Patents

Literature

94results about How to "Guaranteed rolling quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

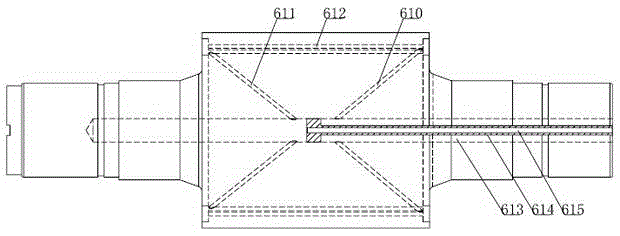

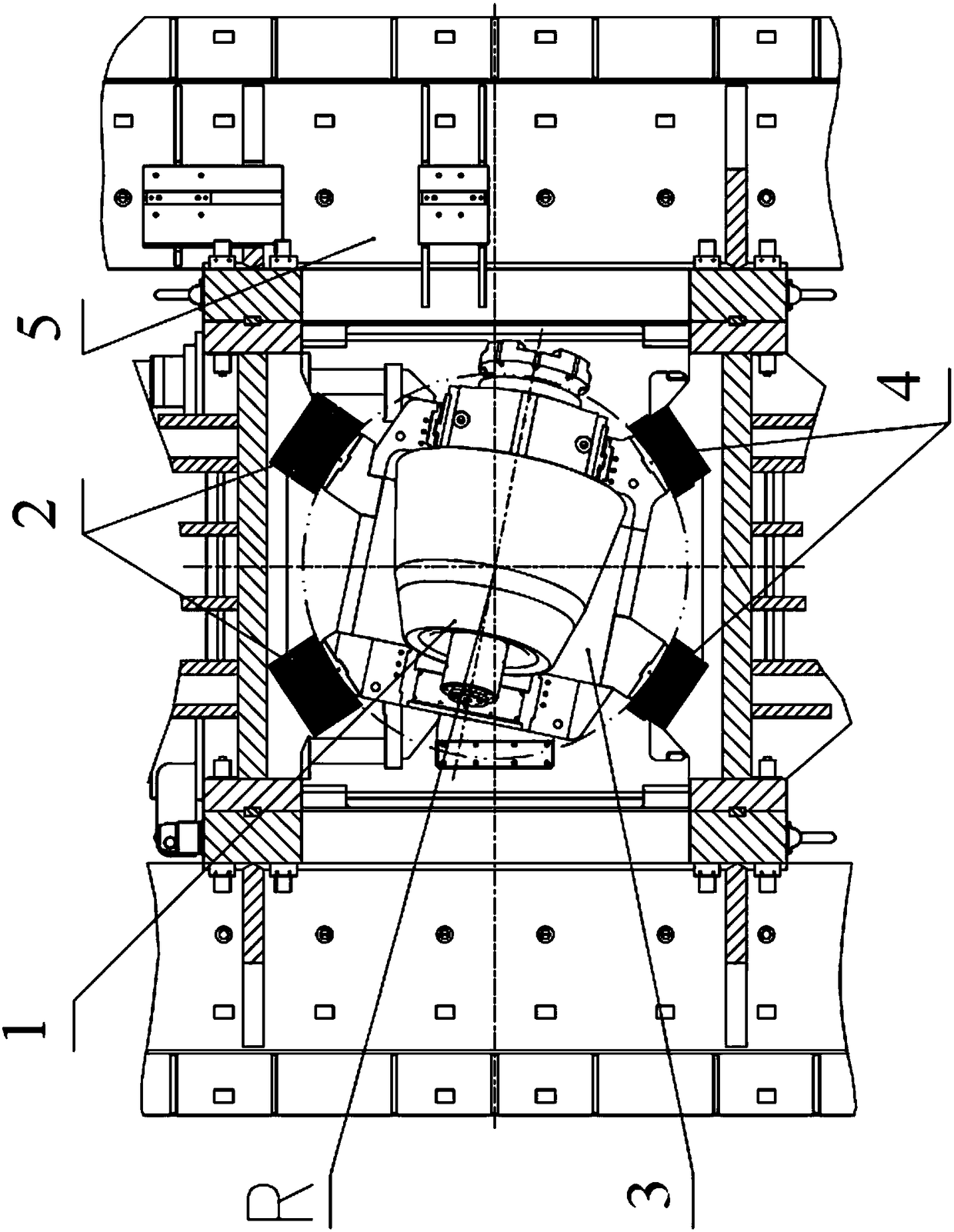

Pole piece roller compression machine

ActiveCN102723461AGuaranteed service lifeGap changes smoothlyElectrode manufacturing processesPulp and paper industry

The invention discloses a pole piece roller compression machine which comprises an unrolling mechanism, a delivery mechanism, a roller compression mechanism and a rolling mechanism. The roller compression mechanism comprises an upper compression roller and a lower compression roller which are oppositely arranged and a compression roller driving mechanism used for driving the upper compression roller and the lower compression roller to move relatively to conduct roller compression. The roller compression mechanism further comprises an inverse driving mechanism coupled to the upper compression roller and / or the lower compression roller. The inverse driving mechanism controllably applies action force with direction opposite to the compression roller drawing close direction on the upper compression roller and / or the lower compression roller to remove or weaken compression roller shock. The pole piece roller compression machine enables the two compression rollers to maintain stable in interval change, and avoids undesirable change in compression of pole pieces by rollers, so that the machine can improve roller compression quality and prolong service life of devices.

Owner:SHENZHEN YINGHE TECH

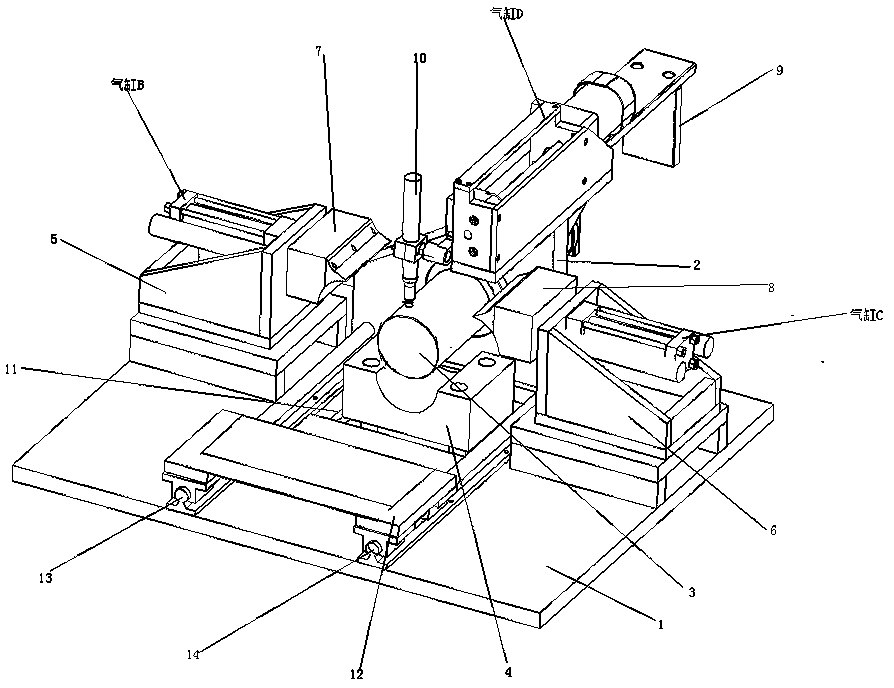

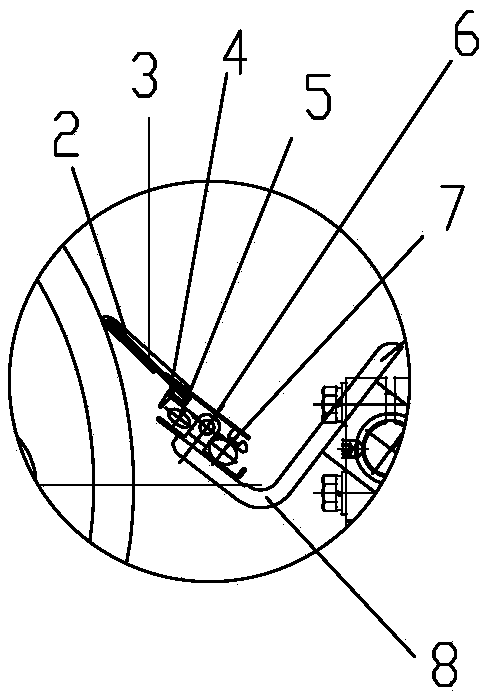

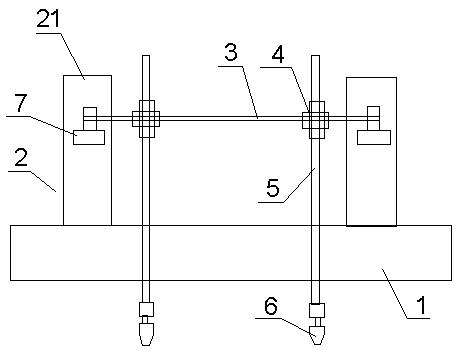

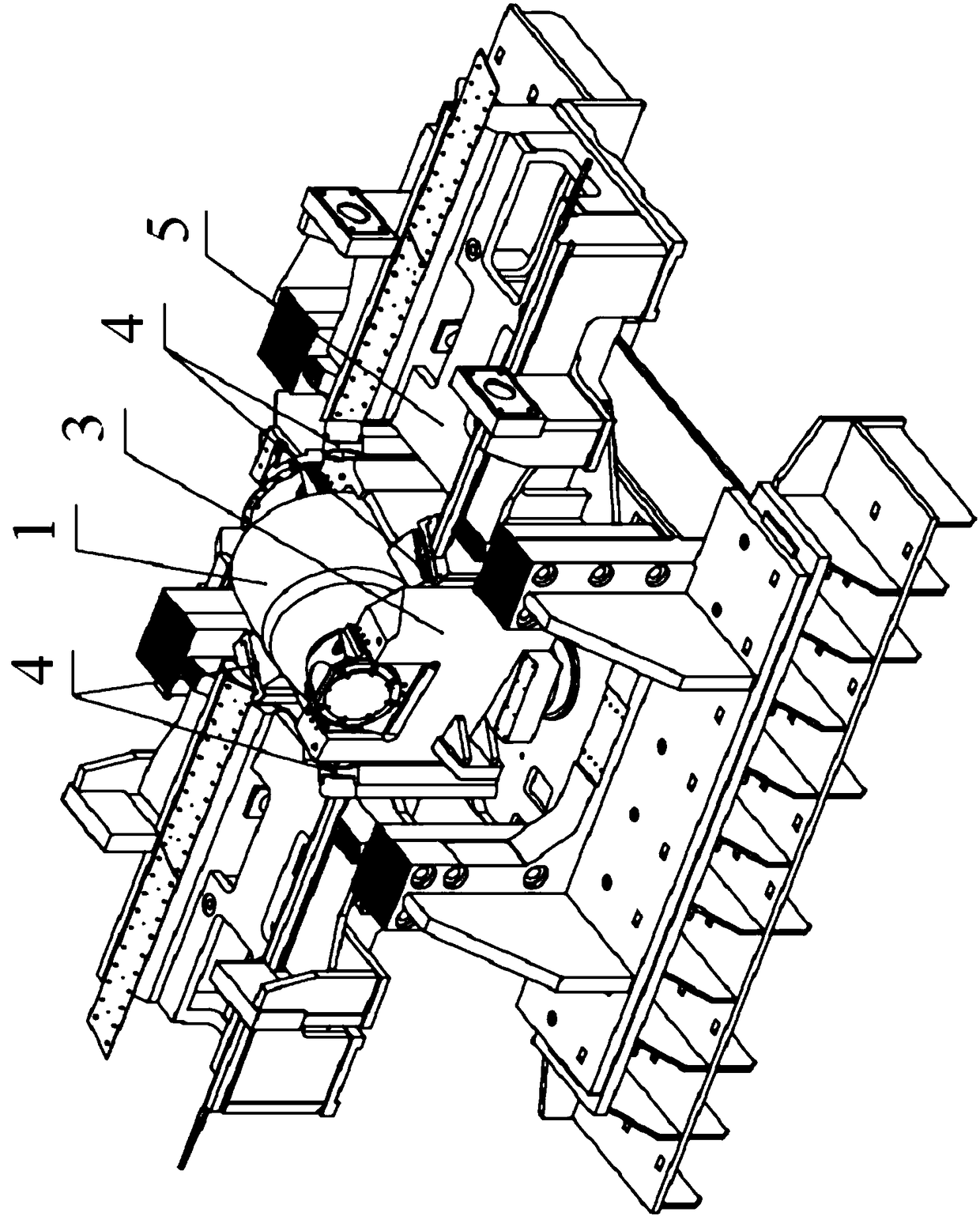

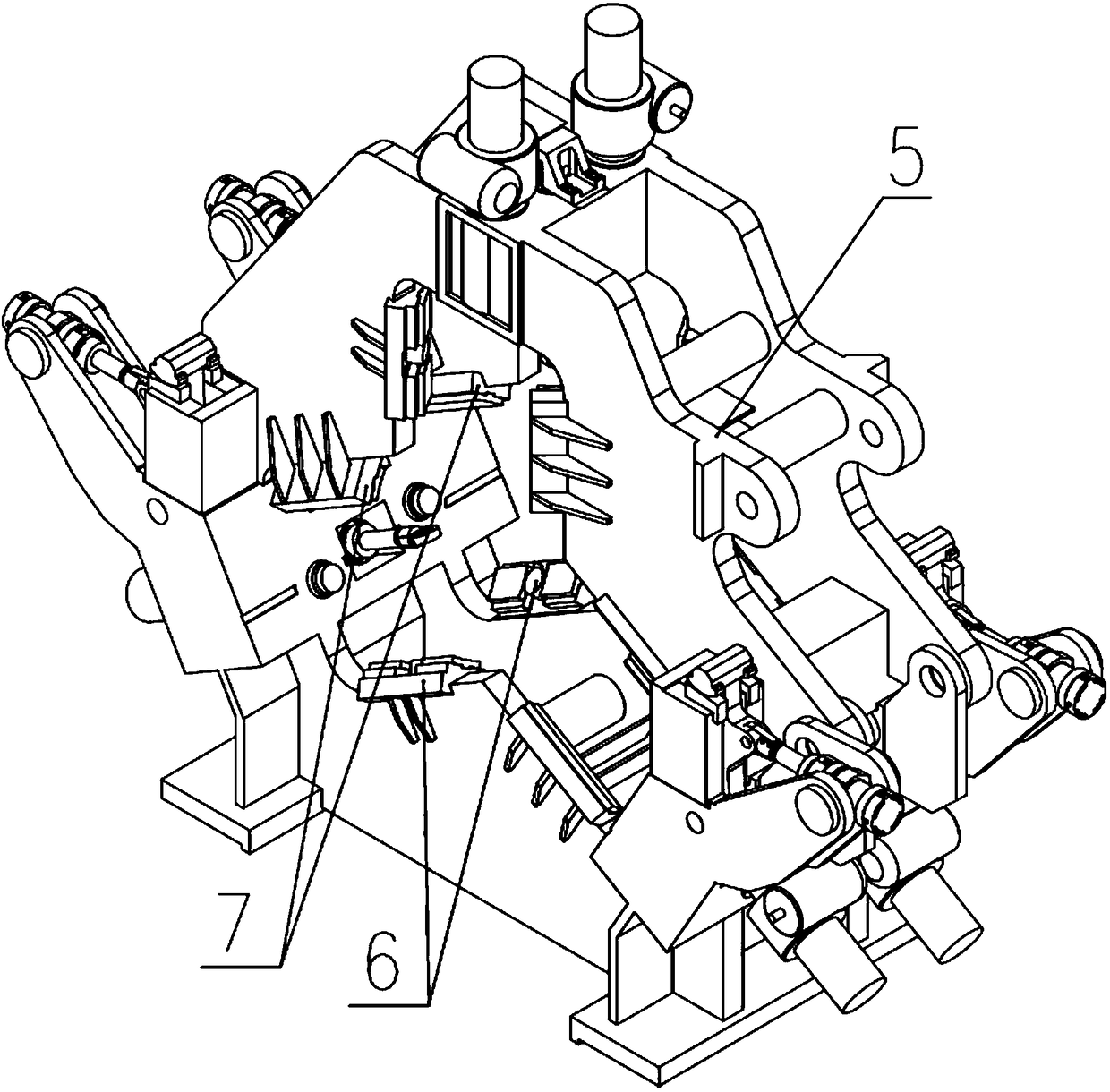

Metal plate rapid rounding and welding integrated device

PendingCN109604372AEasy to shapeNot easy to dentWelding/cutting auxillary devicesAuxillary welding devicesRoundingEngineering

The invention discloses a metal plate rapid rounding and welding integrated device. The device comprises a base, wherein a back plate is arranged at the rear end of the base, the device is characterized in that the back plate is fixedly provided with a sizing mold, a lower mold is arranged right below the sizing mold on the base in a up-down movable mode, a left upper mold support and a right upper mold support are arranged on the two sides of the lower mold in parallel, a left upper mold which can move leftwards and rightwards is arranged on the left upper mold support, the right upper mold support is provided with a right upper mold which can move leftwards and rightwards, a mold cavity of the left upper mold, a mold cavity of the right upper mold and a mold cavity of the lower mold arecombined to form a cylindrical mold cavity matched with the sizing mold; and a welding gun support is fixedly arranged behind the back plate, a welding gun is vertically arranged on the welding gun support, the welding gun can move back and forth, and the welding gun is located right above the sizing mold. According to the device, automatic rounding and automatic welding are achieved, the two procedures are continuously operated, the construction period is shortened, the labor and time cost is reduced, and the production efficiency is improved.

Owner:淮安茂华管业有限公司

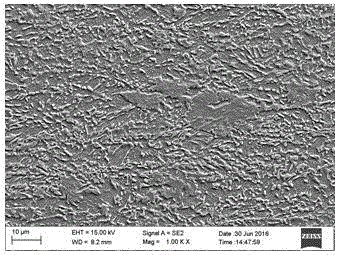

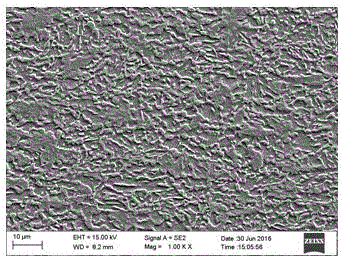

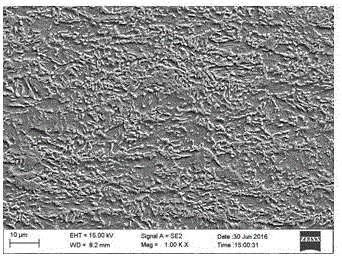

Single-steel multi-level hot-rolled complex-phase high-strength steel plate and production method thereof

The invention discloses a single-steel multi-stage hot-rolled complex-phase high-strength steel plate and a production method thereof. The production method comprises the steps of heating, hot rolling, cooling, coiling, annealing and acid pickling. The steel plate comprises, by weight percentage, 0.08-0.15% of C, 1.80-3.00% of Mn, less than or equal to 0.015% of S, less than or equal to 0.025% of P, 0.50-1.00% of Si, 0.020-0.060% of Als, 0.40-1.0% of Cr, 0.010-0.040% of Ti, 0.10-0.30% of Mo, less than or equal to 0.007% of N, and the balance Fe and inevitable impurities. According to the production method, a composition system is adopted through a reasonable composition design, complex-phase steel with different strength levels is produced by controlling different structure types in the hot rolling and annealing processes, and therefore the special requirement that a steel enterprise can meet the different performance of users by adopting one composition system can be met, the mechanical property of the whole-coil product is uniform, the baking hardening performance is good, and the requirements of the users for small-batch and different-strength-level samples can be met.

