A battery pole sheet rolling equipment with staggered rolls

A battery pole piece and rolling equipment technology, applied in the direction of rolling, metal rolling, metal rolling, etc., can solve the problems of rolling force fluctuations, affecting rolling effects, etc., to reduce vibration, improve service life, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

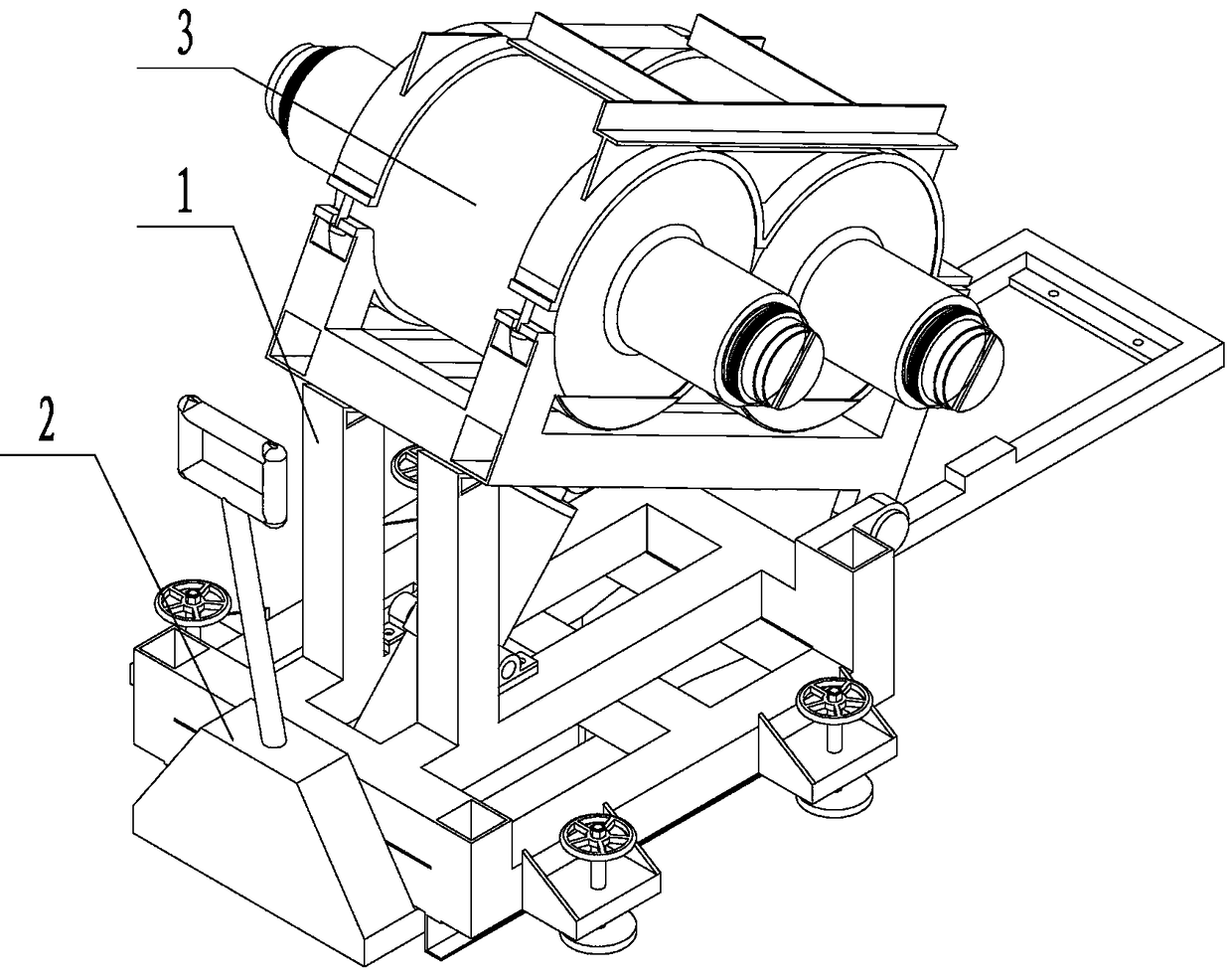

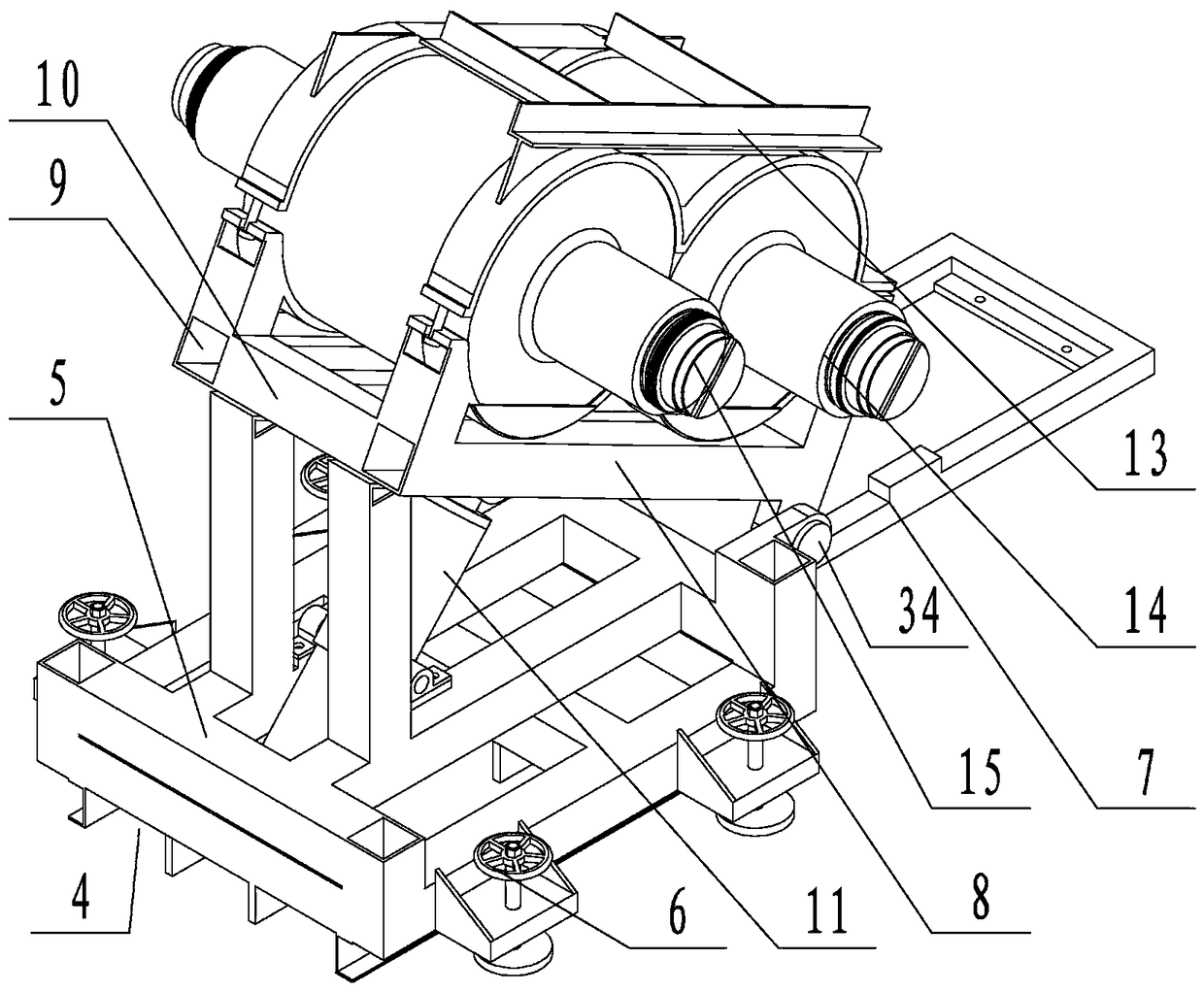

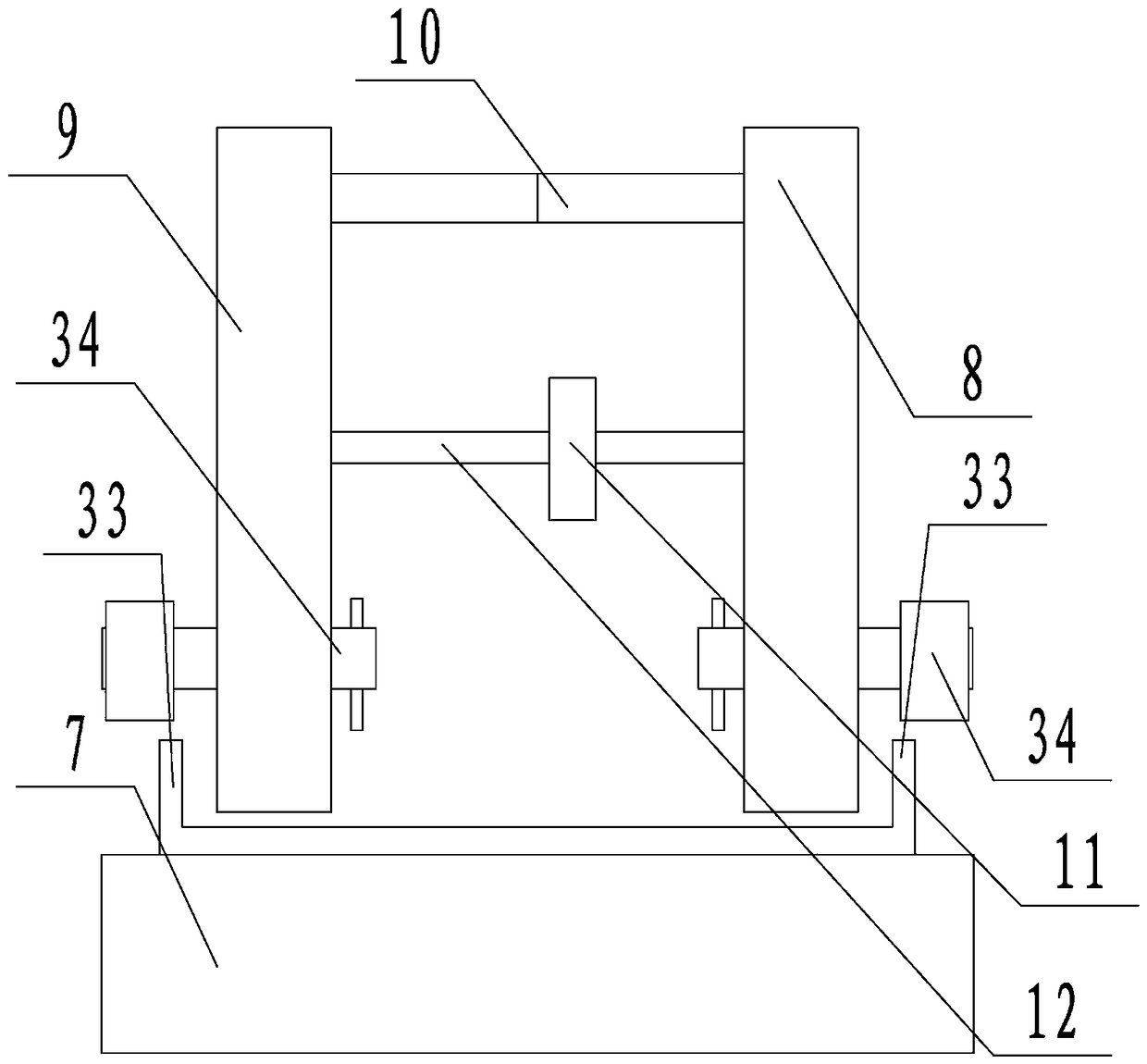

[0030] Such as Figure 1-6 As shown, the present invention includes a frame group 1 and a roll group 3 hingedly arranged on the frame group 1;

[0031] The frame group 1 includes an inclined support chassis 5 and an upright support chassis 7 connected with the inclined support chassis 5;

[0032] The roller set 3 includes a first column 8 and a second column 9 symmetrically arranged on the upright support chassis 7, a lower battery pole piece roller 14 and an upper battery pole piece respectively arranged between the first column 8 and the second column 9 Roller 15 and two movable connection frames 13 connected with the first column 8 and the second column 9 respectively;

[0033] The movable connection frame 13 respectively fixes the lower battery pole piece roll 14 and the upper battery pole piece roll 15 on the corresponding first column 8 and the second column 9;

[0034] The lower battery pole piece roll 14 is located below the upper battery pole piece roll 15, and a ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com