Fully automatic and high-efficiency plastic production equipment

A production equipment, fully automatic technology, applied in the coating and other directions, can solve the problems of deformation of the rubber strip, the cooling intensity cannot be controlled by the water tank, etc., to prevent the deformation of the rubber strip, the drying effect is obvious, and the effect of increasing the exchange of cold and heat can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

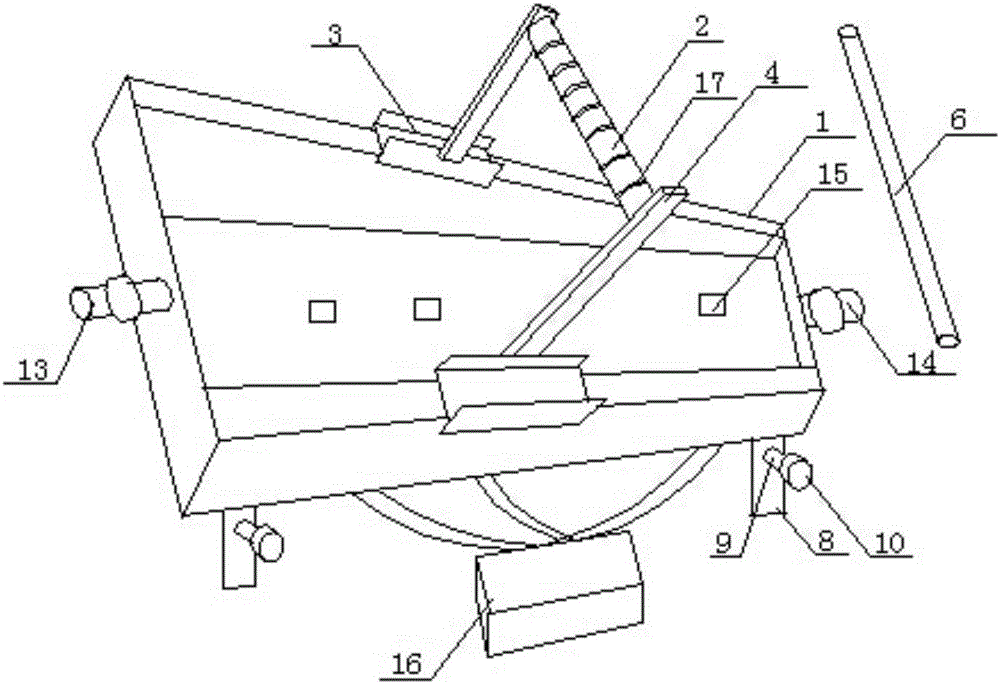

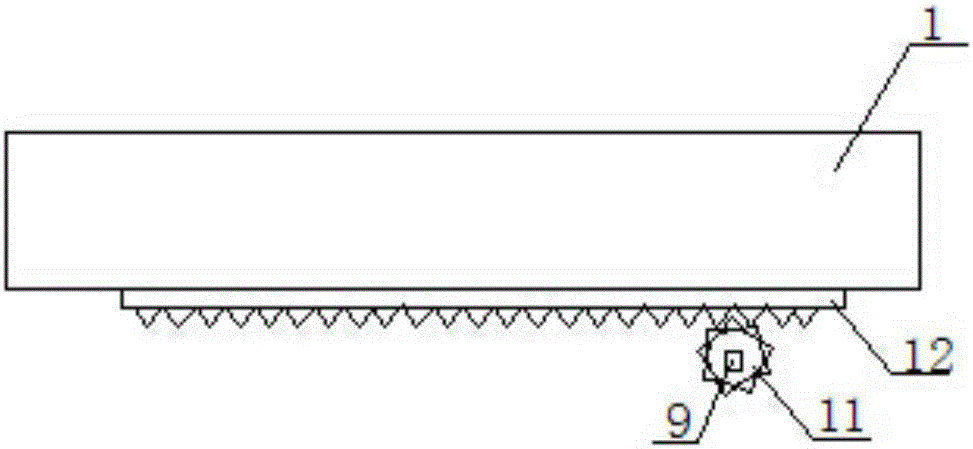

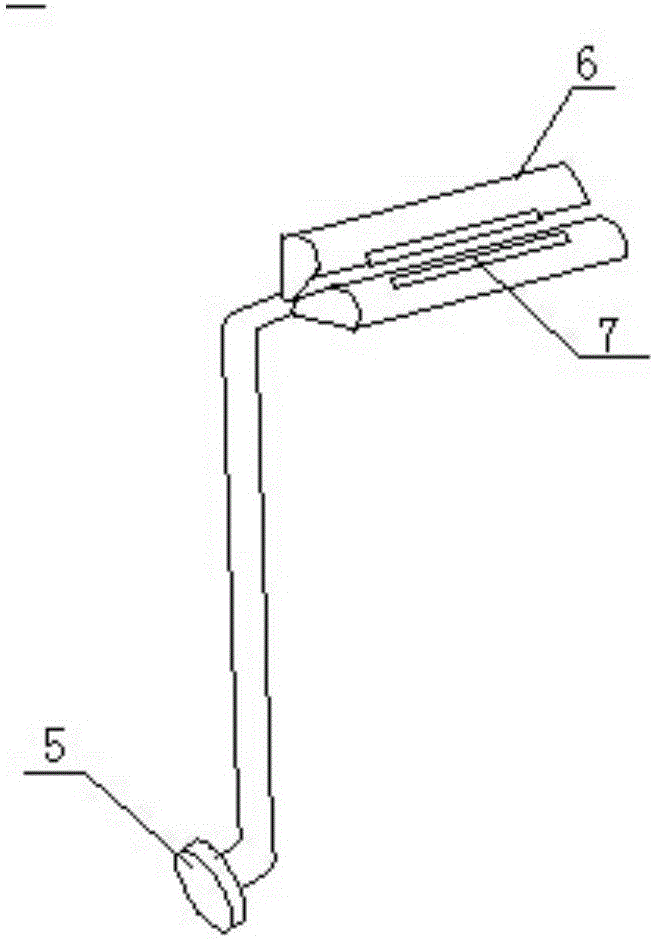

[0031] Fully automatic high-efficiency plastic production equipment, including a water tank 1 and a rotary guide roller 2. Sliders 3 are respectively slid on both sides of the upper end of the water tank 1. A vertical beam 4 is vertically connected to the slider 3. The two sides of the rotary guide roller 2 The ends are respectively rotated and arranged in the vertical beams 4 on both sides; the outlet end of the rubber strip of the water tank 1 is provided with a drying device, the drying device includes a fan 5 and an air outlet pipe 6 connected to the fan 5 and located above the water tank 1, The air outlet pipe 6 is provided with an air outlet 7 facing the rubber strip; support columns 8 are arranged on both sides of the lower end of the water tank 1, and a rotating shaft 9 is arranged between the supporting columns 8 on both sides, and one end of the rotating shaft 9 passes through the supporting column 8 and is connected to a The handwheel 10 is provided with a gear 11 on...

Embodiment 2

[0033] In this embodiment, on the basis of Embodiment 1, one end of the water tank 1 is provided with a water inlet 13, the other end is provided with a water outlet 14, and the bottom of the water tank 1 is provided with several air vents 15, and the air vents 15 are connected to air compressors. machine16.

Embodiment 3

[0035] In this embodiment, on the basis of embodiment 1 or embodiment 2, the air outlet pipe 6 is provided with two upper and lower air outlet pipes, and a rubber strip channel is formed between the two air outlet pipes 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com