Three-roller tube-rolling machine with two threading-bar mode

A technology of three-roll rolling and tube milling, which is applied in the direction of metal rolling, metal rolling, metal processing equipment, etc. It can solve the problems of unstable rolling quality and slow rolling rhythm of thin-walled tubes, and achieve high rolling speed , Guarantee the effect of rolling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

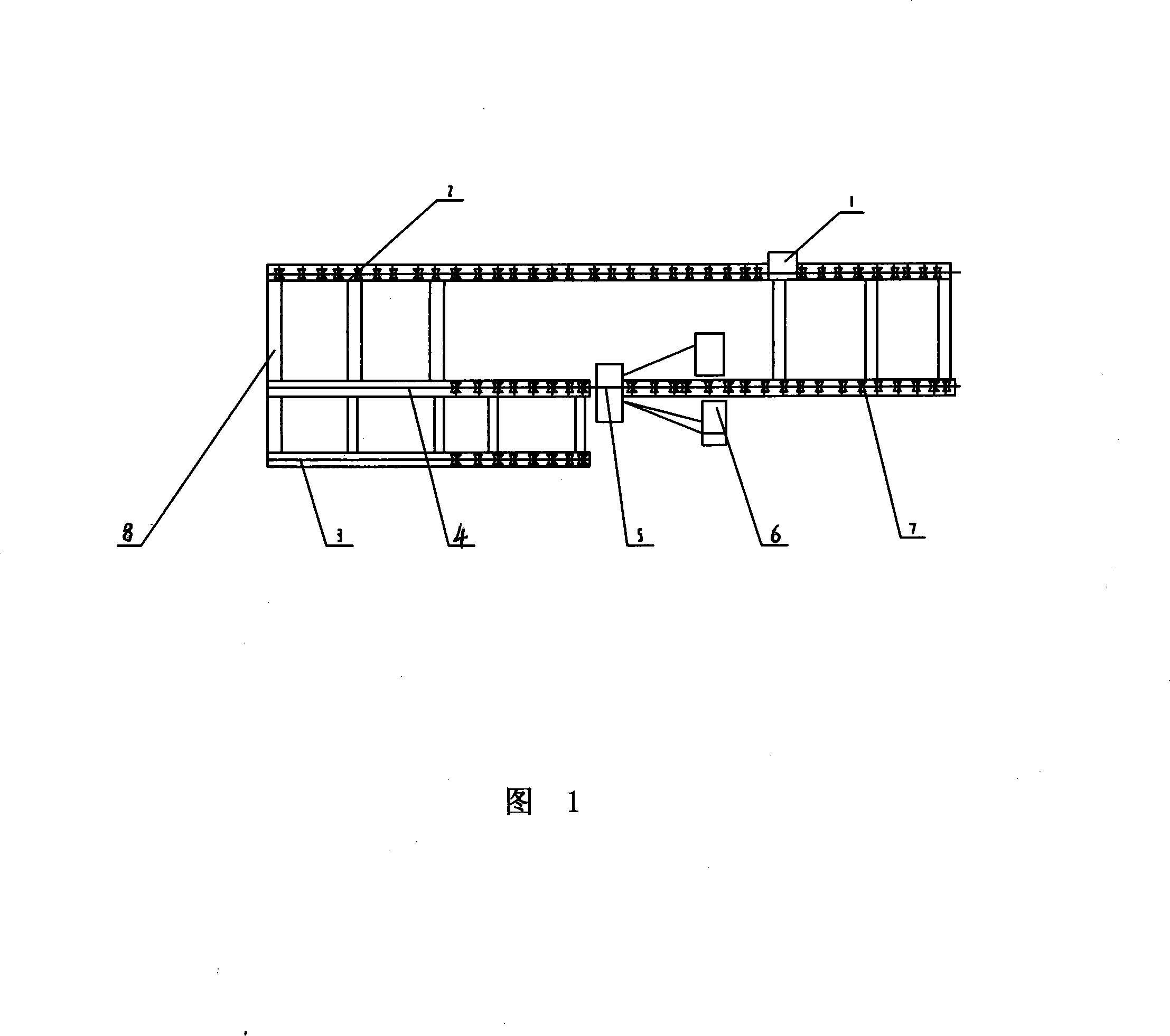

[0009] The three-roll pipe mill with two mandrel threading methods includes the main body of the three-roll pipe mill, the main motor 6, the main body of the three-roll pipe mill 5, and the backstage of the rolling mill 7. On the front desk of the rolling mill, an online rod threading device 4 and a line External rod threading device 3; a traverse mechanism 8 is arranged between the online rod threading device 4 and the external rod threading device 3, to realize the pre-rolled steel pipes of the online mandrel threading and the pre-rolling steel pipes of the mandrel threading outside the line Parallel movement between two stations. The traverse mechanism 8 is an electric traverse mechanism or a hydraulic transmission traverse mechanism. A mandrel cooling and transport device 2 is arranged on the back stand 1 of the rolling mill.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com