Automatic rinsing mechanism used for white tea processing

An automatic, water-passing technology, which is applied in the direction of cleaning methods using liquids, dryers, tea treatment before extraction, etc., can solve the problems of continuous water-passing, unguaranteed water-passing time, and low processing efficiency, etc., to achieve Avoid water splashing, good washing effect, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

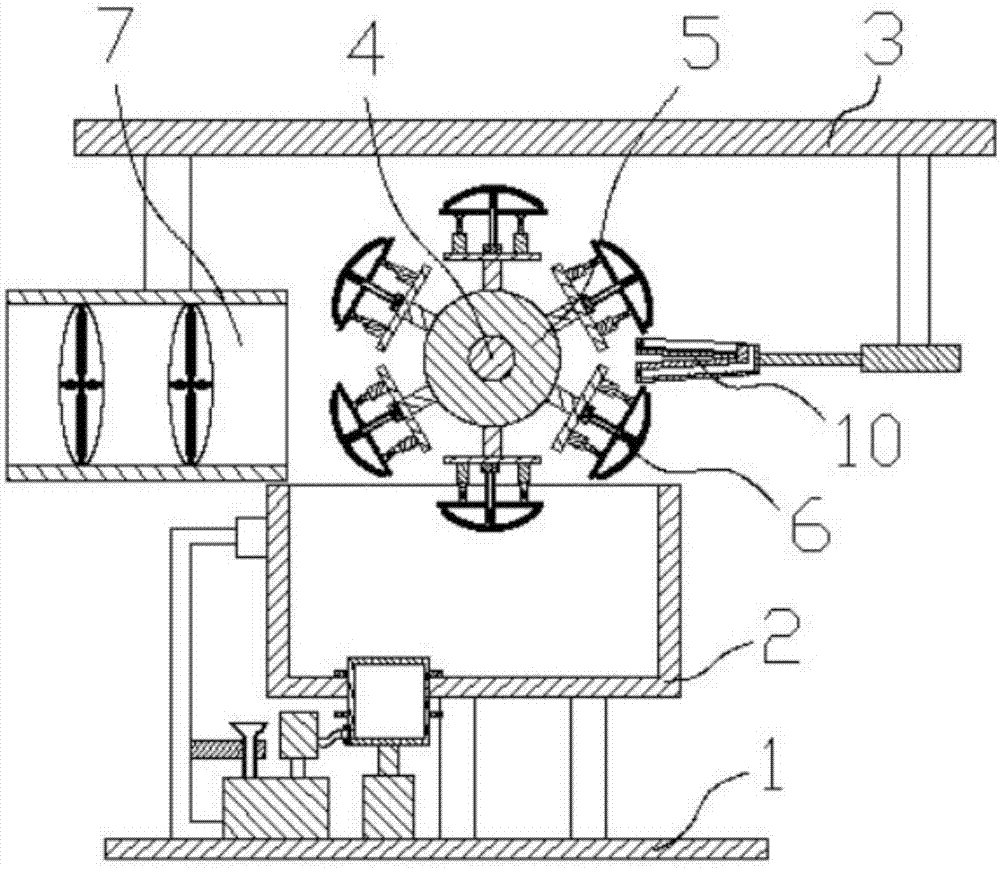

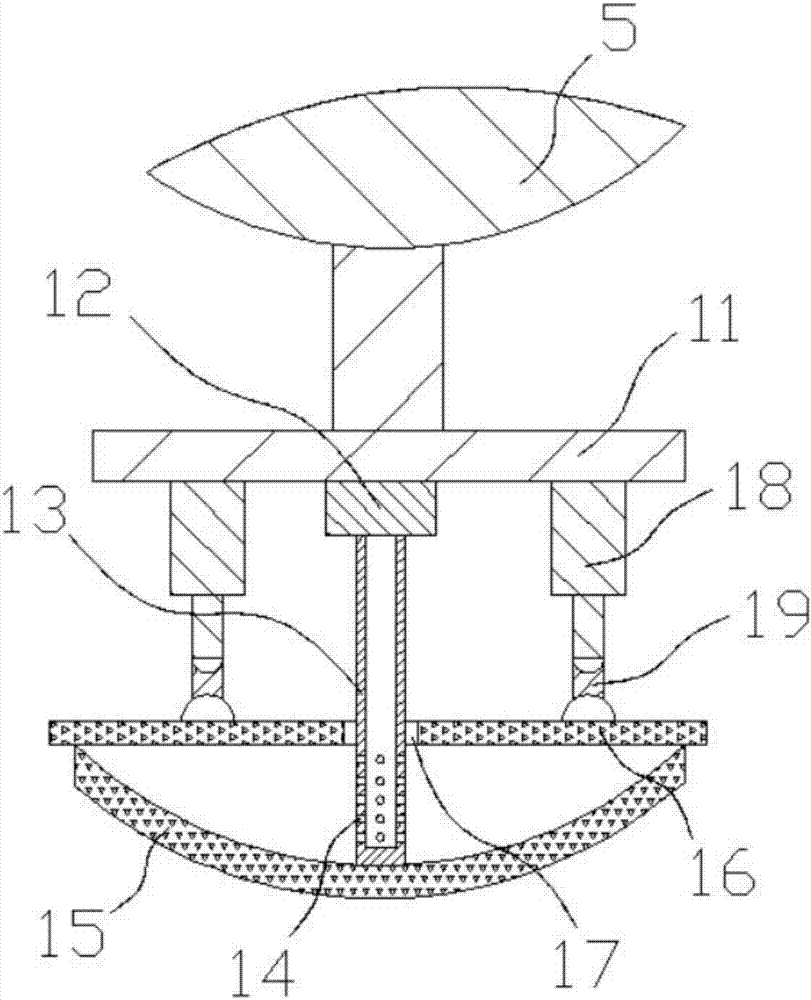

Embodiment 1

[0034] Such as Figure 1-2 , Figure 4-7 As shown, the specific structure of the present invention is: an automatic water passing mechanism for white tea processing, which includes a lower frame 1 and an upper frame 3, the lower frame 1 is provided with a water holding device 2, the The above-mentioned upper frame 3 is equipped with a water-passing rotating shaft 4 and a water-passing stepping motor that cooperate with each other and are horizontally moving forward and backward. 5 is uniformly provided with a charging device 6, and when the charging device 6 is located at the bottom of the water passing turntable 5, it cooperates with the water holding device 2. The charging device 6 includes a patented swivel seat 11 connected to the water passing turntable 5 , the