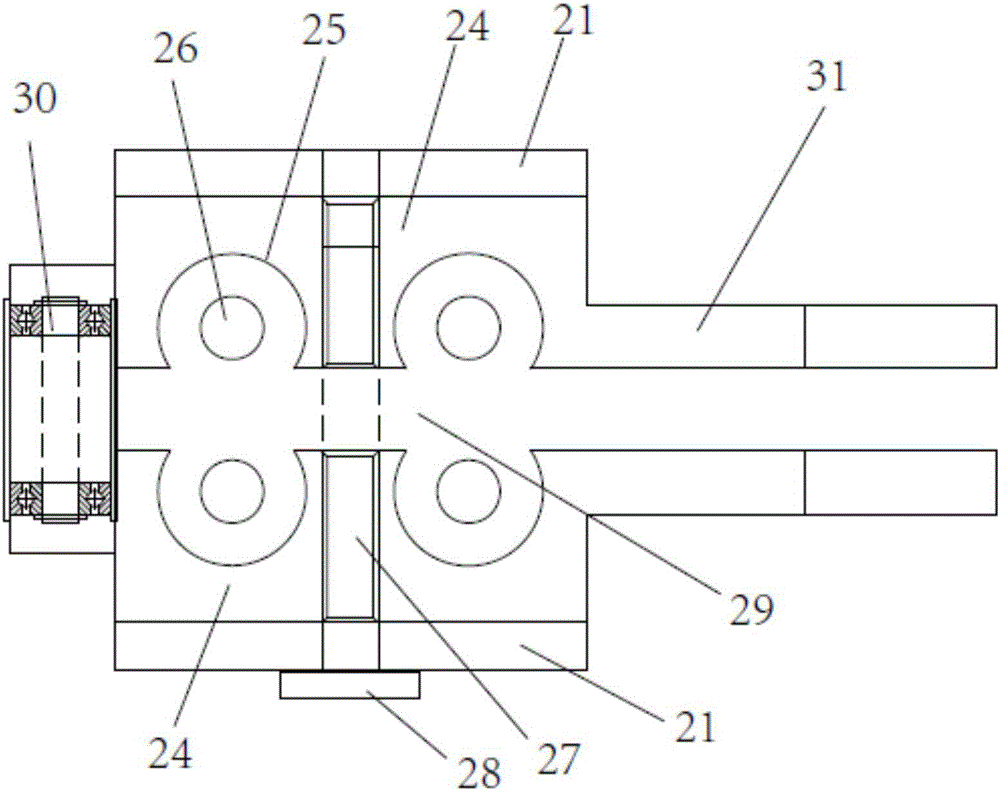

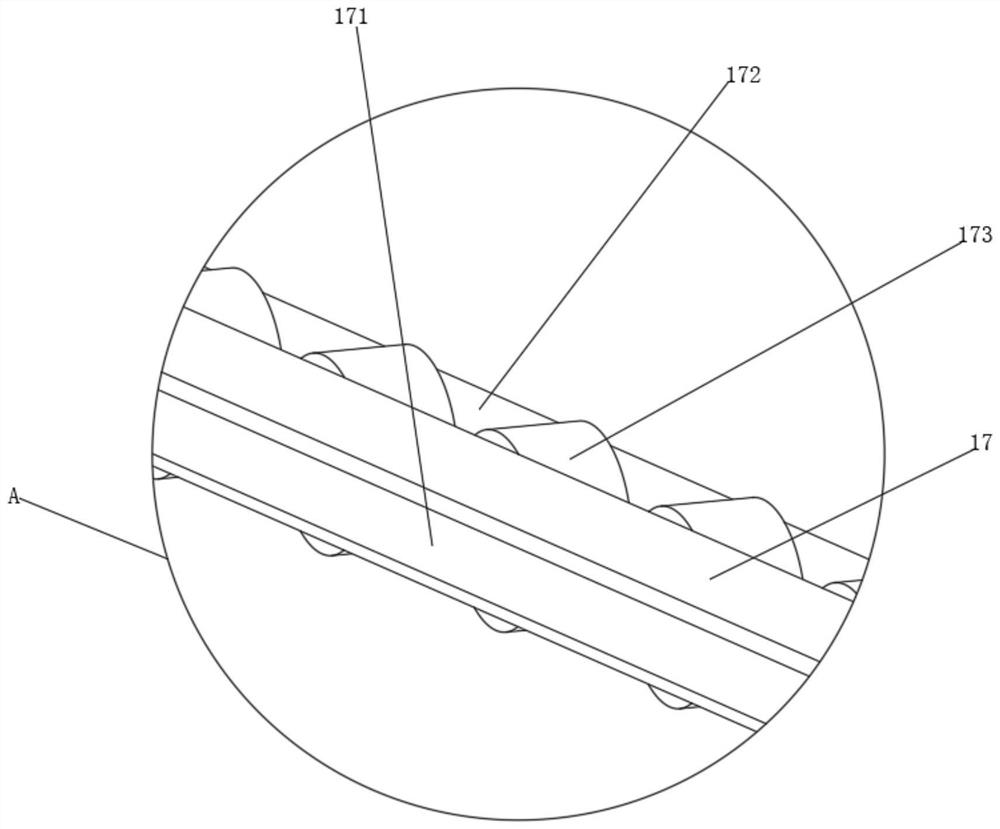

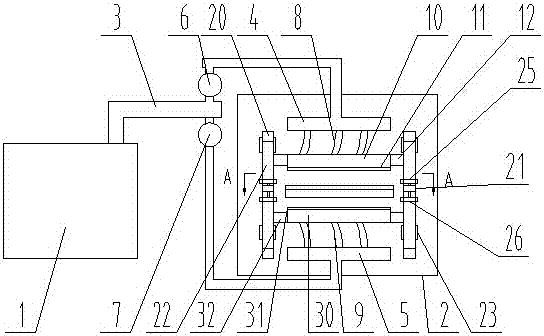

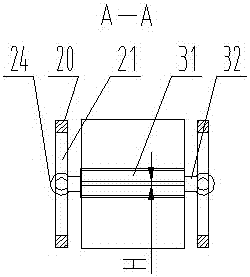

Wire energy-saving blow-drying device

The invention relates to the technical field of on-line blow-drying equipment, in particular to a wire energy-saving blow-drying device. The device is characterized in that the device is composed of asupport frame, an upper module, a lower module, an upper locking bolt and a lower locking bolt; the support frame is square; the square support frame is internally provided with the upper module andthe lower module; an opening gap between the upper module and the lower module is set as a product via hole; the rear side surfaces or the front side surfaces of the upper module and the lower moduleare locked and connected with the support frame through the upper locking bolt and the lower locking bolt correspondingly; the front side and the rear side of the lower end surface of the upper moduleare provided with strip-shaped grooves correspondingly; the front side and the rear side of the upper end surface of the lower module are provided with strip-shaped bosses correspondingly; the left end portions of the front side surfaces or the rear side surfaces of the upper module and the lower module are provided with air inlet blind holes; upper air outlets are formed in the hole wall of theair inlet blind hole of the upper module; and lower air outlets are formed in the hole wall of the air inlet blind hole of the lower module. The device has the advantages of simple structure, convenient use, good blow-drying effect, high drying efficiency, low energy consumption and the like.

