Patents

Literature

115results about How to "Play a stereotyped role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

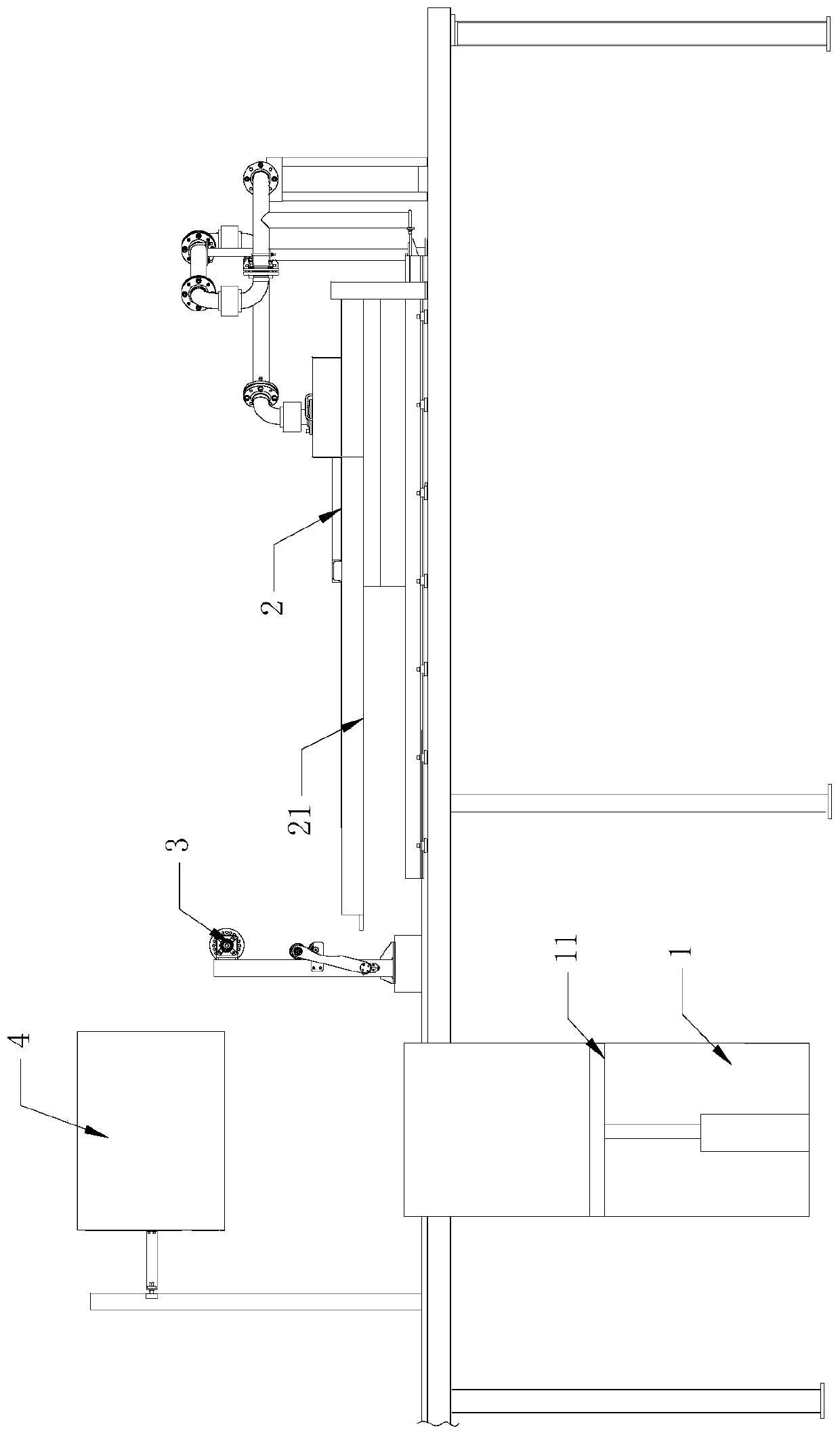

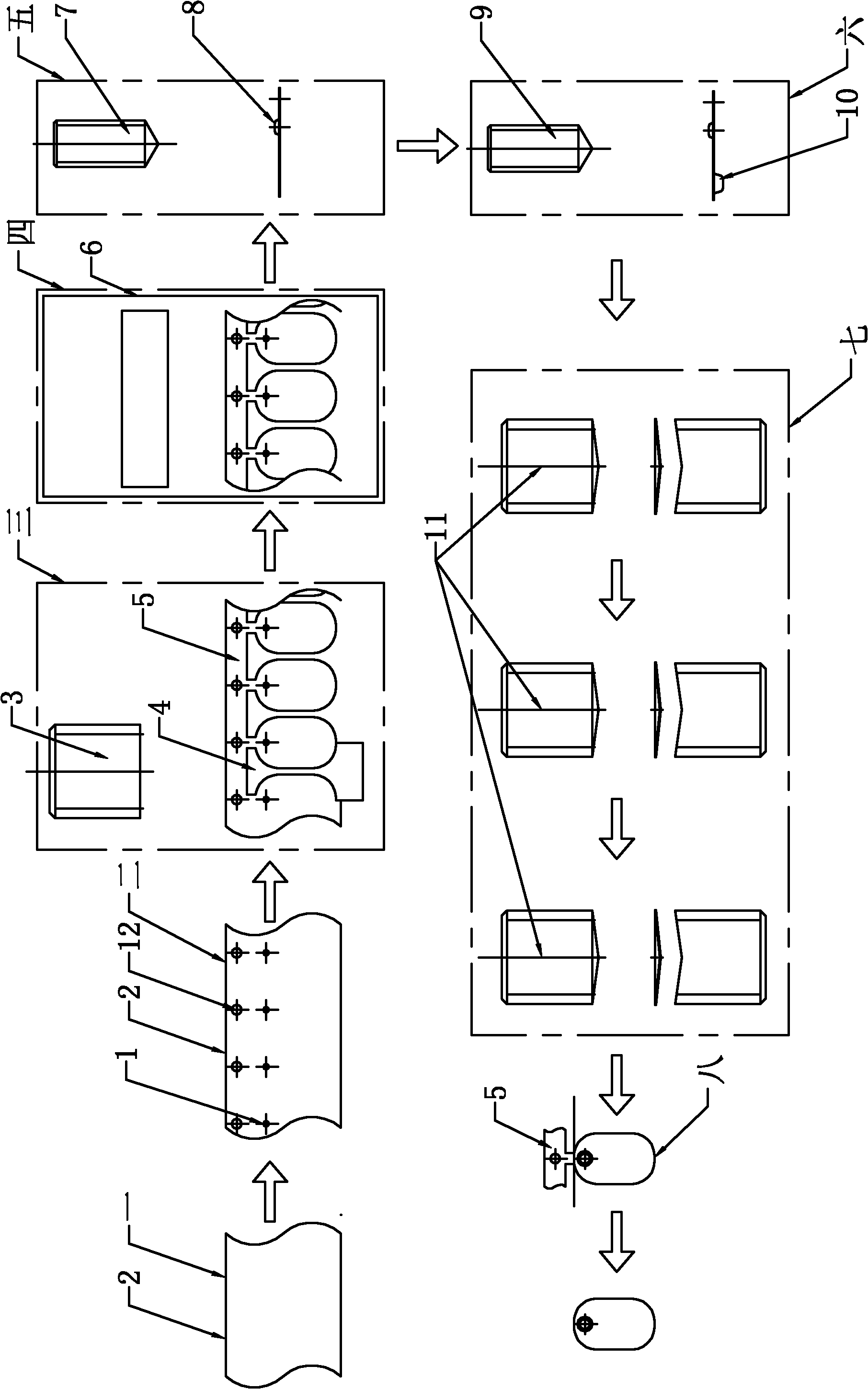

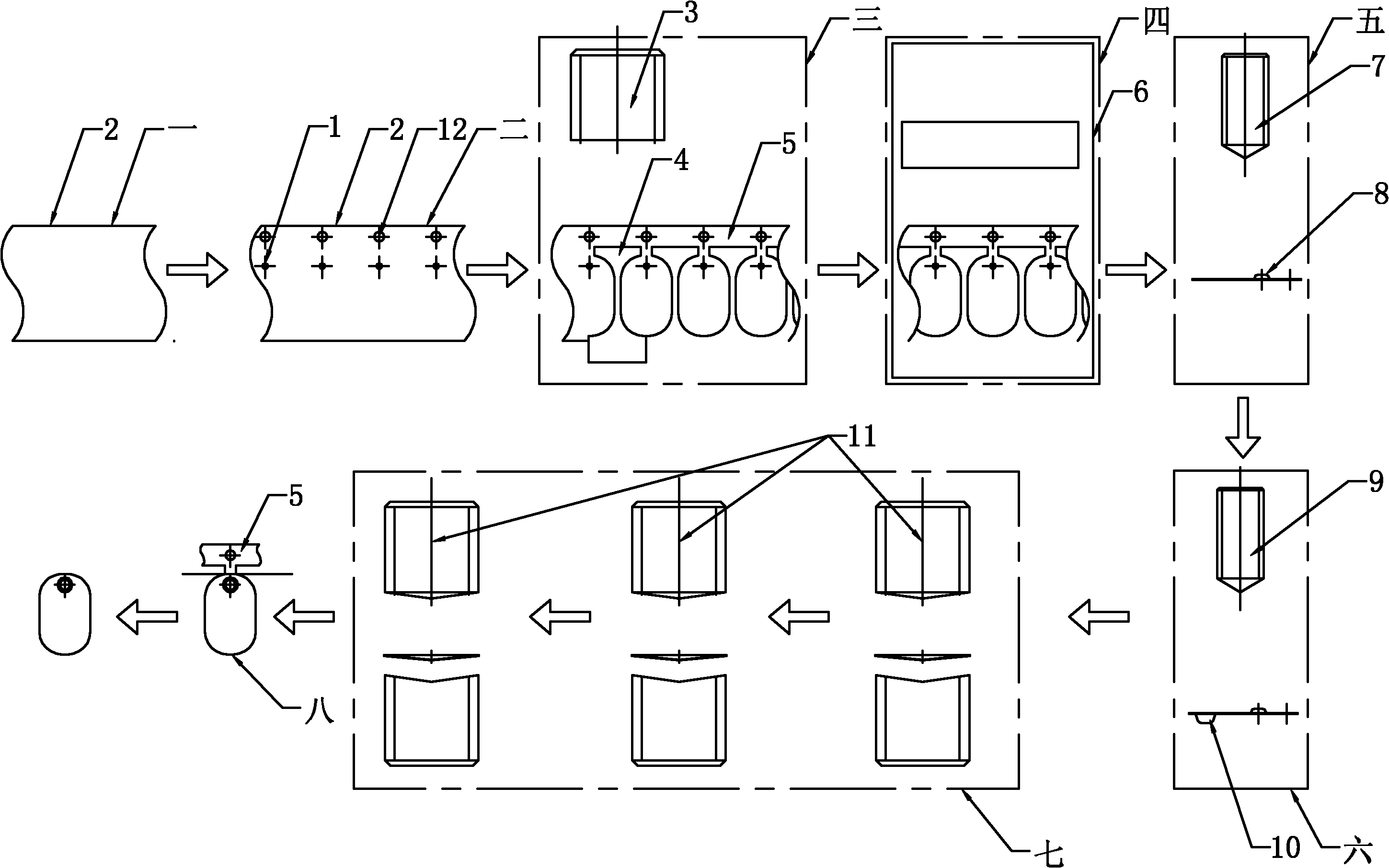

