High-efficiency high-throughput continuous casting and rolling system and process for titanium alloy bars

A continuous casting and rolling, titanium alloy technology, applied in the direction of metal rolling, can solve the problems of low efficiency, high cost, shortening process and cycle, etc., to achieve high efficiency, ensure uniformity, reduce unit cost and time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

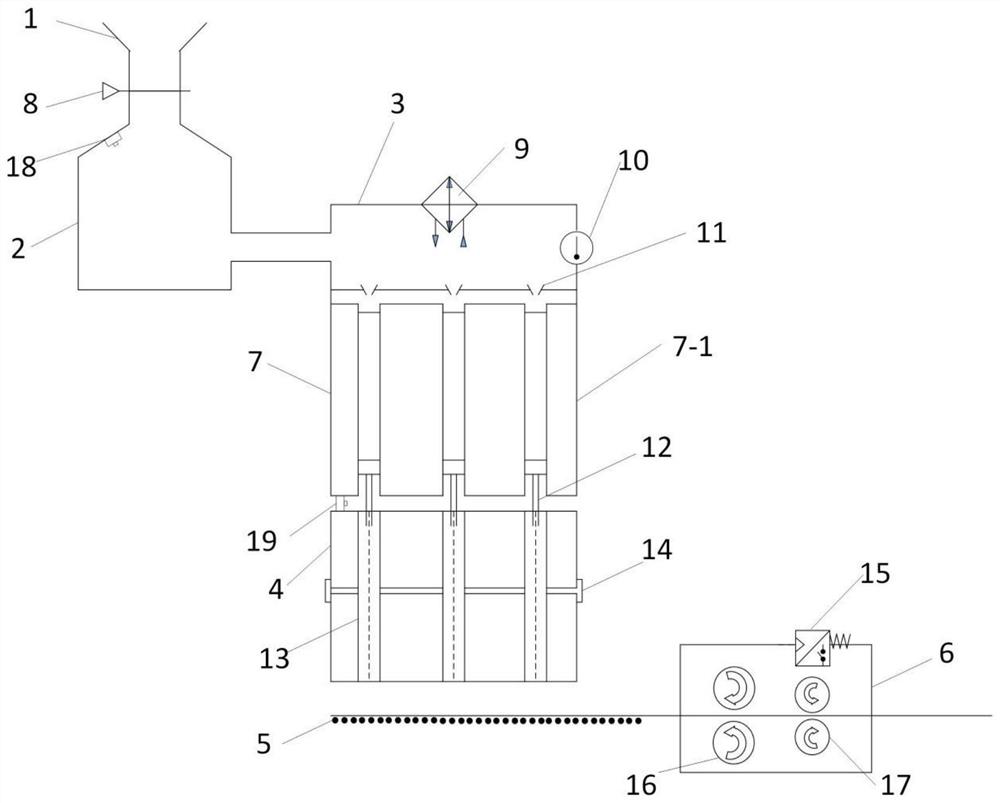

[0071] This embodiment provides a high-efficiency and high-throughput preparation method for titanium alloy (TF400) titanium rods, including the following steps:

[0072] Feeding: Pour 68.53kg of titanium sponge, 1.19kg of Fe particles, and 0.28kg of Fe-B intermediate alloy into the melting chamber along the feed pipe, close the vacuum valve, and fill with argon after rough and fine pumping to 0.5Pa Gas protection gas.

[0073] Alloy melting and splitting: Activate the plasma gun to melt the raw material to a liquid state.

