Upright iron core rolling machine

A coiled iron core, vertical technology, applied in the manufacture of inductors/transformers/magnets, other manufacturing equipment/tools, accessories of shearing machines, etc. , difficult to place and other problems, to ensure the quality of rolling, high work efficiency, labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

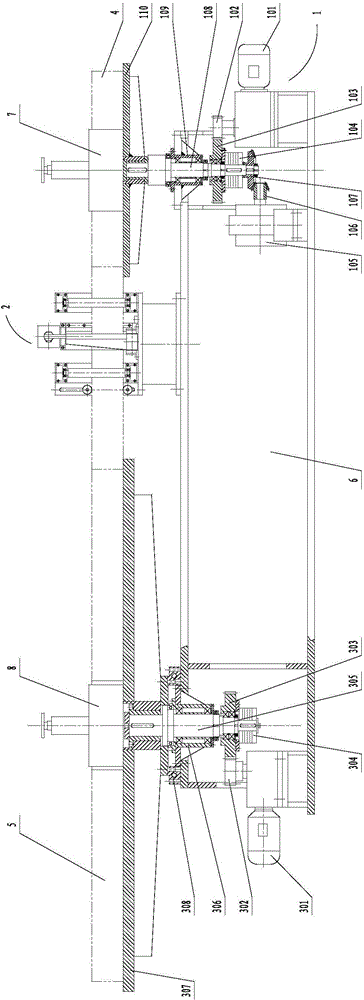

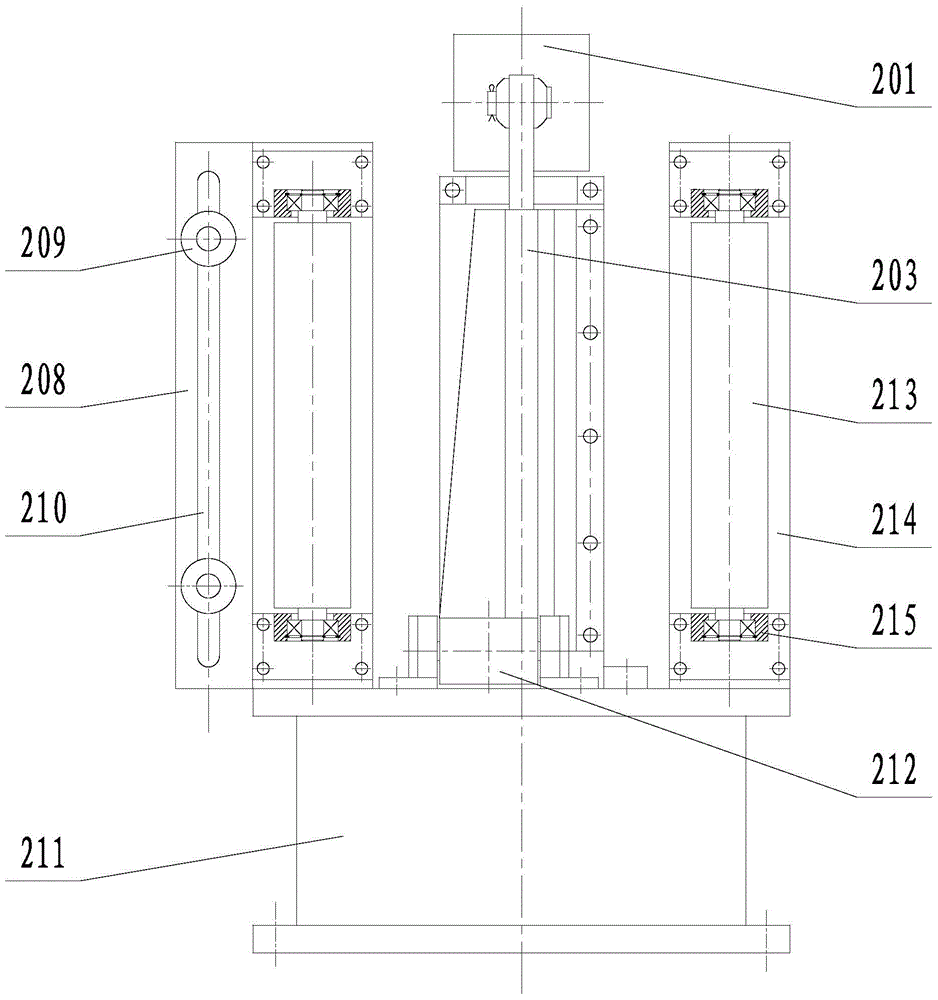

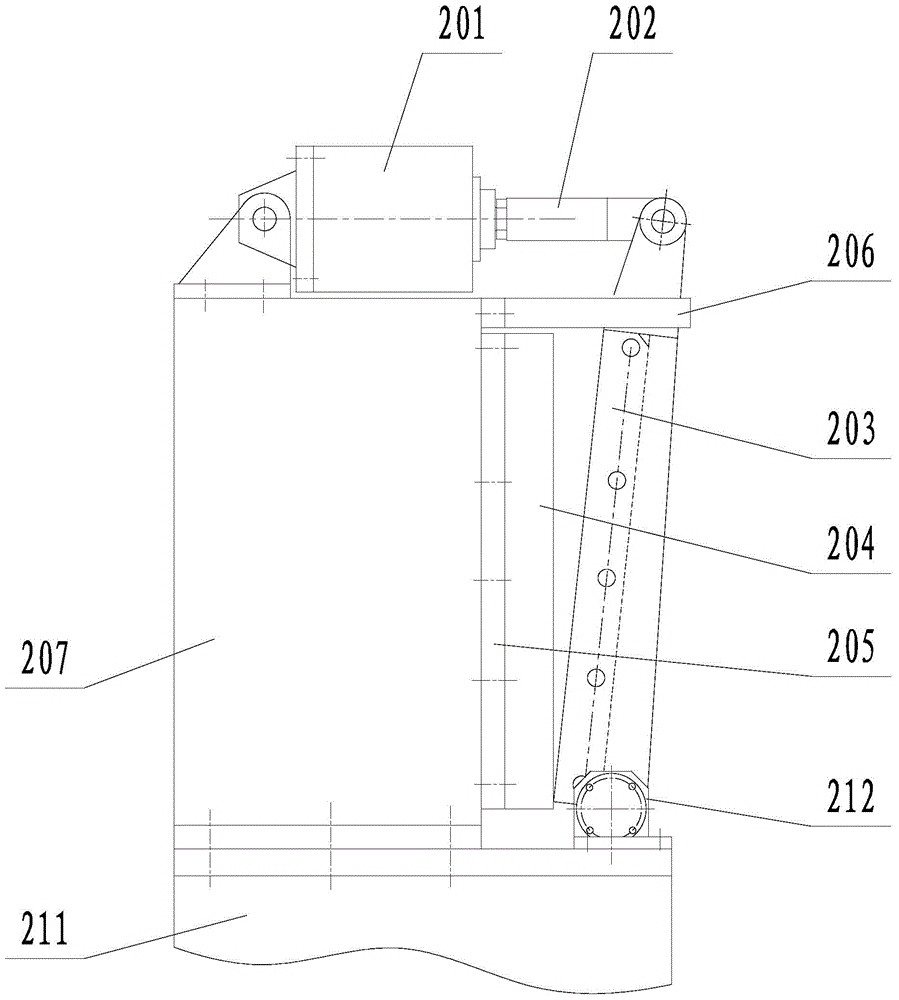

[0030] Such as figure 1 As shown, the present invention comprises unwinding machine 1, shearing machine 2, coiling machine 3, bed 6, coil material tensioning device 7 and workpiece tensioning tire 8, wherein unwinding machine 1, shearing machine 2 and coiling machine 3 are respectively installed on the bed 6, and the shearing machine 2 is located between the unwinding machine 1 and the coiling machine 3.

[0031] The discharge machine 1 includes a first reducer 101, a discharge machine transmission mechanism, a magnetic material brake 105, a first bevel gear 106, a second bevel gear 107, a discharge machine shaft 108, a first bearing seat 109 and a discharge machine working Table 110, the unwinding machine transmission mechanism includes the first pinion gear 102, the first large gear 103 and the first electromagnetic clutch 104, the unwinding machine shaft ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com