Owner:TANGSHAN IRON & STEEL GROUP +1

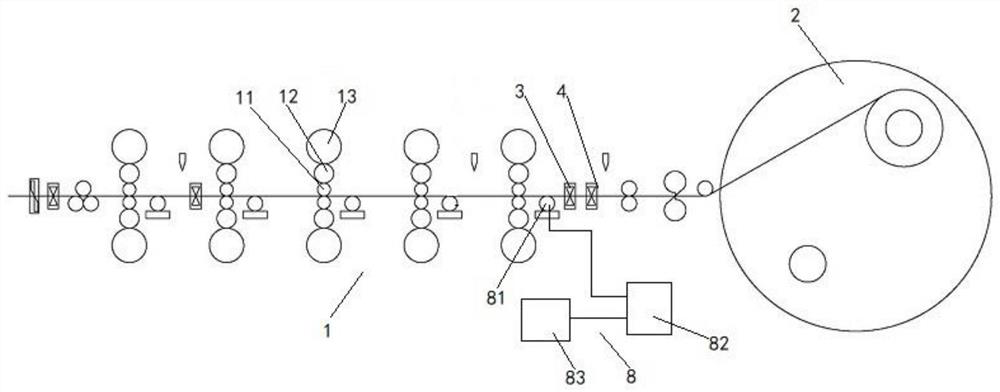

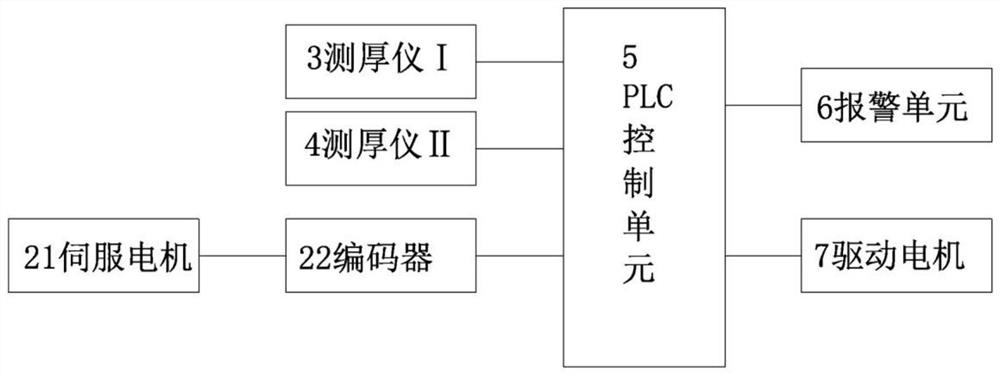

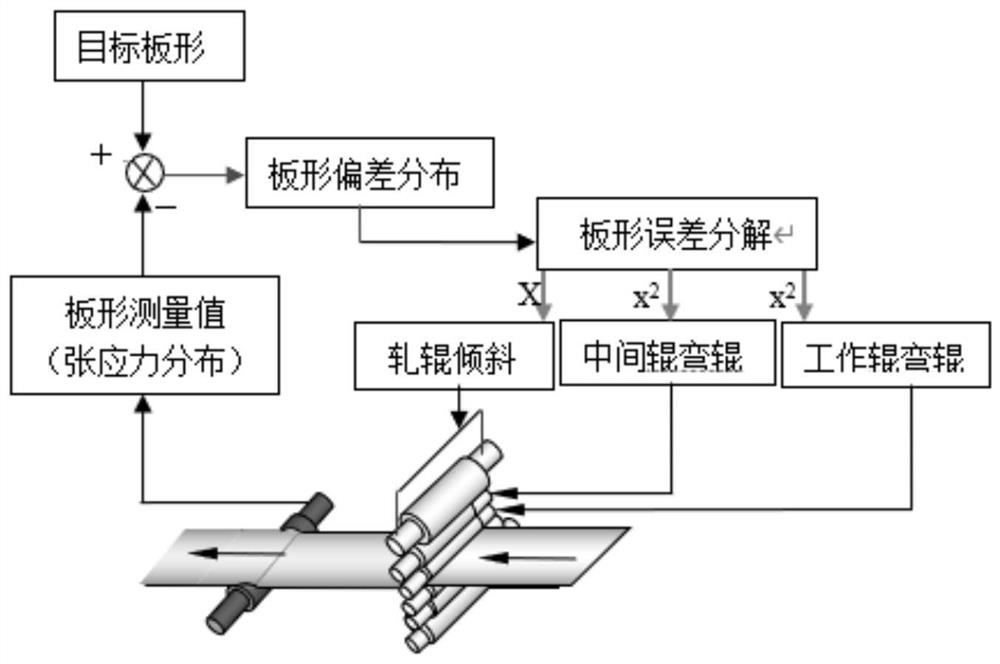

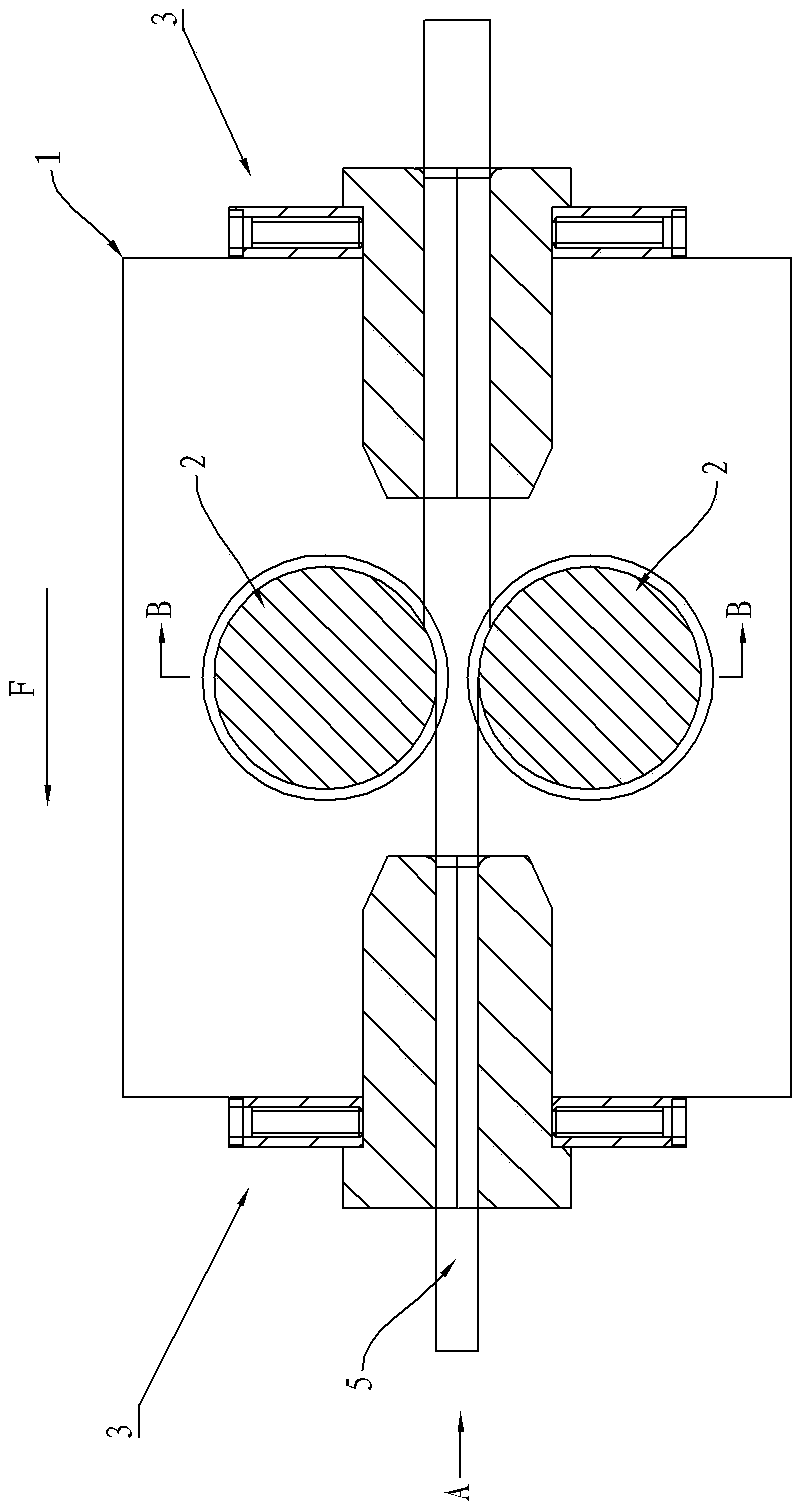

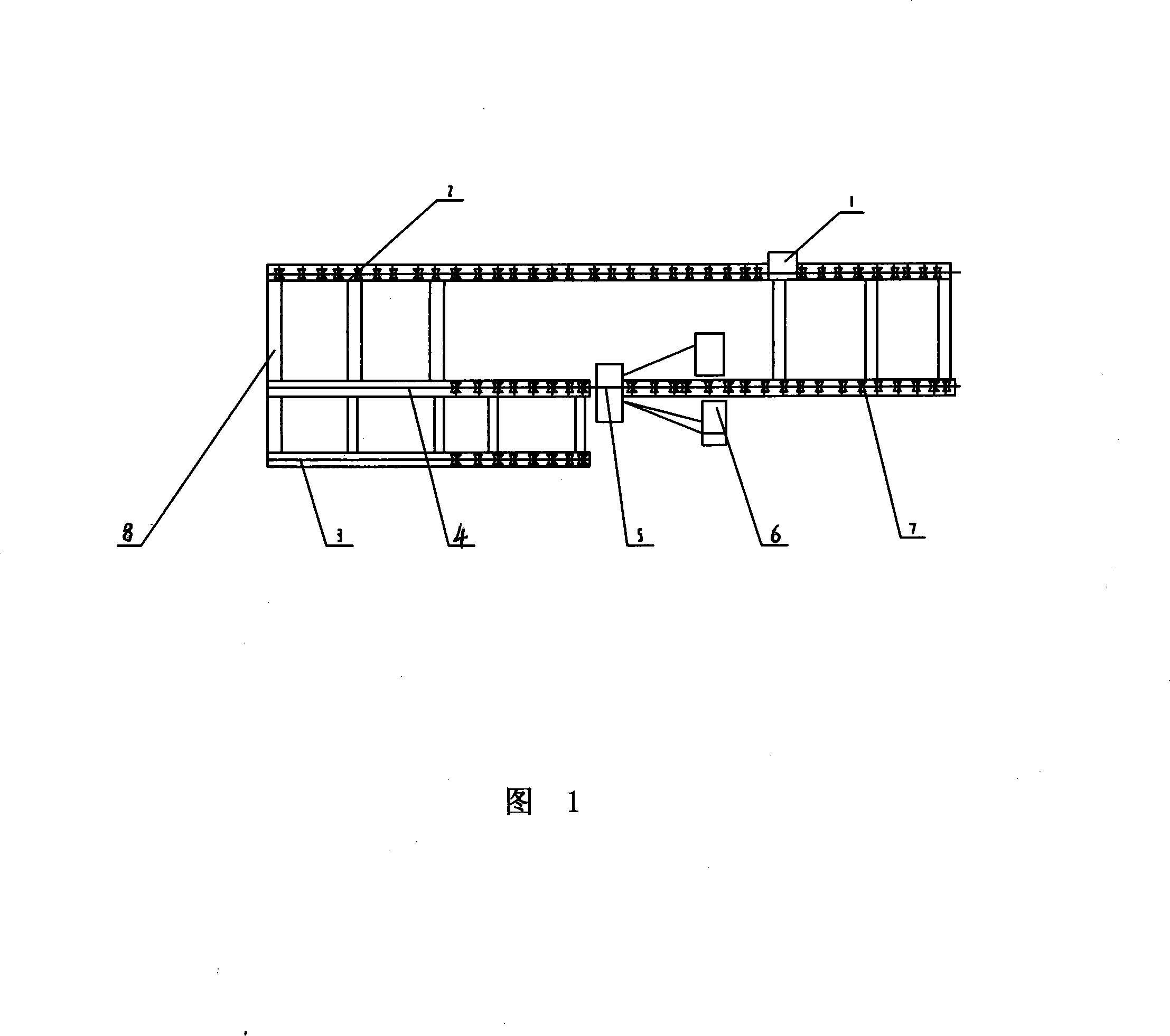

Non-oriented silicon steel cold continuous rolling device and thickness control method

PendingCN111604372AReduce contact pressureSmall amount of depressionMetal rolling stand detailsMeasuring devicesStrip steelMachine

The invention discloses a non-oriented silicon steel cold continuous rolling device and a thickness control method, and belongs to the technical field of non-oriented silicon steel cold rolling and forming. The non-oriented silicon steel cold continuous rolling device comprises a five-rack six-roller cold continuous rolling mill and a double-drum coiling machine, chamfers are correspondingly arranged at the end parts of intermediate rollers on each cold rolling unit of the five-rack six-roller cold continuous rolling mill, chamfers are correspondingly arranged at the end parts of working rollers of first, second and third cold rolling units of the five-rack six-roller cold continuous rolling mill, and the chamfering heights of the working rollers of the first cold rolling unit and the second cold rolling unit are correspondingly greater than the chamfering height of the working roller of the third cold rolling unit. The non-oriented silicon steel cold continuous rolling device has thebeneficial effects that the structure of the cold continuous rolling device and the process of cold continuous rolling are improved and optimized, the measuring accuracy of the longitudinal thicknessof strip steel is ensured, the control force of the transverse thickness of a non-oriented silicon steel strip is improved, the length of out of tolerance thickness of the steel strip head and tail isreduced, the edge thinning of the non-oriented silicon steel strip is reduced, and the qualification rate of longitudinal thickness and transverse thickness of the steel strip is increased.

Owner:新余钢铁股份有限公司

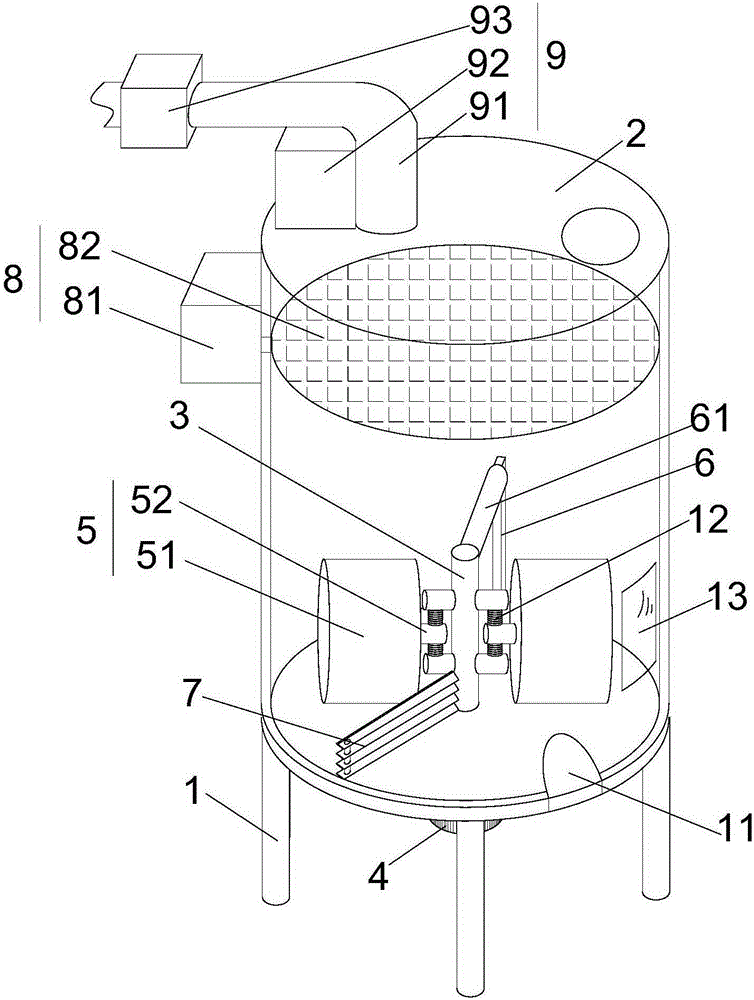

Sand grinding equipment

InactiveCN105170895AIncrease the amount of rollingAvoid accumulationMould handling/dressing devicesEngineeringMechanical engineering

The invention discloses sand grinding equipment. The sand grinding equipment comprises a support, a grinding box, a first rotating shaft, a driving device and at least one grinding roller, wherein the grinding box is mounted on the support; a feed port is formed in the upper part of the grinding box; a discharge port is formed in the lower part of the grinding box; a discharge door is detachably mounted in the position corresponding to the discharge port of the grinding box; the first rotating shaft is rotationally mounted in the grinding box; the driving device is connected with the first rotating shaft and drives the first rotating shaft to rotate; each grinding roller comprises a main grinding roller body and a second rotating shaft, the main grinding roller body is rotationally mounted on the second rotating shaft, the second rotating shaft is mounted on the first rotating shaft through an elastic piece, and the second rotating shaft and the first rotating shaft are perpendicular to each other in the axial direction. According to the sand grinding equipment, the grinding quantity of materials each time can be increased, and the grinding effect of the materials can be guaranteed effectively.