Owner:威海邦德散热系统股份有限公司

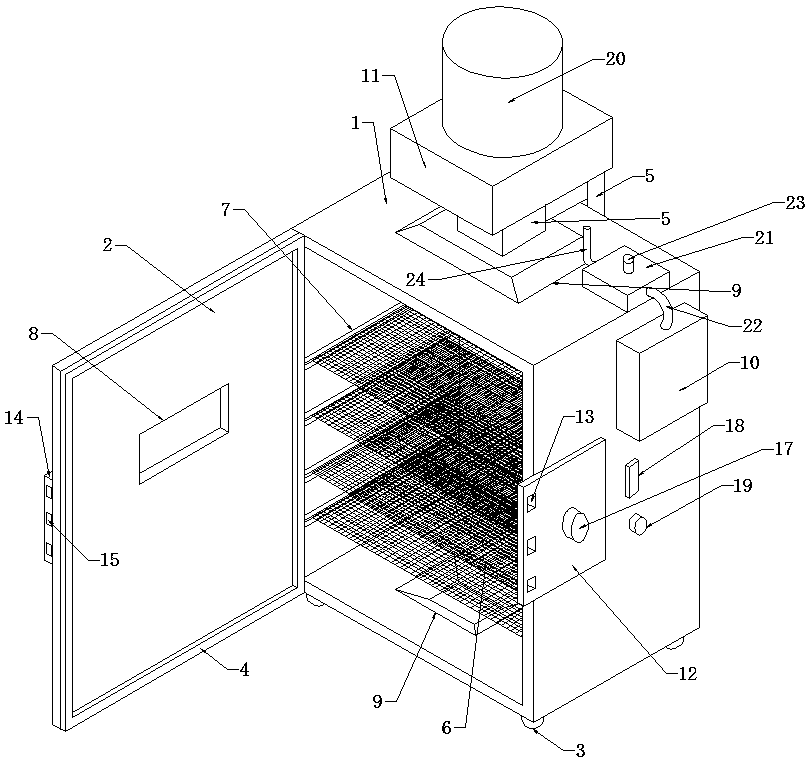

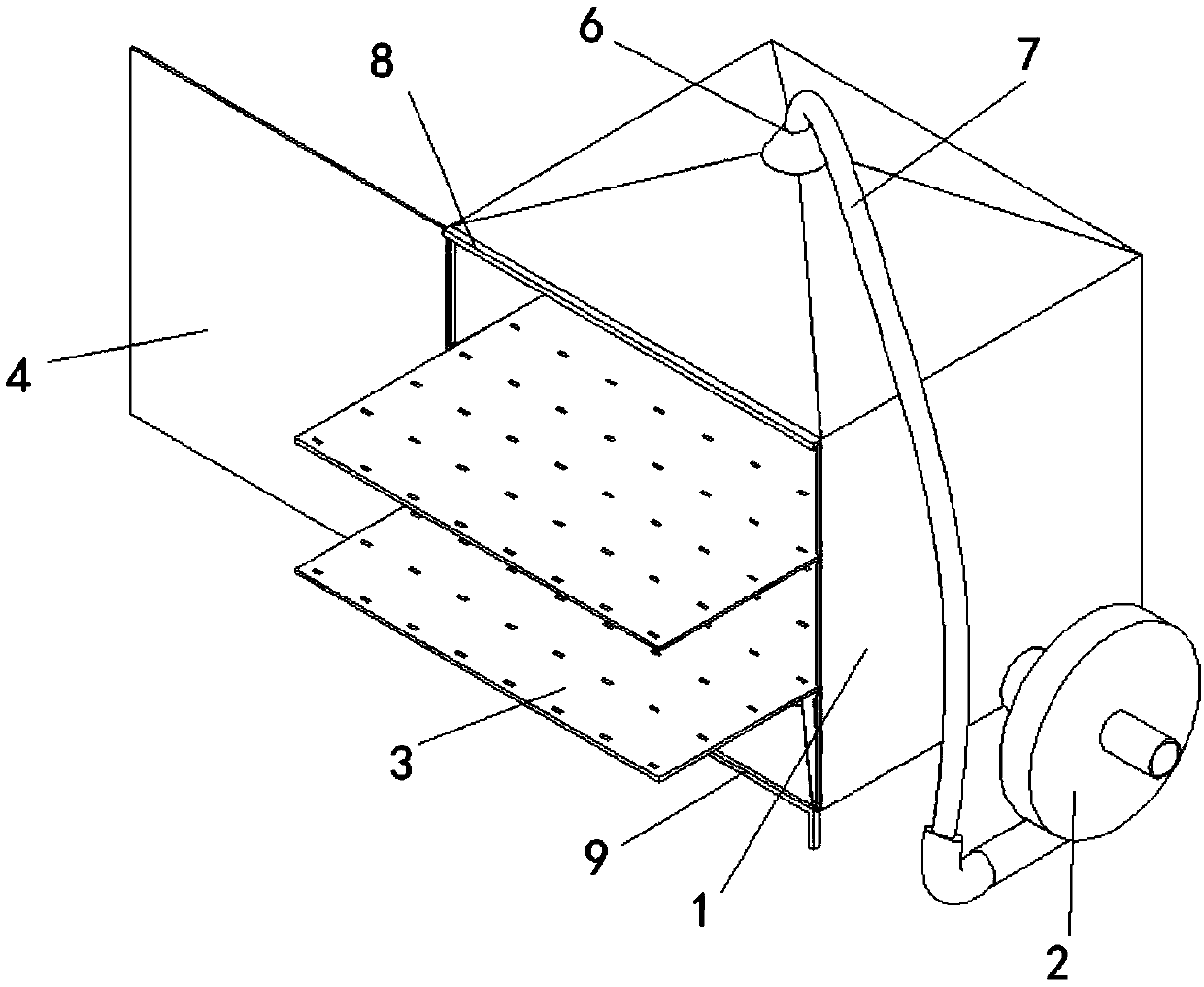

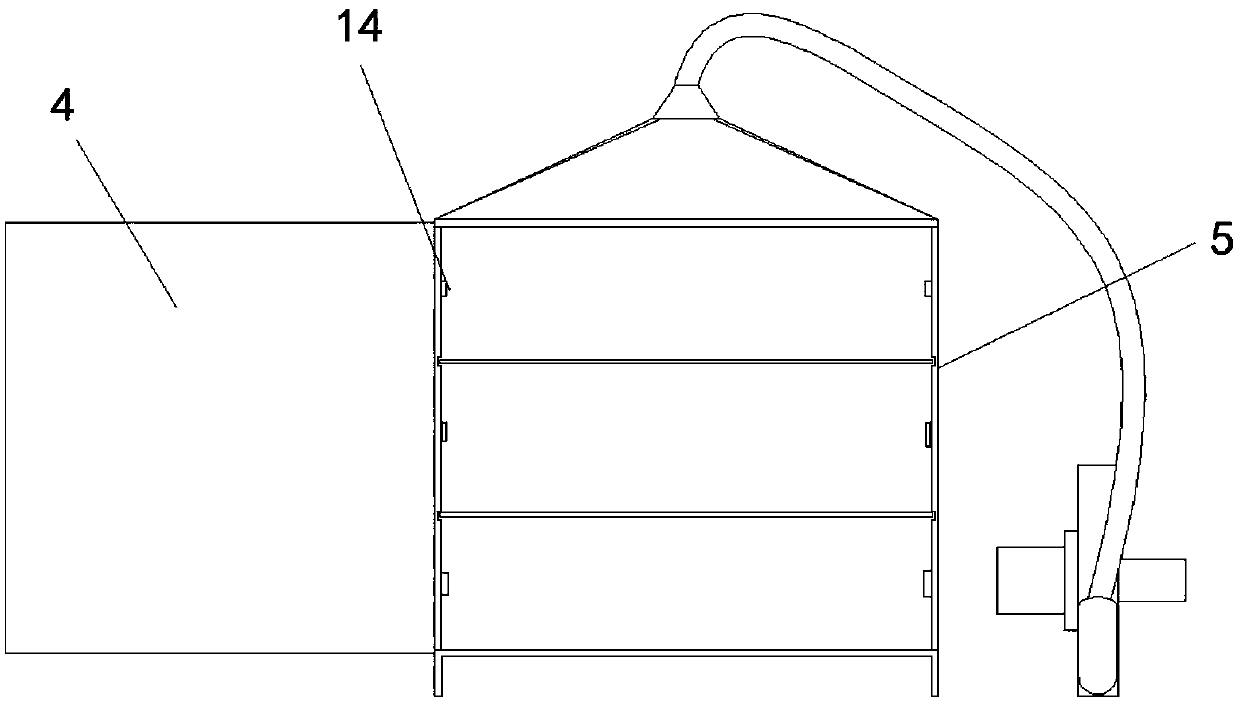

Air blowing type drying box

InactiveCN107664393AAvoid pollutionShorten drying timeDrying gas arrangementsDrying machines with local agitationEngineeringDrying time

The invention relates to a blower type drying box, which comprises a cabinet body, a cabinet door and universal wheels. There are storage grooves on the left and right sides of the cabinet inside the cabinet, and iron grid frames are movably installed on the storage grooves. One side of the cabinet body is There is a lock plate for the activity, a rotary knob is set on the lock plate, one end of the lock plate extends out of the cabinet body, a lock hole is set on the end of the lock plate extending out of the cabinet body, a lock body is set on the outside of the cabinet door, and impurities are set on the side of the cabinet body For the accumulator, a heat exchanger is arranged on the top of the cabinet, and the heat exchanger is connected to the impurity accumulator through a connecting pipe. An air inlet is arranged above the heat exchanger, and an outlet is arranged on the side of the heat exchanger. The beneficial effects of the present invention are: simple operation, good blow-drying effect on Radix Paeoniae Alba, can effectively avoid mixing dust and impurities in Radix Paeoniae Alba, can keep the air circulation in the drying box clean, and avoid polluting Radix Paeoniae Alba , through the setting of the motor and the circulating outer tube, the drying time of the white peony root is greatly reduced, and the labor intensity is reduced, and it is not affected by weather changes, which effectively saves the cost.