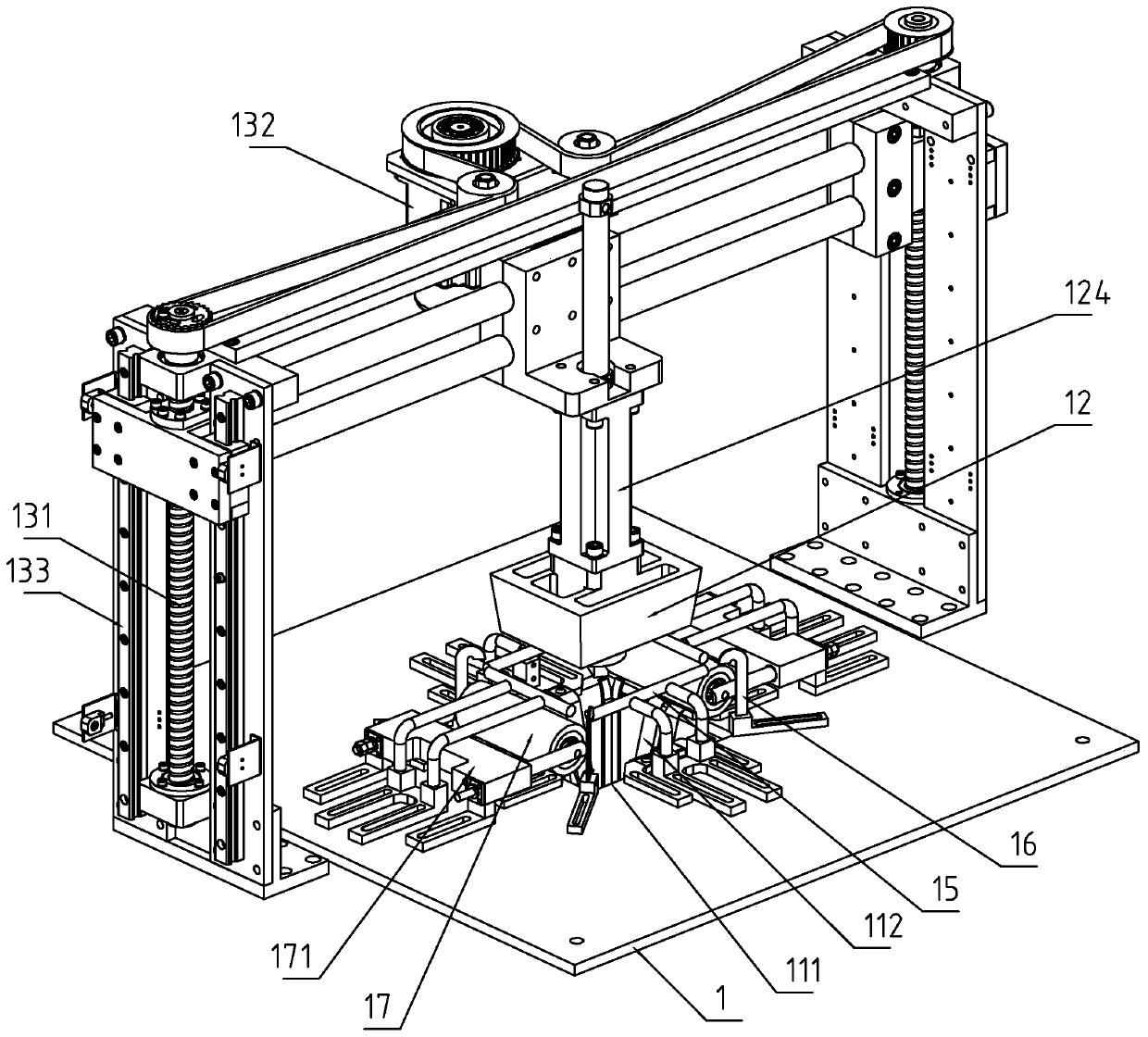

Metal plate rapid rounding and welding integrated device

PendingCN109604372AEasy to shapeNot easy to dentWelding/cutting auxillary devicesAuxillary welding devicesRoundingEngineering