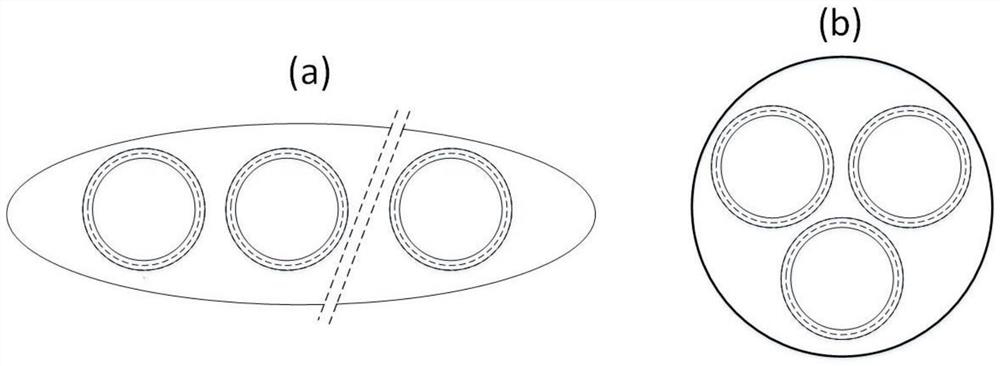

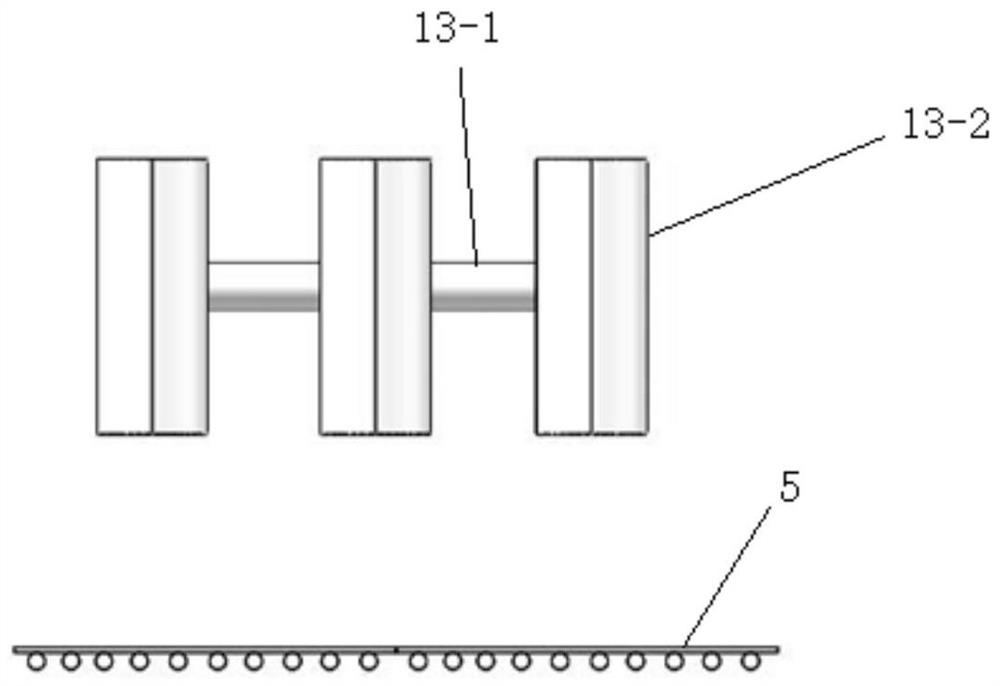

[0074] Splitting and solidification: After the melt flows into the splitting chamber, turn on the heating device to ensure that the temperature of the melt is between 1200-1350°C to avoid cooling down of the melt. The high-temperature melt flows into the three crystallizers through the diversion gap, and each mold is wrapped with a 7YSZ thermal barrier coating to ensure that there is no heat conduction and heat influence between different molds, and the t...

Embodiment 2

[0080] This embodiment provides a high-efficiency and high-throughput preparation method for Ti-6Al-4V rods, including the following steps:

[0081] Feeding: Pour 63kg of sponge titanium and 7kg of Al-V intermediate alloy into the melting chamber along the feeding pipe, close the vacuum valve, and fill it with argon protective gas after rough and fine pumping to 0.5Pa.

[0082] Alloy melting and splitting: Activate the plasma gun to melt the raw material to a liquid state.

[0083] Splitting and solidification: After the melt flows into the splitting chamber, turn on the heating device to ensure that the temperature of the melt is between 1400-1500°C to avoid cooling down of the melt. The high-temperature melt flows into the three crystallizers through the diversion gap, and each mold is wrapped with a 7YSZ thermal barrier coating to ensure that there is no heat conduction and heat influence between different molds, and the thermal uniformity of a single mold is guaranteed. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com