Owner:NINGGUO SOUTHERN WEAR RESISTANT MATERIALS

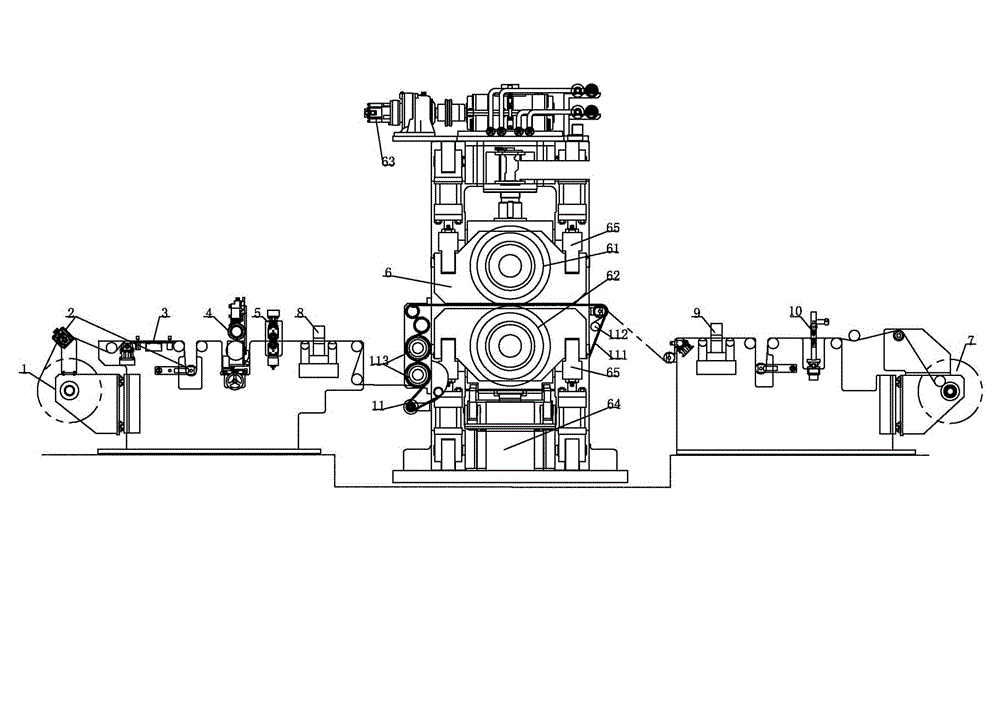

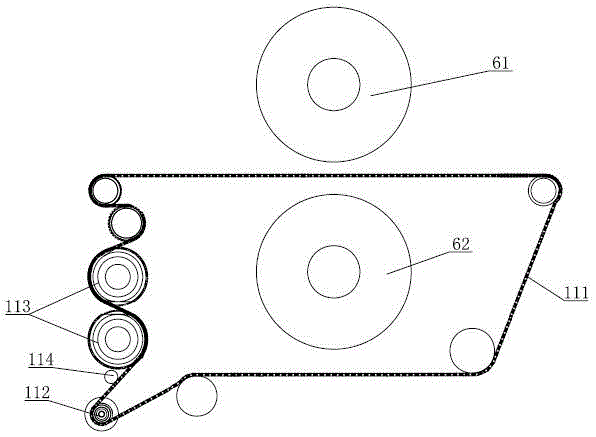

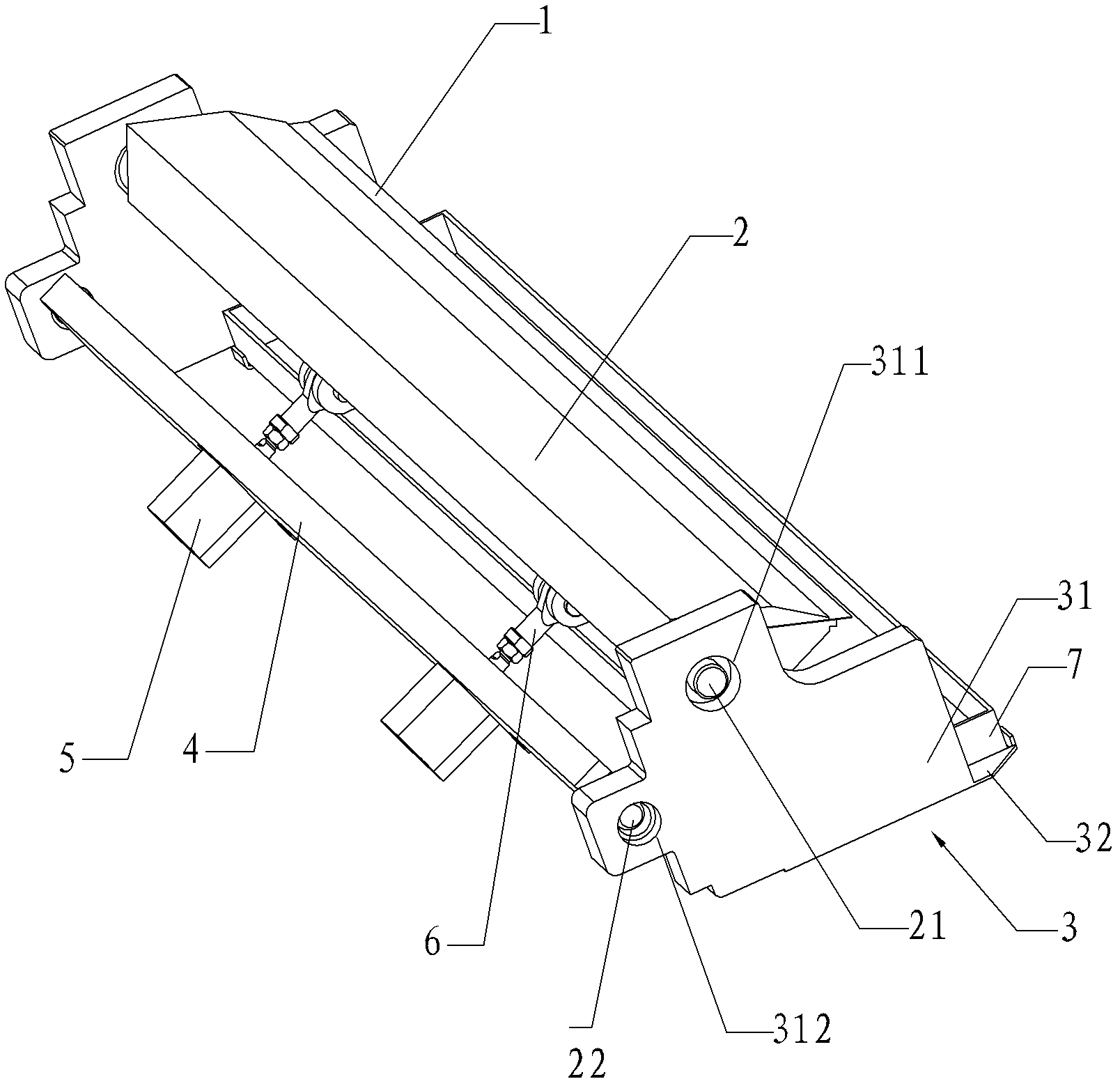

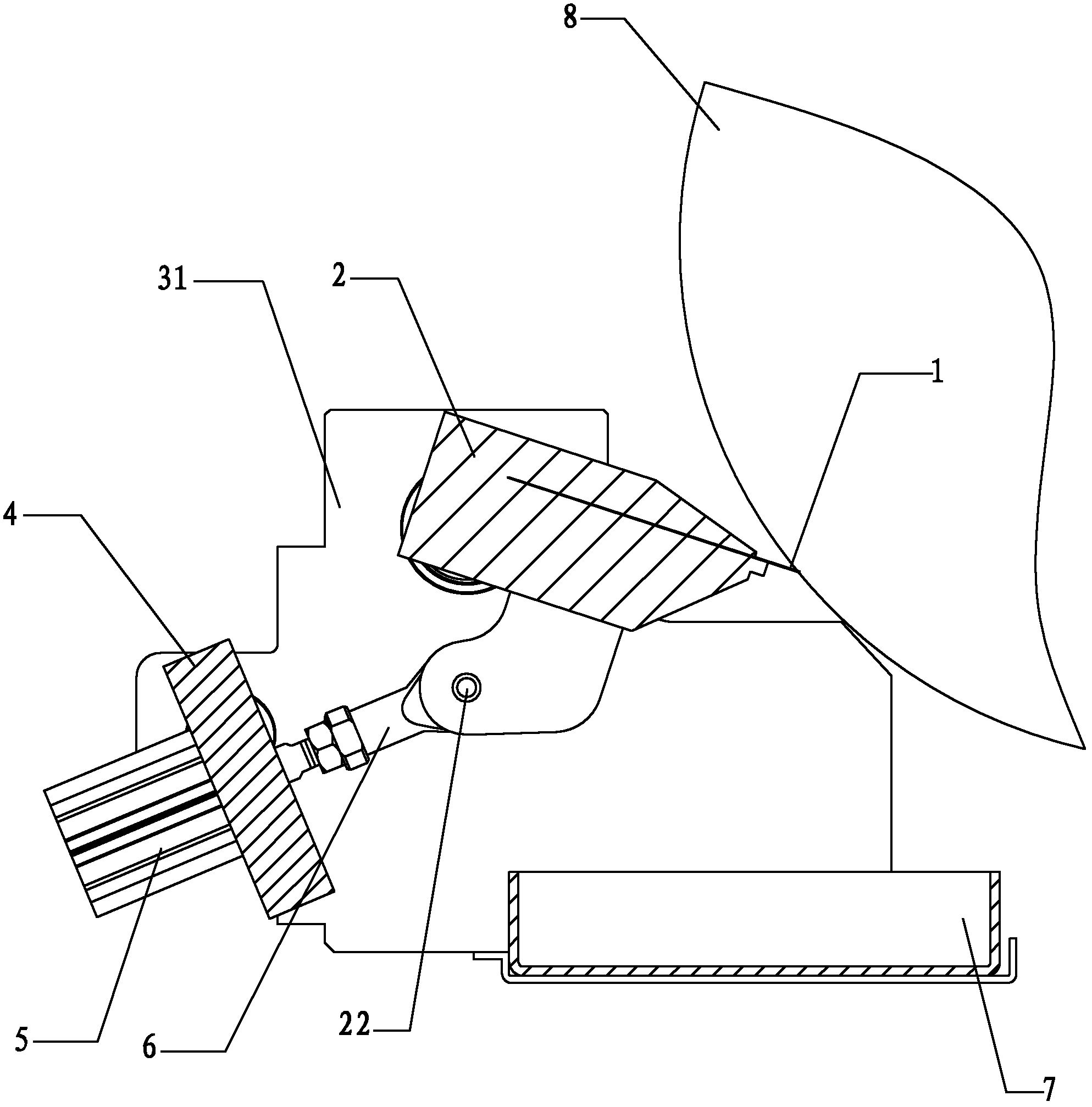

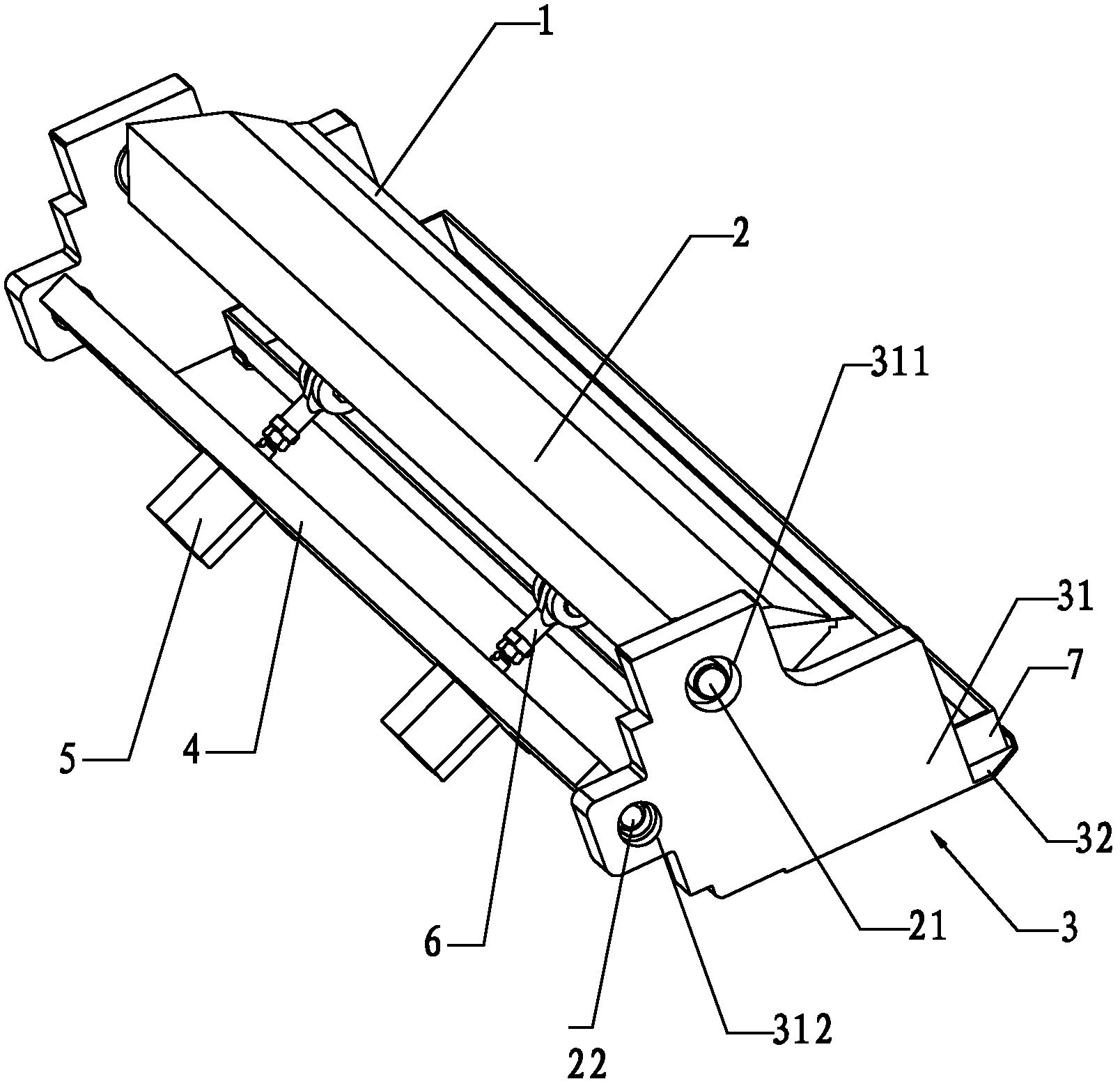

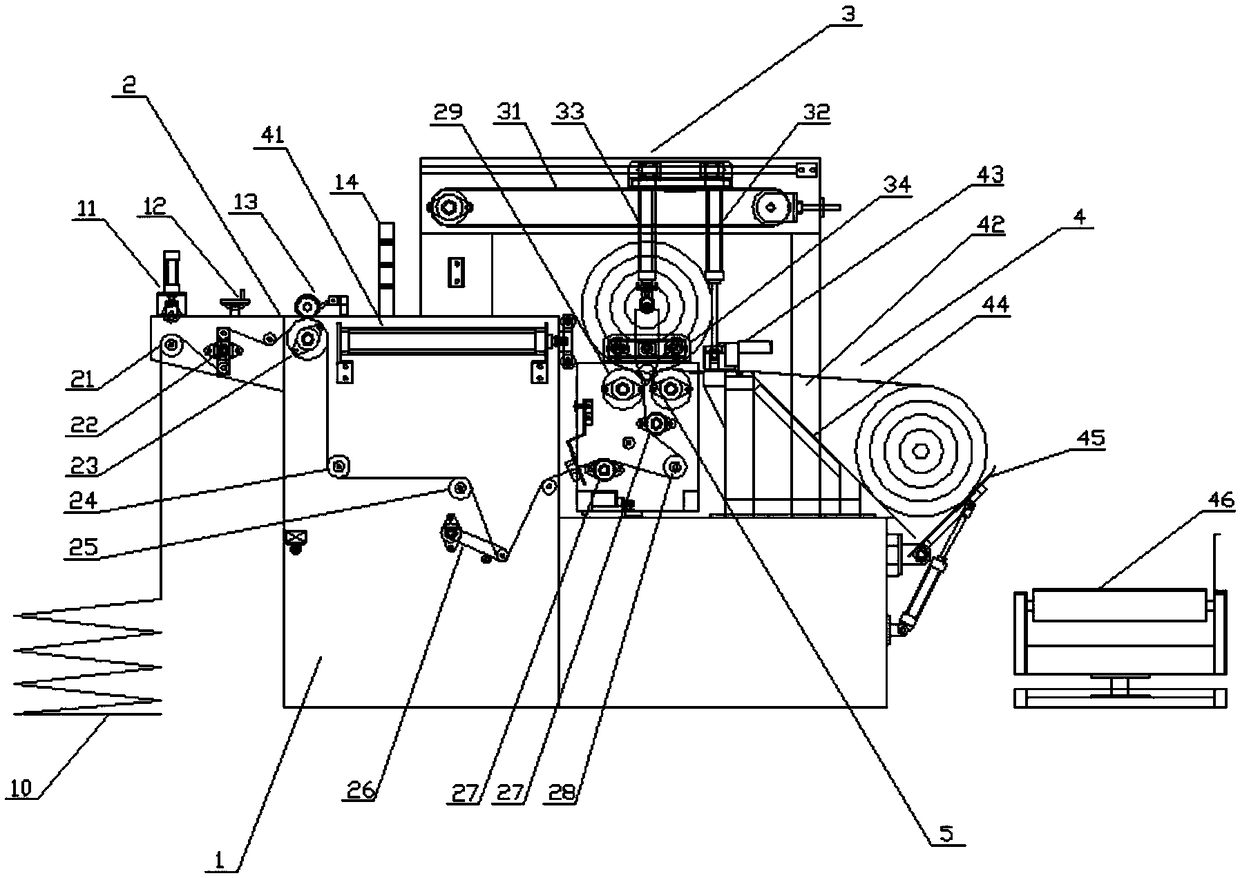

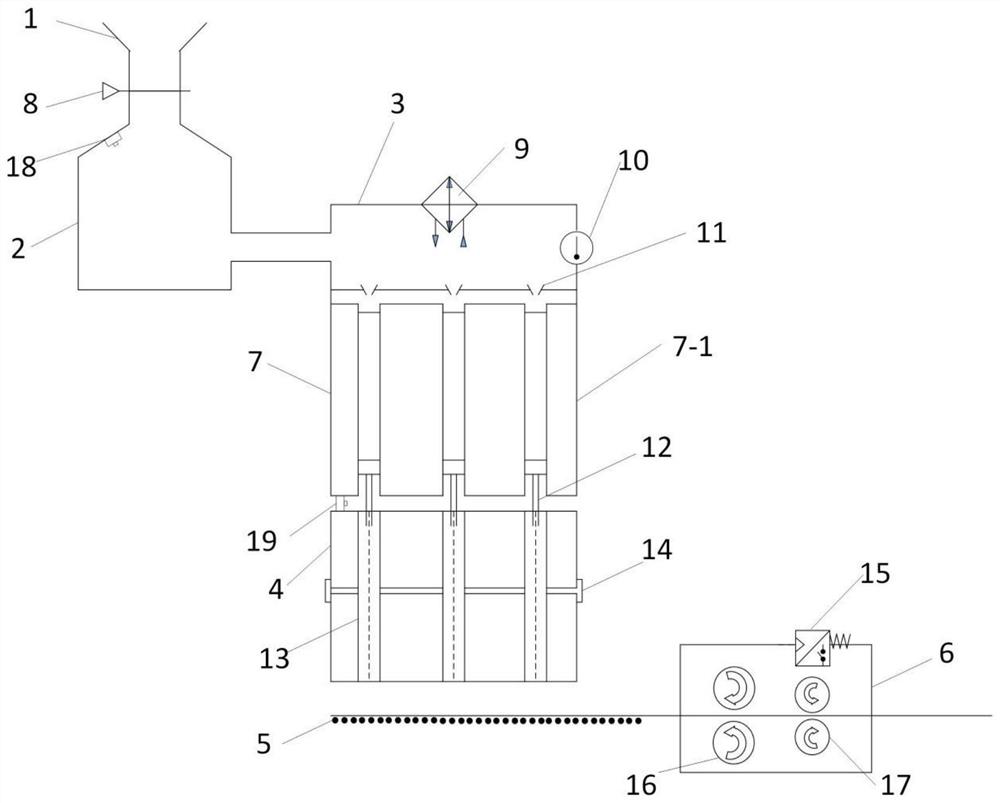

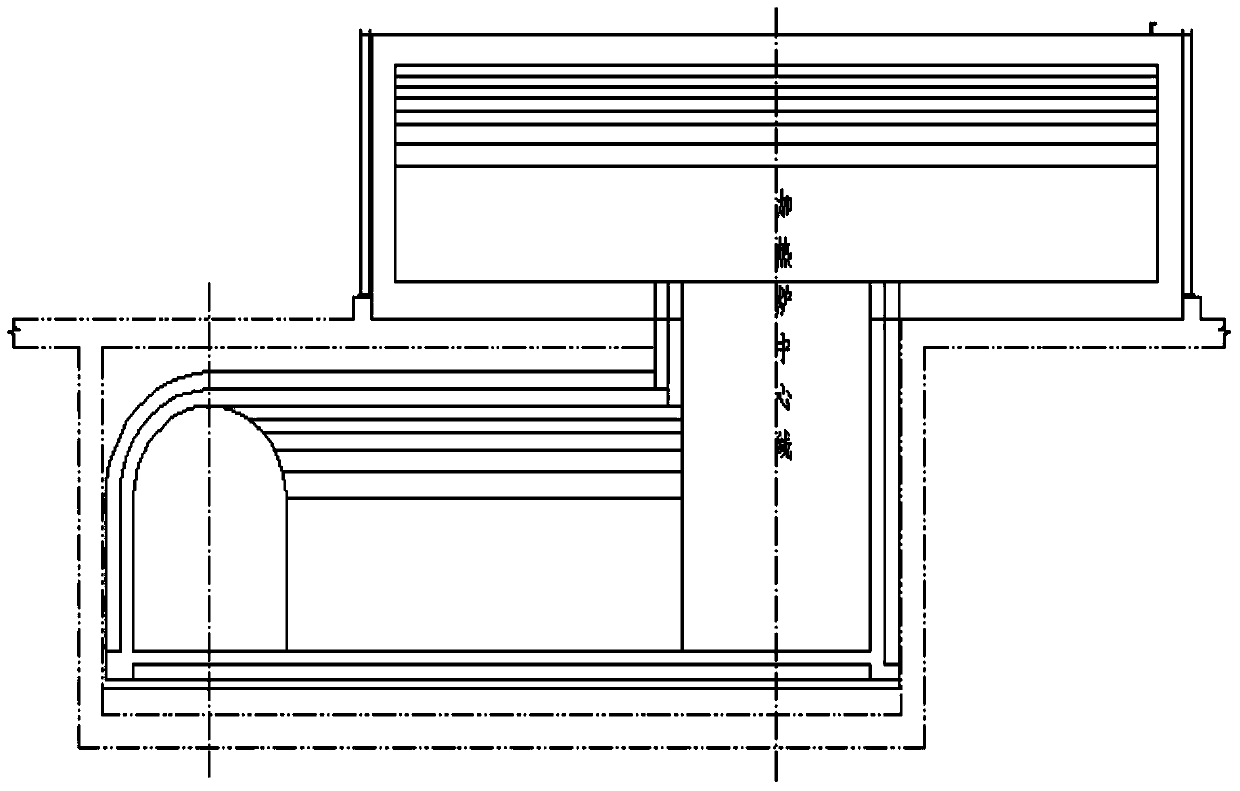

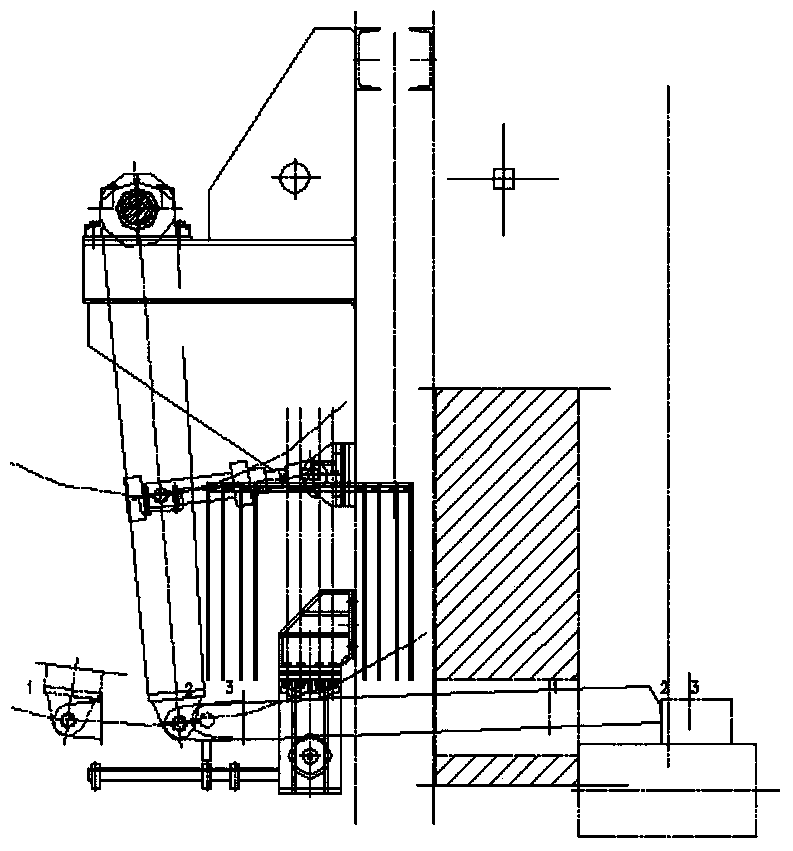

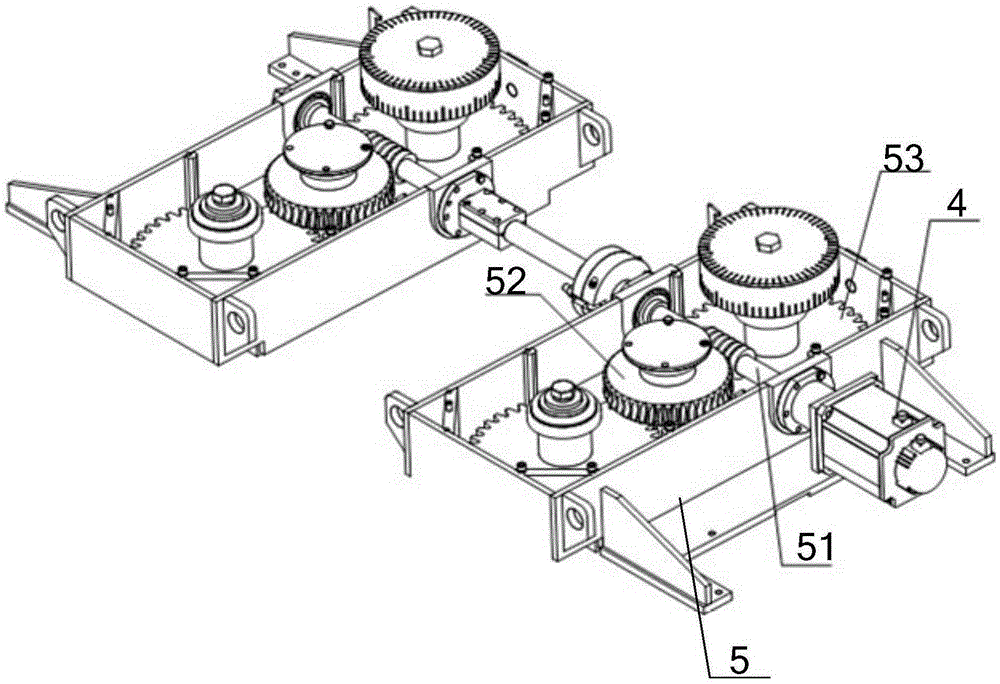

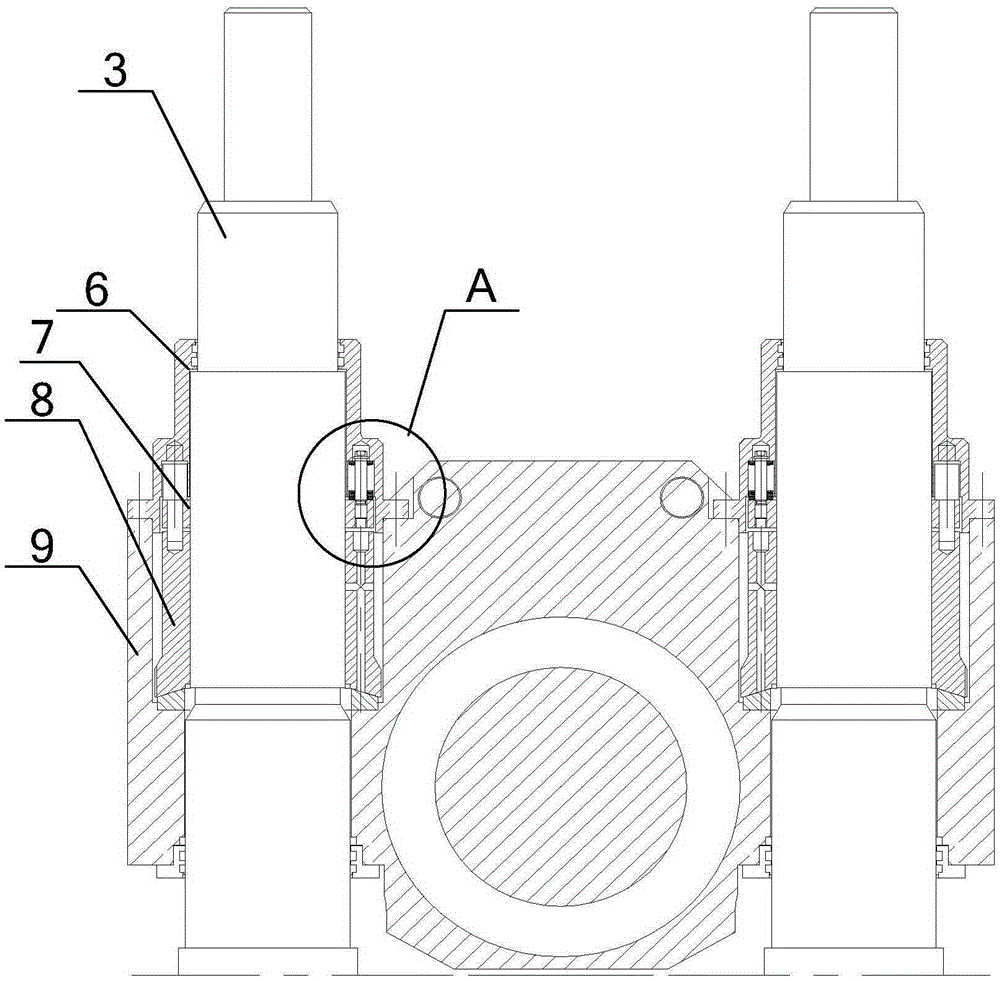

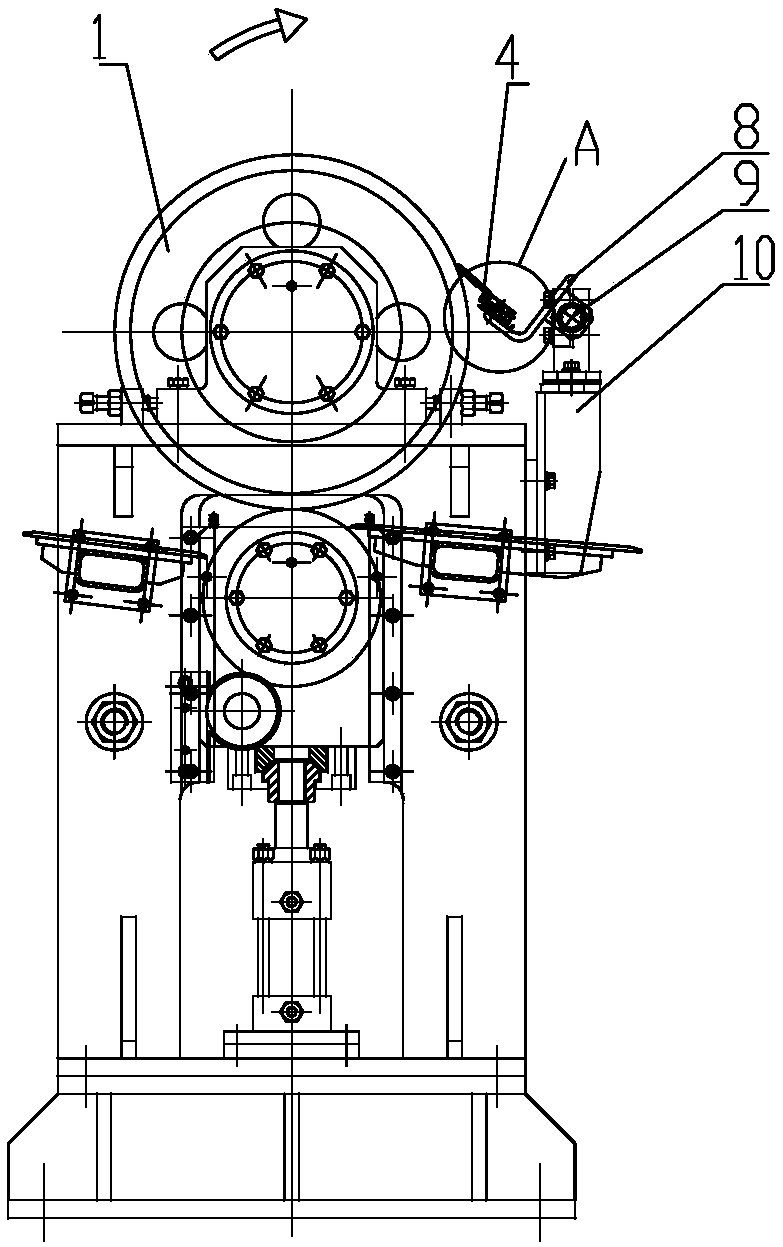

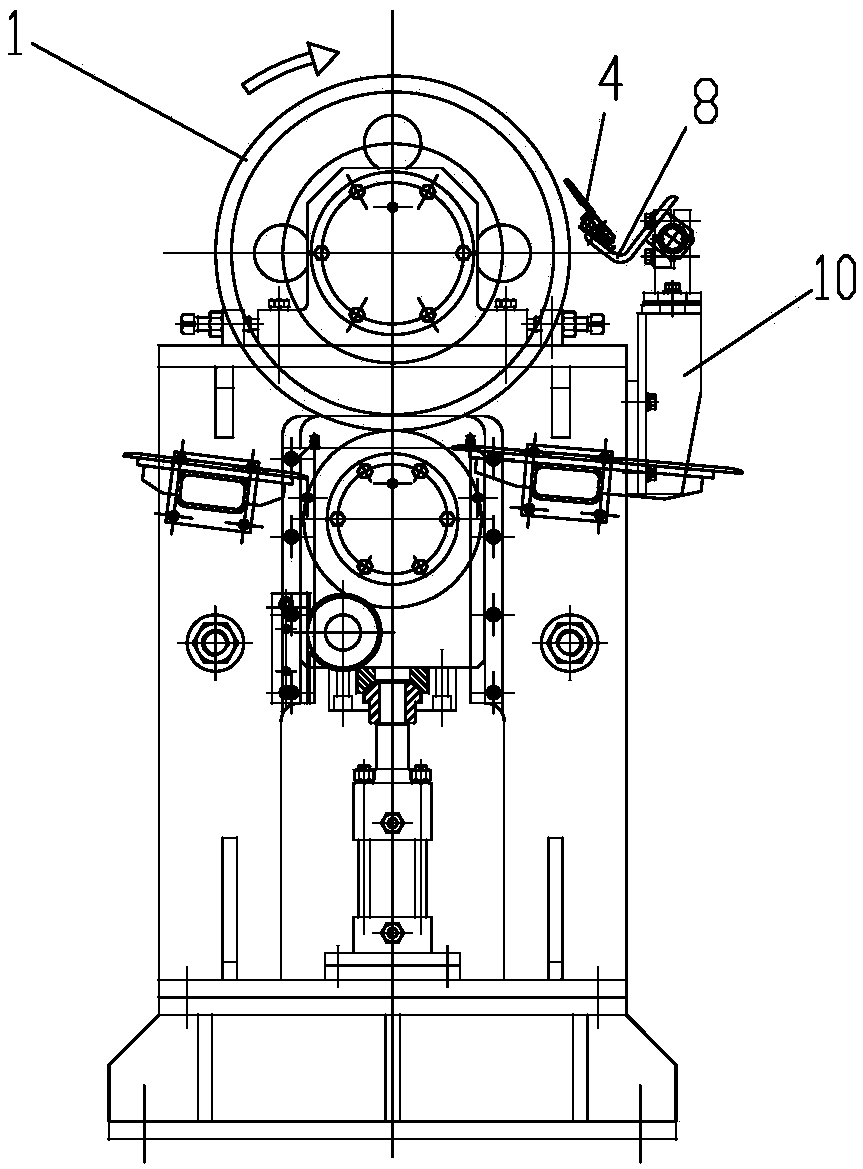

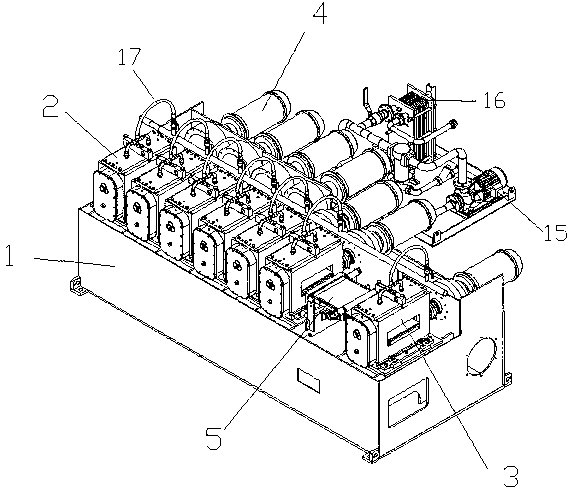

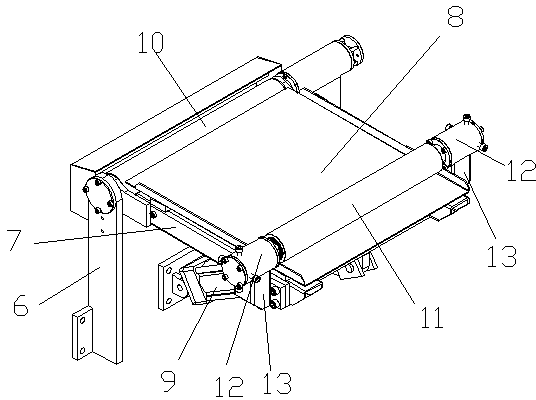

Film rolling machine and roller surface cleaning device thereof for battery pole pieces