Owner:SICHUAN BIAOYI TRADITIONAL CHINESE MEDICINE TECH CO LTD

A rubber tire hot film air-drying pressing roller device

The invention relates to the field of rubber tire hot film production and processing devices, in particular to a rubber tire hot film air drying compression roller device. The device comprises a base,a feeding structure, an adjusting structure, a guide structure, an air inlet structure, a discharging structure and a hanging structure; the interior of a fixing sleeve is connected to three internalhollow hanging rods which are in a triangular structure in a rotating mode through a second bearing, each of the three hanging rods is of a continuous S-shaped structure, so that the contact area between the hanging rods and the rubber tire hot film can be effectively reduced, and thus a better blow-drying effect is achieved; a plurality of air holes which are in 45-degree included angles with the fixing sleeve are formed in each hanging rod, so that when the rubber tire hot film is in contact with the hanging rods, the air holes cannot be influenced to blow air to the rubber tire hot film; and a plurality of blades are distributed on the outer part of each hanging rod in an annular array mode, the blades can slightly rotate when airflow enters an air channel, then the hanging rods are driven to rotate, further, the rubber tire hot film on the hanging rods can vibrate, and therefore a better drying effect is achieved.

Owner:嘉兴华竹电子有限公司

A converging belt rolling production line

ActiveCN106180253BStable thicknessGuaranteed rolling qualityExtrusion cleaning devicesProduction lineWire rod

The invention discloses a calendaring production line for busbars. The calendaring production line comprises a pay-off rack, a wire drawing machine, a calendaring machine, a traction machine, an annealing device, a tin coating machine and a take-up machine, wherein the pay-off rack, the wire drawing machine, the calendaring machine, the traction machine, the annealing device, the tin coating machine and the take-up machine are sequentially arranged in the wire conveying direction. The calendaring machine comprises a machine frame. An operation platform is arranged on the machine frame. A wire straightening machine, a roughing mill, a forming mill and a finishing mill are sequentially arranged on the operation platform in the wire conveying direction. A wire inlet guiding nozzle is arranged on the wire inlet side of the roughing mill. A first diameter measuring gauge is arranged on the wire outlet side of the roughing mill. A first edge trimming machine is arranged on the wire inlet side of the forming mill. A second diameter measuring gauge is arranged on the wire outlet side of the forming mill. A second edge trimming machine is arranged on the wire inlet side of the finishing mill. A third diameter measuring gauge is arranged on the wire outlet side of the finishing mill. The tin coating machine comprises a cleaning part and a tin feeding part. According to the calendaring production line, the production speed is high, and the production quality is high.