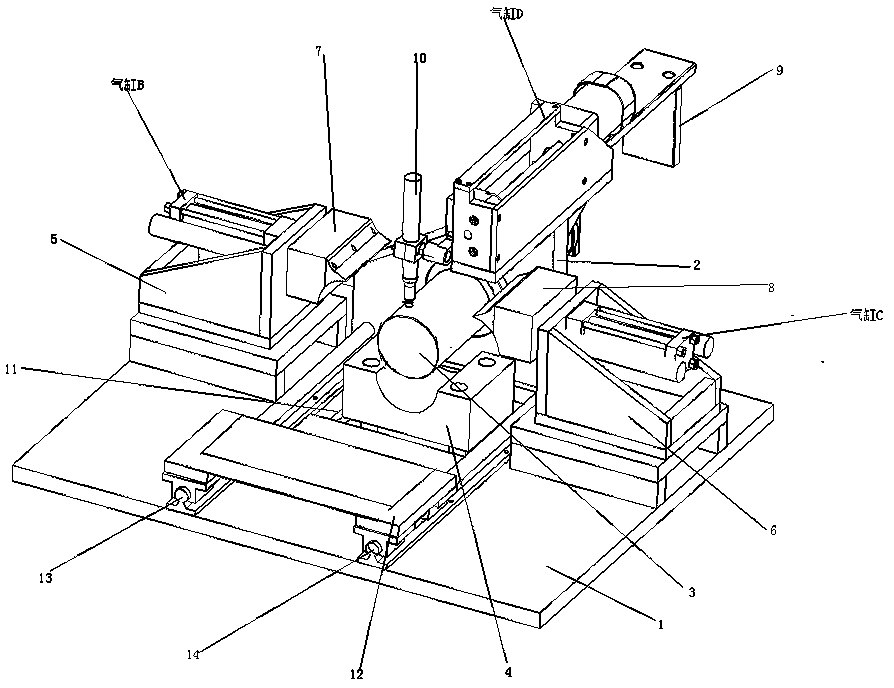

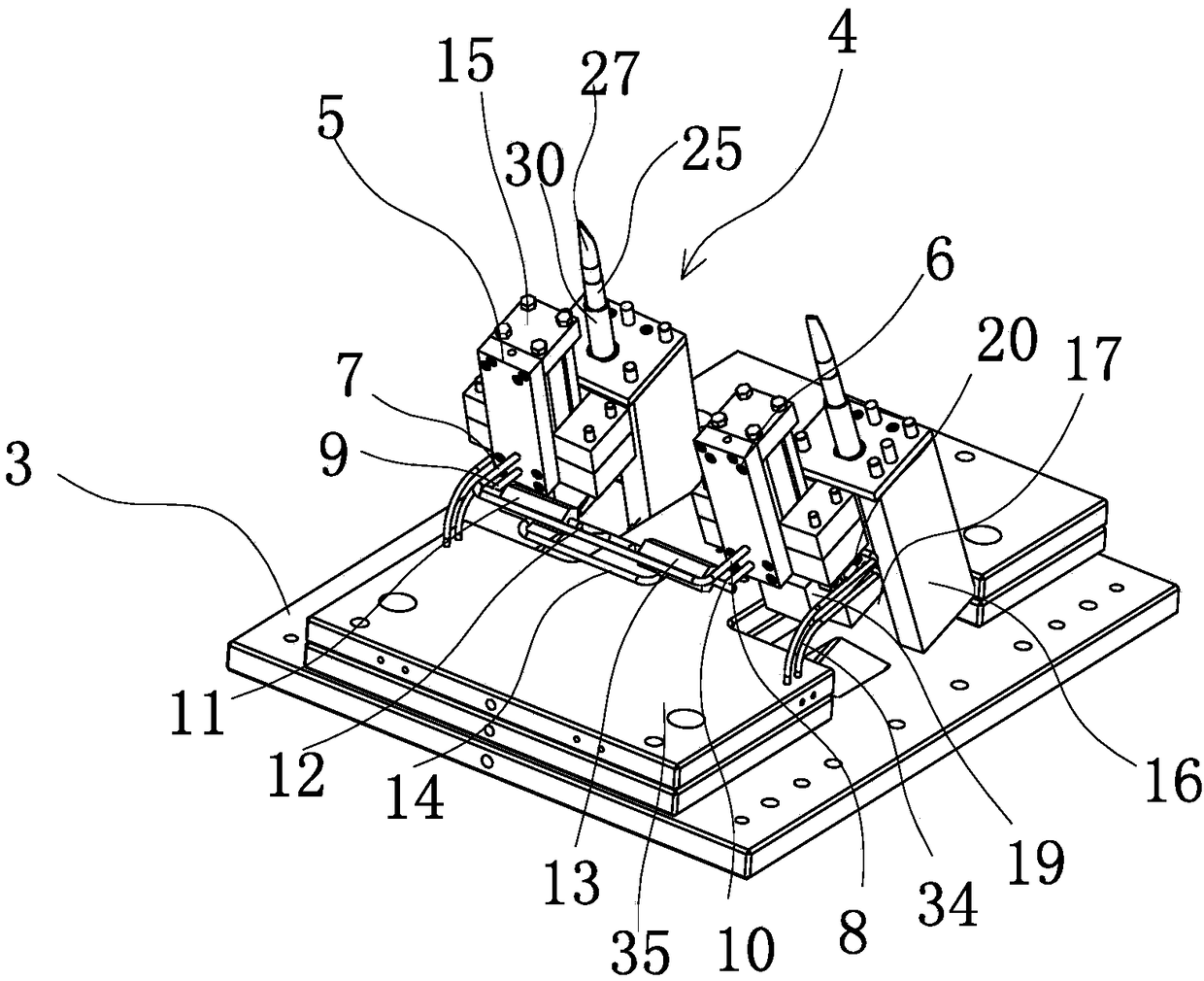

The invention discloses a metal plate rapid rounding and welding integrated device. The device comprises a base, wherein a back plate is arranged at the rear end of the base, the device is characterized in that the back plate is fixedly provided with a sizing mold, a lower mold is arranged right below the sizing mold on the base in a up-down movable mode, a left upper mold support and a right upper mold support are arranged on the two sides of the lower mold in parallel, a left upper mold which can move leftwards and rightwards is arranged on the left upper mold support, the right upper mold support is provided with a right upper mold which can move leftwards and rightwards, a mold cavity of the left upper mold, a mold cavity of the right upper mold and a mold cavity of the lower mold arecombined to form a cylindrical mold cavity matched with the sizing mold; and a welding gun support is fixedly arranged behind the back plate, a welding gun is vertically arranged on the welding gun support, the welding gun can move back and forth, and the welding gun is located right above the sizing mold. According to the device, automatic rounding and automatic welding are achieved, the two procedures are continuously operated, the construction period is shortened, the labor and time cost is reduced, and the production efficiency is improved.

Owner:淮安茂华管业有限公司

Phase-change-material-based thermal management material, preparation method and applications thereof

ActiveCN108199113AImprove thermal conductivityGood temperature control functionSecondary cellsHeat-exchange elementsFiberPhase-change material

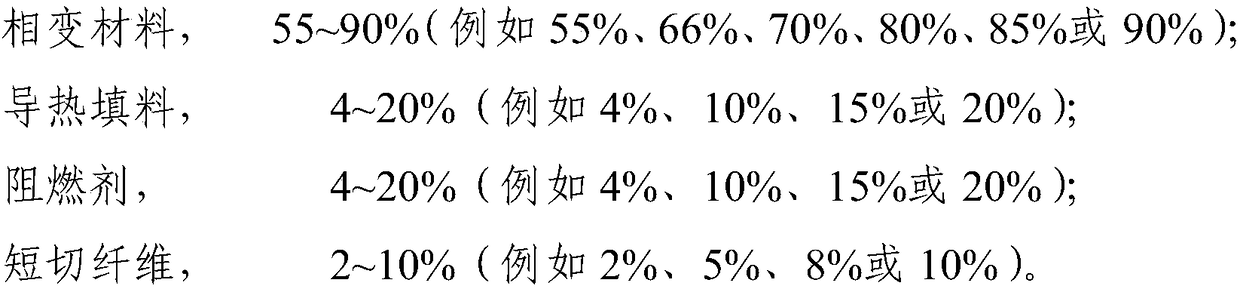

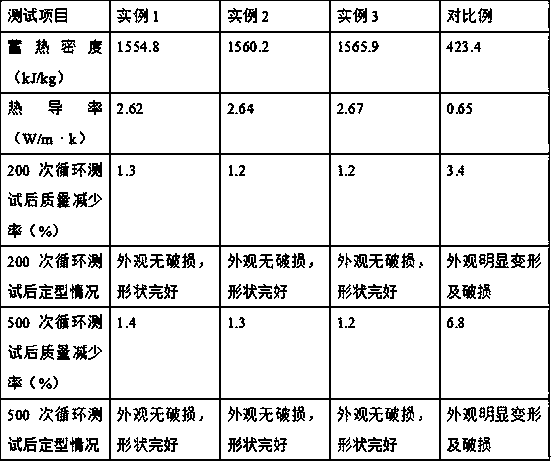

The invention relates to a phase-change-material-based thermal management material, a preparation method and applications thereof, wherein the thermal management material comprises, by mass, 55-90% ofa phase change material, 4-20% of a thermal conduction filler, 4-20% of a flame retardant, and 2-10% of chopped fiber. According to the present invention, by adding an appropriate amount of the chopped fibers, the deformation of the phase change material due to volume expansion or contraction can be effectively prevented, such that the content of the phase change material in the thermal management material can be substantially increased so as to improve the heat storage capacity of the thermal management material and stably regulate and control the temperature.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Easy-adhesion copolyester fiber and fabric thereof

InactiveCN103184572AIncreased adhesion areaHigh bonding strengthMonocomponent copolyesters artificial filamentFiberAlcohol

The invention discloses easy-adhesion copolyester fiber. An acid component forming the copolyester fiber mainly has terephthalic acid structural units. In a dihydric alcohol component forming the copolyester fiber, the content of aliphatic diol structural units comprising side chain and carbon atom number under 6 is 20-90mol%. The fiber has no melting point or low melting point. When the fiber is prepared into fabric and when the fabric is heated by using a common iron or other heating devices, a partial fusion phenomenon occurs to the fabric, and an adhesion effect is provided. The fabric can be used in side locking of positions such as cuffs and trouser bottoms, and can be used in shaping of collars and the like, such that clothes can be provided with certain stiffness.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