ActiveCN102773261AGuaranteed rolling qualityTimely and automatic clearingRolling equipment maintainenceCleaning using toolsSurface cleaningEngineering

The invention provides a film rolling machine and a roller surface cleaning device thereof for battery pole pieces. The roller surface cleaning device composed of a gluing roller mechanism and a scraper mechanism is additionally arranged on the film rolling machine for the battery pole pieces, the two mechanisms can press fit or separate from a roller surface of a roller of the film rolling machine for the battery pole pieces automatically as required, the whole automation degree is quite high, the cleaning device can automatically clean adhered substances on the roller surface timely and reliably, the condition that manual cleaning is not in place is avoided, the roller surface is maintained clean in real time, rolling quality of the pole pieces is guaranteed, and labor cost during a production process is reduced simultaneously.

Owner:SHENZHEN HAONENG TECH

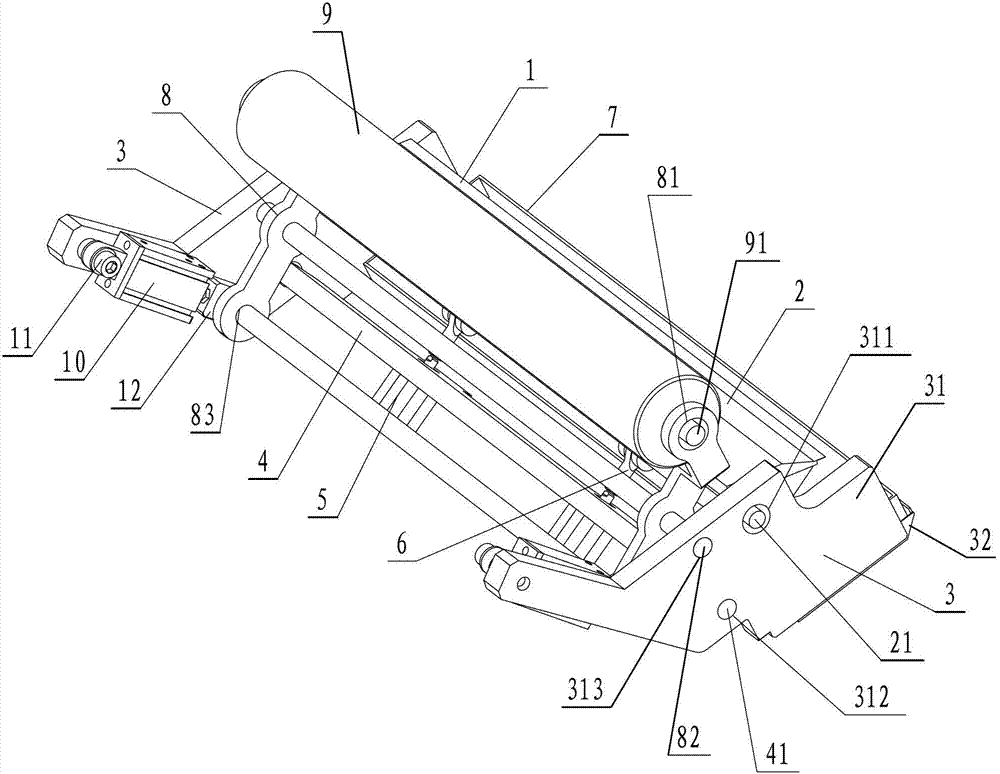

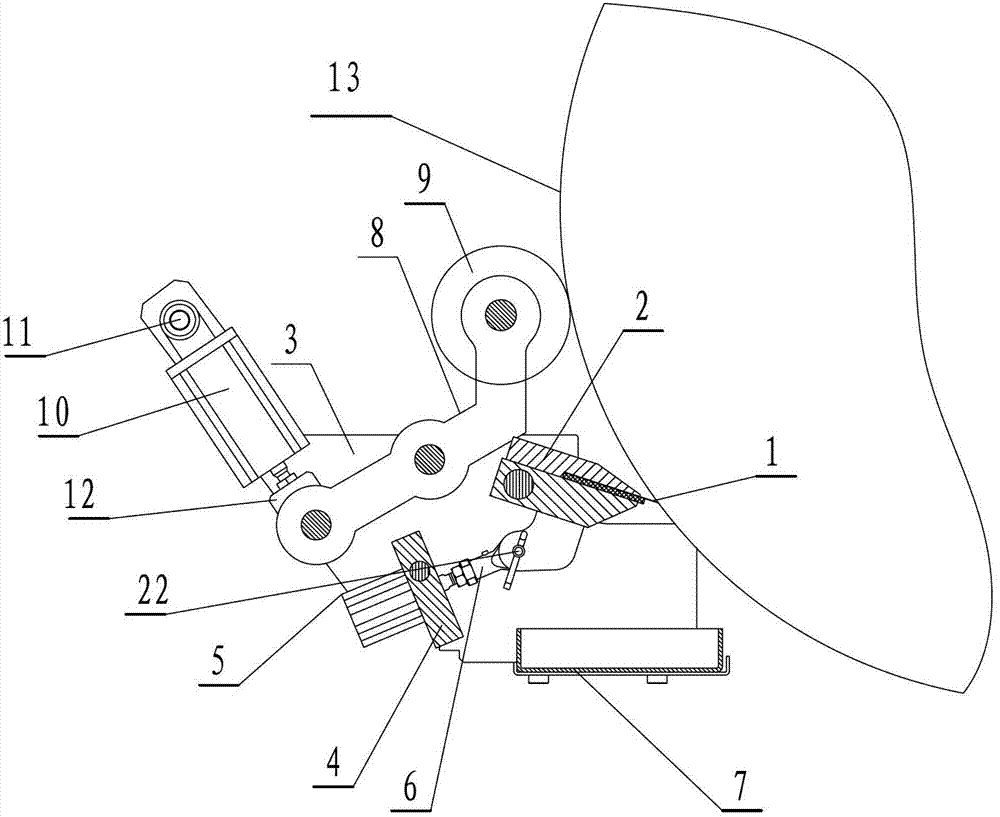

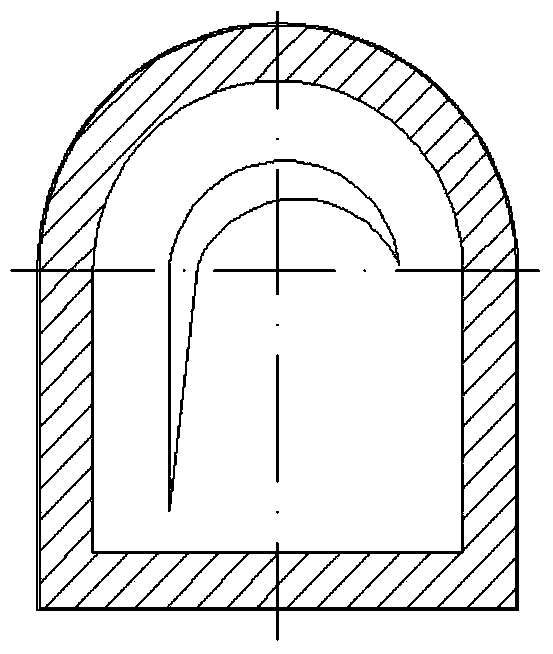

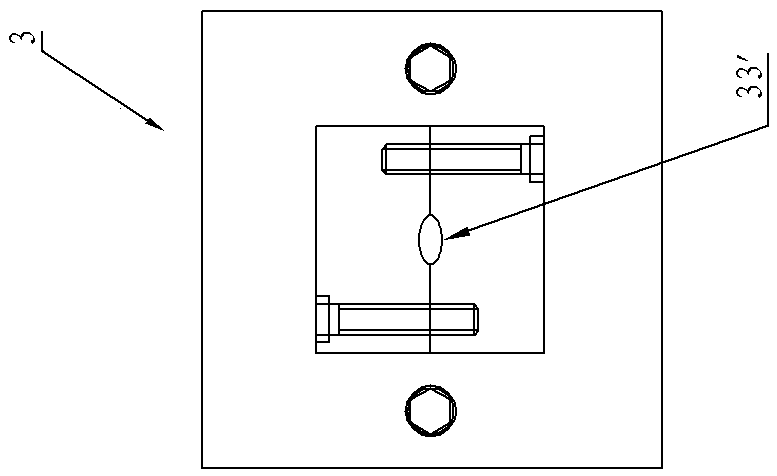

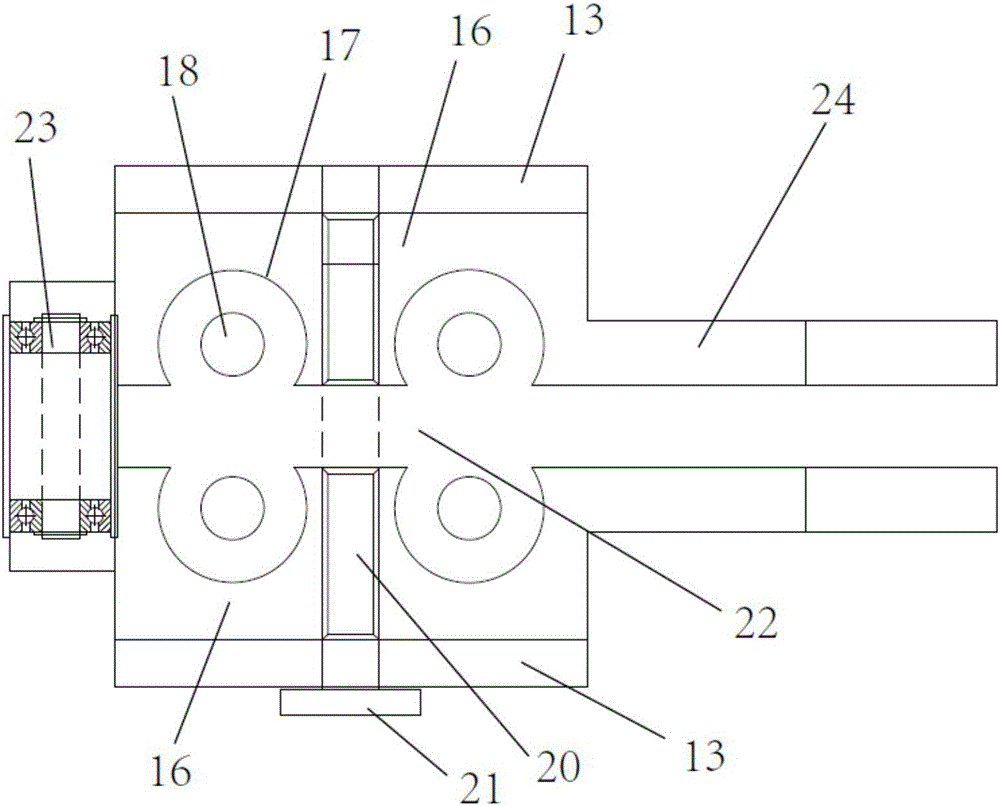

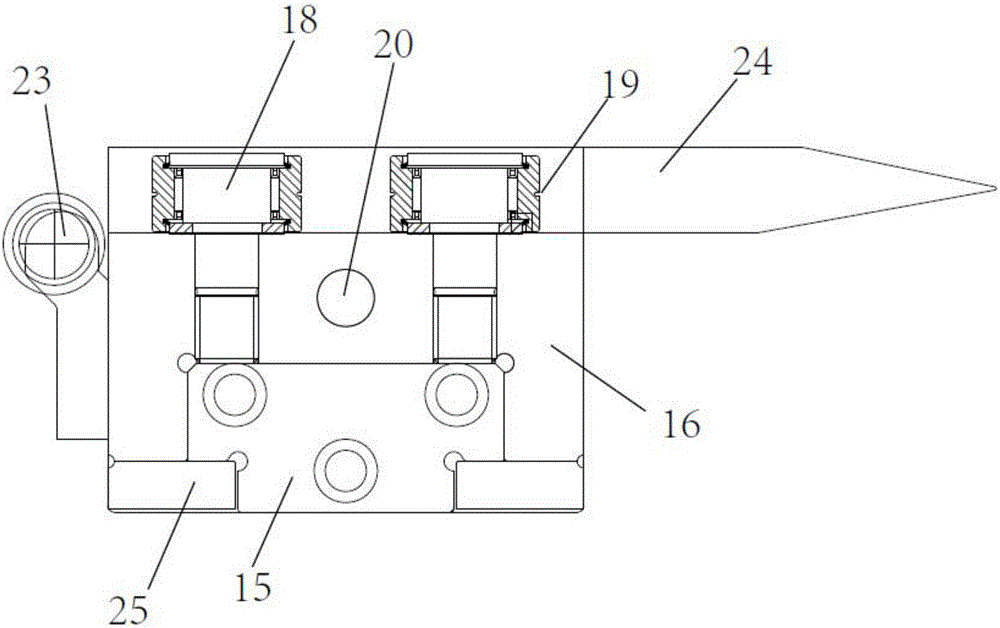

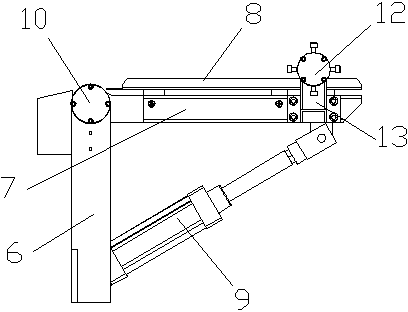

Rolling surface adhesive object scraping device for battery pole piece rolling machine

InactiveCN102581017ATimely and automatic clearingReliable automatic removalRolling equipment maintainenceCleaning using toolsFixed frameAdhesive

The invention discloses a rolling surface adhesive object scraping device for a battery pole piece rolling machine. The rolling surface adhesive object scraping device comprises a fixed supporting seat, a blade fixing frame, a blade, a power cylinder and a power cylinder fixing frame, wherein the fixed supporting seat comprises two parallel side walls and a connection plate connected with the two side walls; the blade fixing frame is arranged on the fixed supporting seat in a rotatable manner that first pin shafts are matched with first rotation holes; the power cylinder is arranged on the power cylinder fixing frame; the power cylinder fixing frame is arranged on the fixed supporting seat in a rotatable manner that second pin shafts are matched with second rotation holes on two sides; the power cylinder comprises a cylinder body and a piston rod; and one end of the piston rod, which extends out of the cylinder body, is hinged with the blade fixing frame. The rolling surface adhesive object scraping device can automatically clear away rolling surface adhesive objects on a roller immediately and reliably, so that a phenomenon that a worker does not clean the adhesive objects completely is avoided, and the surface of the roller can be kept clean in real time; the rolling quality of a pole piece is guaranteed; and the labor cost during production is reduced.

Owner:SHENZHEN HAONENG TECH

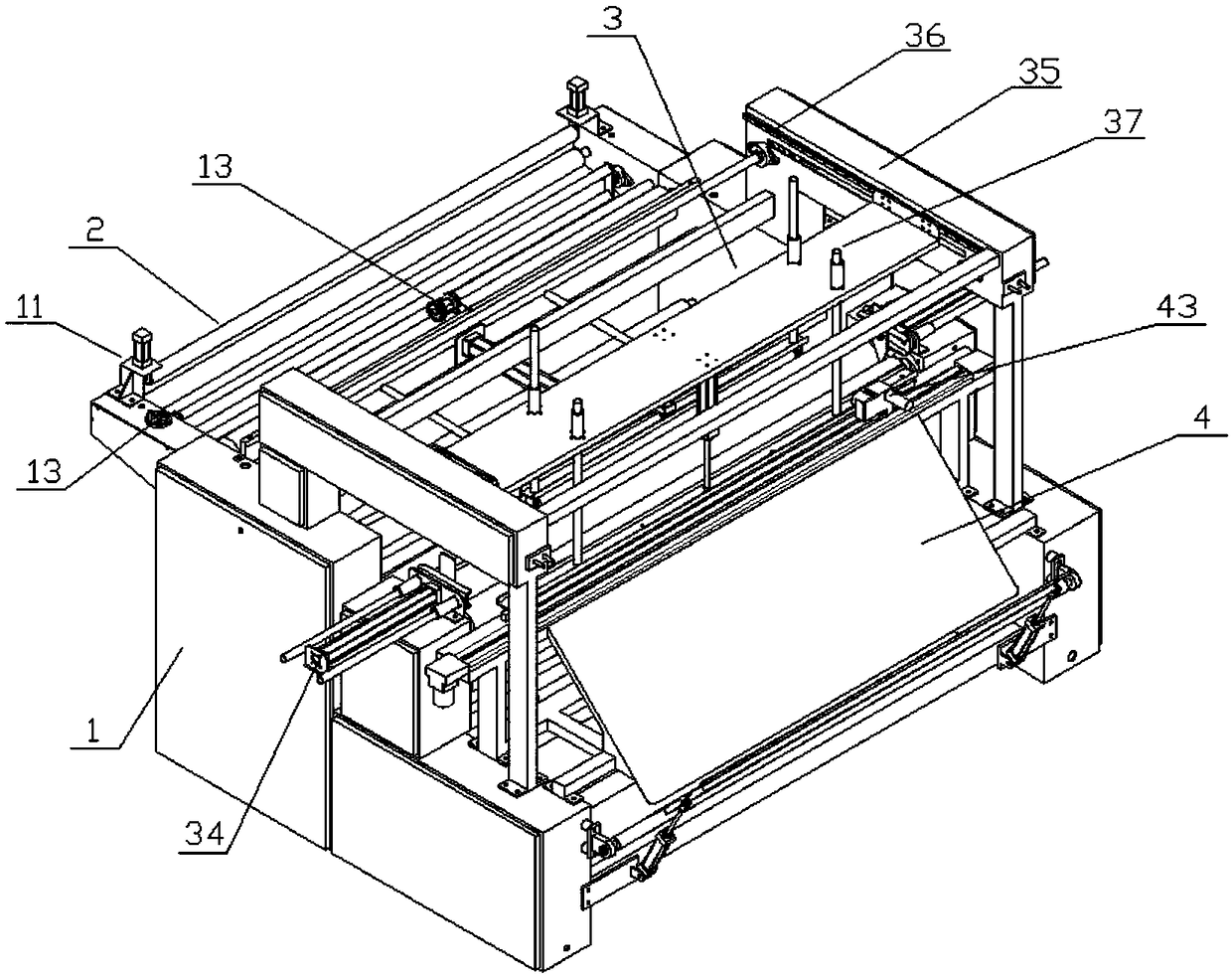

Automatic cloth rolling machine

The invention discloses an automatic cloth rolling machine, which comprises a rack, a controlling cabinet, a cloth feeding device, a cloth rolling device and a discharging device. The cloth feeding device comprises a guide assembly, a transmission assembly, a cloth stretching assembly and a cloth swinging roller. The transmission assembly comprises a first transmission roller and a second transmission roller. The cloth stretching assembly comprises a front area cloth stretching roller and a pair of rear area silk separating rollers. The cloth swinging roller is arranged between the first transmission roller and the rear area silk separating rollers. The cloth rolling device is arranged on the upper portion of the second transmission roller and comprises a driving mechanism, a cloth drivingmechanism, a cloth fixing mechanism and a correcting mechanism. The discharging device comprises a boosting mechanism and a discharging table. The discharging table is provided with an automatic cutting knife. The practical cloth feeding device can stretch cloth adequately and eliminate creases. The cloth rolling device automatically places to-be-rolled cloth onto a cloth rolling paper barrel, cloth rolling is carried out and meanwhile cloth edge tidying operation can be realized, and the quality of rolling production is guaranteed. The discharging device can realize the functions of automatic cloth cutting, automatic conveying and automatic weighing, and manual operation is not required.

