Pipe washing and blowing device

A technology for washing and blowing tubes and cleaning sleeves, which is applied in the field of auxiliary production equipment for heat-shrinkable tubes, can solve problems such as poor production continuity, lack of cleaning functions, and single functions, and achieve good cleaning and drying effects, simple structure, and easy connection. firm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

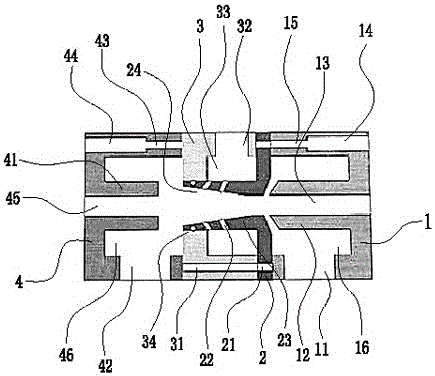

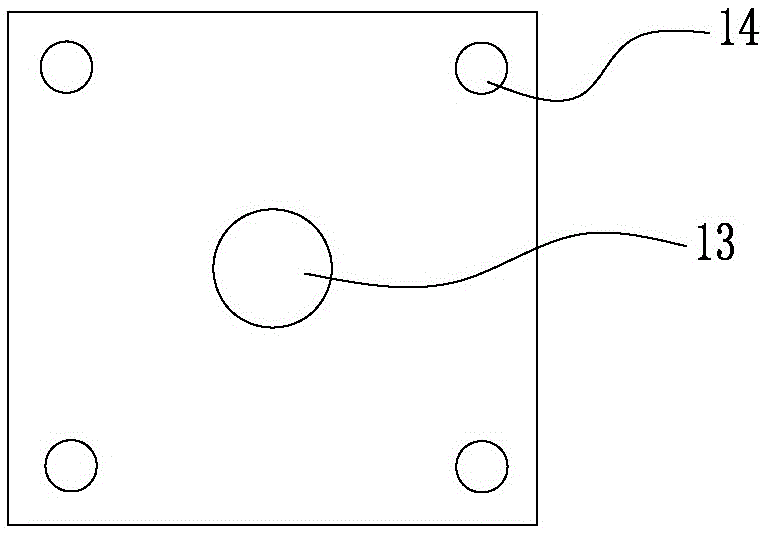

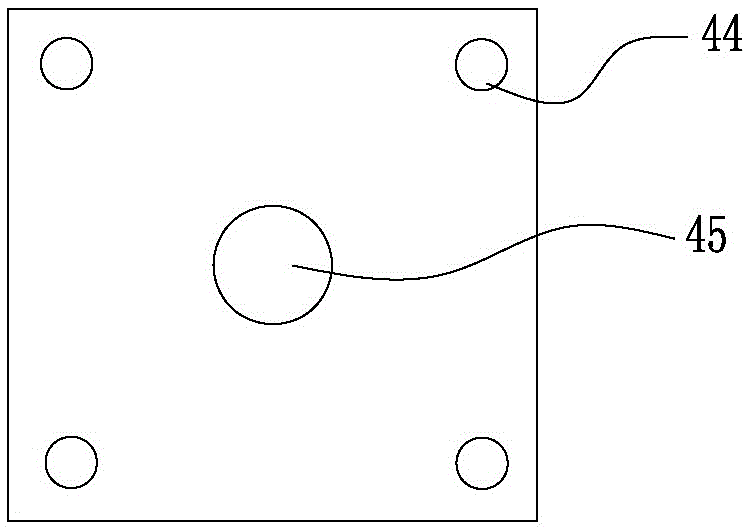

[0017] Such as Figure 1-3 As shown, a pipe washing and blowing device includes a drying sleeve 1, a cleaning sleeve 2, a water injection sleeve 3 and a feeding sleeve 4; Square counterbore 16, the center of the bottom surface of the first square counterbore 16 is formed with a first protruding post 12, the center of the first protruding post 12 is provided with a first through hole 13, the inner side of the first square counterbore 16 is below Air intake holes 11 are provided; four first counterbores 14 are provided at the four corners of the outer end surface of the drying cover 1, and the first through holes 15 are provided in the center of the bottom surface of the first counterbore 14; the drying cover 1 The inner side of the cleaning sleeve 2 is provided with a cleaning cover 2, the shape of the end surface of the cleaning cover 2 is square, and the center of the inner end surface of the cleaning cover 2 is formed with a cleaning column 23, and the center of the cleaning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com