Owner:JIANGSU YOUZHA MACHINE CO LTD

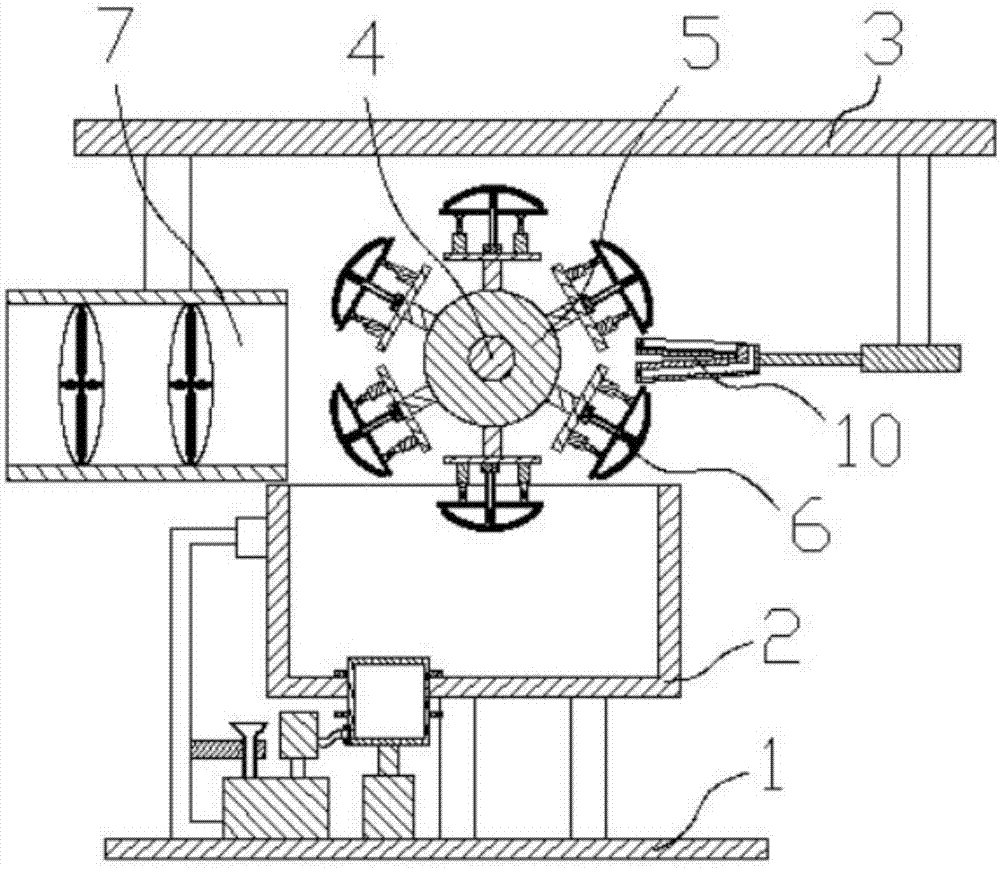

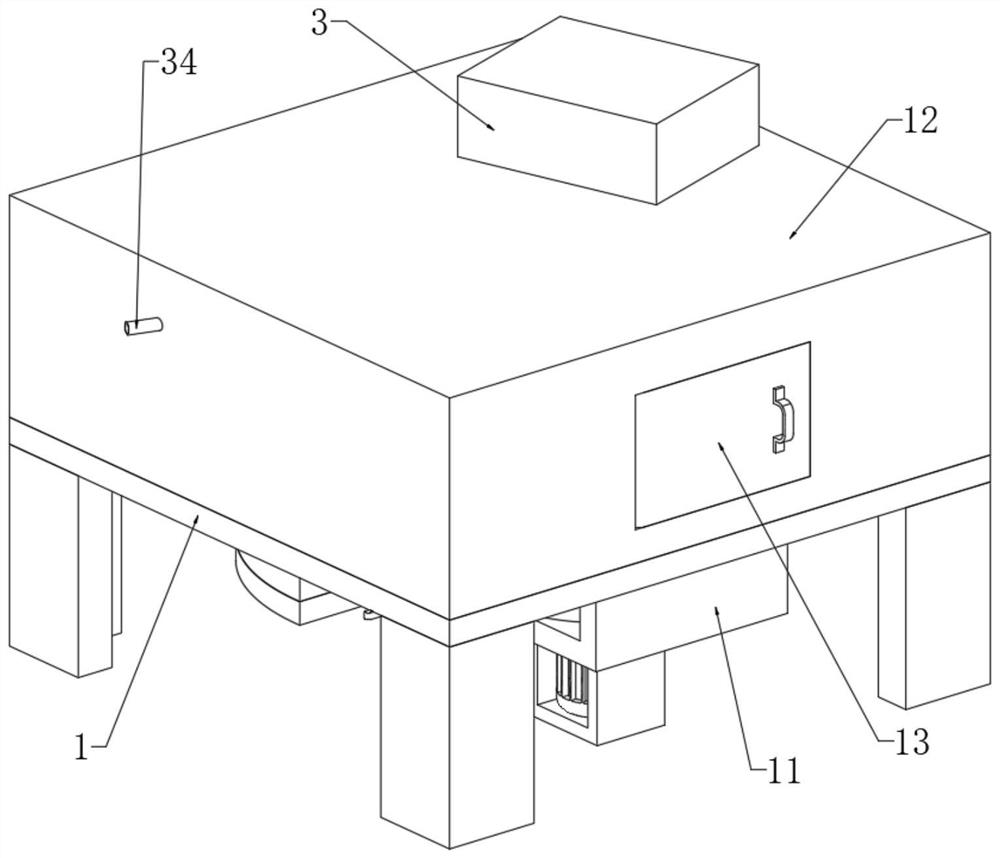

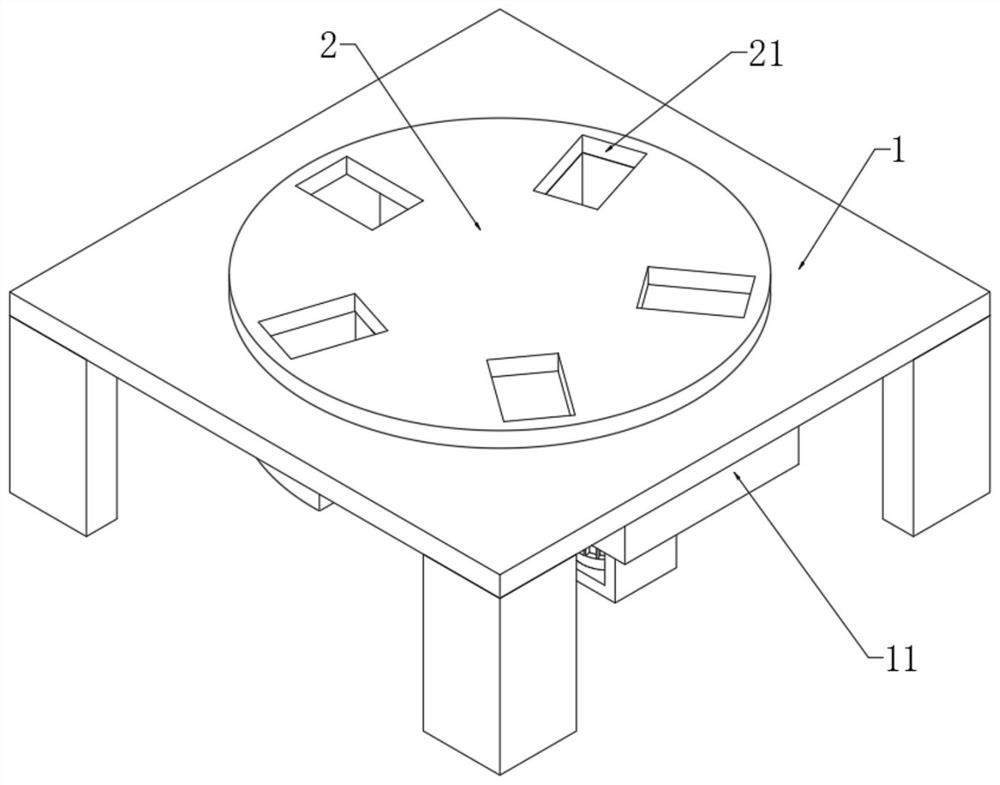

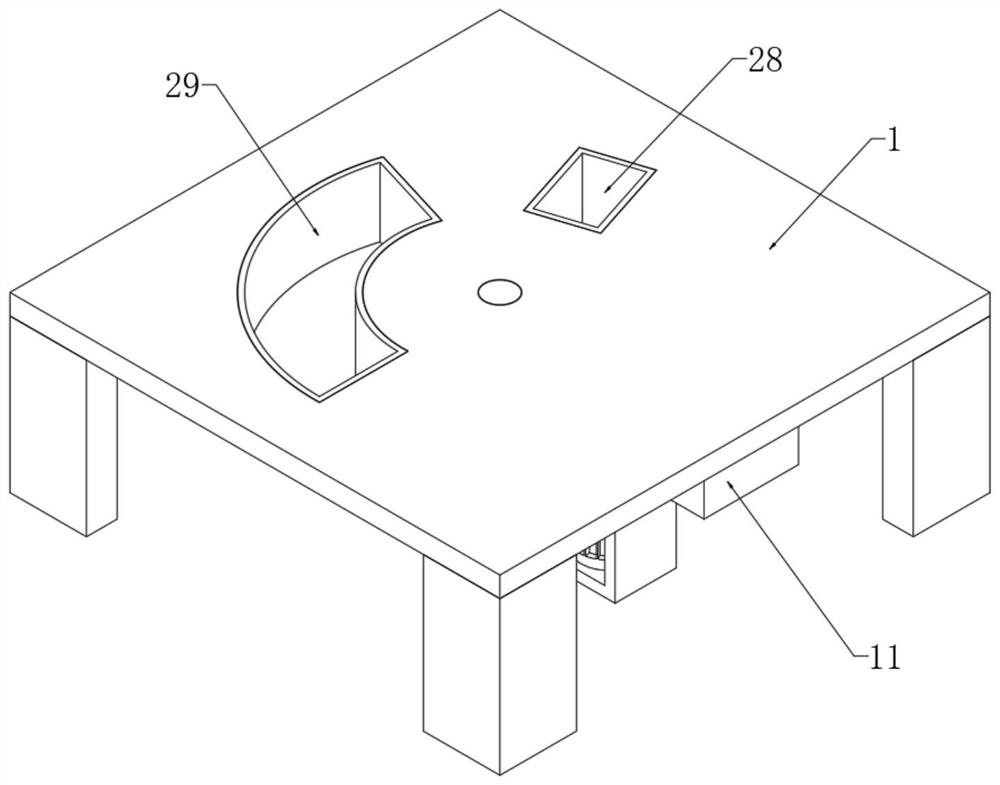

Etching equipment for integrated circuit production

ActiveCN114554713AThe installation process is simple and convenientThe disassembly process is simple and convenientFinal product manufacturePrinted circuit dryingIc productionMechanical engineering

The invention relates to the technical field of etching devices, in particular to etching equipment for integrated circuit production, which comprises a supporting table, a supporting frame is welded at the lower end of the supporting table, a protective shell is welded at the upper end of the supporting table, a box door is mounted on the side surface of the protective shell, and a turntable is arranged at the upper end of the supporting table. The device has the beneficial effects that the arranged intermittent rotating mechanism drives the turntable to intermittently rotate, so that the integrated circuit board intermittently rotates circumferentially, and the integrated circuit board sequentially rotates below the etching device main body, the cleaning mechanism and the blow-drying mechanism; the integrated circuit board stops for a period of time when being located below the etching device main body, the cleaning mechanism and the blow-drying mechanism, the etching device main body is used for etching the integrated circuit board, the cleaning mechanism is used for flushing etching liquid on the integrated circuit board, and the blow-drying mechanism is used for blow-drying water stains on the integrated circuit board.

Owner:富璟信息数字科技(深圳)有限公司

Fully automatic and high-efficiency plastic production equipment

InactiveCN106346752AAvoid deformationGuarantee product qualityCoatingsUltimate tensile strengthFully automatic

The invention describes fully automatic and high-efficiency plastic production equipment, comprising a water tank and a rotary guide rod. The both upper ends of the water tank are provided with sliders respectively on which the vertical beams are vertically connected, and the ends of the rotary guide rollers are mounted on the vertical beams which can rotate. And the drying unit, which is mounted at the adhesive strip outlet side of the water tank, comprises a fan and an outlet pipe disposed above the water tank connected with the fan; and the outlet pipe is provided with an air outlet towards the adhesive strip; and supports are arranged on both sides of the lower end of the water tank, which are provided with rotatory shafts on both sides; one end of a rotary shaft, going though the supports, is connected with a hand wheel, which is provided with a gear. A gear rod matching to the gear is equipped at the bottom of the water tank, and guide rails are fixed on both sides of the lower end of the water tank, with sliding clips which are arranged outside the supports. The guide rails on the water tank moves along the supports in the horizontal direction by the rotatory hand wheel, so that the distance between the water tank and the extruder can be controlled, so as to adjust the cooling strength of the strip.

Owner:成都君华睿道科技有限公司

Uniform cleaning device suitable for cleaning structure of precision machine tool equipment

ActiveCN114535197APrevent leakageImprove washing effectDrying gas arrangementsCleaning using liquidsReciprocating motionStructural engineering

The invention discloses a uniform cleaning device suitable for a cleaning structure of precision machine tool equipment, which comprises a box body, an air injection and water spraying assembly, guide structures and an anti-leakage structure are arranged in the box body, the guide structures are symmetrically mounted on opposite box walls in the box body, the air injection and water spraying assembly is connected with a power cylinder, and the power cylinder is arranged below the outside of the box body. The air and water spraying assembly can be driven by the power air cylinder to reciprocate in the box body along the guide structure, and an anti-leakage structure is arranged at the bottom of the box body below the air and water spraying assembly; a water vapor spraying opening is formed in the top of the box body above the air spraying and water spraying assembly, the air spraying and water spraying assembly comprises an air spraying knife, a water spraying knife, a knife holder and a supporting column, the air spraying knife and the water spraying knife are the same in structure and are connected to the knife holder in parallel, the supporting column is connected to the lower portion of the knife holder and penetrates through the anti-leakage structure, and the bottom of the box body is connected with the power air cylinder. A continuous water curtain and a continuous air curtain can be sprayed out, the integration degree is higher, and cleaning is more uniform.

Owner:沈阳和研科技股份有限公司

Device for drying surface moisture of storage battery by blowing

InactiveCN106410253AReduce distanceImprove drying effectAssembling battery machinesFinal product manufactureSurface moistureEngineering

The invention discloses a device for drying surface moisture of a storage battery by blowing. The device comprises a conveying belt used for moving the storage battery; guide rods are arranged at two sides of the conveying belt; a bracket is arranged over the guide rods; a support plate is arranged below the bracket; a through hole is arranged on the support plate, and used for installing an air pipe; the pipe mouth of the air pipe corresponds to the storage battery on the conveying belt; and an adjusting switch is arranged on the conveying belt. The air pipe is placed by setting of the liftable support plate, so that the storage battery on the conveying belt can be rapidly dried by being blown; and the device disclosed by the invention is simple in structure, convenient to operate and ideal in blowing-drying effect.