Owner:江苏澳得玛机械科技有限公司

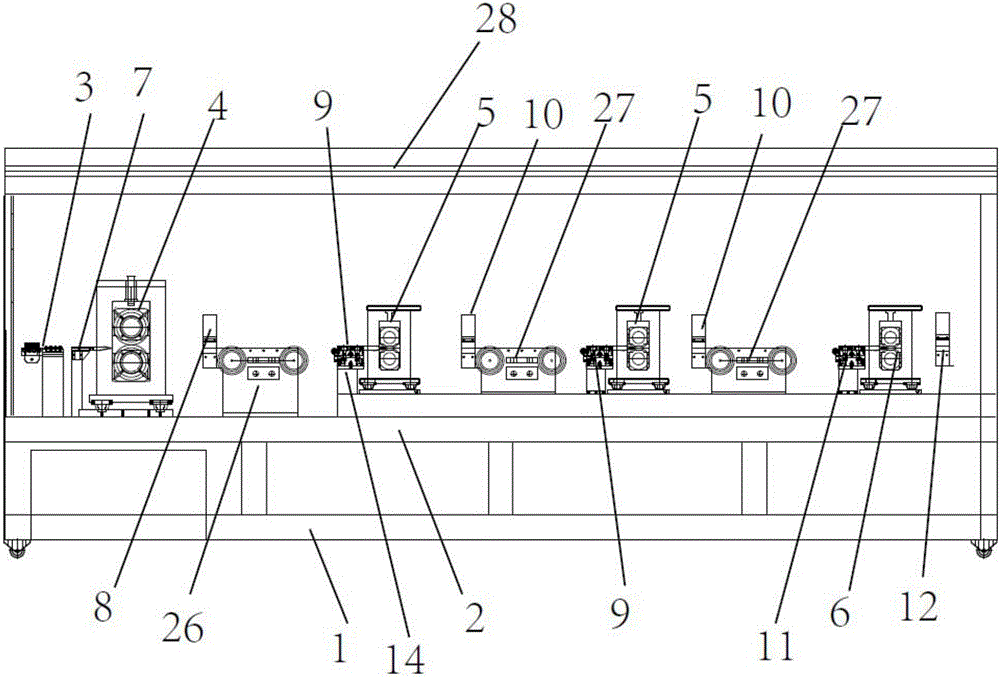

Plate production method by hot continuous rolling

ActiveCN102847709AReduce labor intensityIncrease production capacityRoll force/gap control deviceRollsWork rollUltimate tensile strength

The invention discloses a plate production method by hot continuous rolling and belongs to the technical field of steel rolling. The method includes heating, rough rolling, finish rolling and cooling processes, working rolls used by frames F1, F2, F3, F4 and F5 during checkered plate rolling and flat plate rolling in a finishing rolling unit in the finish rolling process are identical in roll type configuration, the convexity of the working roll of the frame F1 is -0.12--0.14mm, the convexity of the working roll of the frame F2 is -0.12--0.14mm, the convexity of the working roll of the frame F3 is -0.12--0.14mm, the convexity of the working roll of the frame F4 is -0.10--0.14mm, and the convexity of the working roll of the frame F5 is -0.10--0.14mm. When checkered plate rolling and flat plate rolling are switched mutually, change of the working rolls of the frames F1-F5 is omitted, 5 minutes can be averagely saved each time, rolled steel can be increased by more than 20 tons, labor intensity of workers is relieved, and production capacity of rolling machines is further improved.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

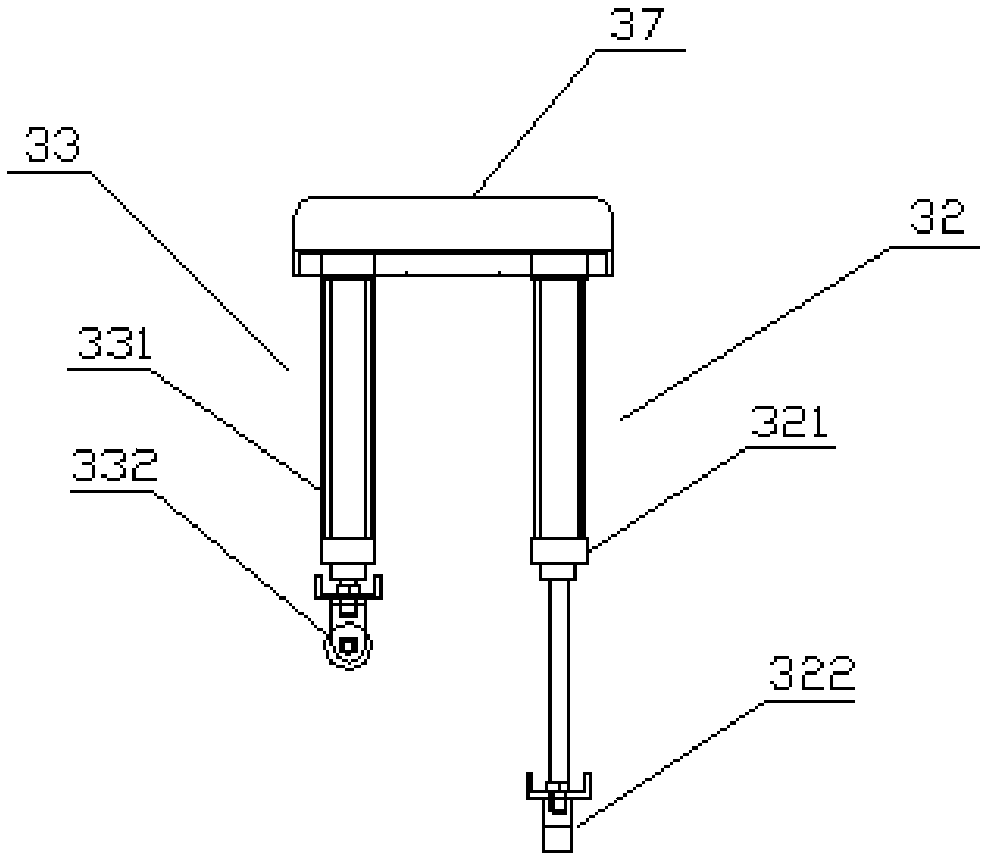

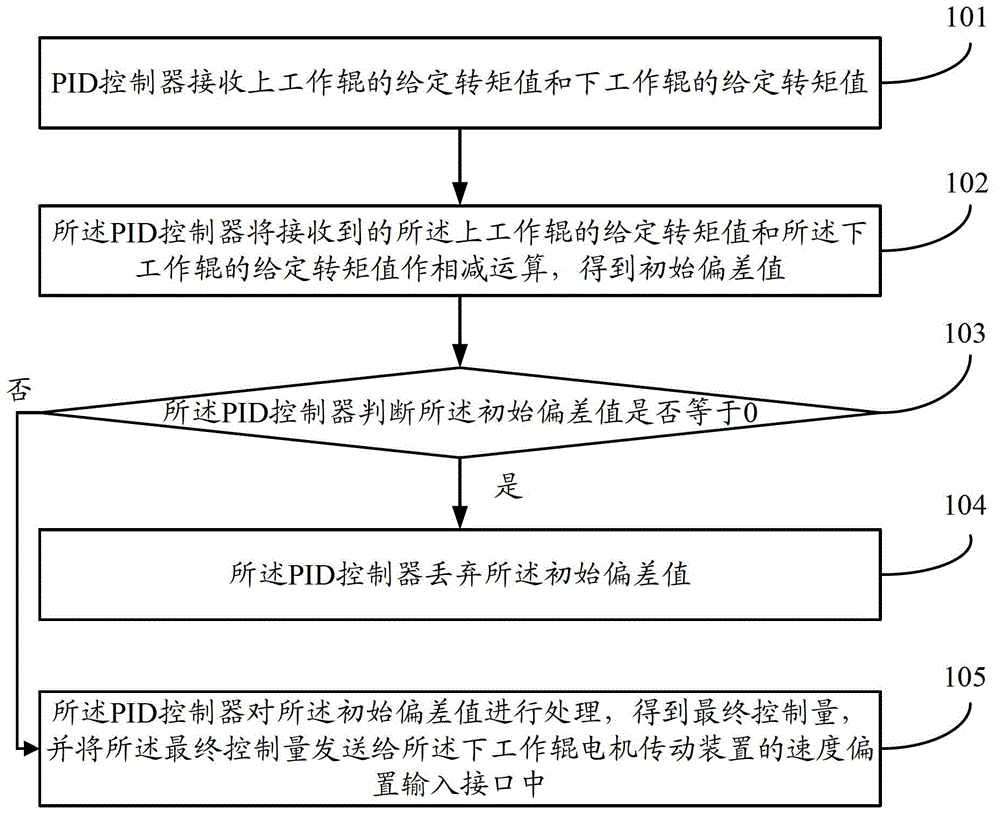

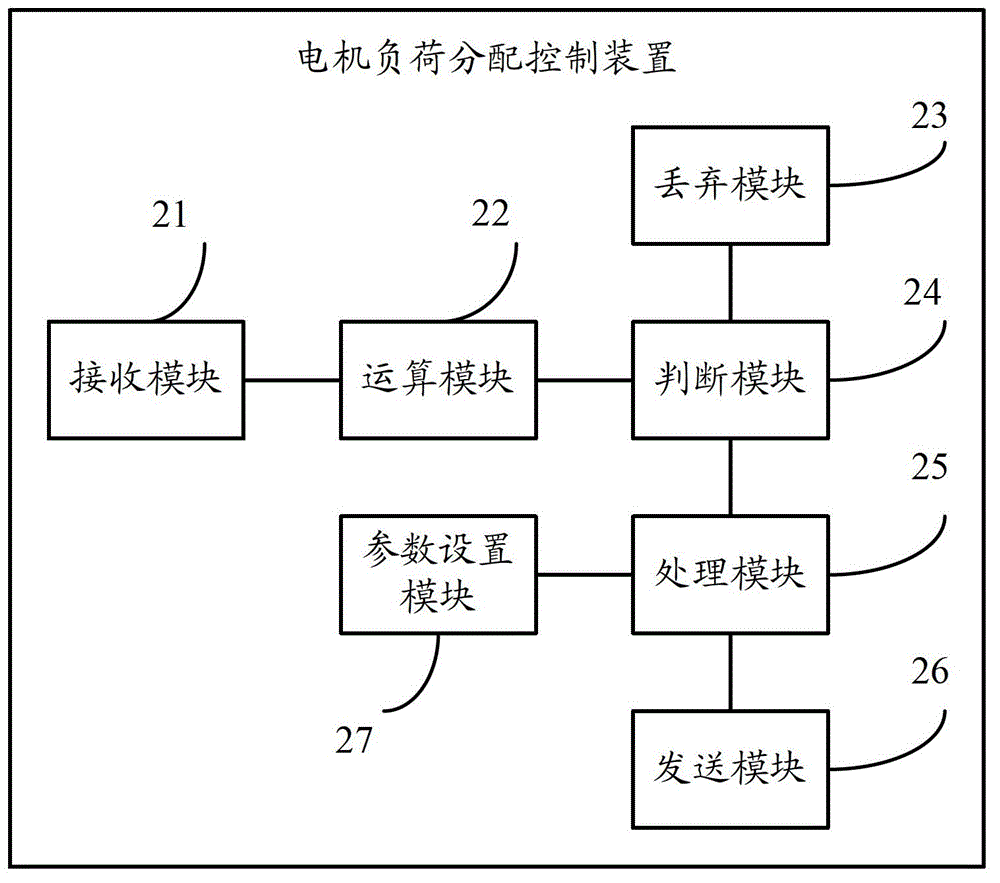

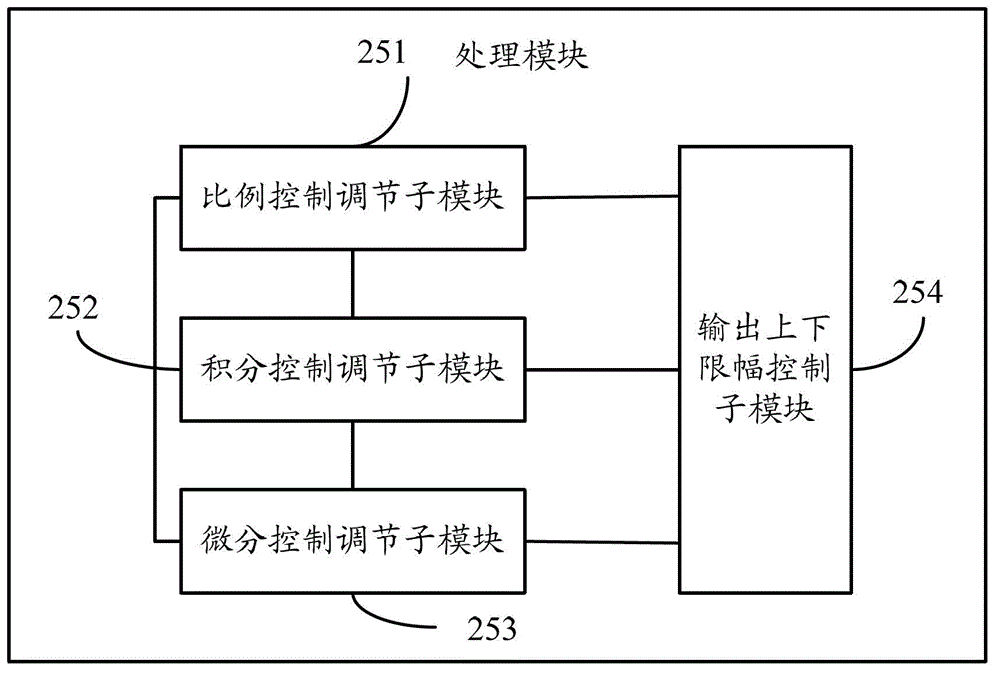

Motor load distribution control method and motor load distribution control device

ActiveCN102744267AGuaranteed rolling efficiency and finished product qualityTo achieve the effect of load balancingRoll speed control deviceDistribution controlLoad distribution

The invention provides a motor load distribution control method and a motor load distribution control device. A difference value of a given torque value of an upper work roller and a given torque vale of a lower work roller are used as the input of a PID (proportion integration differentiation) controller, the output of the PID controller is used as the speed of the lower work roller to realize the additional giving, the goal of regulating the upper and lower work roller load distribution is reached through regulating the speed of the lower work roller, and further, the load balance effect of upper and lower roller transmission motors is realized, so the rolling efficiency and the finished product quality of the steel rolling process are ensured.

Owner:北京景新电气技术开发有限责任公司

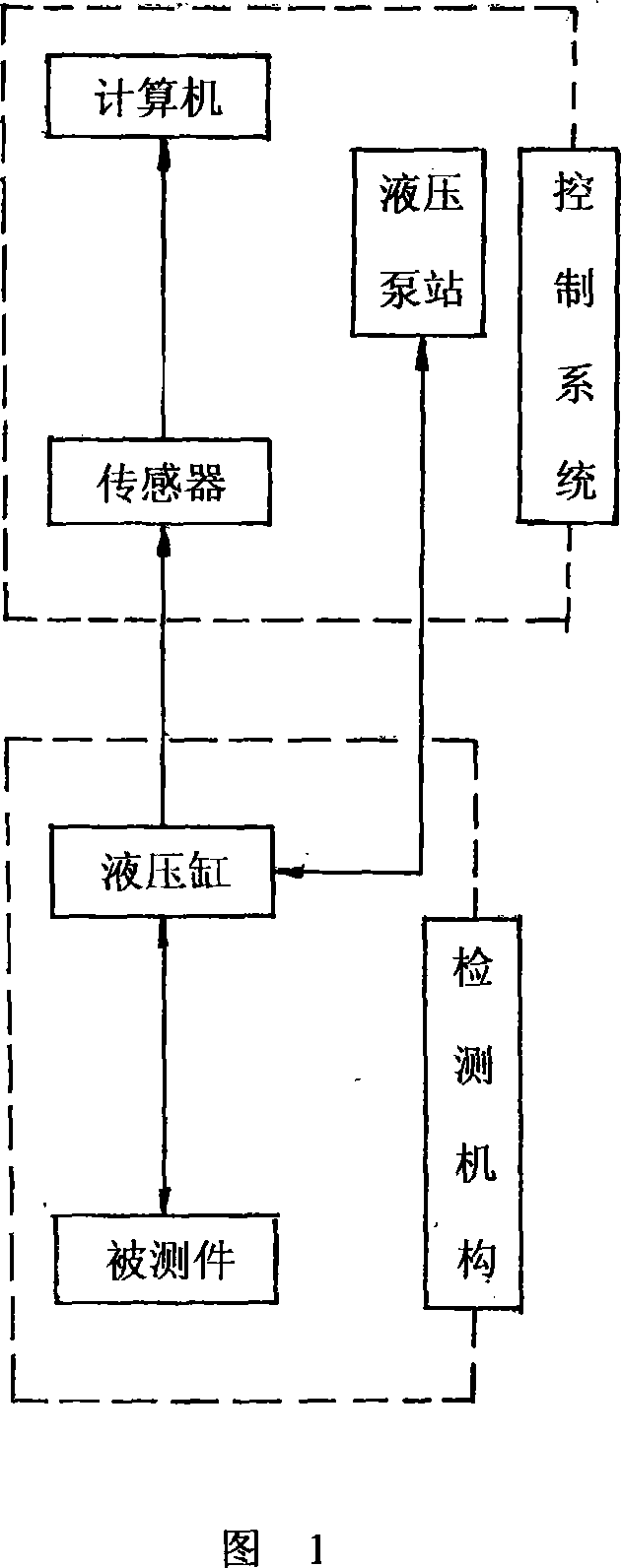

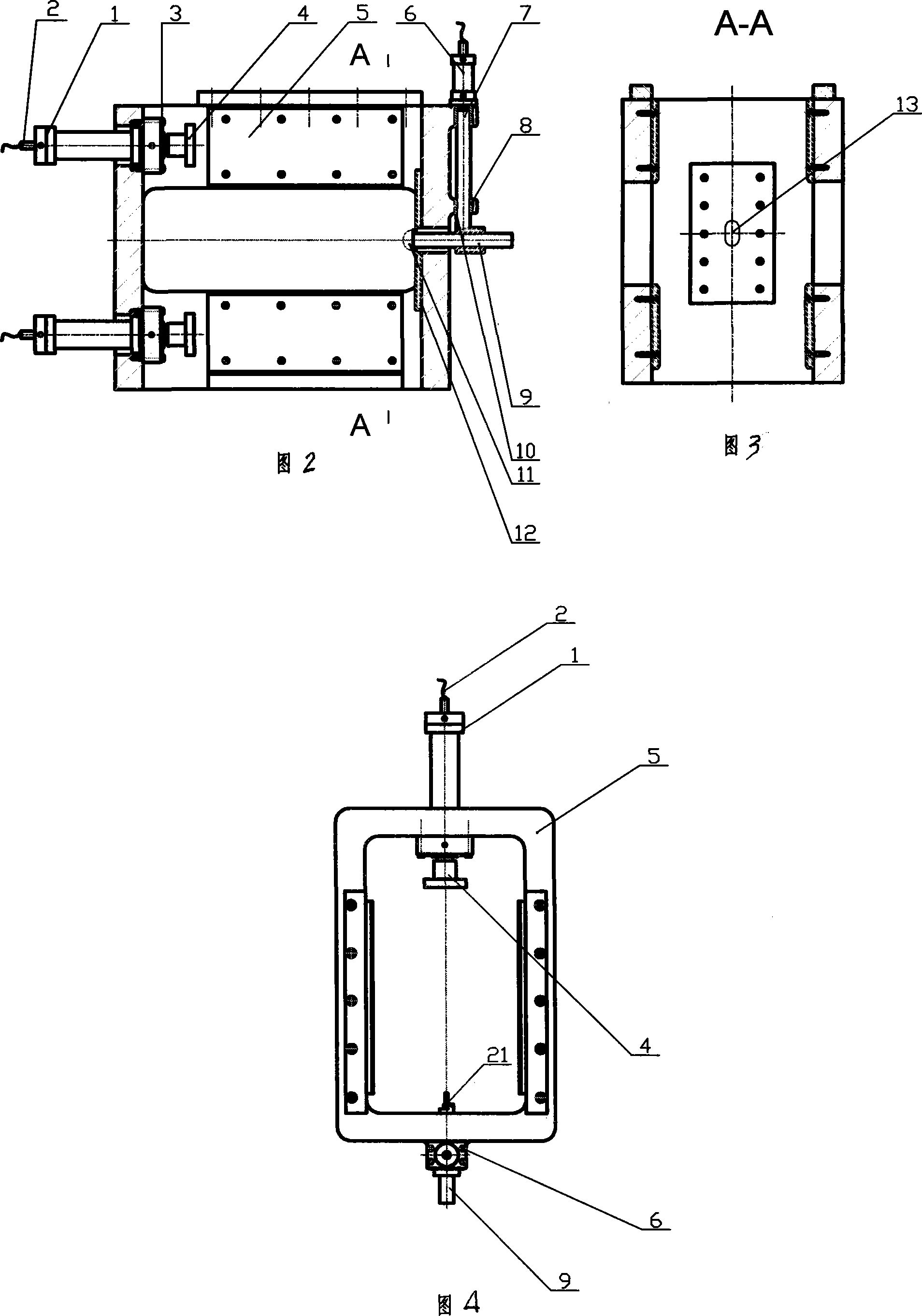

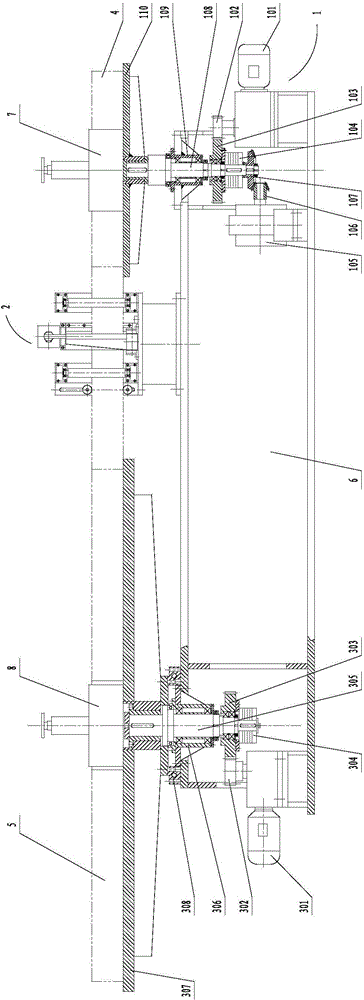

Error measuring device of weldless pipe continuous rolling mill roller and detecting method thereof

InactiveCN101108397AEliminate gapsHigh precisionMeasuring devicesUsing fluid meansHydraulic cylinderTest frame

The invention relates to a seamless pipe tandem rolling machine rolling roller bias test device and the test method, a lifting hydraulic pressure cylinder and an impelling hydraulic pressure cylinder of the displacement sensor are fixed on the test frame, which are connected with a computer by cable and are communicated with a hydraulic pressure pump. A rolling roller and a bearing box are arranged on the test frame, the impelling hydraulic pressure cylinder presses the rolling roller loop against to a return board; the displacement sensor inputs the tested numerical value to the computer to converse and sort out, then get the practical bias value of the top nest work surface of the bearing box from the centre line of the rolling roller. The lifting hydraulic pressure cylinder makes the pore-typed sample stick to the roller roll pore, the displacement sensor inputs the tested numerical value to the computer to sort out, then achieve the practical bias value of the cushion block working surface of the bearing box from the centre of the rolling roller pore. The invention overcomes the gap among the machines, excludes artificial error and removes safety danger, which makes the measurement accuracy is increased into 2 to 3 times than the artificial measurement value, the test time can be shorten for 5 hours.