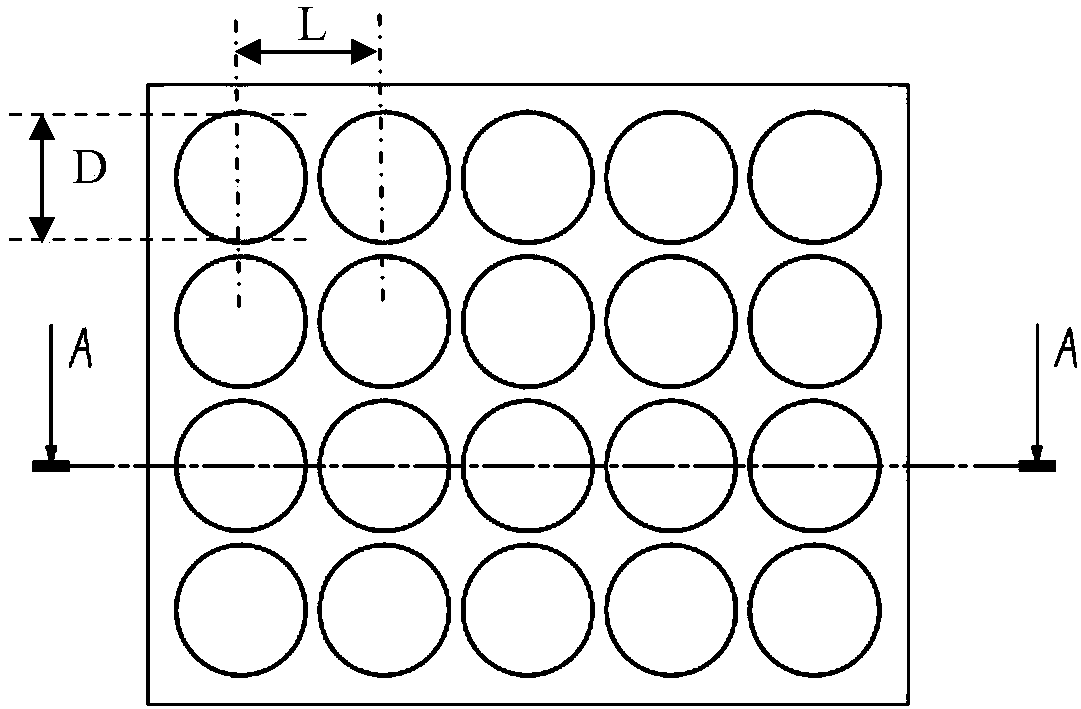

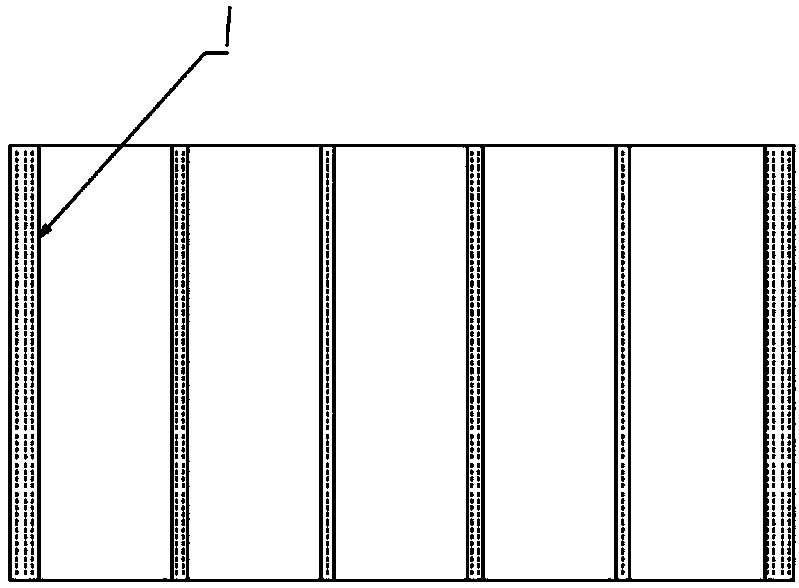

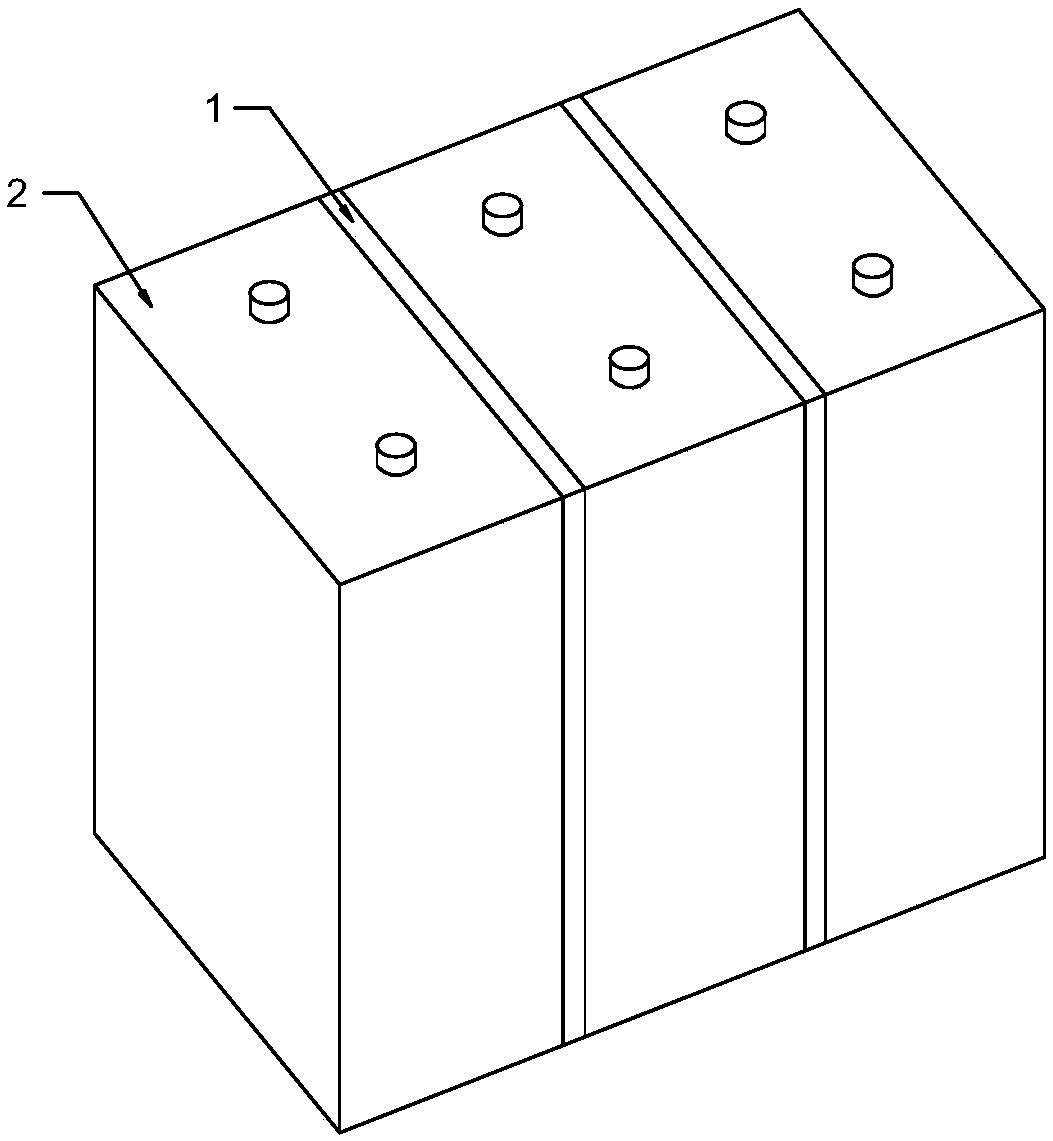

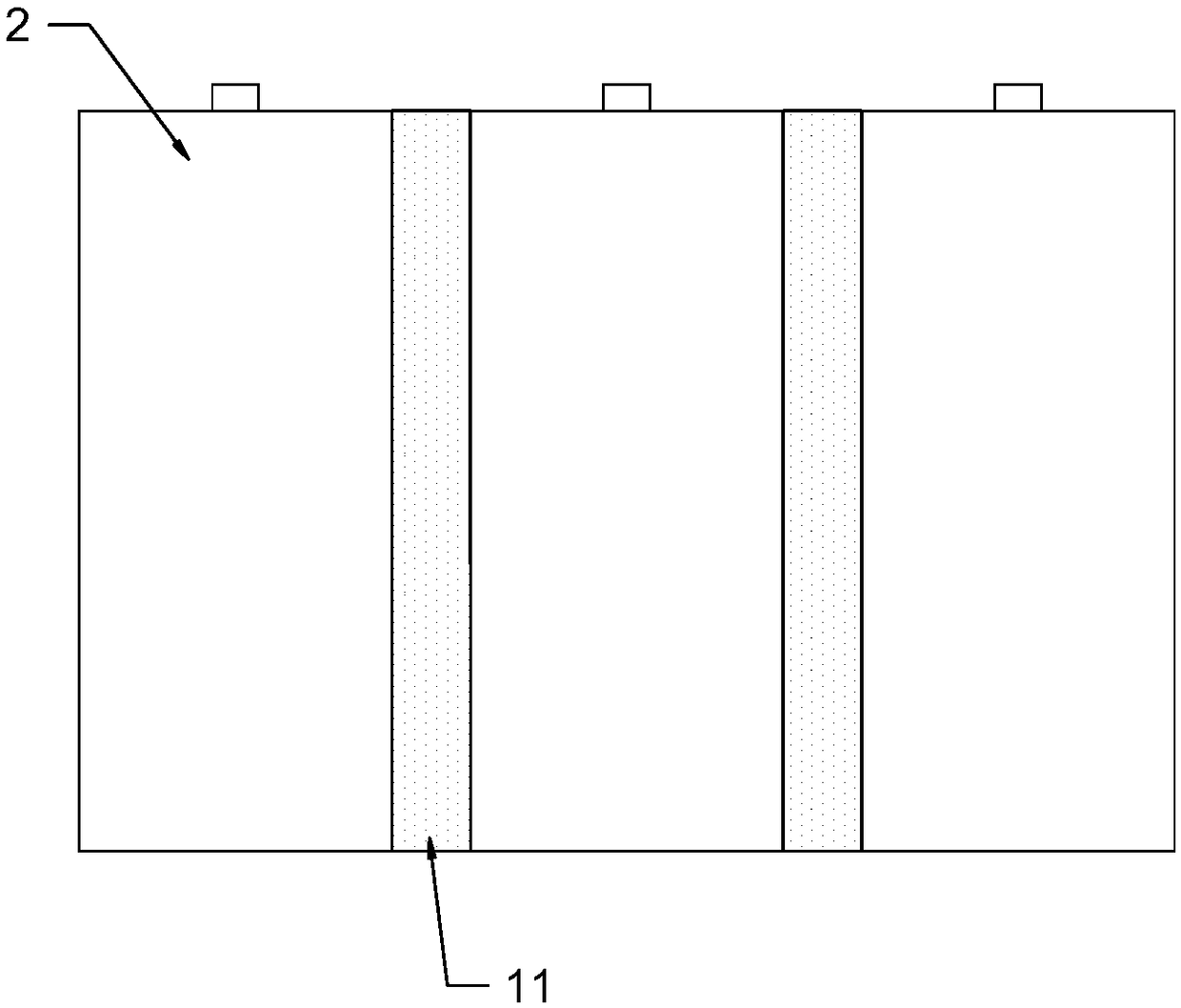

Heat management module for cylindrical batteries and preparation method thereof and battery pack

ActiveCN108288739AImprove thermal conductivityGuaranteed temperature uniformityBattery isolationSecondary cellsFiberHeat management

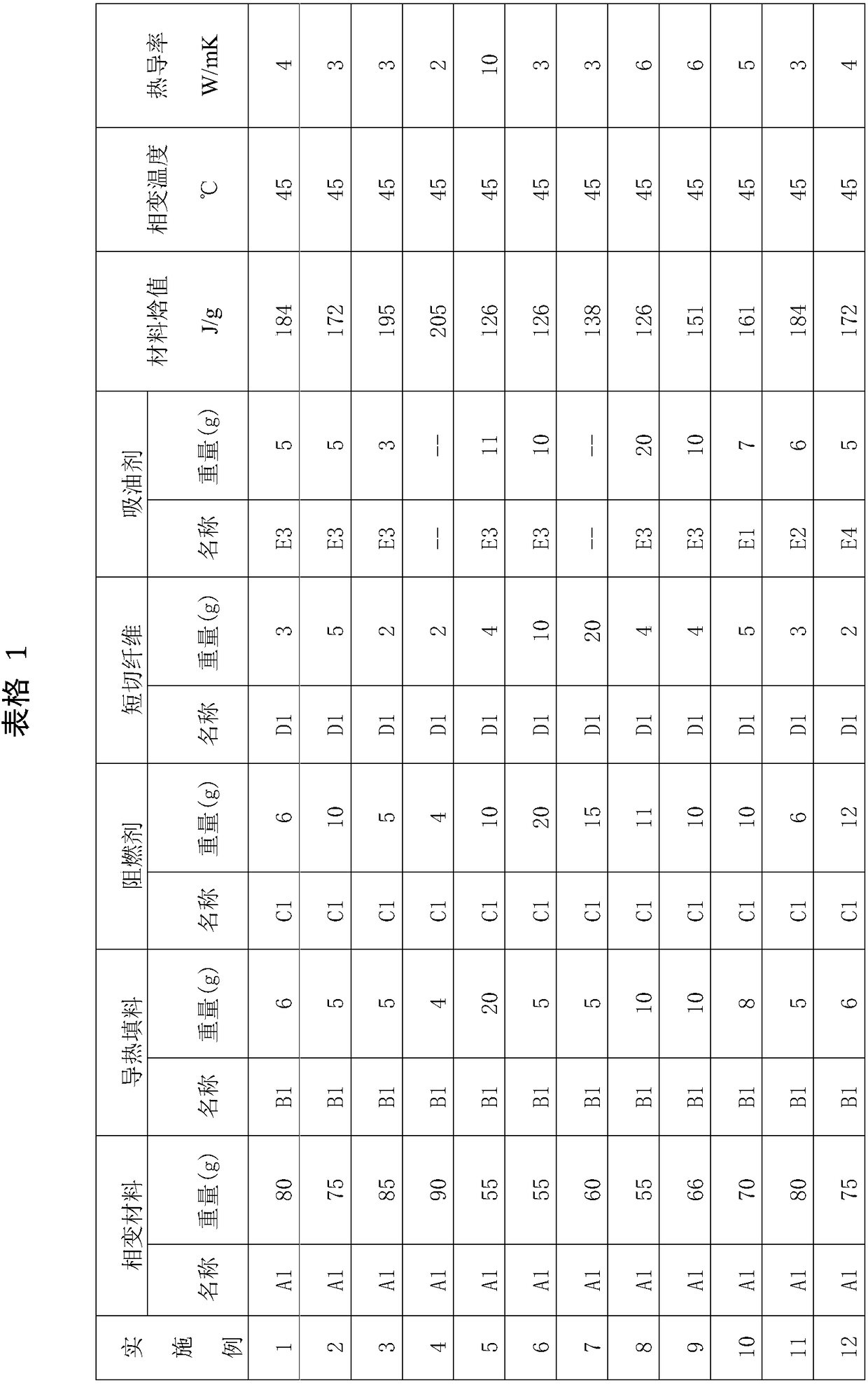

The invention relates to a heat management module for cylindrical batteries and a preparation method thereof and a battery pack. The heat management module comprises a heat management material mouldedbody; a plurality of cylindrical holes for accommodating the cylindrical batteries are formed in the heat management material moulded body; the heat management material moulded body is prepared froma heat management material by a moulding method; and the heat management material comprises the following components in percent by mass: 55-90% of a phase change material, 4-20% of a heat-conducting filler, 4-20% of a flame retardant and 2-10% of chopped fiber. Through addition of the chopped fiber into the heat management module, an effective enhancing effect can be achieved; the content of the phase change material in the heat management material can be increased to a relatively large extent, and thus the heat storage capacity of the heat management module is improved, so that the heat management module regulates and controls the temperature more stably.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