Owner:TIANNENG BATTERY WUHU

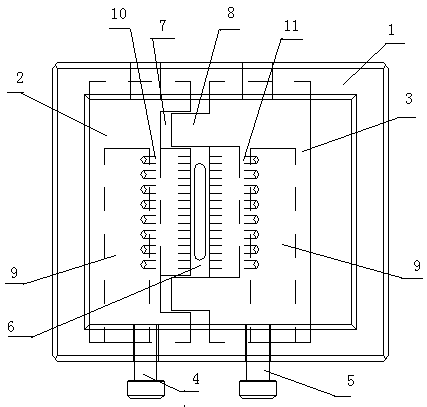

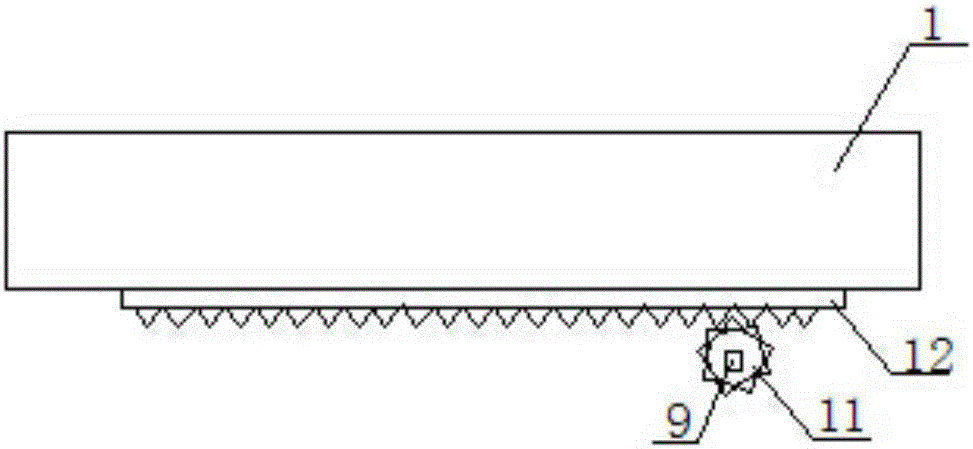

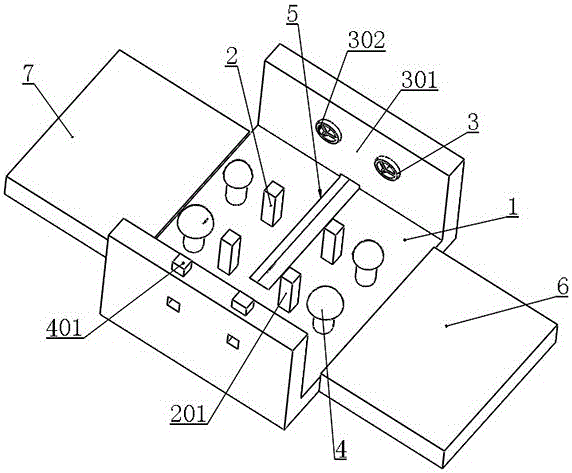

Blow-drying device used for wood-plastic floors

ActiveCN106426684AImprove power utilizationBlow drying effect is goodWood working apparatusFlat articlesElectric energyBiochemical engineering

The invention belongs to the technical field of manufacturing and processing equipment of wood-plastic floors, and particularly relates to a blow-drying device used for the wood-plastic floors. The blow-drying device used for the wood-plastic floors comprises a blow-drying device base board, supporting units, blow-drying fan units and fan power-on units. The supporting units are arranged on the blow-drying device base board and used for supporting the wood-plastic floors and the blow-drying device base board, the blow-drying fan units are arranged on the blow-drying device base board, and the fan power-on units are used for triggering the blow-drying fan units to conduct blow-drying action. The blow-drying fan units are arranged on the two sides of the supporting units. According to the blow-drying device used for the wood-plastic floors, blow-drying is triggered after the wood-plastic floors are placed into the device, the blow-drying fan units are located on the two sides of the wood-plastic floors, and thus the blow-drying way capable of achieving a high electric energy utilization ratio and a good blow-drying effect is achieved. The blow-drying device used for the wood-plastic floors has the advantages of being simple and effective in structure, good in blow-drying effect, efficient and capable of saving energy.

Owner:浙江天博生物新材料股份有限公司

Walking board conveying table for spraying water pipe pressure groove type template

ActiveCN113751237ANot easy to dropConvenience for later workPretreated surfacesCoatingsStructural engineeringAir blower

The invention relates to the technical field of aluminum template production, in particular to a walking board conveying table for spraying a water pipe pressure groove type template. The table comprises a conveying table, L-shaped frames are symmetrically welded and fixed at two ends and two sides of the conveying table respectively, a rack supporting device is welded and fixed between the L-shaped frames at the two ends, first shaft holes are symmetrically formed in the two ends and the two sides of the conveying table correspondingly, the number of the first shaft holes in each side is four, the number of the first shaft holes in the upper sides of the L-shaped frames is two, the number of the first shaft holes in the lower sides of the L-shaped frames is two, the first shaft holes in the two sides of the L-shaped frames are symmetrical about the L-shaped frames, rack driving devices are inserted into the middles of the first shaft holes, air blowers are arranged on the two sides of the conveying table, under the action of an air blowers, a certain blow-drying effect can be achieved on a template on the conveying table, so that spray paint on the template conveyed on the conveying table can be solidified to a certain degree, it is guaranteed that the spray paint cannot prone to falling off in the template conveying process, and later work is facilitated.

Owner:广东鹏港建筑科技股份有限公司

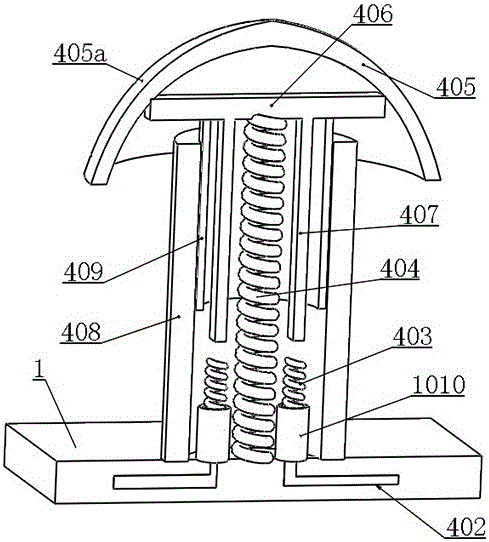

A tilting wood-plastic plate drying machine

The invention belongs to the technical field of wood-plastic panel manufacturing devices, and particularly relates to an inclined type wood-plastic panel blow-drying machine comprising a blow-drying machine base. The inclined type wood-plastic panel blow-drying machine further comprises a panel supporting plate arranged on the blow-drying machine base, a turnover unit and a three-way blow-drying unit. The turnover unit is arranged below the panel supporting plate and is used for unloading completely-blow-dried panels by overturning the panel supporting plate. The three-way blow-drying unit is arranged on the blow-drying machine base. The panel supporting plate is arranged on the blow-drying machine base in an inclined manner. By means of the manner that the panels are placed in an inclined manner and then three-way blow-drying is conducted in the upper direction, the lower direction and the hole forming direction of the panels, the blow-drying operation of the panels with middle holes is completed, and the inclined type wood-plastic panel blow-drying machine has the beneficial effects that the structure is simple and effective, the blow-drying operation is convenient and rapid, the blow-drying effect is good and the inclined type wood-plastic panel blow-drying machine is suitable for the panels with the middle holes.

Owner:浙江天博生物新材料股份有限公司

Pipe washing and blowing device

InactiveCN106269722ASimple structureEasy to operateHollow article cleaningDrying gas arrangementsEngineeringMechanical engineering

The invention relates to a pipe washing and blowing device. The pipe washing and blowing device comprises a blow drying sleeve, a washing sleeve, a water injection sleeve and a feeding sleeve, wherein the washing sleeve is arranged on the inner side of the blow drying sleeve; the center of the inner side end face of the water injection sleeve is provided with a second square counter bore; the center of the bottom surface of the second square counter bore is provided with a third through hole; the front end of a washing post on the washing sleeve is inserted into the third through hole; the feeding sleeve is arranged on the outer side of the water injection sleeve. Water current enters from a water injection hole in the water injection sleeve, passes through current-dividing holes in the washing sleeve, and washes a casing, and wind is injected from an air inlet hole in the blow drying sleeve and is blown towards the surface of the casing through a gap between the blow drying sleeve and the washing sleeve, so that a blow drying effect is achieved.

