MT inserting core blow-drying equipment

A ferrule and equipment technology, applied in the field of MT ferrule drying equipment, can solve the problems of high labor intensity of workers, hinder production efficiency, cannot further improve the cleanliness of guide holes, etc., and achieve good drying effect and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

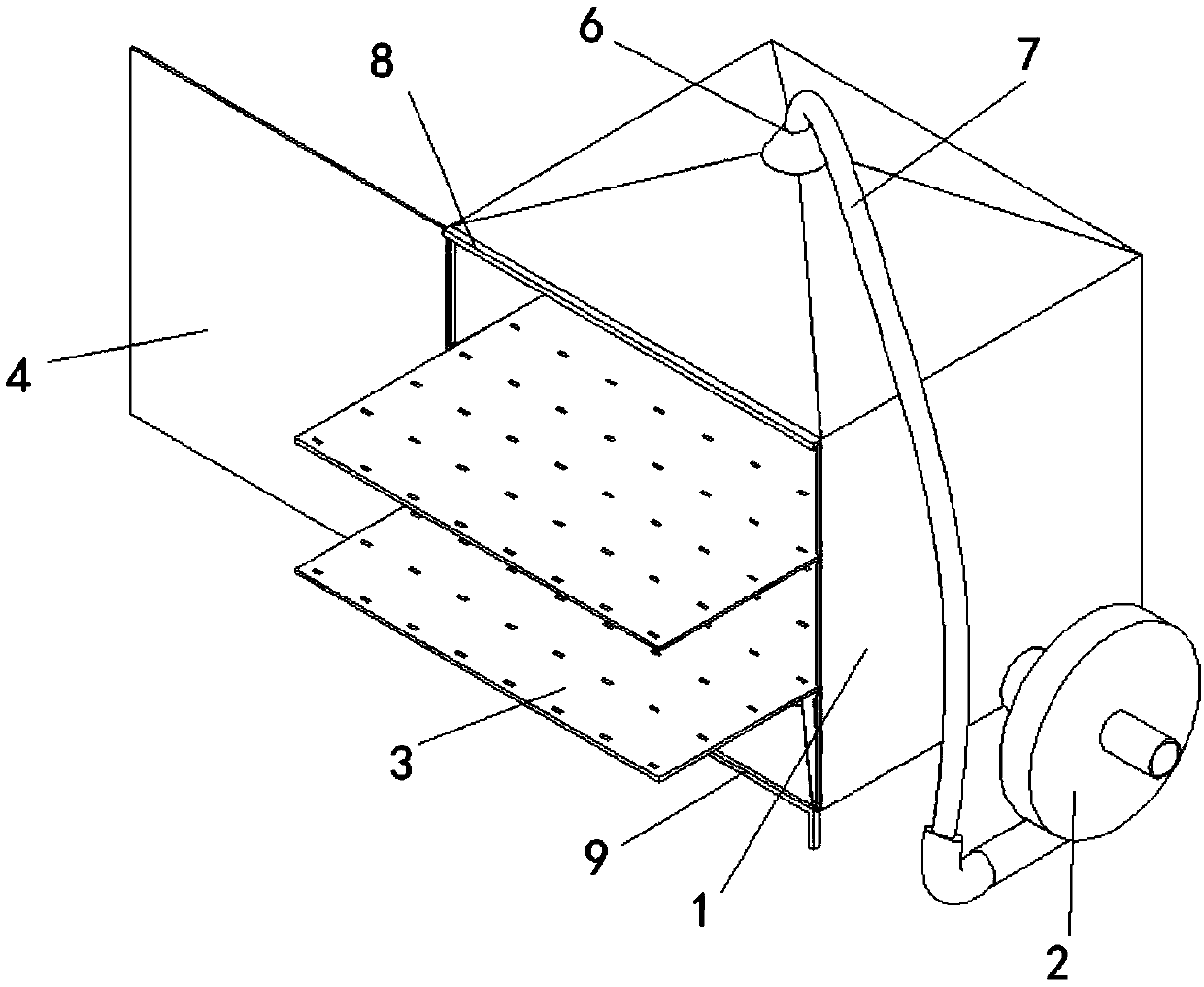

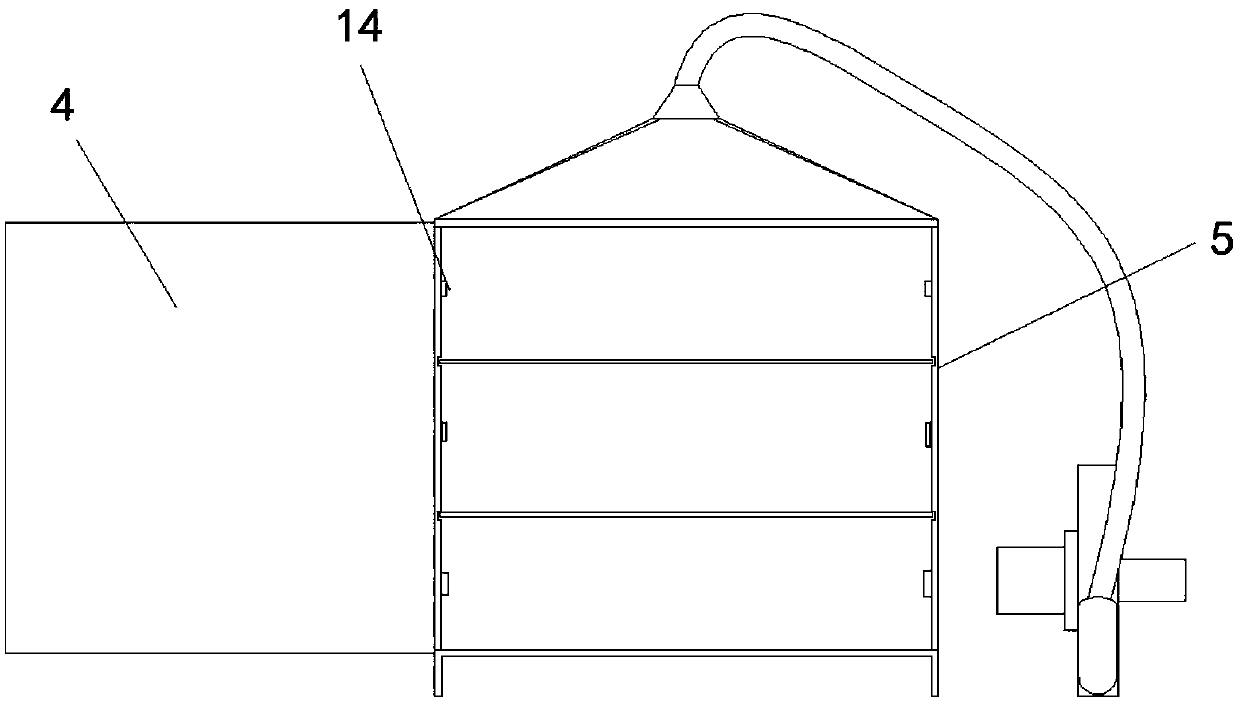

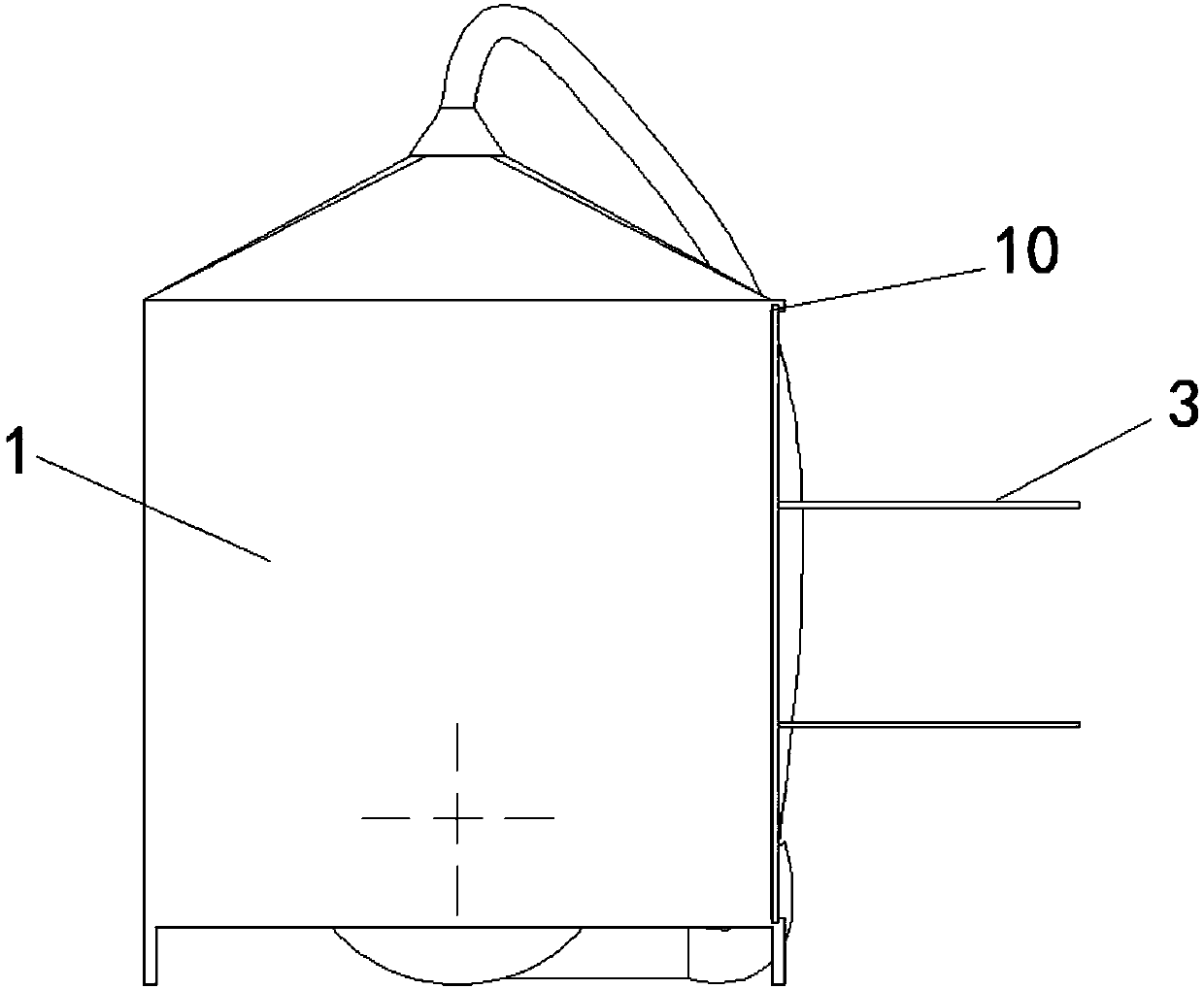

[0017] Embodiment 1: refer to Figure 1 to Figure 4 , a kind of MT ferrule drying equipment, including shell 1, air blower 2, MT ferrule fixing plate 3 and inserting plate 4, shell 1 is hollow structure, shell 1 front is provided with opening, and shell 1 is provided with for MT ferrule The groove 5 where the fixing plate is inserted, two corresponding grooves form a groove group, the top of the shell 1 is provided with a blower 6, the blower 6 communicates with the blower 2 through the pipe 7, the bottom of the shell 1 is a frame structure, and the front of the shell 1 is set There are upper ribs 8 and lower ribs 9 , and corresponding positions on the upper ribs 8 and lower ribs 9 are provided with grooves 10 for insertion of the plugboard 4 .

[0018] In order to fix the MT ferrule so that it is not easy to blow off when it is blown dry in the equipment, and at the same time improve the drying effect, the MT ferrule fixing plate 3 is provided with a groove 12 for inserting t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com