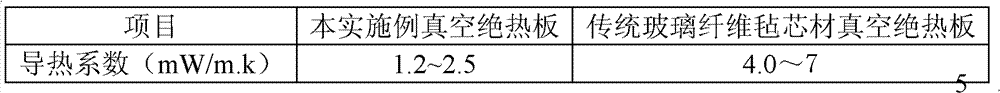

Glass fiber chopped strand mat, production method and core material for vacuum heat-insulation boards

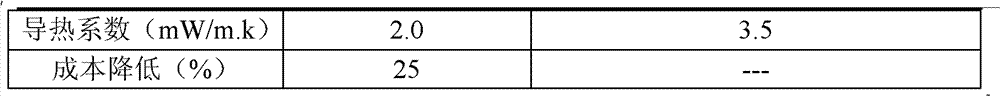

ActiveCN102953230ALow thermal conductivityReduce manufacturing costThermal insulationSynthetic cellulose/non-cellulose material pulp/paperGlass fiberFiber

The invention discloses a glass fiber chopped strand mat which is made of glass fibers 4-25mm in length and 5-15 micrometers in diameter by steps of preparing pulp by adding thickeners, dispersing agents and defoaming agents and then dewatering and drying, and is 0.1-2.0mm in thickness. The glass fibers are scraps from glass fiber production enterprises. The production method of the glass fiber chopped strand mat includes the process of manufacturing paper with pulp in the paper making technology. On the premise of the same production manner, production cost of a core material is reduced by 10-50%, and the heat conduction coefficient of a vacuum heat-insulation board made by the core material is reduced by 25-65%.

Owner:FUJIAN SUPERTECH ADVANCED MATERIAL

Thermal management module for square battery, and preparation method thereof, and battery pack

ActiveCN108199112AImprove thermal conductivityGuaranteed temperature uniformitySecondary cellsFiberComputer module

The invention relates to a thermal management module for a square battery, and a preparation method thereof, and a battery pack. The thermal management module comprises a thermal management material molding body, which is prepared from a thermal management material through a molding method, wherein the thermal management material contains, by mass, 55-90% of a phase change material, 4-20% of a thermal conduction filler, 4-20% of a flame retardant, and 2-10% of chopped fiber. According to the present invention, by adding the chopped fiber, the thermal management module can provide the effectiveenhancing effect, and can greatly increase the phase change material content in the thermal management material so as to improve the heat storage capacity of the thermal management module and stablyregulate and control the temperature.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