Owner:东莞三联热缩材料有限公司

Hot blowing mechanism of glass washing machine at cold end of float glass production line

ActiveCN105444552BReasonable structural designSave energyDrying gas arrangementsProduction linePulp and paper industry

The hot blowing mechanism of the glass washing machine at the cold end of the float glass production line includes the annealing kiln (1) and the glass washing machine (2). The material end is connected, and it also has a hot blowing mechanism, which includes the main hot air pipe (3), the upper hot air pipe (4), the lower hot air pipe (5), the upper high pressure fan (6), and the lower high pressure fan (7) , a set of upper hoses (8), a set of lower hoses (9), a set of air knife support and limit devices, an upper air knife assembly and a lower air knife assembly. The waste heat of the annealing kiln at the hot end of the float glass production line greatly saves energy, and the adjustable design of the hot air knife is carried out, which has a better drying effect and has good practical value.

Owner:FUYAO GRP TONGLIAO CO LTD

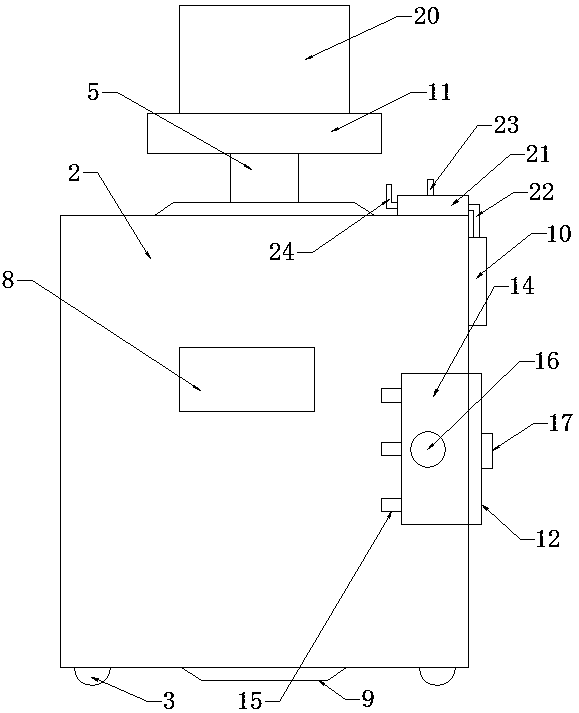

MT inserting core blow-drying equipment

InactiveCN109901266ASimple structureBlow drying effect is goodCoupling light guidesIndustrial equipmentEngineering

The invention relates to the field of industrial equipment, in particular to MT inserting core blow-drying equipment. According to the following adopted technical scheme, the MT inserting core blow-drying equipment comprises a shell, an air blower, MT inserting core fixing plates and an inserting plate; the shell is of a hollow structure, an opening is formed in the front face of the shell, grooves allowing the MT inserting core fixing plates to be inserted are formed in the shell, and every two corresponding grooves constitute a groove set; an air blowing opening is formed in the top of the shell and communicates with the air blower through a pipeline; and the bottom of the shell is of a frame structure, an upper flange and a lower flange are arranged on the front face of the shell, and the corresponding positions of the upper flange and the lower flange are provided with grooves allowing the inserting plate to be inserted. The MT inserting core blow-drying equipment is simple in structure, and good in blow-drying effect.

