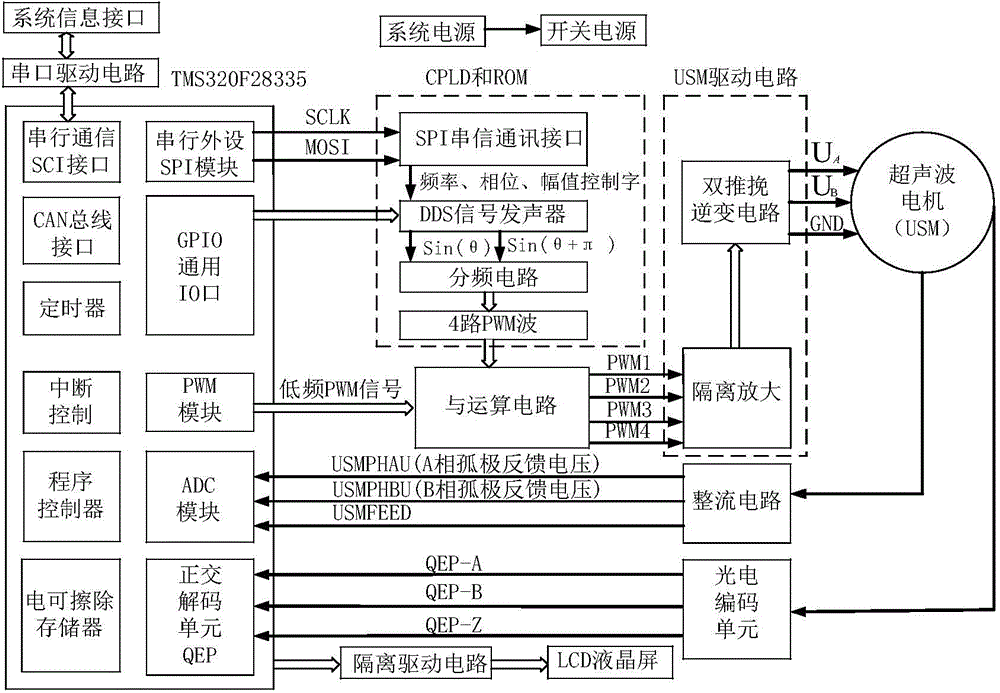

Low-frequency PWM and single neuron self-adaption-based ultrasonic motor control system

An ultrasonic motor, a single neuron technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

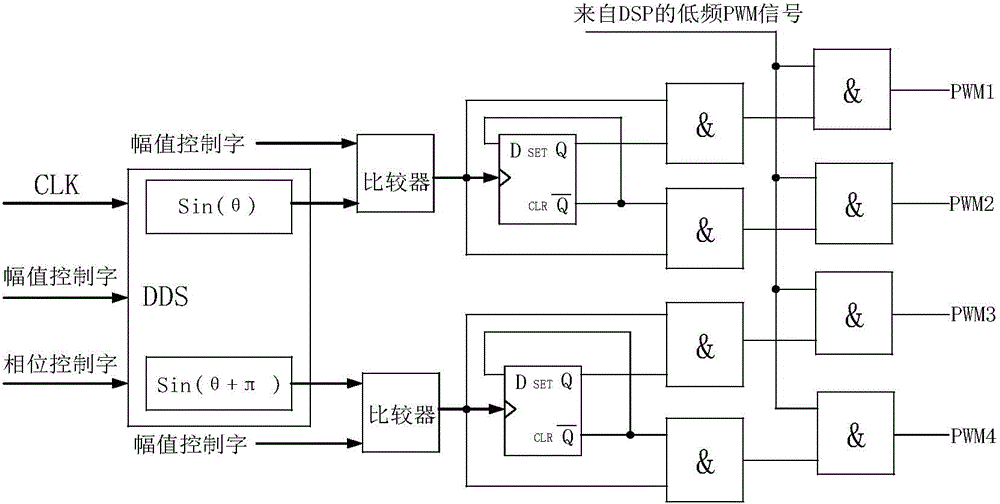

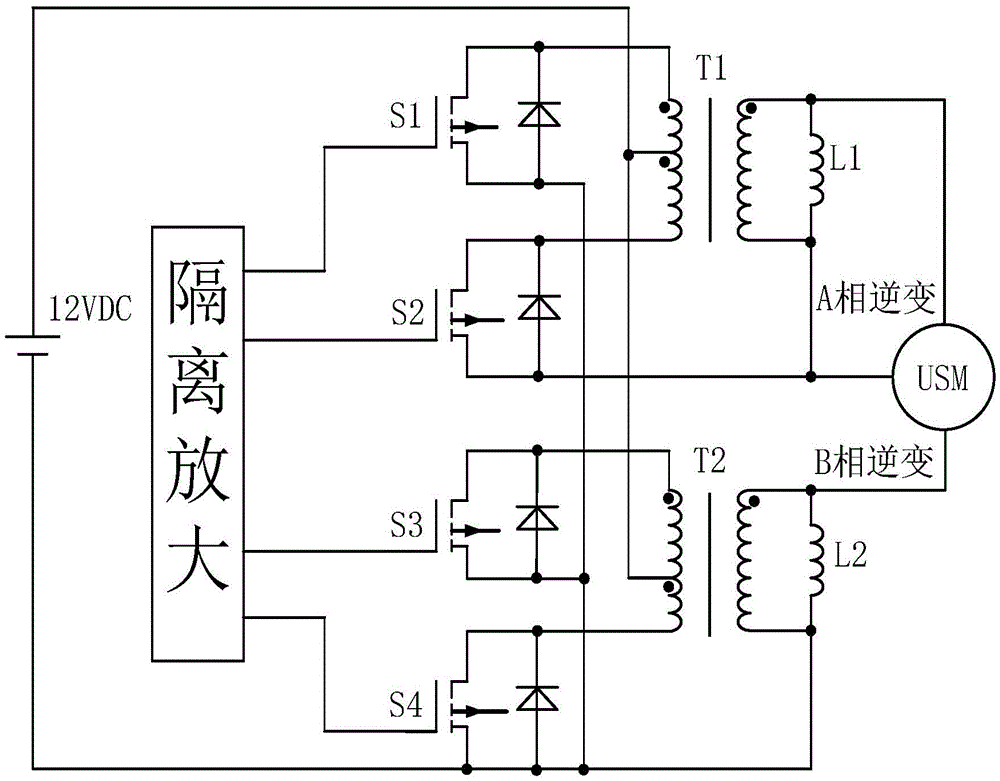

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0020] 1. Switching power supply circuit

[0021] The system power supply of this control system is connected to a switching power supply circuit with overvoltage and overcurrent protection, which provides power in three states of 12VDC, 5VDC, and 3.3VDC for the system, of which the 12VDC switching power supply provides DC regulated power for the USM drive circuit, and the 5VDC switch The power supply provides DC regulated power supply for the isolated drive circuit, the photoelectric encoding unit and the serial port drive circuit. 3.3VDC switching power supply provides DC regulated power supply for high-speed microprocessor DSP and CPLD. The switching power supply used is high-efficiency power supply with anti-high voltage and anti-overcurrent, and has a good energy-saving effect;

[0022] 2. Selection of high-speed m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com