Metal plate rapid rounding and welding integrated device

A metal plate, fast technology, applied in the field of mechanical processing, can solve the problems of large operation errors and high labor costs, and achieve the effects of reducing labor and time costs, shortening the construction period, and not being easy to sag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

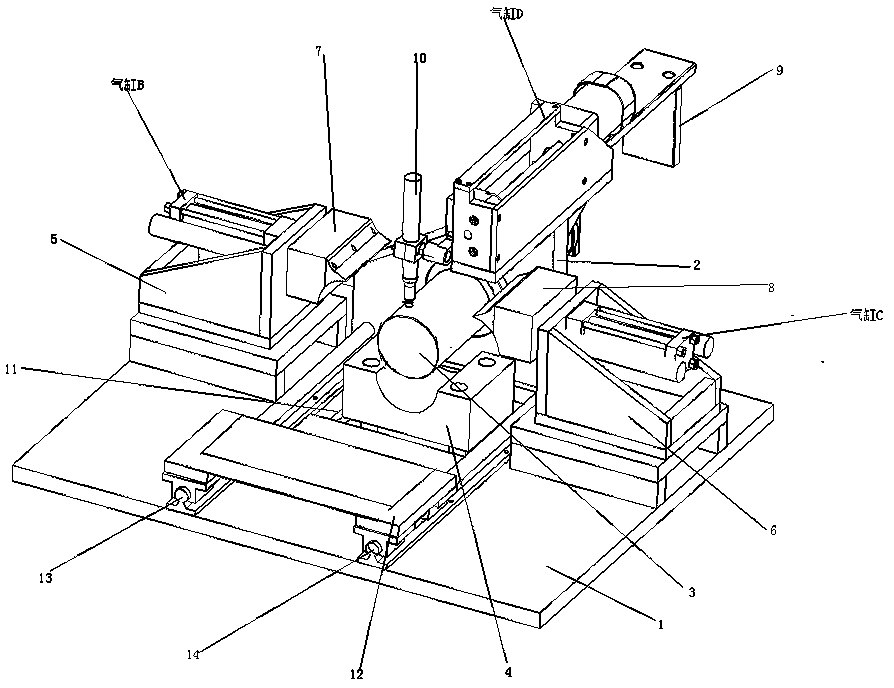

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] An integrated device for rapid rolling and welding of metal sheets, including a base 1, a back plate 2 is provided at the rear end of the base 1, and a sizing die 3 is fixed on the back plate 2. On the base 1, the front of the sizing die 3 is The bottom is provided with a groove 11, and the lower mold 4 is fixed on the base 1 or in the groove 11 by the cylinder A, and the left upper mold support 5 and the right upper mold support 6 are arranged in parallel on both sides of the lower mold 4, and the left upper mold The support 5 is provided with a left upper die 7 that can move left and right through the cylinder B, and the right upper die support 6 is provided with a right upper die 8 that can move left and right through the cylinder C. The left upper die 7, the right upper die 8 and the lower die 4 After the mold cavity is combined, a cylindrical mold cavity ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com