Cistanche tubulosa vibration washing and drying machine and washing and drying method

A technology of Cistanche tuberosa and drying machine, which is applied in the fields of application, food processing, food science, etc. It can solve the problems of not being suitable for the follow-up treatment of Cistanche tuberosum, increasing energy consumption, wasting water resources, etc., and achieves the effect of cleaning and drying Good, quality assurance, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

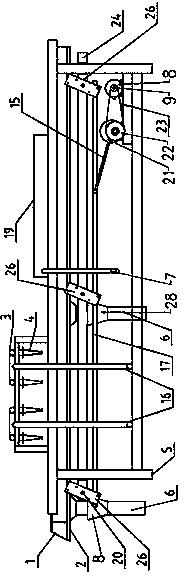

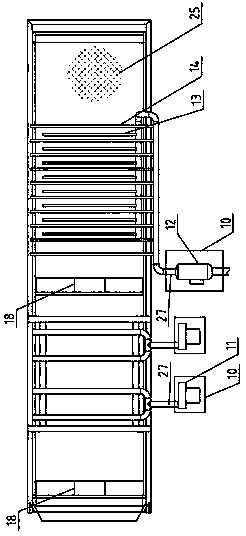

[0022] Such as figure 1 , figure 2 As shown, the present invention includes a frame (5) and a screen frame arranged on the frame (5), a vibrating device, a high-pressure spray device and a high-pressure blowing device, and the screen is erected on the middle and upper part of the frame (5). The screen frame is connected with the vibrating device through the vibrating swing arm plate (26), the high-pressure spraying device is arranged on the upper right part of the frame (5), and the high-pressure blowing device is arranged on the upper left part of the frame (5).

[0023] The screen frame is a double-layer structure composed of an upper screen (25) and a lower water-collecting bottom frame (2). 2) There are water outlets (18) in the middle and the left side, and the water outlets (18) are all aligned to the water receiving bucket (28), and the lower end of the water receiving bucket (28) is connected with the drain pipe (6).

[0024] Said vibration device is composed of mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com