Owner:吴晓洁

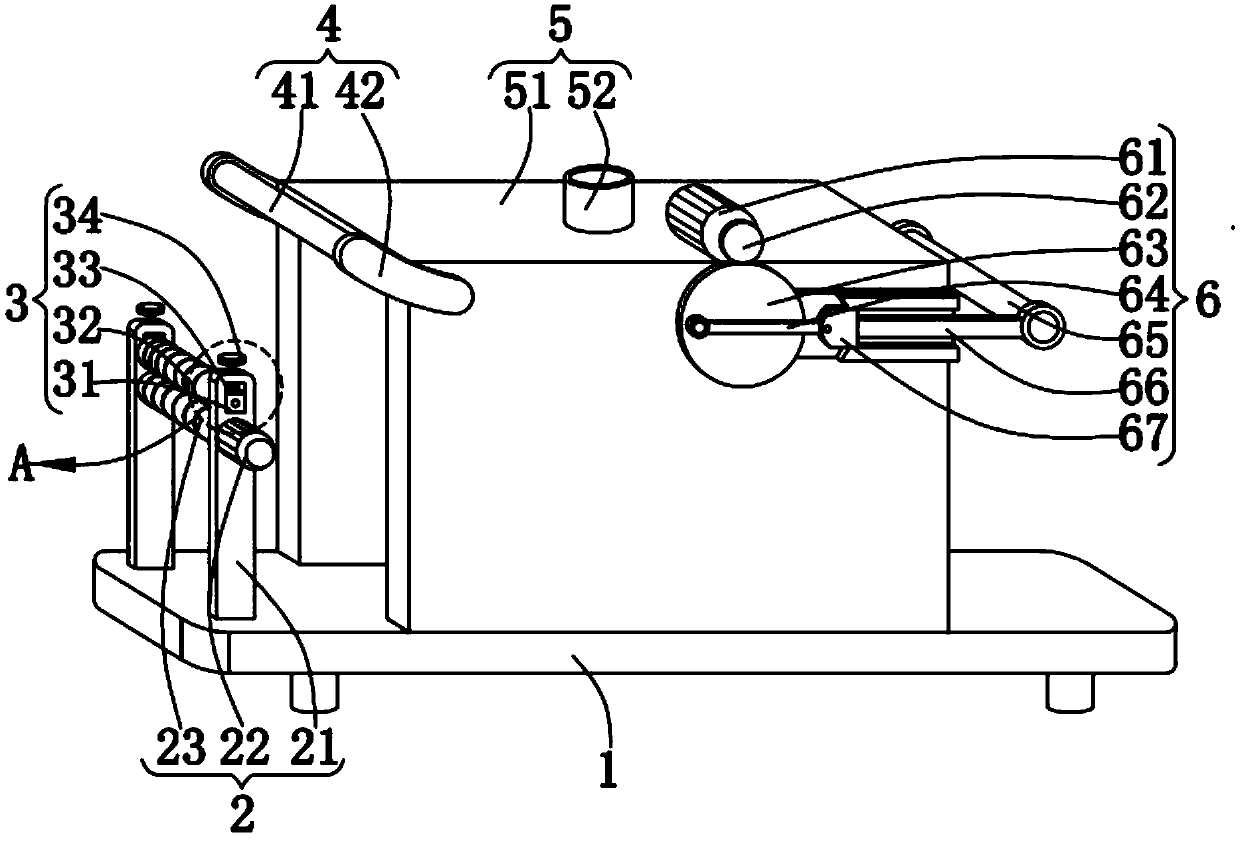

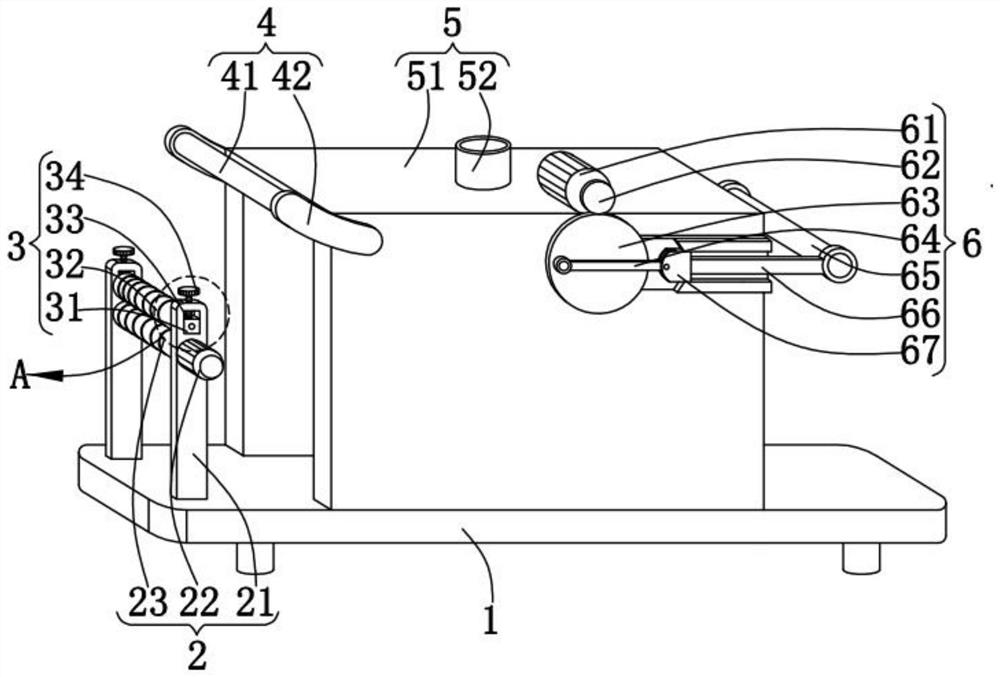

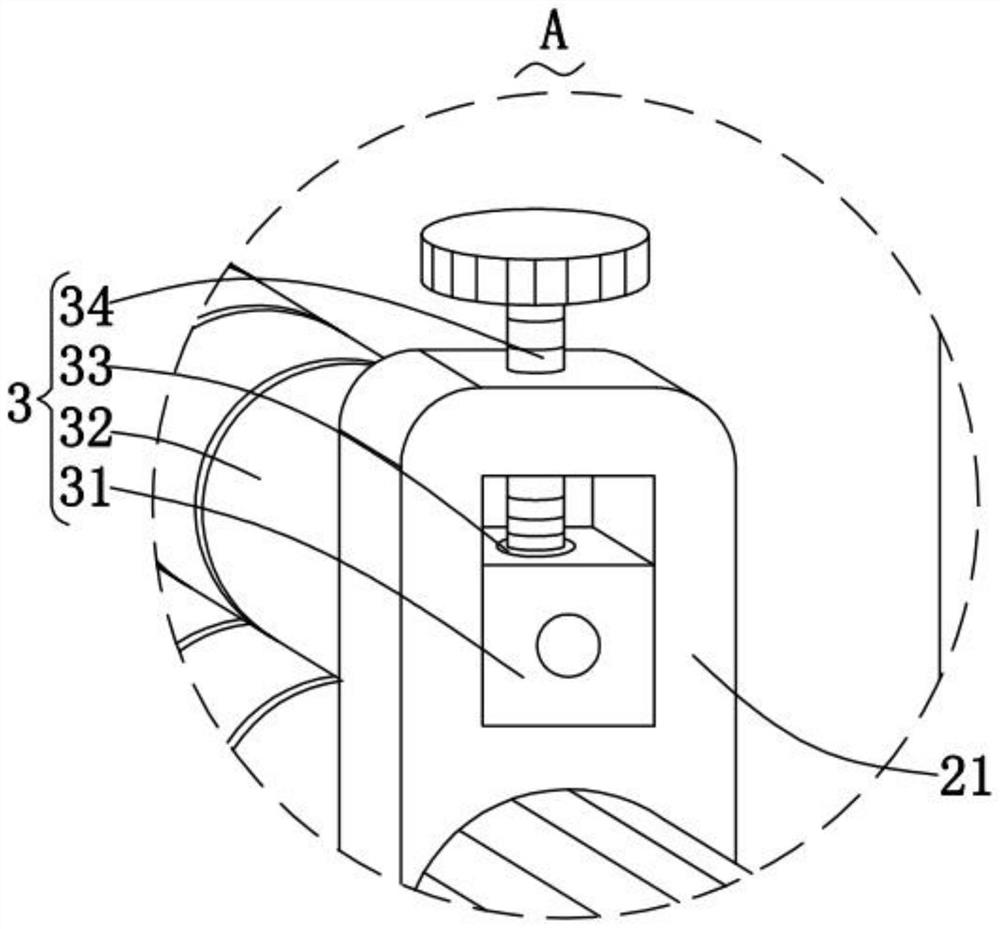

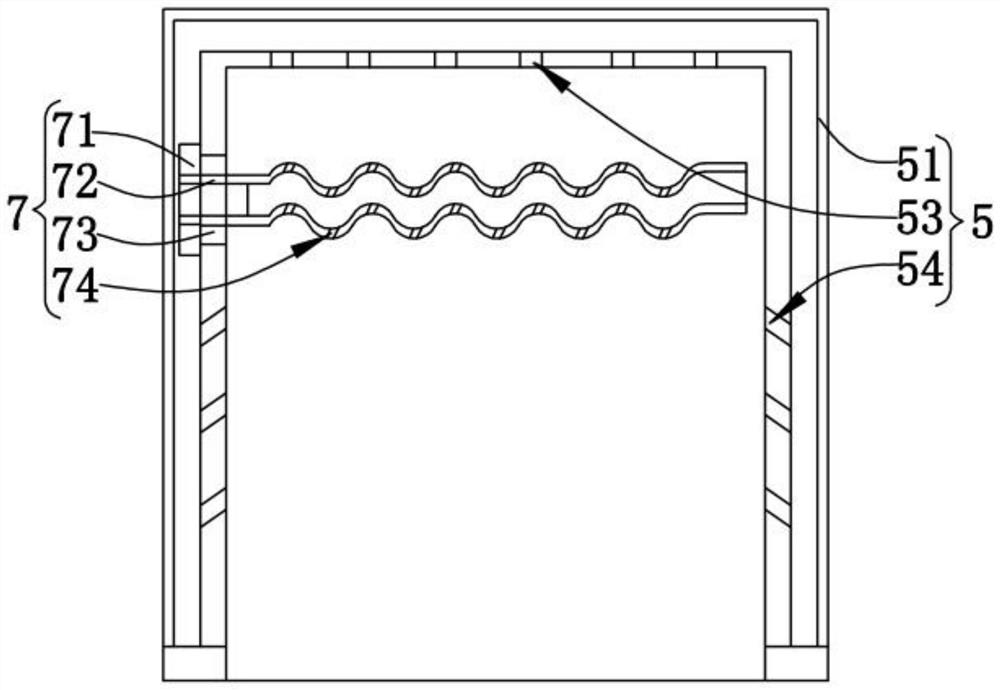

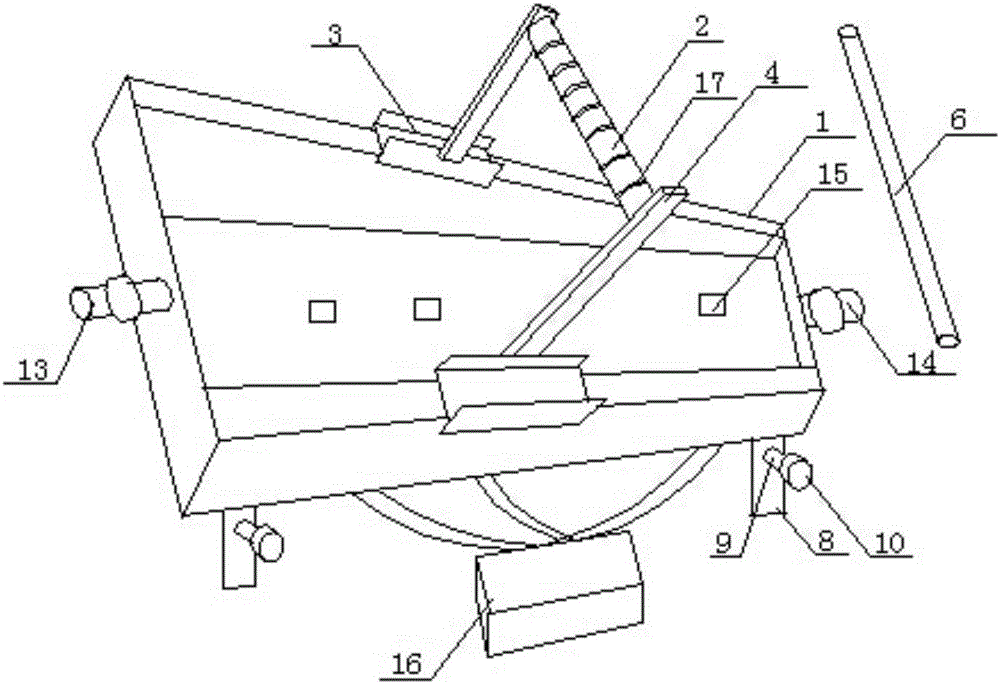

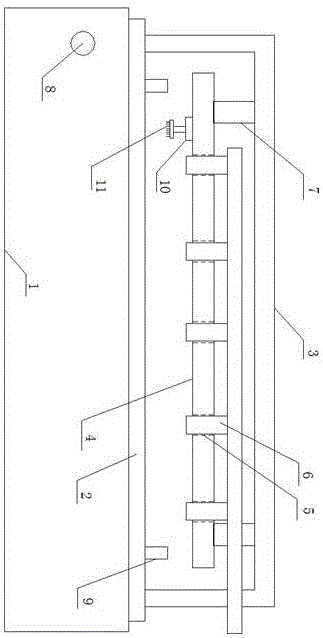

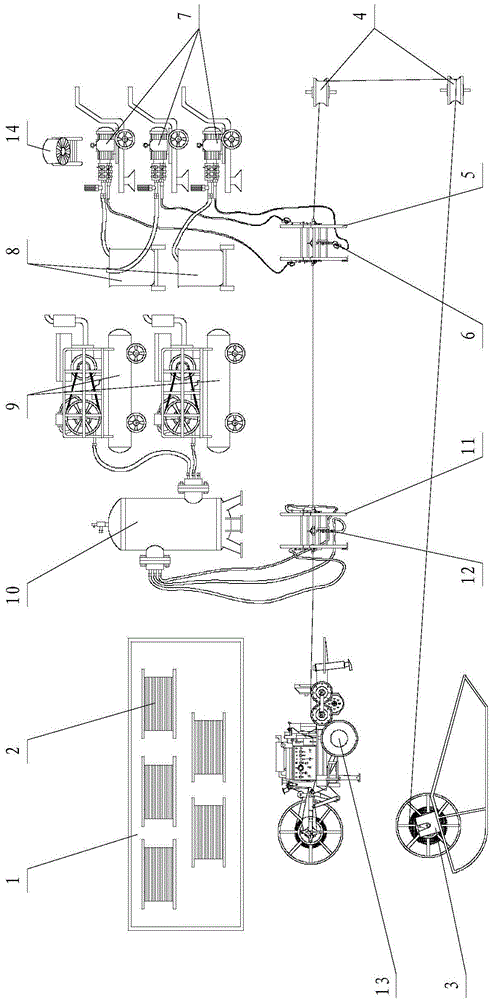

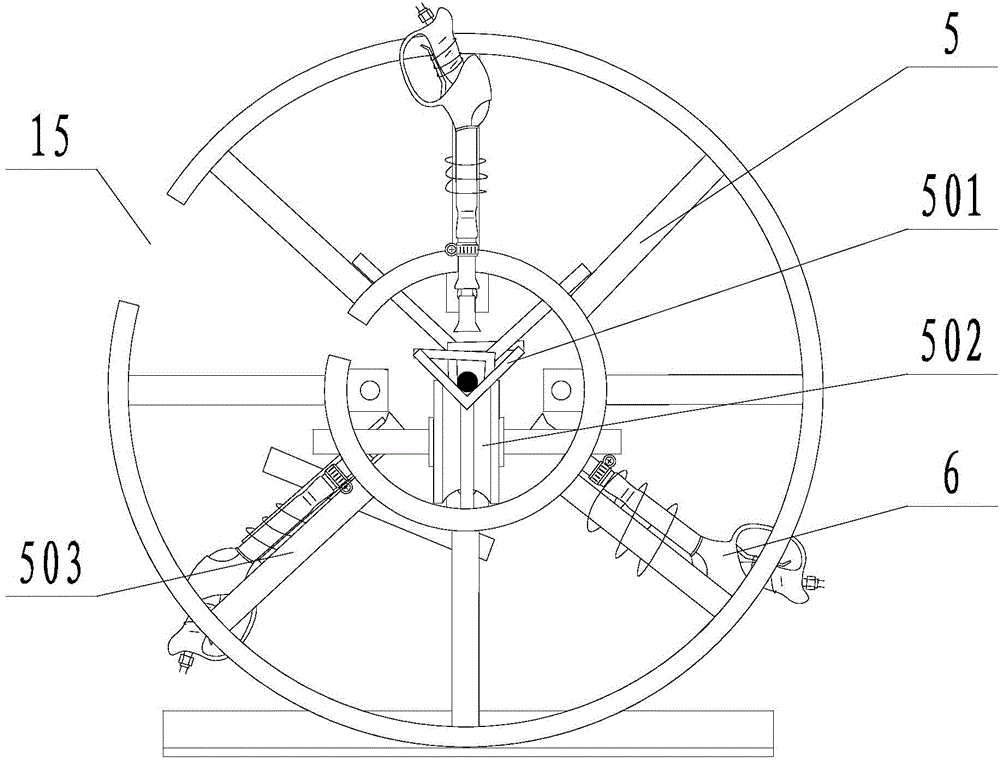

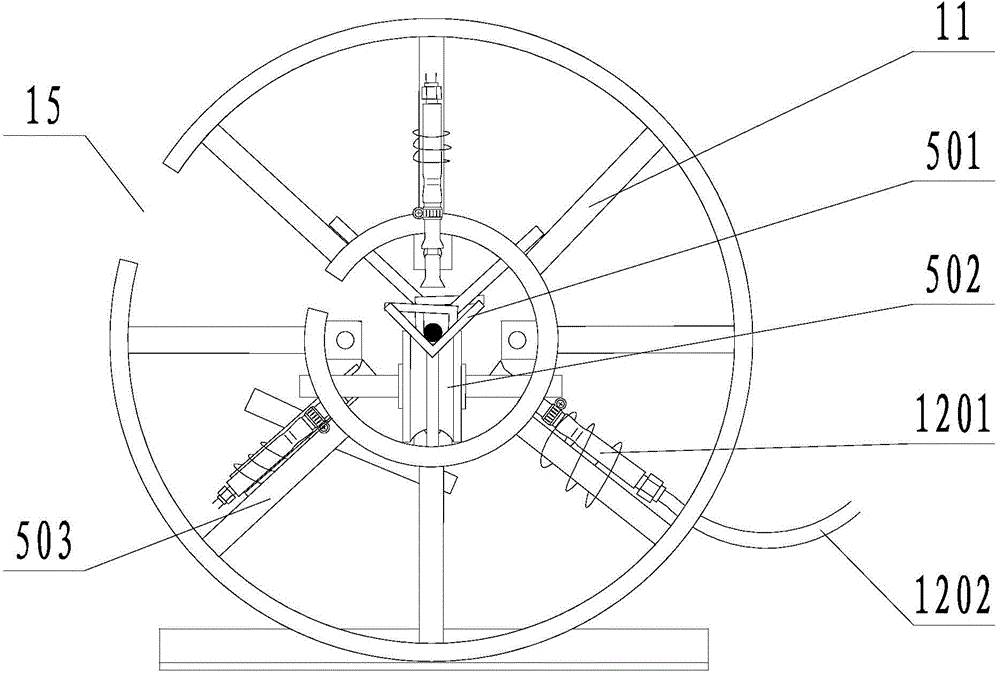

Dirt-removing, washing and processing device for steel wire rope

ActiveCN105457932APerformance is not affectedAvoid scrappingDrying gas arrangementsCleaning using liquidsAir compressorConductor Coil

The invention relates to construction equipment for electric transmission and distribution circuits, in particular to a dirt-removing, washing and processing device for a steel wire rope. The dirt-removing, washing and processing device comprises a ship type frame, a washing mechanism, a blow-drying mechanism and a traction machine. A winding drum wrapped with the steel wire rope is installed on the ship type frame after being soaked in a soaking pool. The washing mechanism comprises a water pump, a water bucket, a hydraulic gun support and a plurality of hydraulic guns evenly distributed on the hydraulic gun support. The water pump is communicated with the water bucket and all the hydraulic guns and supplies water for all the hydraulic guns. The to-be-washed steel wire rope on the winding drum penetrates through the hydraulic gun support to be washed through water sprayed by all the hydraulic guns. The blow-drying mechanism comprises an air compressor, an air storage tank, an air gun support and a plurality of air guns evenly distributed on the air gun support. The air storage tank is communicated with the air compressor and all the air guns and supplies air for all the air guns. The washed steel wire rope penetrates through the air gun support to be blown and dried through all the air guns. The blow-dried steel wire rope is put away through traction of the traction machine. The dirt-removing, washing and processing device has the characteristics of being simple and practical in structure, high in efficiency, good in washing effect, low in cost and free of influences on the performance of the steel wire rope.