Owner:ANGANG STEEL CO LTD

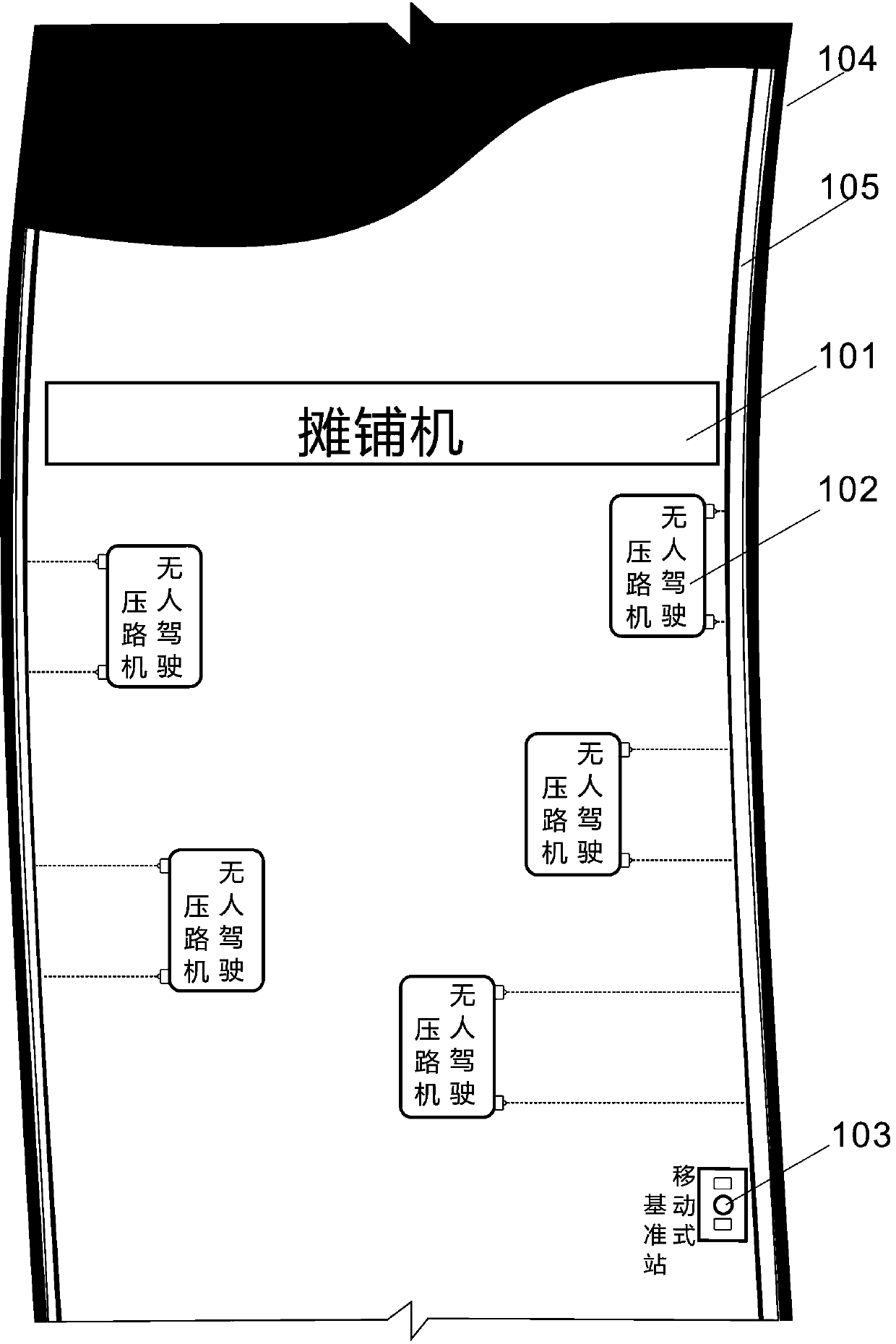

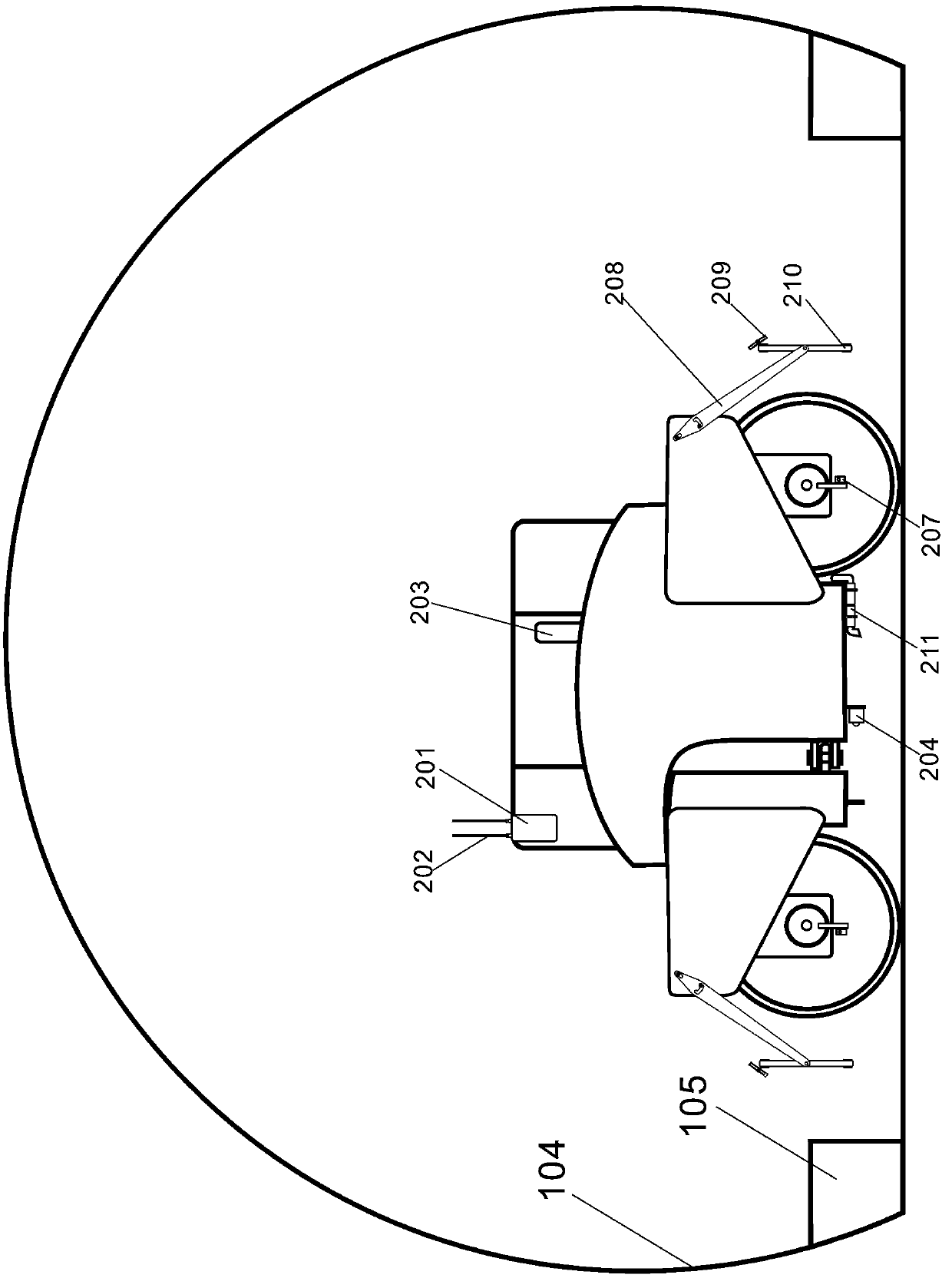

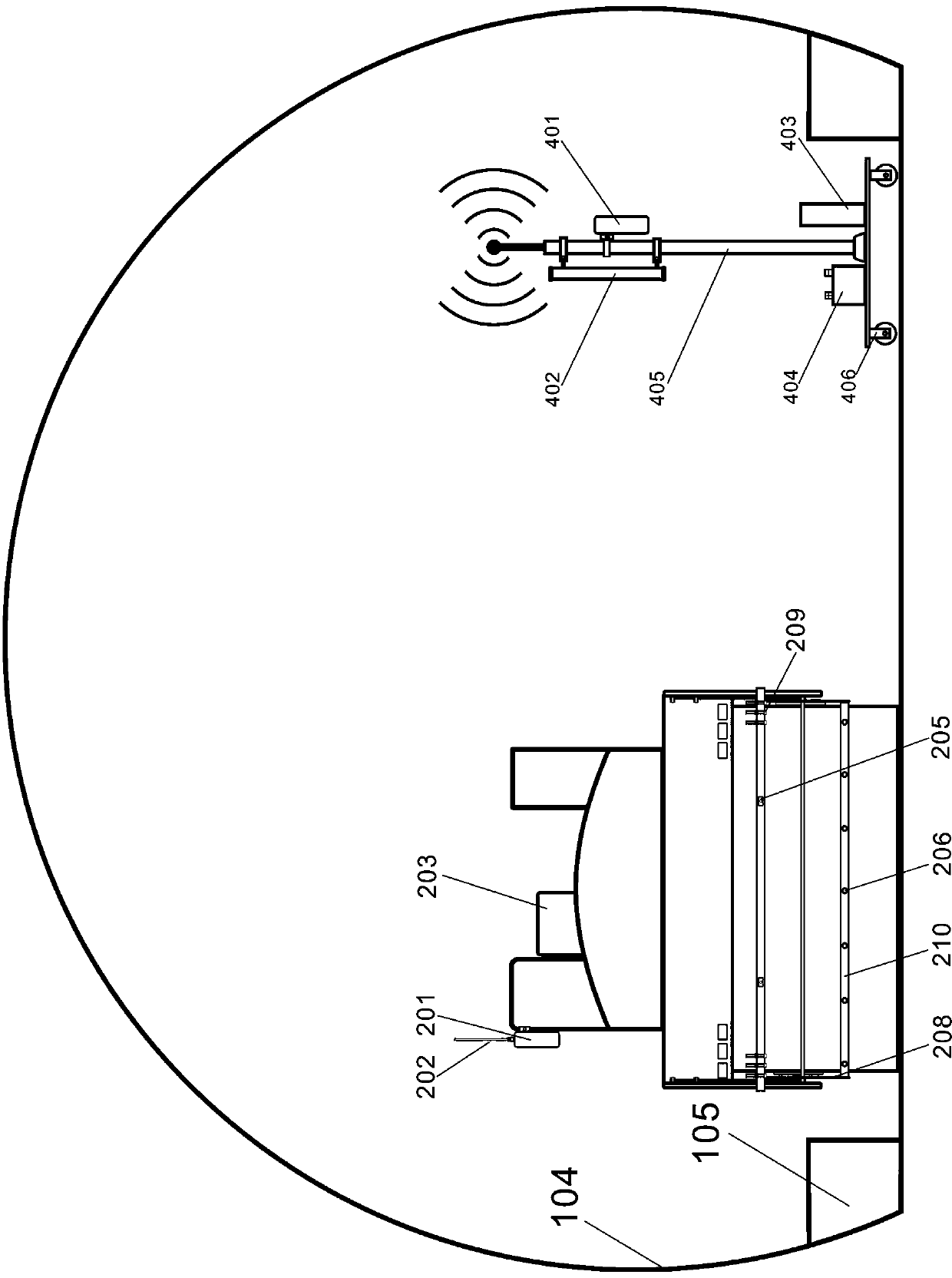

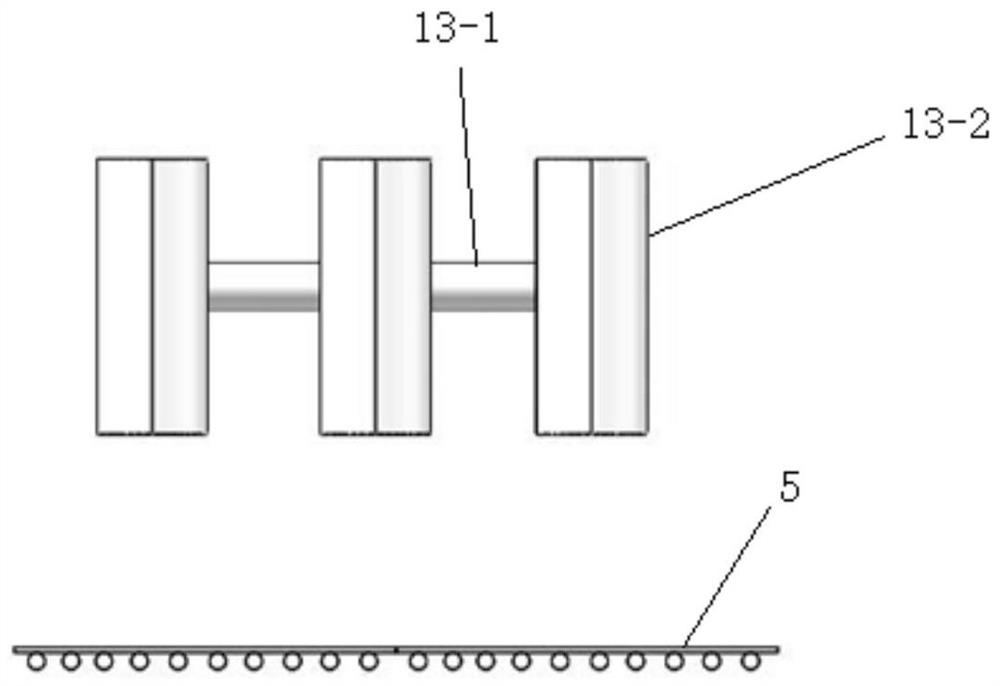

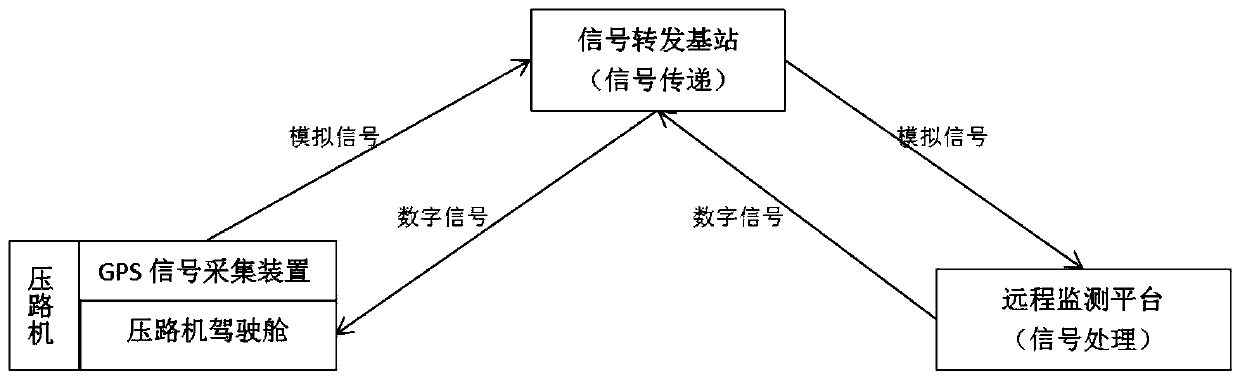

Unmanned road roller rolling system in tunnel without satellite signal

PendingCN110258260ARealize unmanned rolling operationAvoid sufferingRoads maintainenceLaser rangingMicrowave

The invention discloses an unmanned road roller rolling system in a tunnel without a satellite signal. The unmanned road roller rolling system in the tunnel without the satellite signal is characterized in that an unmanned road roller group composed of a plurality of road rollers, a path planning system arranged on a paver, and a mobile reference station form the unmanned road roller rolling system in the tunnel without the satellite signal; lateral laser distance measuring sensors are laterally arranged at the positions of the left side and the right side in front and back of a vehicle body of each road roller in a manner of forming a 90-degree angle with a running direction separately; the sidewall of a drainage ditch in the tunnel is taken as a reference substance, distances between vehicle wheels of each road roller and the sidewall of the drainage ditch are tested through the laser distance measuring sensors arranged on the road roller to set the running track of each amplitude of the road roller; the running of each road roller is controlled through microwave communication, and operating personnel of the road roller are prevented from working under an environment of mixing emitted tail gas and a high-temperature asphalt mixture; and the advantages of effectively protecting the occupational health of the operating personnel of each road roller is realized, avoiding the harm of poisonous and harmful substances to human bodies, and ensuring the rolling quality for an asphalt road surface in the tunnel.

Owner:SICHUAN CHUANJIAO ROAD & BRIDGE +1

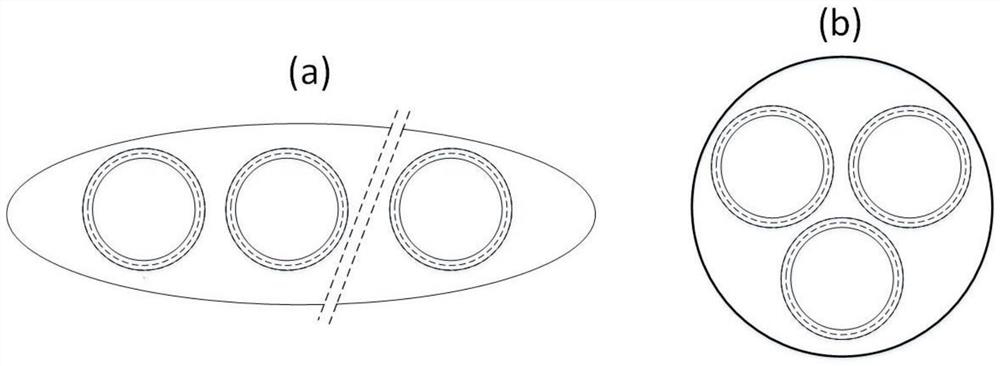

High-efficiency high-throughput continuous casting and rolling system and process for titanium alloy bars

The invention provides a high-efficiency high-throughput continuous casting and rolling system and process for titanium alloy bars. The system involves a feeding mechanism, a smelting chamber, a flowdividing chamber, a flow dividing mechanism, a multi-channel crystallization mechanism, pull-down mechanisms, material receiving mechanisms, conveying belts and a rolling mechanism; the smelting chamber is provided with a water-cooled copper furnace hearth, and a raw material is heated and smelted through plasma guns to form molten metal; the metal molten is guided into the flow dividing chamber and flows to the multi-channel crystallization mechanism in a divided mode, and the multi-channel crystallization mechanism is provided with a plurality of crystallizers in one-to-one correspondence with flow dividing openings; the material receiving mechanisms are arranged below the multi-channel crystallization mechanism and are provided with material receiving pipes in one-to-one correspondencewith the crystallizers, the material receiving pipes are opened after being turned over, titanium alloy billet bars slide onto the conveying belts, and the conveying belts convey the titanium alloy billet bars into the rolling mechanism for continuous rolling forming; and the crystallizers are water-cooled copper crystallizers, the crystallizers are vertically arranged at equal intervals, and thermal barrier material coatings are arranged on the outer surfaces of the crystallizers.

Owner:NANJING UNIV OF TECH

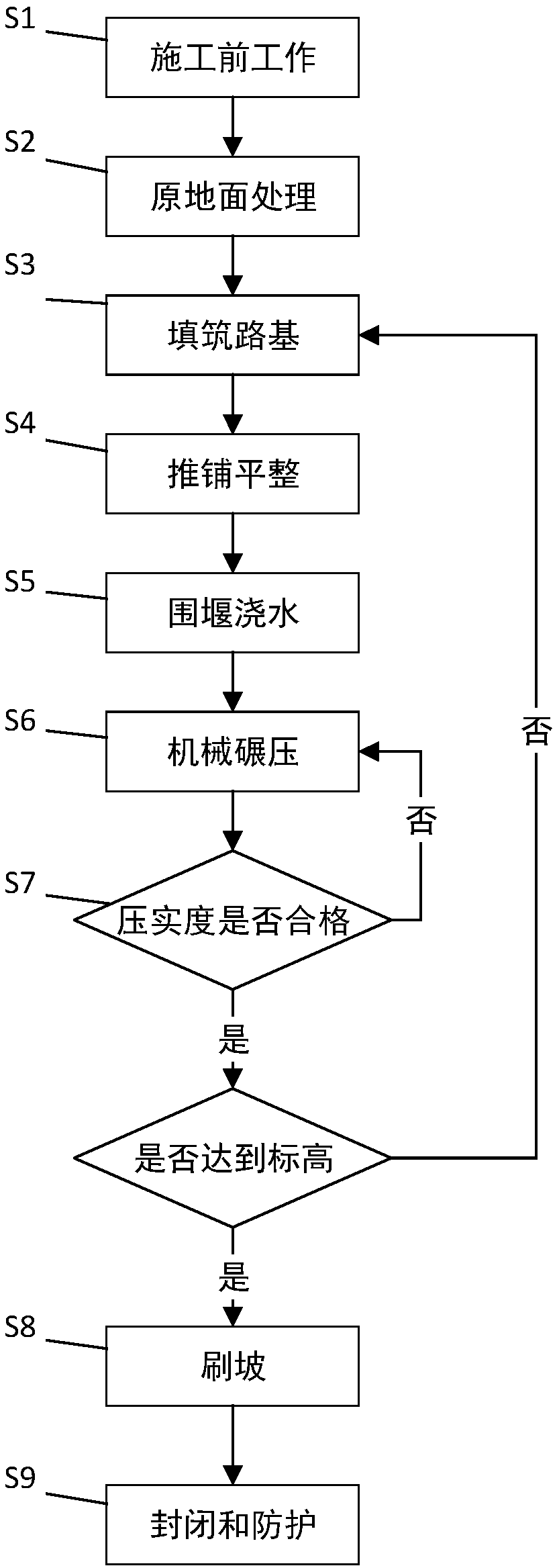

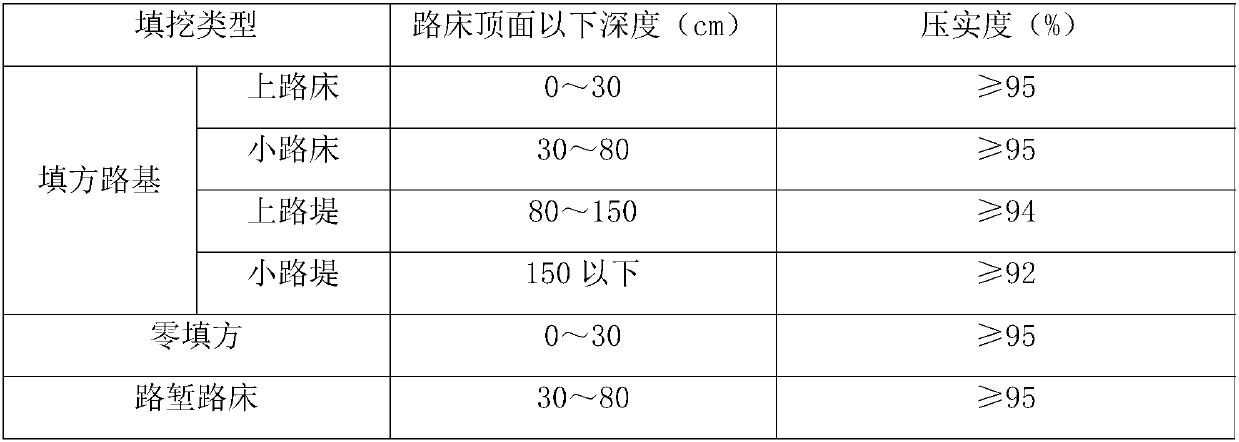

A subgrade filling construction method utilizing aeolian sand

InactiveCN107587414AReduced dune presenceImprove environmental qualityExcavationsRoads maintainenceEnvironmentally friendlySubgrade

The invention relates to a subgrade filling construction method utilizing aeolian sand. The method includes 1) finishing preparatory work before construction; 2) clearing the surface of a subgrade, and rolling the subgrade surface before filling operation; 3) filling the subgrade with the aeolian sand; 4) spreading out and leveling a filler pushed and conveyed into a filling road segment, and controlling the loose laying depth by adopting a line hanging process; 5) arranging a cofferdam, digging a ponding facility in a lower wet section, arranging a water feeding pipeline and performing watering treatment; 6) performing mechanical rolling, after the subgrade is compacted, and spraying water on the surface to stabilize compaction; 7) measuring the field compaction density by adopting a cutting ring process, detecting the foundation coefficient of the subgrade, and if the field compaction density and the foundation coefficient in a detection result are unqualified, repeating the step 6)until the field compaction density and the foundation coefficient in a detection result are qualified; 8) repeating the step 3) to the step 7) until the subgrade is filled to a set standard height, and performing slope cutting; and 9) sealing and protecting the top surface and side slopes of the subgrade. The scientific and reasonable subgrade filling construction method utilizing the aeolian sandis provided and has advantages of capability of being energy saving and environmentally friendly, capability of reducing the cost, and the like.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

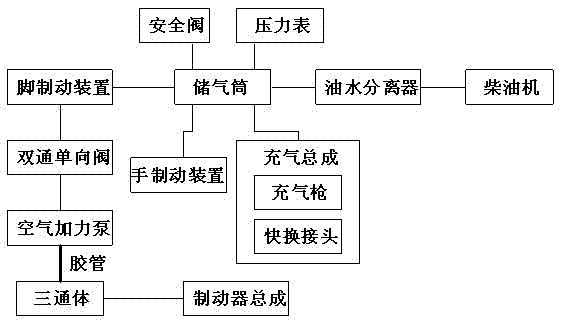

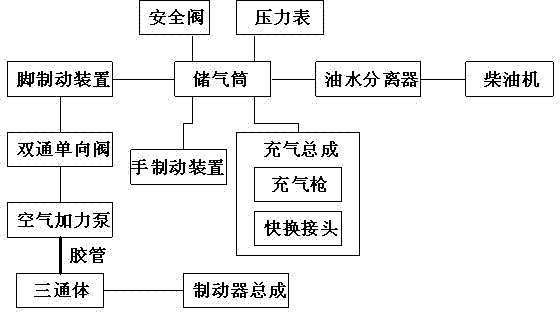

Pneumatic pressure regulation device for tire road roller

InactiveCN102390226AGuaranteed flatnessGuaranteed rolling qualityTyre measurementsRoads maintainenceAutomatic controlRoad surface

The invention discloses a pneumatic pressure regulation device for a tire road roller, and belongs to the technical field of autocontrol. The pneumatic pressure regulation device comprises an air booster pump, an air reservoir, a safety valve, an oil-water separator, a hand braking device, a foot braking device, an inflation assembly, a bi-pass non-return valve, and a brake assembly. An diesel engine is connected with the oil-water separator; the oil-water separator is connected with the air reservoir; the air reservoir is connected with the inflation assembly, the hand braking device, and the foot braking device; the foot braking device is connected with the bi-pass non-return valve; the bi-pass non-return valve is connected with the air booster pump; and the air booster pump is connected with the brake assembly. The invention has the benefits that the use is convenient, and the tire and ground fully contact, so that road surface flatness is good and coarse aggregates on the road surface layer are not crushed.

