A tilting wood-plastic plate drying machine

A drying machine and tilting technology, applied in the field of tilting wood-plastic board drying machines, can solve the problem of not being suitable for the drying operation of intermediate perforated boards, and achieve convenient and fast drying operation, simple and effective structure, and drying. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following descriptions are only preferred embodiments of the present invention, and do not limit the scope of the present invention.

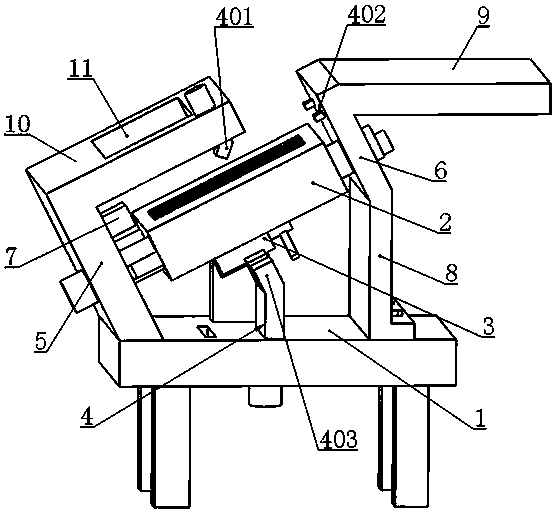

[0023] Example: as attached figure 1 , 2 , 3 and attached Figure 4 As shown, a tilting wood-plastic plate blowing machine includes a blowing machine base 1, and also includes a plate support plate 2 arranged on the blowing machine base 1, and is arranged under the plate support plate 2 by turning The plate supporting plate 2 is used to unload the flip unit 3 of the plate that has been dried and the three-way drying unit 4 arranged on the base 1 of the drying machine, the plate supporting plate 2 is obliquely arranged on the Dryer base 1.

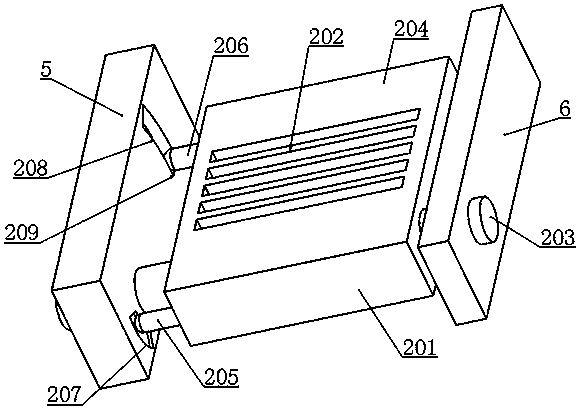

[0024] The plate support plate 2 includes a support plate main body 201, a support plate opening 202 arranged in the middle of the support plate main body 201 for the three-way drying unit 4 to dry, and a support plate opening 202 arranged in the support plate opening 202. The supporting plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com