Blow-drying device used for wood-plastic floors

A technology for wood-plastic flooring and bottom boards, applied in applications, household appliances, household components, etc., can solve the problems of low drying operation efficiency, unsuitable wood-plastic flooring, residual moisture, etc., and achieve high-efficiency and energy-saving blow-drying effects with simple structure Effective and high energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following descriptions are only preferred embodiments of the present invention, and do not limit the scope of the present invention.

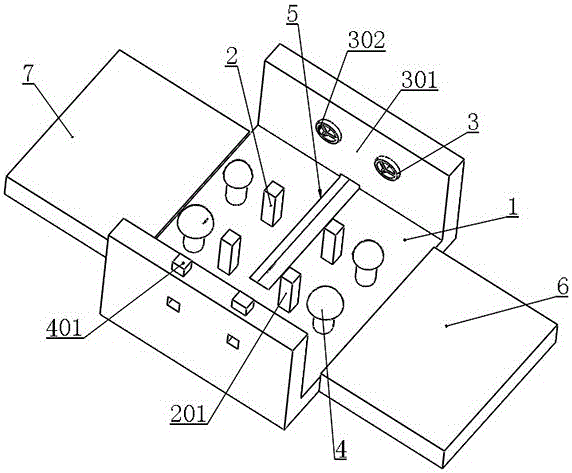

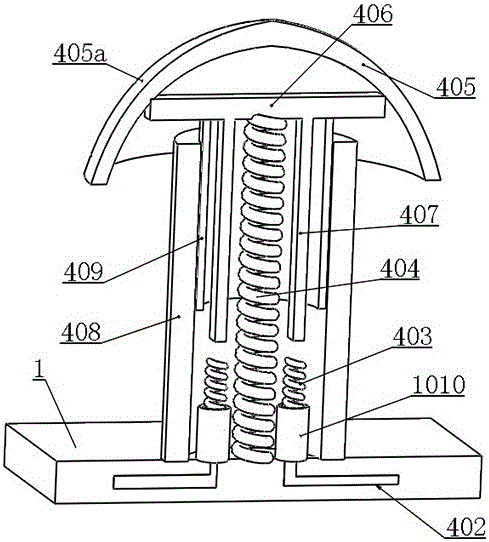

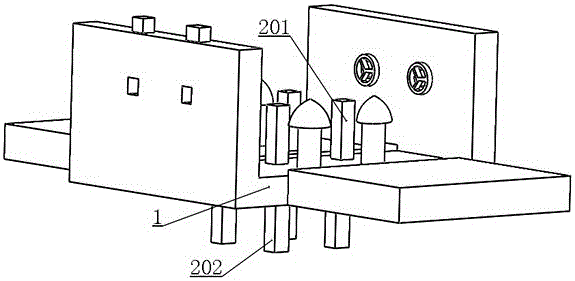

[0023] Example: as attached figure 1 , 2 , 3 and attached Figure 4 As shown, a drying device for wood-plastic flooring includes a drying device bottom plate 1, a support unit 2 arranged on the drying device bottom plate 1 for supporting the wood-plastic floor and the drying device bottom plate 1 , the drying fan unit 3 arranged on the base plate 1 of the drying device and the fan power supply unit 4 for triggering the drying fan unit 3 to carry out the drying action, the drying fan unit 3 is arranged on the support Both sides of unit 2.

[0024] In this embodiment, the wood-plastic floor is placed on the support unit 2, and the fan energization unit 4 is pressed down, so that the fan energization unit 4 is turned on, and the drying fan unit 3 is dried. action, wherein the blowing direction of the drying fan unit 3 is consistent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com