Owner:XUZHOU WBEST CIVIL CONSTR EQUIP & SERVICES

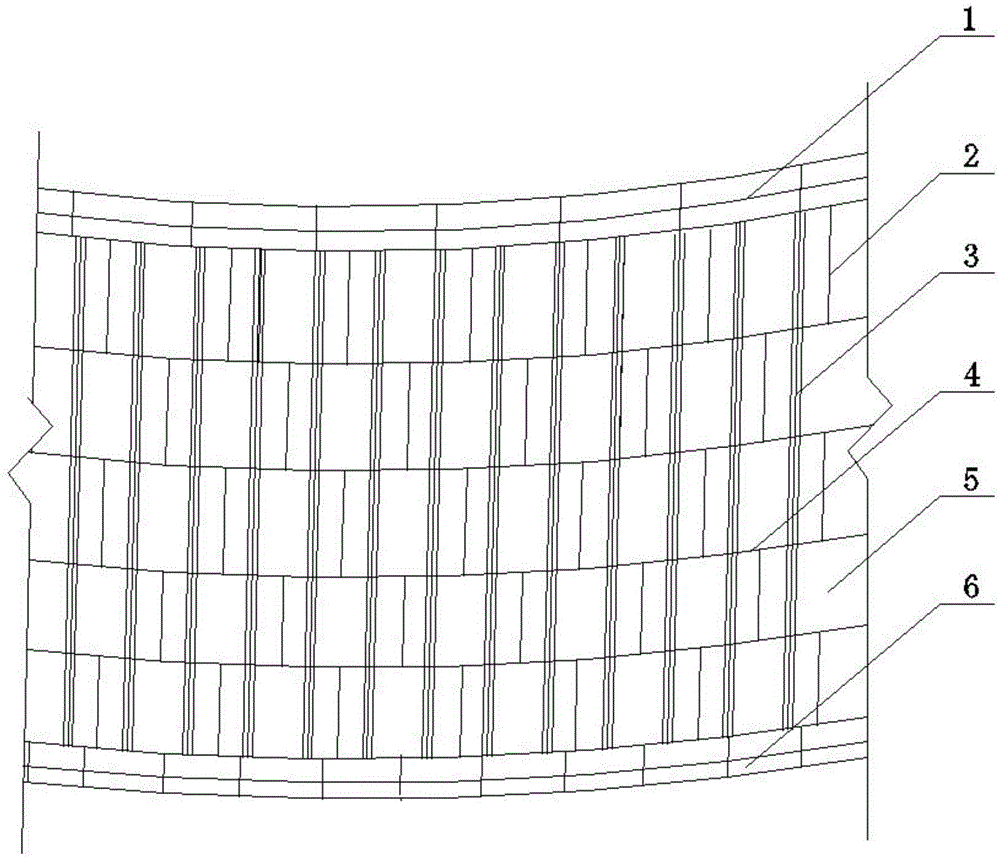

Triangular-strip-groove-based annular heating furnace bottom working layer construction method

ActiveCN105543467AHeating evenlyEvenly placedCharge composition/stateFurnace typesEngineeringHeating furnace

The invention relates to a triangular-strip-groove-based annular heating furnace bottom working layer construction method which comprises the following steps: (1) reference line construction; (2) erection of strip groove mold: arranging a radial spacing rack of the strip groove mold on a working layer castable surface between an internal ring beam and an external ring beam; (3) working layer formation: erecting a working layer castable mold, and casting the working layer castables at intervals; and after finishing casting all the working layer castables, removing the mold so as to form the strip grooves on the annular heating furnace bottom working layer surface at radial intervals, thereby finishing the construction of the annular heating furnace bottom working layer, wherein the strip grooves form a triangle. The steel billet can not roll or tilt in the heating process of the furnace bottom; and thus, the steel billet is heated uniformly, thereby avoiding the overoxidation of the steel billet, preventing the iron scales from melting or corroding the furnace bottom working layer castable, prolonging the service life of the furnace bottom and reducing the overhaul frequency.

Owner:MCC TIANGONG GROUP

Rod and wire heating furnace achieving flexible matching direct hot loading of casting machine and rolling mill

ActiveCN103808150AIncrease hot delivery and hot charging rate and furnace entry temperatureIncrease productionCharge manipulationWaste heat treatmentFlueCharge type

The invention provides a rod and wire heating furnace achieving flexible matching direct hot loading of a casting machine and a rolling mill, and belongs to the technical field of industrial furnaces. The rod and wire heating furnace comprises a cantilever roller bed side-inlet and side-outlet step-type heating furnace body, accessory equipment, a loading end lower smoke exhausting tube, a smoke exhausting flue, a flexible matching loading machine and a suspension furnace-charging type pusher. The flexible matching loading machine is arranged at the end of the cantilever roller bed side-inlet and side-outlet step-type heating furnace body and the end of the accessory equipment, the suspension furnace-charging type pusher is arranged on the end of the cantilever roller bed side-inlet and side-outlet step-type heating furnace body, the end of the accessory equipment and the upper portion of the flexible matching loading machine, and the exhausting tube and the smoke exhausting flue are arranged at the end of the cantilever roller bed side-inlet and side-outlet step-type heating furnace body, the end of the accessory equipment and the lower portion of the flexible matching loading machine. The rod and wire heating furnace has the advantages that the problem that the steel making continuous casting machine and the steel rolling mill are not matched in production speed and production and maintaining system is solved, the hot conveying and hot loading furnace charging rate and hot conveying billet furnace charging temperature can be improved, and energy consumption of the heating furnace is reduced.

Owner:BEIJING SHOUGANG INT ENG TECH

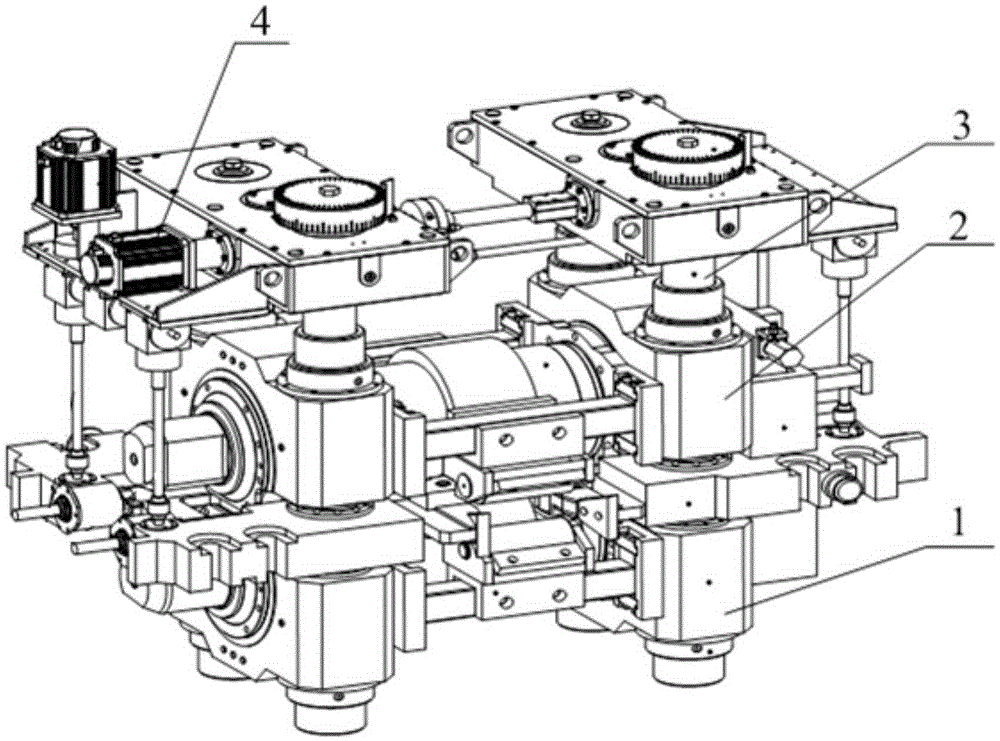

Upright iron core rolling machine

ActiveCN105798619ARealize rollingImprove work efficiencyShearing machinesInductances/transformers/magnets manufactureReducerEngineering

The invention belongs to the field of electric reactor iron cores, and particularly provides an upright iron core rolling machine which comprises a machine body, a feeding device, a shearing machine and a rolling device. A feeding device shaft in the feeding device is rotatably mounted on the machine body and connected with a first reducer mounted on the machine body through a feeding device transmission mechanism. A feeding device workbench for bearing rolled materials is mounted at one end of the feeding device shaft, and a rolled material supporting unit is arranged on the feeding device workbench. The other end of the feeding device shaft is connected with a magnetic material brake used for providing tension for the rolling device for rolling iron cores. A rolling device shaft in the rolling device is rotatably mounted on the machine body, a rolling device workbench is mounted at one end of the rolling device shaft, a workpiece supporting tyre is arranged on the rolling device workbench, and the other end of the rolling device shaft is connected with a second reducer mounted on the machine body through a rolling device transmission mechanism. The shearing machine is located between the feeding device and the rolling device. By means of the upright iron core rolling machine, the iron cores of novel electric reactors are rolled, work efficiency is high, labor is saved, and the rolled workpieces fully meet the quality requirement.

Owner:沈阳特变电工电气工程有限公司

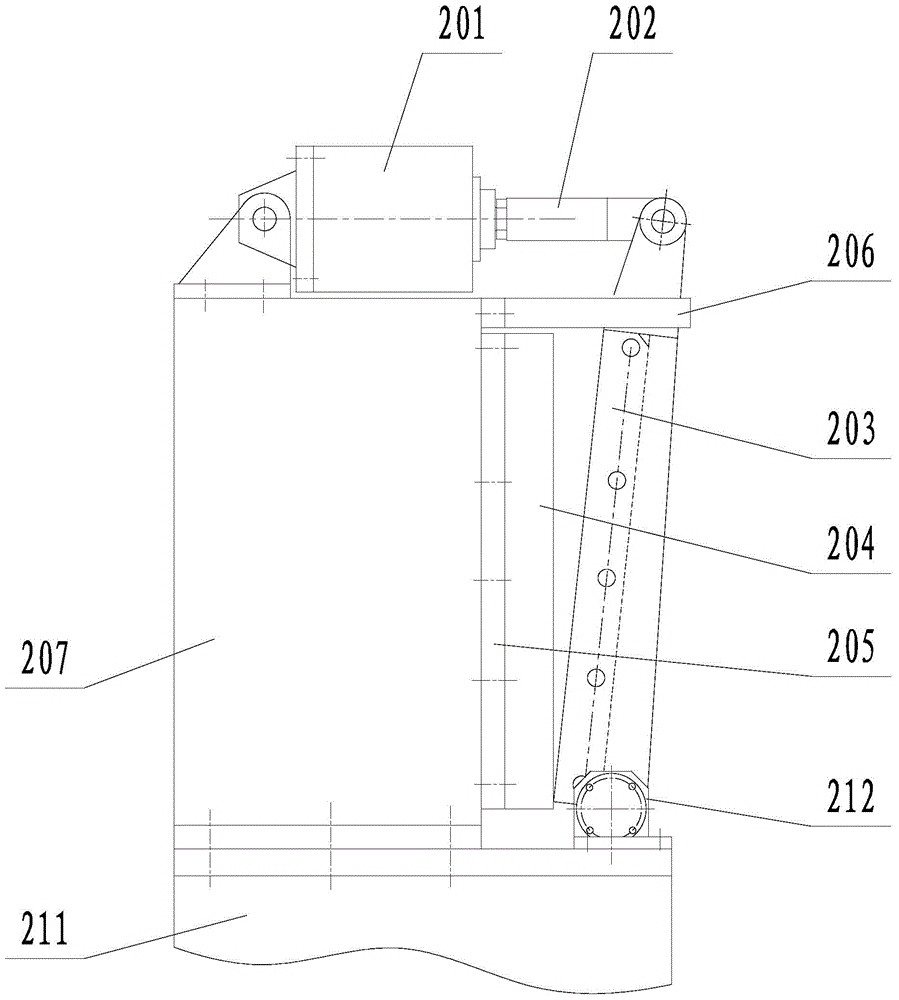

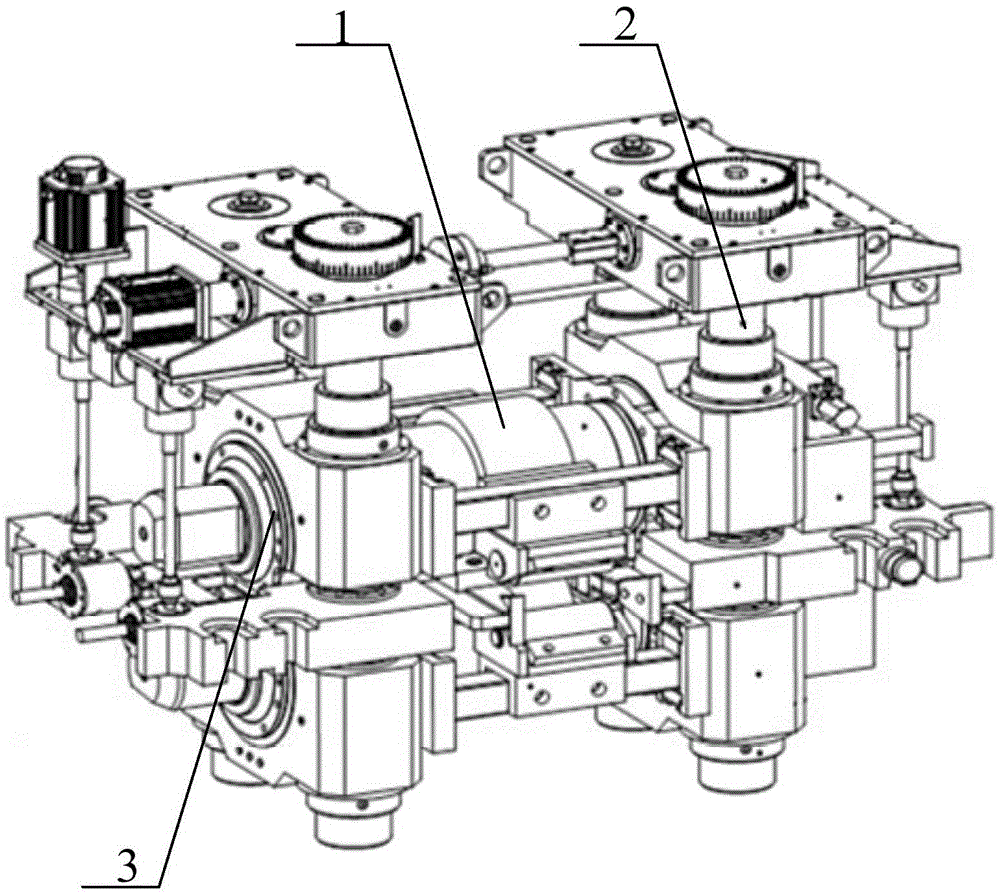

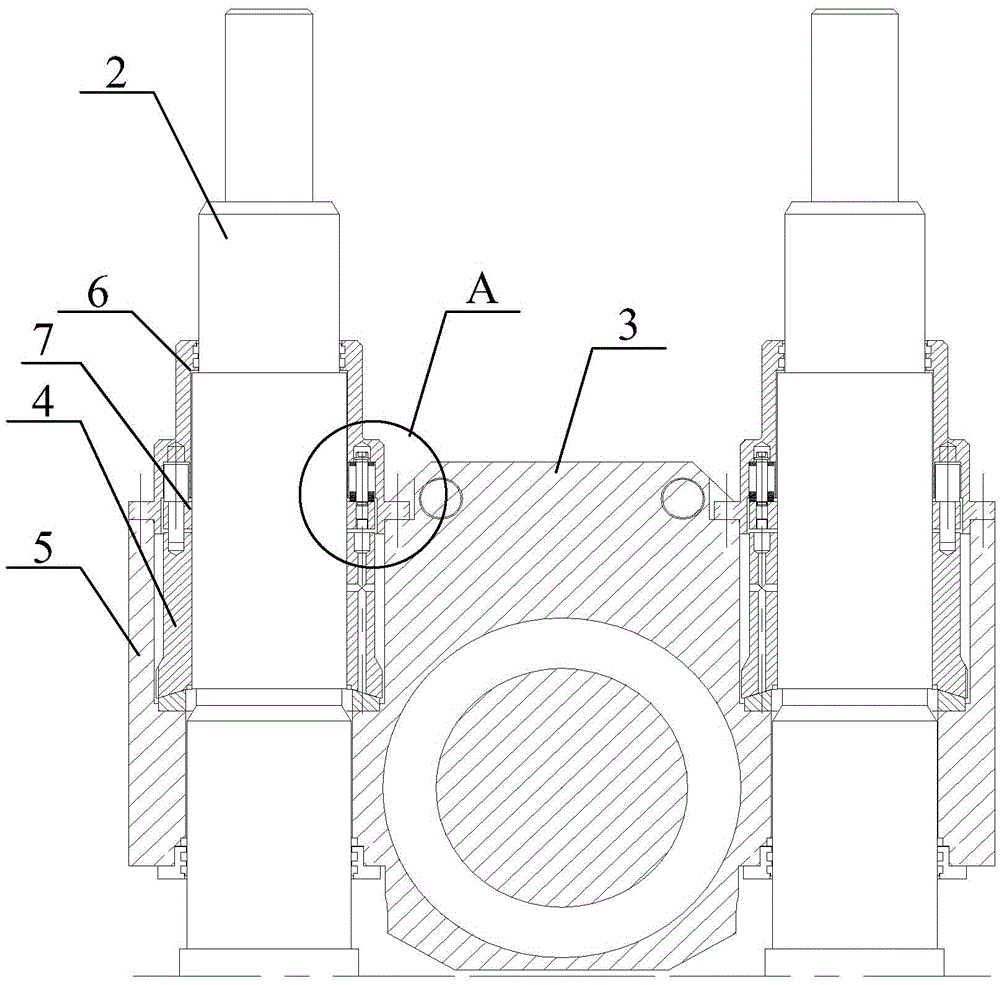

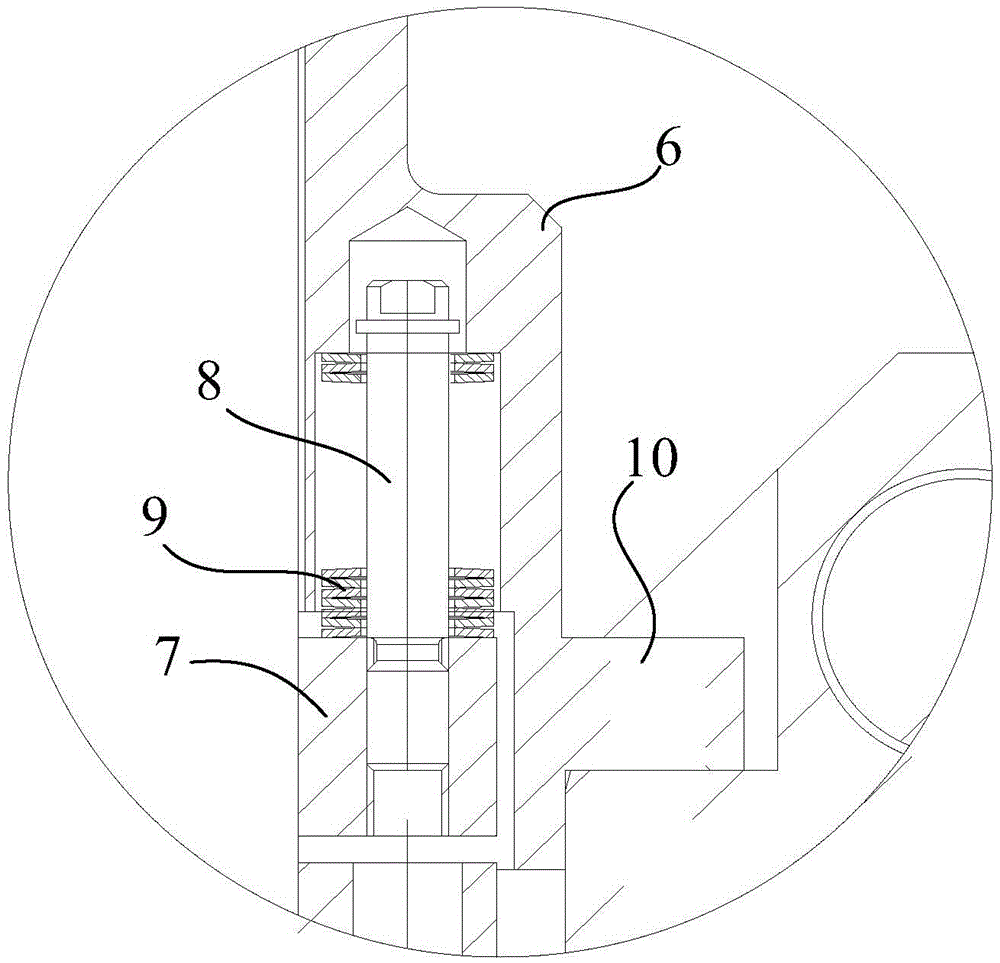

Roll gap adjusting mechanism of rolling mill

InactiveCN105414199AAchieve regulationGuaranteed rolling qualityMetal rolling stand detailsGuiding/positioning/aligning arrangementsEngineeringScrew thread

The invention relates to a roll gap adjusting mechanism of a rolling mill. The roll gap adjusting mechanism comprises a lower guide roll bracket, a lower guide roll, an upper guide roll bracket and an upper guide roll, wherein the two ends of the lower guide roll bracket are correspondingly connected with bottom end bearing bases; the lower guide roll is rotationally arranged on the lower guide roll bracket; the two ends of the upper guide roll bracket are correspondingly connected with upper end bearing bases; the upper guide roll bracket is corresponding to the lower guide roll bracket; the upper guide roll is rotationally arranged on the upper guide roll bracket; the bearing bases are in threaded connection with lead screws through inner-layer sleeves; the bottom ends of outer-layer sleeves are butted against the inner-layer sleeves through spherical surface sleeve pads; balance nuts are connected to the lead screws through threads; through covers coat the lead screws, and the lower ends of the through covers are fixedly connected with the outer-layer sleeves; and pretightening springs are arranged between the through covers and the balance nuts. As the guide roll brackets are arranged on the bearing bases, a guide roll gap can be synchronously adjusted when adjusting a mill roll gap; and the pretightening springs apply an upward elastic force to the through covers, and the elastic force is transferred to the outer-layer sleeves through the through covers and transferred to the inner-layer sleeves through the outer-layer sleeves so as to upwards lift the inner-layer sleeves to eliminate a thread gap.

Owner:CHONGQING MAITUO TECH CO LTD

Roller wiping mechanism for steering roller

The invention aims to provide a roller wiping mechanism for a steering roller. The technical problem of cleaning the surface of the steering roller is solved. The roller wiping mechanism for the steering roller comprises a scraper blade, a tool post, a loosening airbag, a clamping airbag, a tool post rotary shaft support, an adjusting rotary shaft and a fixed base, wherein the fixed base is mounted on one side of the steering roller, and the tool post rotary shaft support is mounted on the fixed base through the adjusting rotary shaft; the tool post is hinged with the tool post rotary shaft support through a loosening and clamping rotary shaft, the loosening airbag and the clamping airbag are separately arranged between the tool post and the tool post rotary shaft support, the loosening airbag is positioned at the front end of the loosening and clamping rotary shaft, and the clamping airbag is positioned at the rear end of the loosening and clamping rotary shaft; and the scraper bladeis arranged at the outer end of the tool post. The roller wiping mechanism disclosed by the invention has the beneficial effects that effective cleaning on the surface of the steering roller can be realized, and roller pressing quality of plates through the steering roller is ensured. According to the use needs, the position of the roller wiping mechanism also can be adjusted, and therefore, the roller wiping mechanism is flexible to use.

