Roller wiping mechanism for steering roller

A technology of turning rollers and rotating shafts, applied in cleaning methods and utensils, cleaning methods using tools, chemical instruments and methods, etc., to achieve the effect of flexible use and guaranteed quality of rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

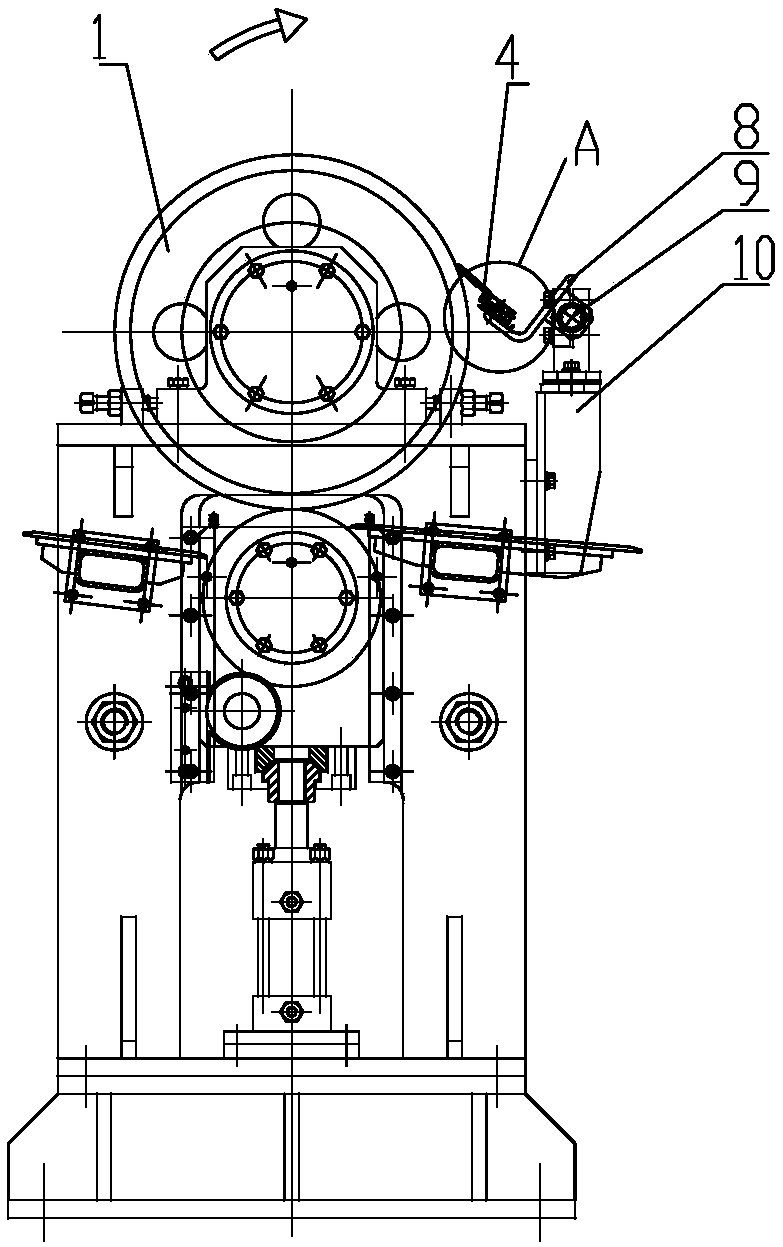

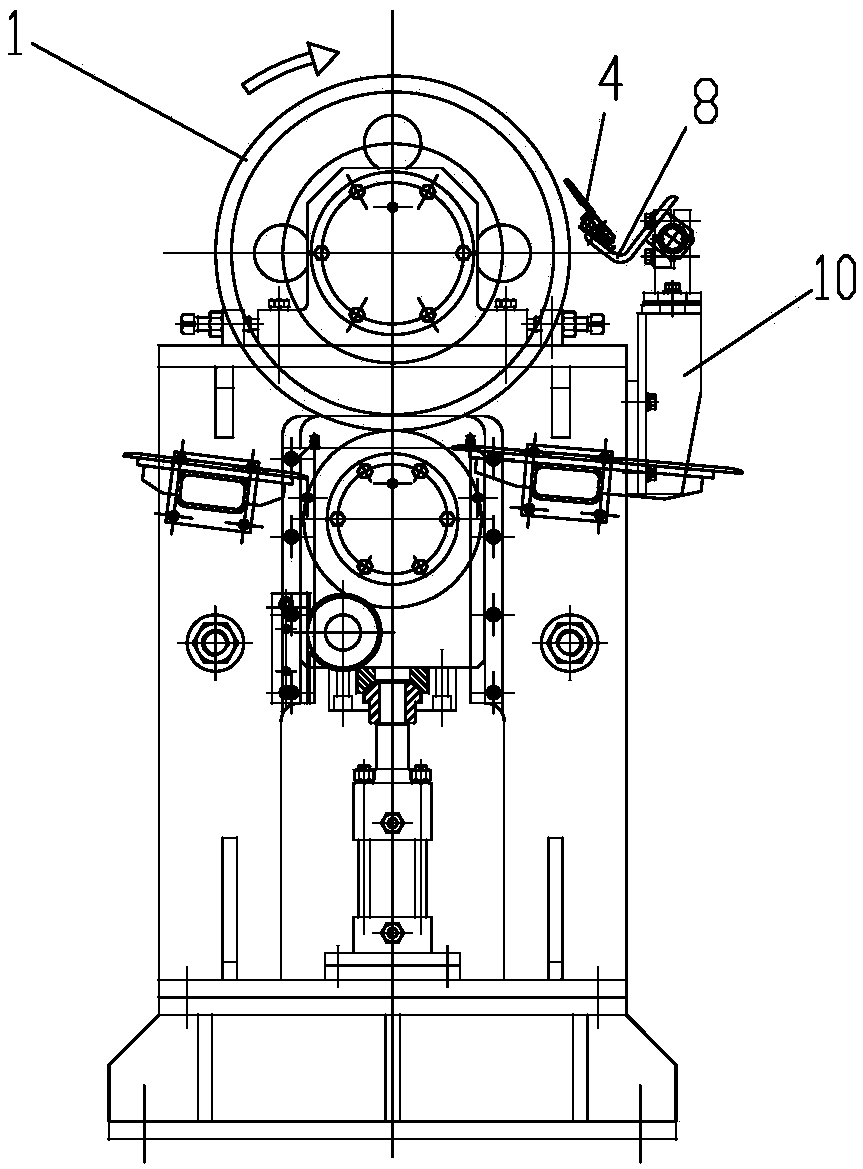

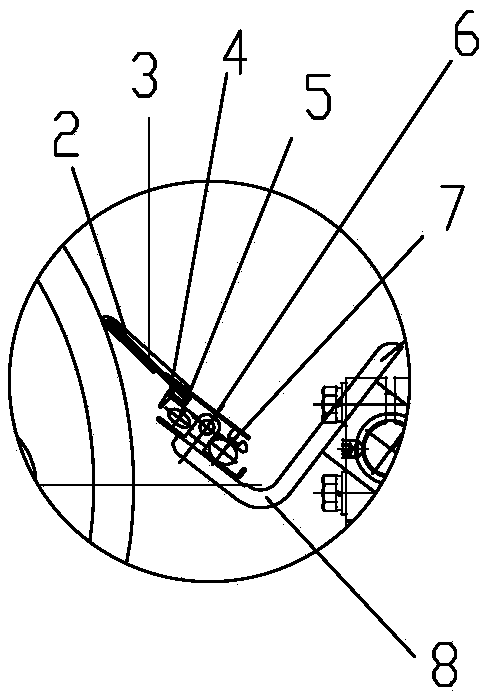

[0018] In order to clearly illustrate the technical features of the present solution, the present invention will be described in detail below through specific implementation methods and in conjunction with the accompanying drawings. It should be noted that components illustrated in the figures are not necessarily drawn to scale. Descriptions of well-known components and techniques are omitted herein to avoid unnecessarily limiting the present invention.

[0019] Such as Figures 1 to 3 As shown, a steering roller rubbing mechanism includes a scraper blade 3, a knife holder 4, an unclamping airbag 5, a clamping airbag 7, a knife holder rotating shaft support 8, an adjusting rotating shaft and a fixed seat 10.

[0020] The fixing seat 10 is installed on one side of the steering roller 1, and mainly plays the role of fixing and installing other functional components. Described knife post rotating shaft support 8 is installed on the upper end of described fixed seat 10 by adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com