Owner:LIAONING POWER TRANSMISSION & TRANSFORMATION PROJECT +3

A device for double-sided cleaning and drying of boards before painting

ActiveCN111744860BGuaranteed stabilityAvoid poor cleaning effect or even safety accidentsDrying gas arrangementsPretreated surfacesElectric machineryFan blade

The invention discloses a new type of double-sided cleaning and drying device for plates before painting, which includes a water tank and a placement mechanism. The inside of the water tank is provided with a filter sponge plate, and the top of the water tank is fixedly installed with a column and a group of first bearings in turn. frame, two sets of second bearing support frames, and two U-shaped frames. The right side of the column is fixedly installed with the first bearing seat and the second bearing seat in sequence from top to bottom. The first bearing seat and the second bearing seat are respectively A first round rod and a second round rod are rotatably connected. The outer surface of the first round rod is fixedly sleeved with the first pulley and the round wheel from left to right. The outer edge of the round wheel is fixedly welded with fan blades. The outer surface of the two round rods is fixedly sleeved with the second pulley and the turbine in turn from left to right, the first belt is connected between the first pulley and the second pulley, and the number of the first bearing support frame is two, And the two first bearing support frames are symmetrically distributed on the top of the water tank. This invention washes and cleans on both sides, and uses a motor to realize blowing and drying, which is highly efficient and energy-saving.

Owner:泉州台商投资区国进信息技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com