Owner:JINAN EAGLE CNC MASCH CO LTD

Rolling mill and pretightening balance system thereof

InactiveCN105414192AGuaranteed rolling qualityExtended service lifeRolling equipment maintainenceMetal rolling arrangementsScrew threadRolling mill

The invention relates to a pretightening balance system of a rolling mill. The pretightening balance system comprises pull rods, inner-layer sleeves, outer-layer sleeves, balance nuts, through covers and pretightening springs, wherein the pull rods are arranged at the two ends of a mill roll, and are provided with external threads; the inner-layer sleeves are connected to the pull rods through threads, and form lead screw and slide block mechanisms with the pull rods; the outer-layer sleeves are fixedly connected to bearing bases, and sleeve the pull rods; the bottom ends of the outer-layer sleeves are butted against the inner-layer sleeves through sleeve pads; one surfaces, in contact with the inner-layer sleeves, of the sleeve pads are spherical surfaces; the balance nuts are connected to the pull rods through threads, and form lead screw and slide block mechanisms with the pull rods; the through covers sleeve the pull rods, and the lower ends of the through covers are fixedly connected with the outer-layer sleeves and the bearing bases; the through covers cover the balance nuts inside; the two ends of the pretightening springs are correspondingly butted against the through covers and the balance nuts; and the pretightening springs are in a compression state. The pretightening balance system is more reliable in work and longer in service life. The invention further discloses a rolling mill adopting the pretightening balance system.

Owner:CHONGQING MAITUO TECH CO LTD

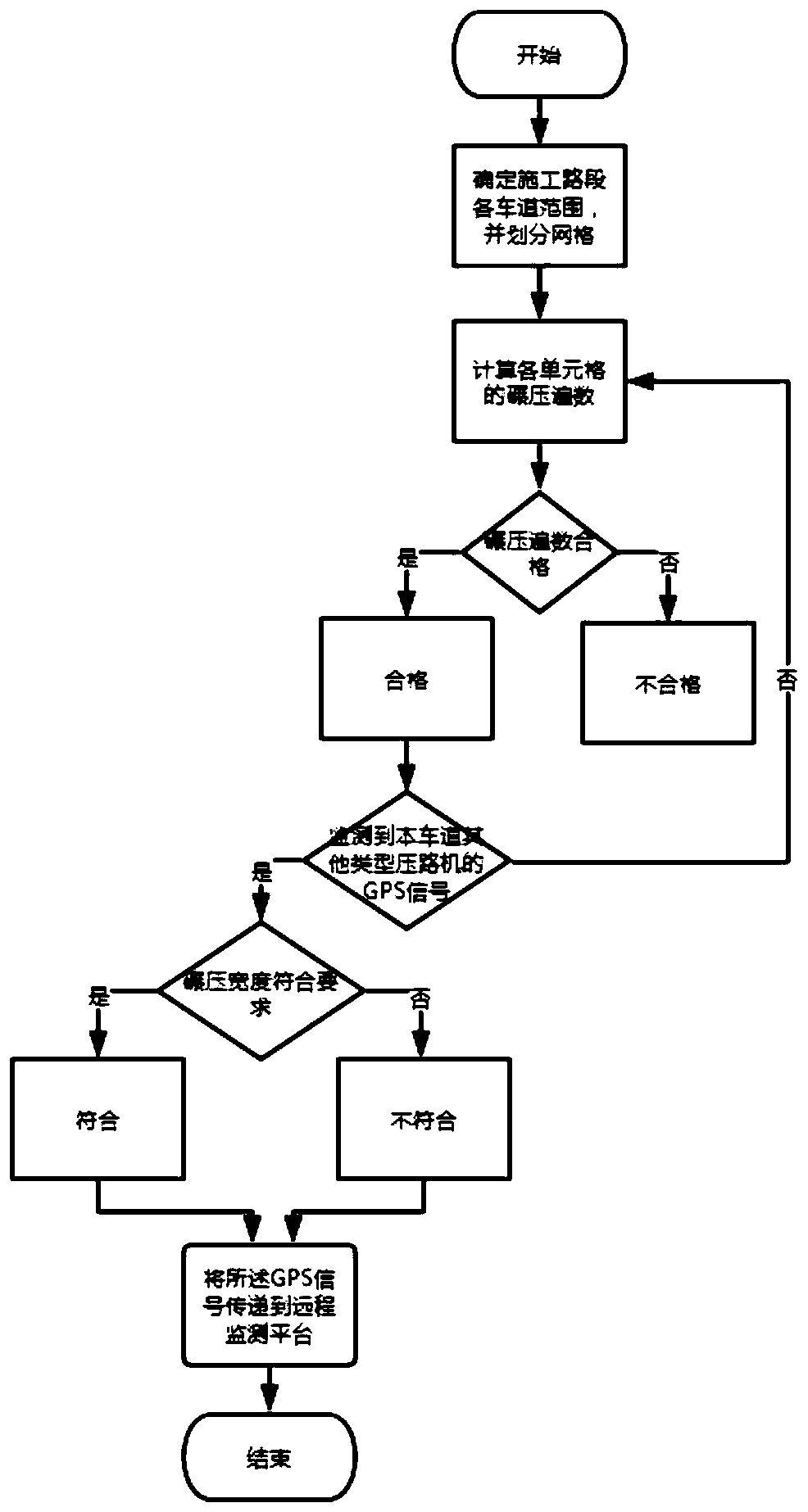

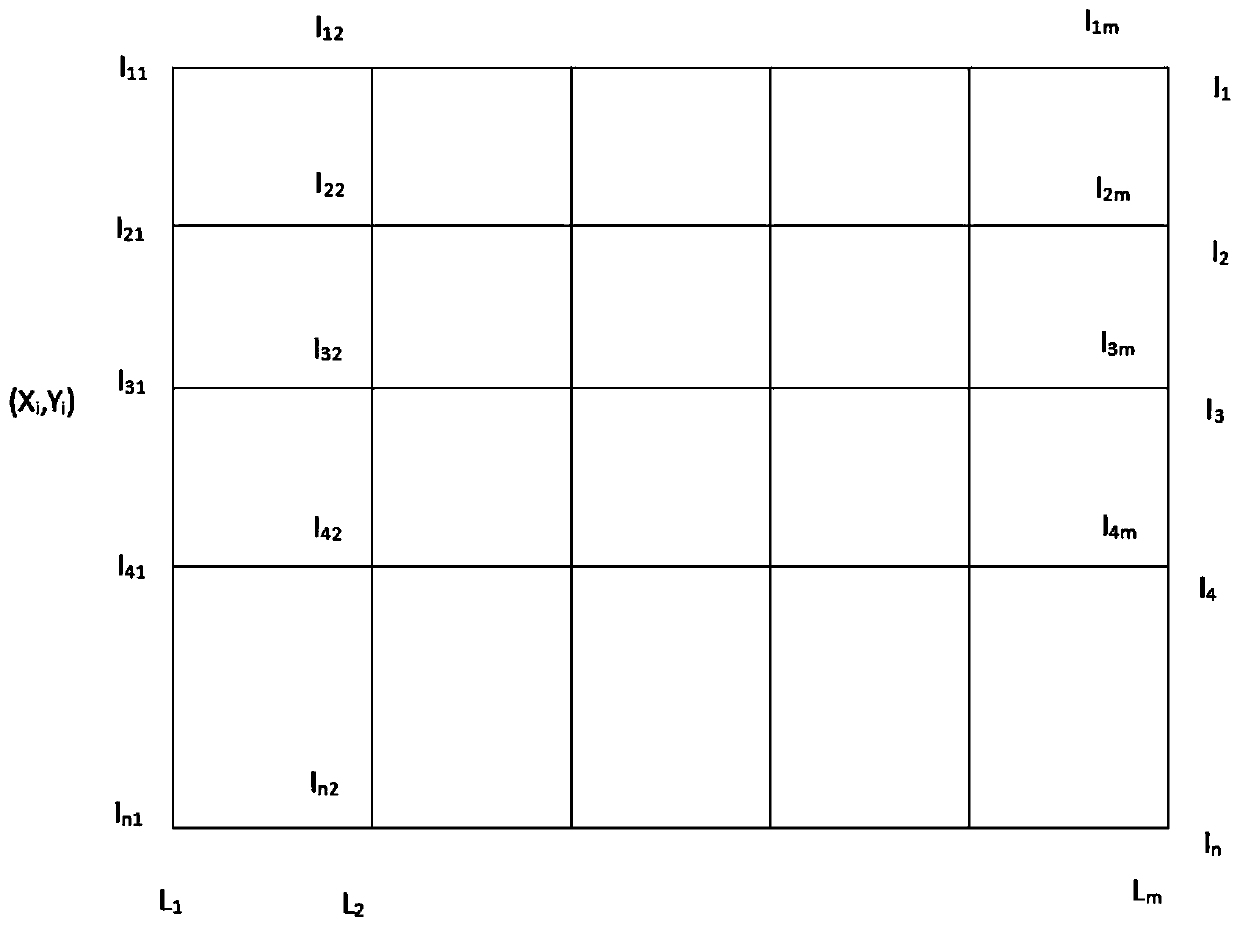

Method and apparatus for monitoring number of rolling passes of roller and determining whether rolling is qualified

InactiveCN110646813AGuaranteed rolling qualitySolve the disease problemUsing electrical meansSatellite radio beaconingControl engineeringStructural engineering

The present invention discloses a method and an apparatus for monitoring the number of rolling passes of a roller and determining whether the rolling is qualified. The present invention belongs to thefield of road construction, and particularly relates to a method for monitoring the number of rolling passes of a roller and determining whether the rolling is qualified. The method comprises: S1: determining a range of each lane of a road section constructed by using a roller, and dividing each lane into cells; S2: calculating the number of rolling passes of each cell; S3: determining whether the number of rolling passes of the cell is qualified; and S4: determining whether the rolling overlap width between adjacent lanes meets the requirements. According to the technical scheme provided bythe present invention, the number of rolling passes of cells of each lane is monitored in real time, and the number of rolling passes of the lane is monitored to prevent missing rolling or excessive rolling and improve the rolling quality.

Owner:CHANGAN UNIV

Two-roller cold rolling mill structure for copper rod

ActiveCN105363778APrevent twistingAvoid the problem of scratching the surface of the copper rodGuiding/positioning/aligning arrangementsRollsCopperRolling mill

The invention provides a two-roller cold rolling mill structure for a copper rod. By using the two-roller cold rolling mill structure, the problem that trimming and crackling phenomena are easily generated in the rolling process of the copper rod by using the existing two-roller cold rolling mill structure for the copper rod can be solved, meanwhile, the problem of scratching the surface of the copper rod in the rolling process can be solved, and the machining quality is ensured. The two-roller cold rolling mill structure for the copper rod comprises a rack, a pair of roller devices and guide devices, wherein two rollers of the pair of roller devices are symmetrically arranged in the rack; the guide devices are set into two groups; the two groups of guide devices are symmetrically arranged at a copper rod inlet and a copper rod outlet of the rack; guide grooves are formed in the guide devices; roller half-grooves are formed in the peripheral surfaces of the rollers; and the two roller half-grooves of the two rollers are spliced to form a circumference-closed roller groove when two symmetric rollers are used for rolling the copper rod. The two-roller cold rolling mill structure for the copper rod is characterized in that the guide grooves and the roller groove are polygonal grooves which are same in shape and are axisymmetric.

Owner:WUXI CHAOZHOU TECH CO LTD

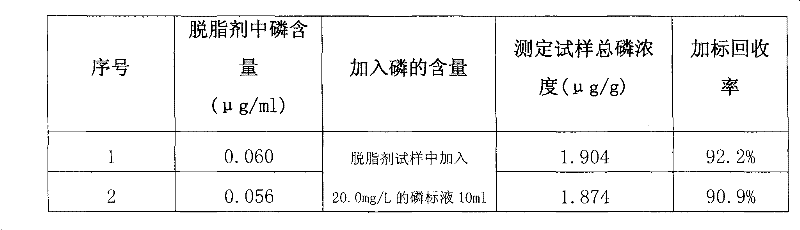

Method for measuring phosphor content in cold rolled degreasing agent

InactiveCN102411026ARemove colorRemove complexityMaterial analysis by electric/magnetic meansOptical radiationPhosphor

The invention relates to a cold rolled auxiliary agent, concretely relates to a method for detecting the quality of a cold rolled degreasing agent. The method for measuring phosphor content in the cold rolled degreasing agent comprises the following steps: weighting 2.0000g sample degreasing agent in a teflon beaker, adding a few pure water, adding dilute nitric acid for regulating the pH value of 4-9; adding 2-5 milliliters nitric acid with volume ratio of 1:1, degrading on an electric furnace; slowly adding 2-8 milliliters hydrogen peroxide after boiling, keeping the slight boiling state for 10 minutes; transferring a digestion solution in a volumetric flask, controlling 0.5-2% of nitric acid medium, diluting by using water to scale, uniformly sharking to obtain the sample to be measured; injecting the sample in a ICP quartz tube, determining optical radiation intensity generated under the 213.618nm detection wavelength of ground state atom of phosphor by a plasma spectra method, thereby the phosphor content in the degreasing agent sample can be quantified. The determination method of the phosphor content has strong anti-interference capability, and is especially suitable for detecting complex matrix of degreasing agent and the like.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

Purging device for emulsion on surface of strip steel on rolling mill outlet

InactiveCN109622639AGuaranteed rolling qualityAvoid residueWork treatment devicesMetal rolling arrangementsEmulsionStrip mill

The invention discloses a purging device for emulsion on the surface of strip steel on a rolling mill outlet. The purging device comprises a rolling mill outlet cover plate, a support, a cross beam, pipe clamps, gas pipes and spray nozzles. The support is arranged on the top face of the rolling mill outlet cover plate. The cross beam is horizontally arranged on two stand rods of the support. The gas pipes are arranged on the two sides of the cross beam through the pipe clamps. Each spray nozzle is arranged at the front end of the corresponding gas pipe. The tail end of each gas pipe is connected with a gas source. By means of the purging device, emulsion purging is achieved for the surface of the rolled strip steel, residues of the emulsion on the surface of the strip steel and caused corrosion are avoided, and therefore the rolling quality of the strip steel is ensured.

Owner:SHANGHAI BAOYE GRP CORP

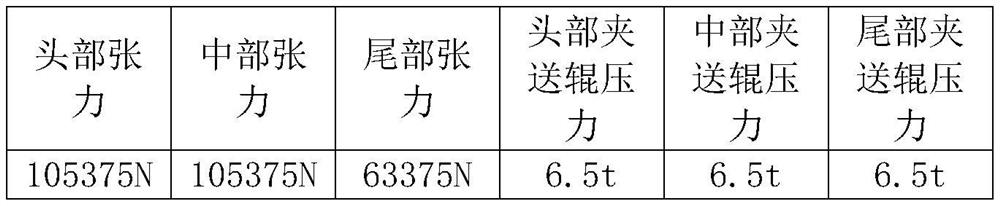

Coiling shape control method for medium-high carbon steel with omega (C) larger than or equal to 0.45%

ActiveCN113441549AReduce safety risks and quality lossGuaranteed rolling qualityTension/compression control deviceMetal rolling arrangementsPhysicsShape control

The invention relates to a coiling shape control method for medium-high carbon steel with omega (C) larger than or equal to 0.45%. The control method comprises the following steps that (1) when a coiling model receives the steel grade, CT temperature, thickness and width of strip steel conveyed by a finish rolling model, and according to parameter values already set by a model background, the coiling unit tension required by the strip steel and the pressure value of a corresponding pinch roll are calculated out ; (2) after the pinch roll at the head of the strip steel bites steel, the pinch roll enters pressure ring control according to previously-set pressure; (3) the head of the strip steel is wound to a winding drum; (4) after the tail of the strip steel is subjected to F7 steel throwing, the pinch roll begins to output reverse torque, and tension building between the winding drum and finish rolling gradually begins to turn to tension building between the winding drum and the pinch roll; and (5) after F7 steel throwing, the coiling tension is reduced through the winding drum and finish rolling and turns to tension building of the winding drum and the pinch roll till strip steel coiling is completed. The strip steel coiling quality is guaranteed to the maximum degree. Similar problems exist in hot continuous rolling production lines.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

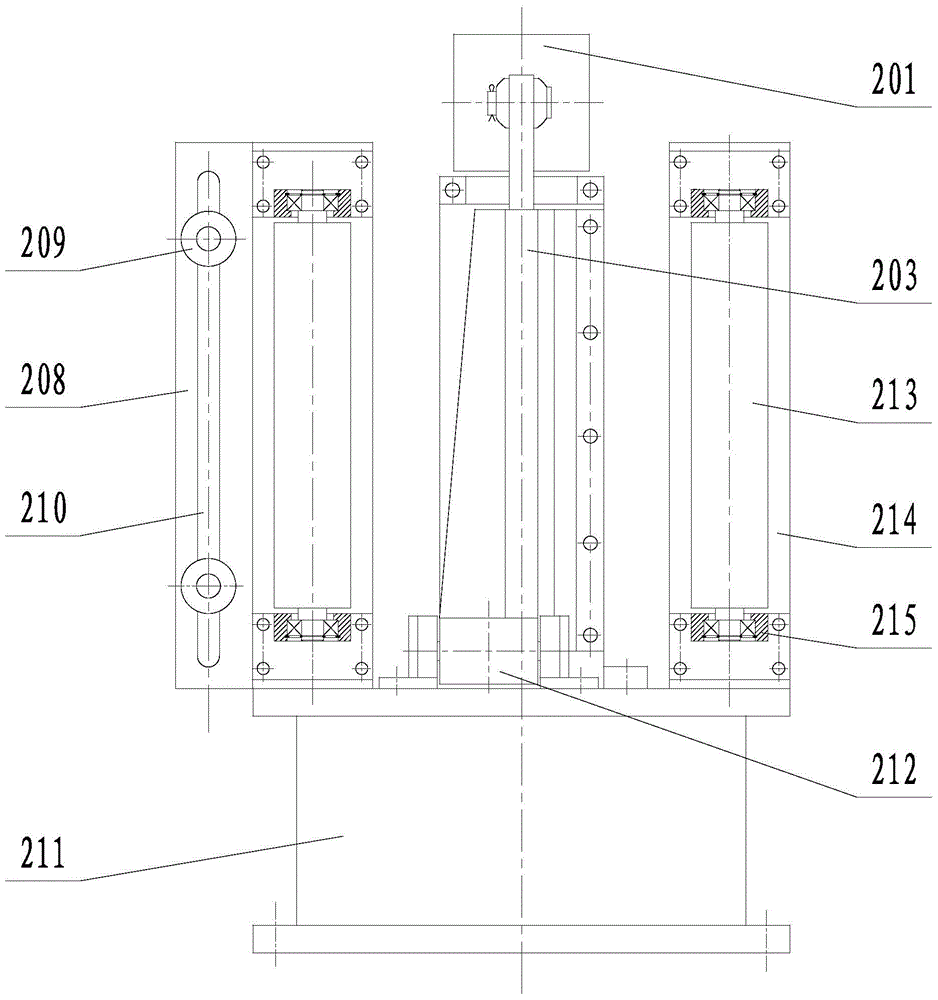

Three-roller tube-rolling machine with two threading-bar mode

InactiveCN101214499AGuaranteed rolling qualityIncrease rolling speedMandrelsMetal rolling arrangementsSteel tubeThin walled

The invention discloses a three roll pipe mill adopting two methods of threading-core rod, which belongs to the production equipment of seamless steel tube. The invention solves a technical problem of slow rolling resulting from on-line threading rod or unstable rolling quality of a thin-wall tube resulting from off-line threading rod adopted by the existing three roll pipe mill with a full floating mandrel. The invention comprises the main body of three roll pipe mill, a main motor (6), a mill background (7), an on-line rod-threading device (4) and an off-line rod-threading device (3) arranged on a mill foreground. A traverse mechanism is arranged between the on-line rod-threading device (4) and the off-line rod-threading device (3) and used for realizing parallel movement between two work stations of a pre-rolled steel pipe adopting on-line threading-core rod and the pre-rolled steel pipe adopting off-line threading-core rod. The invention has the beneficial effect that both the on-line rod-threading device and the off-line rod-threading device are arranged. One of threading-core methods can be adopted according to product and production process. As a result, rolling quality can be ensured and rolling speed can be improved.

Owner:TAIYUAN TONGZE HEAVY IND

Confluence belt rolling equipment

ActiveCN106180182AStable thicknessGuaranteed rolling qualityMetal rolling stand detailsRoll mill control devicesEngineeringProduction quality

The invention discloses confluence belt rolling equipment. The confluence belt rolling equipment comprises a rack provided with an operation platform. The operation is provided with a wire straightening machine, a roughing mill, a forming mill and a finishing mill sequentially in the wire conveying direction. The part, located on the wire inlet side, of the roughing mill is provided with a wire inlet guide mouth. The part, located on the wire outlet side, of the roughing mill is provided with a first diameter measuring gauge. The part, located on the wire inlet side, of the forming mill is provided with a first trimmer. The part, located on the wire outlet side, of the forming mill is provided with a second diameter measuring gauge. The part, located on the wire inlet side, of the finishing mill is provided with a second trimmer. The part, located on the wire outlet side, of the finishing mill is provided with a third diameter measuring gauge. The confluence belt rolling equipment has high production speed, and the production quality is high.

Owner:JIANGSU YOUZHA MACHINE CO LTD

Continuous mill

ActiveCN103008344AReduce lossGuaranteed rolling qualityGuiding/positioning/aligning arrangementsWork treatment devicesEngineeringAutomation

The invention provides a continuous mill used for milling lead belts. The continuous mill comprises a machine frame, a first mill group, a second mill group, a driving device and a controller, wherein the first mill group and the second mill group are arranged on the machine frame in a serial connection way, the first mill group comprises four to six mills in serial connection arrangement, the second mill group comprises one to two mills in serial connection arrangement, the driving device is used for driving each mill to work, the controller is used for coordinating and controlling the work of each mill, during the milling, blank lead belts enter the continuous mill to be continuously milled by a plurality of mills, and the lead belts with the set thickness can be obtained. The continuous mill disclosed by the invention has the advantages that the automation degree is high, the lead belts with the set thickness and width can be directly obtained through the continuous cooperated operation of five to seven mills of the two mill groups, in addition, the continuous mill is also provided with an expansion mechanism and a cooling system, and the assurance is further provided for the finished product quality of the lead belts to a great degree.

Owner:JIANGSU SANHUAN IND HLDG CO LTD

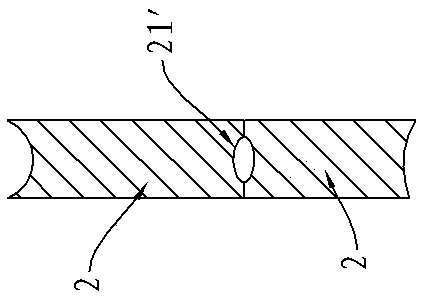

Slant wedge locking device for eliminating clearance of rotating drum of oblique rolling machine and oblique rolling machine

PendingCN108453134ASolve worn clearance problemsExtended service lifeMetal rolling stand detailsMetal rolling arrangementsHydraulic cylinderEngineering

The invention discloses a slant wedge locking device for eliminating the clearance of a rotating drum of an oblique rolling machine and the oblique rolling machine. The slant wedge locking device comprises a frame (20), a driving slant wedge (21), a follow-up slant wedge (22) and a hydraulic cylinder (23). When the hydraulic cylinder (23) drives the driving slant wedge (21) to move in the Y-axis direction, the driving slant wedge (21) slides relative to the follow-up slant wedge (22) and moves in the X-axis direction along with the follow-up slant wedge (22). The slant wedge locking device foreliminating the clearance of the rotating drum of the oblique rolling machine is mounted in a rack; the slant wedges are driven by the hydraulic cylinders; the device is used for eliminating the clearance of the rotating drum for adjusting the rolling feeding angle of a roller of a perforating machine or the oblique pipe rolling machine; and the device is simple in structure, steady and reliable.The number of times of replacing a sliding plate or a liner plate can be effectively reduced, and in addition, the service life of the hydraulic cylinder can be improved conveniently; the adjustmentaccuracy and precision of the rolling feeding angle are improved; and rolling quality is further guaranteed.

Owner:BEIJING JINGCHENG RUIXINCHANGCAI ENG TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com