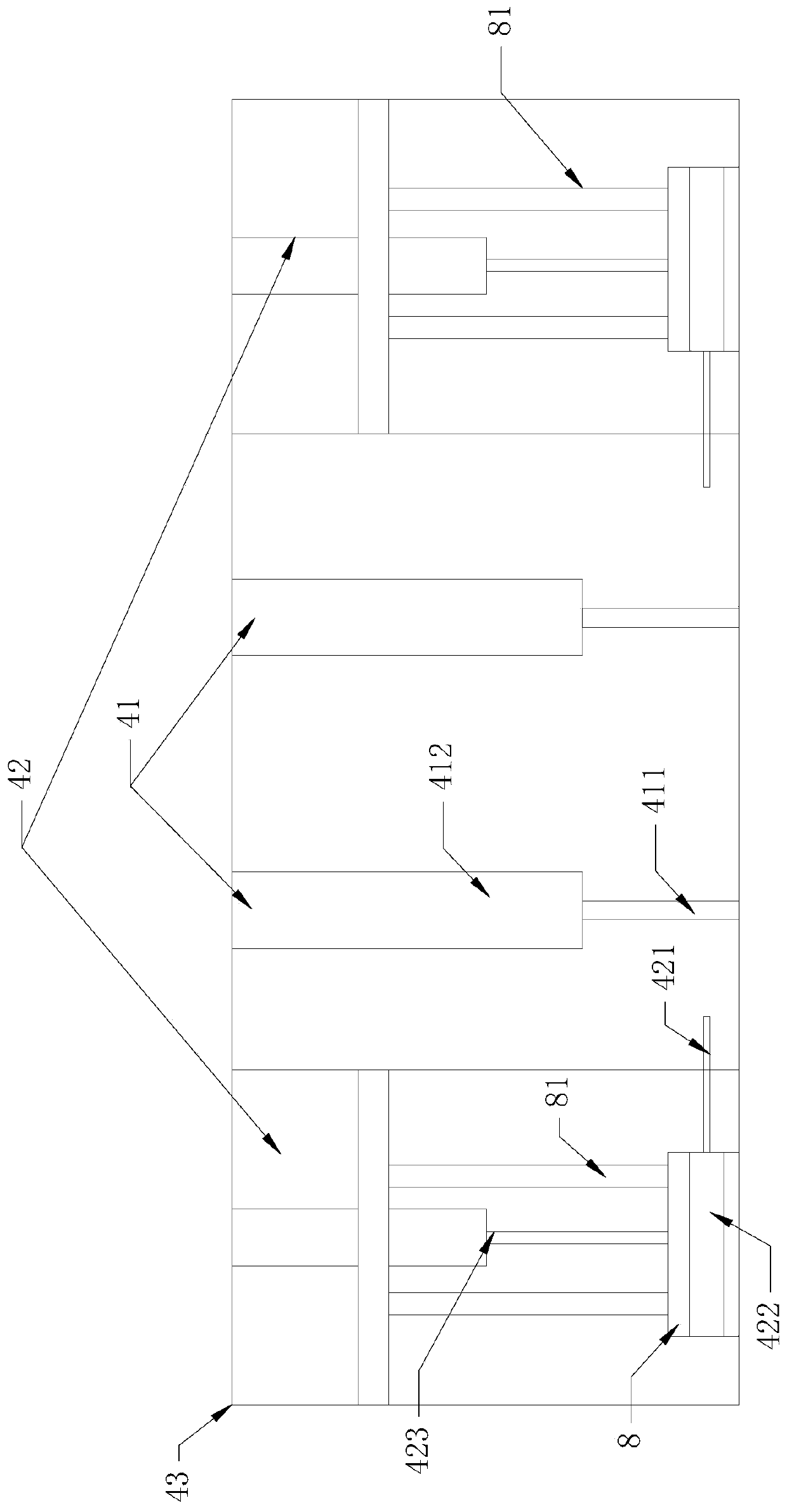

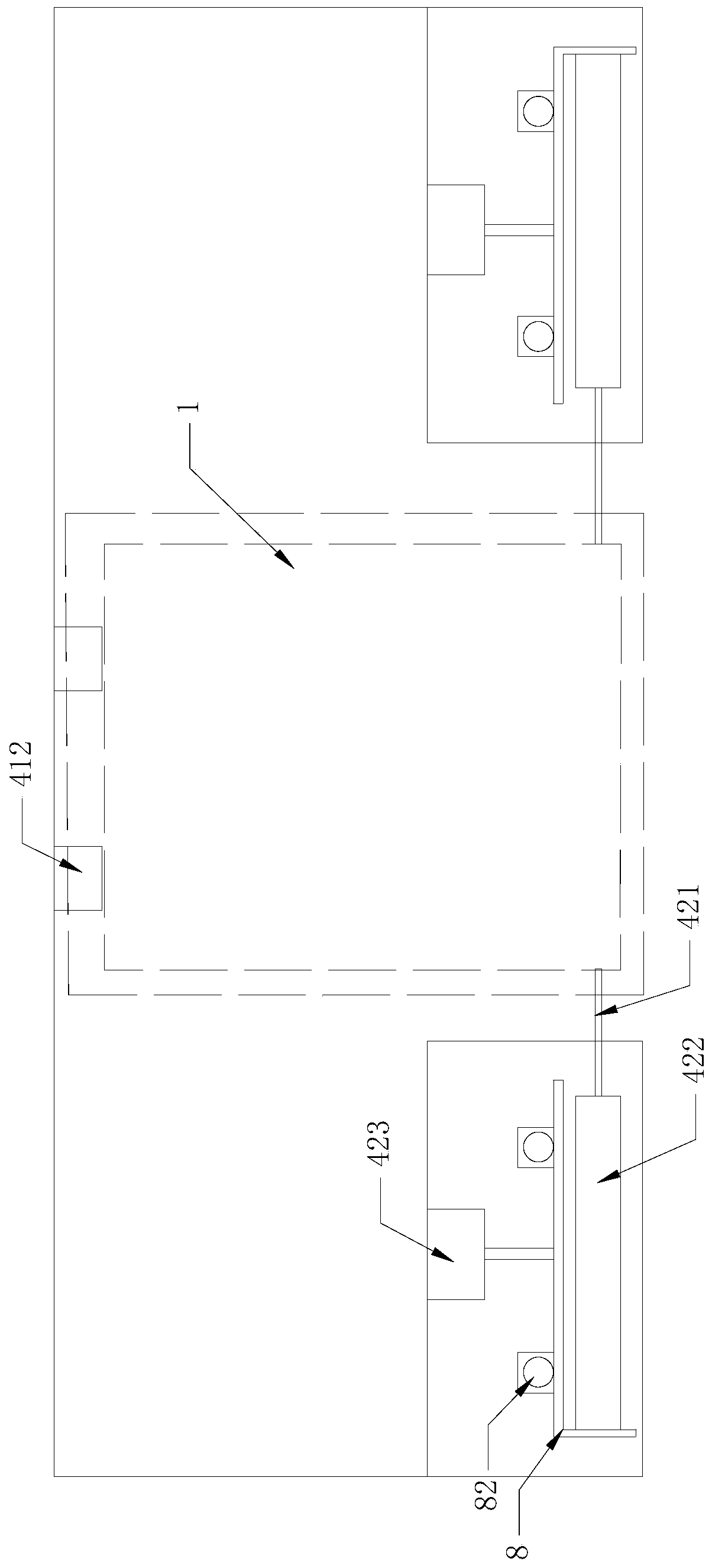