revolving material revolving seat 11 is connected with an opening charging net scoop 15 through a radial charging connecting pipe 13, and the opening of the charging net scoop 15 is matched with a charging net cov...

Embodiment 2

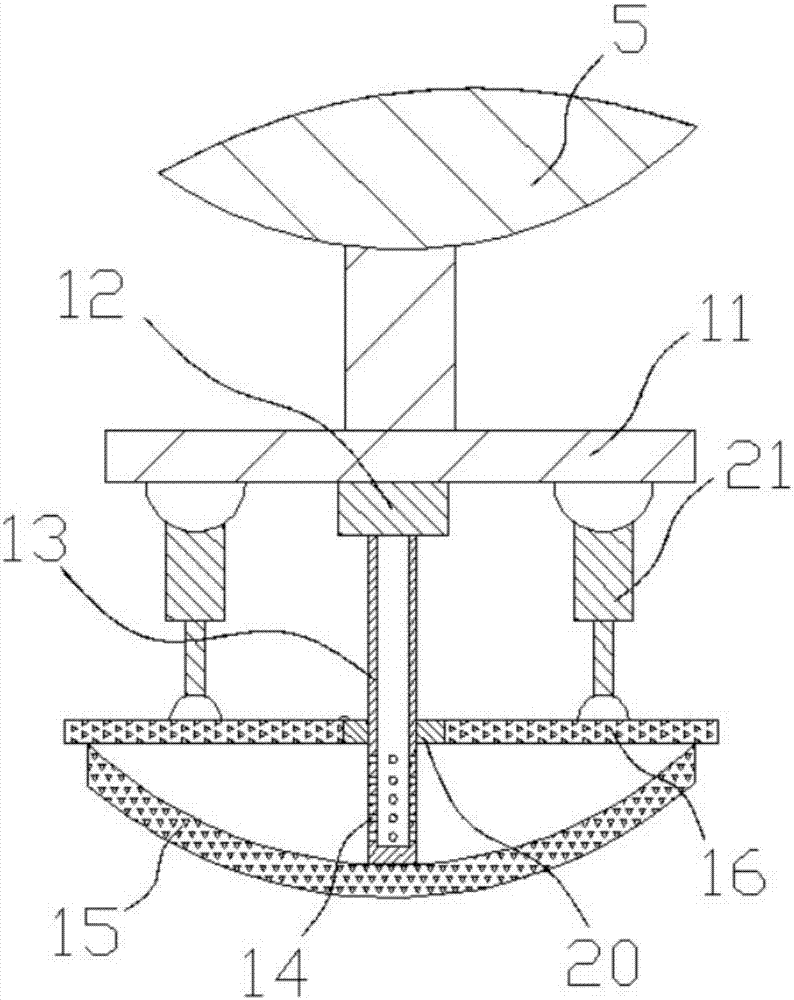

[0044] Such as figure 1 , Figure 3-7 As shown, the specific structure of the present invention is: an automatic water passing mechanism for white tea processing, which includes a lower frame 1 and an upper frame 3, the lower frame 1 is provided with a water holding device 2, the The above-mentioned upper frame 3 is equipped with a water-passing rotating shaft 4 and a water-passing stepping motor that cooperate with each other and are horizontally moving forward and backward. 5 is uniformly provided with a charging device 6, and when the charging device 6 is located at the bottom of the water passing turntable 5, it cooperates with the water holding device 2. The charging device 6 includes a patented swivel seat 11 connected to the water passing turntable 5 , the revolving material revolving seat 11 is connected with an opening charging net scoop 15 through a radial charging connecting pipe 13, and the opening of the charging net scoop 15 is matched with a charging net cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com