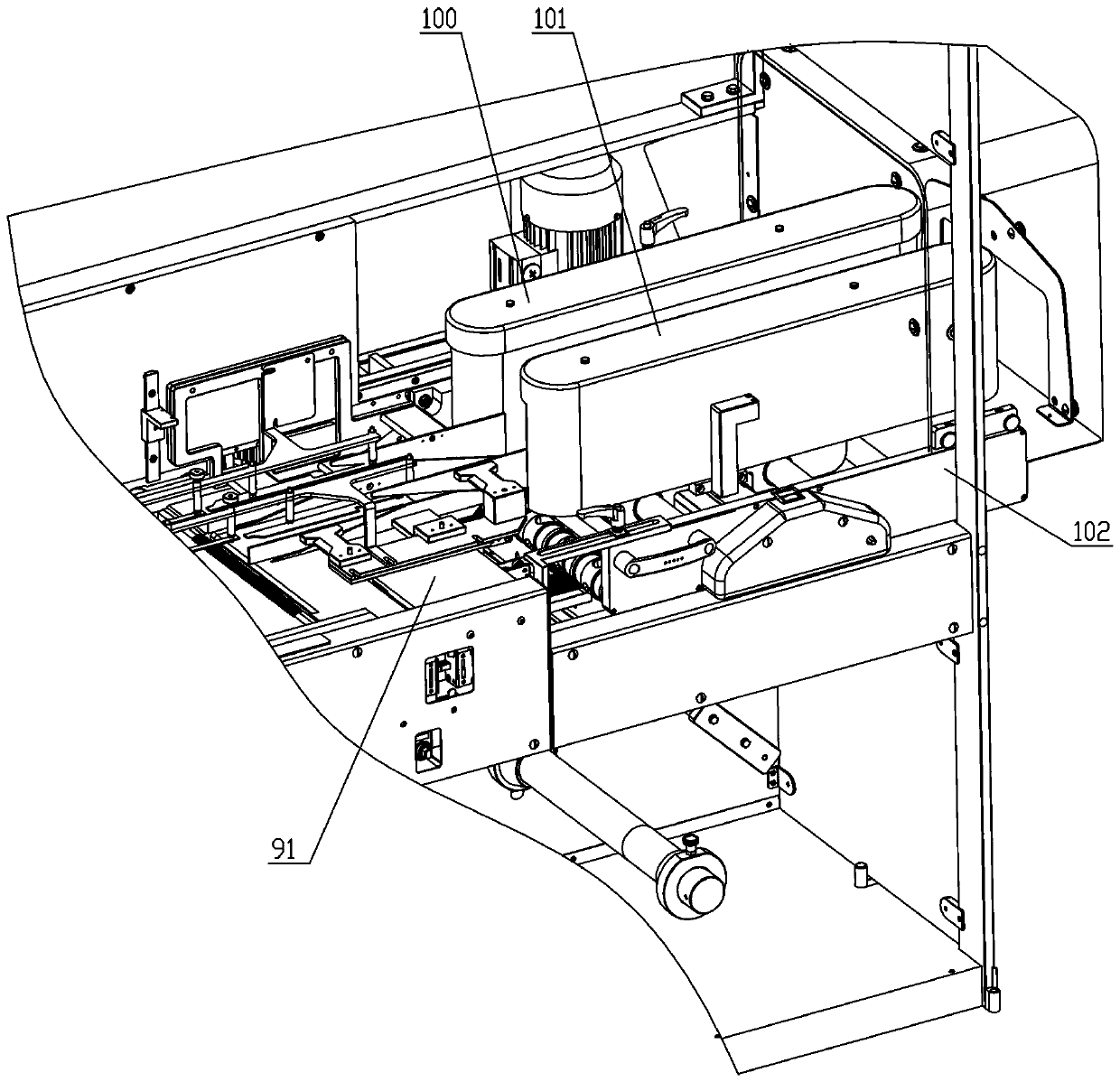

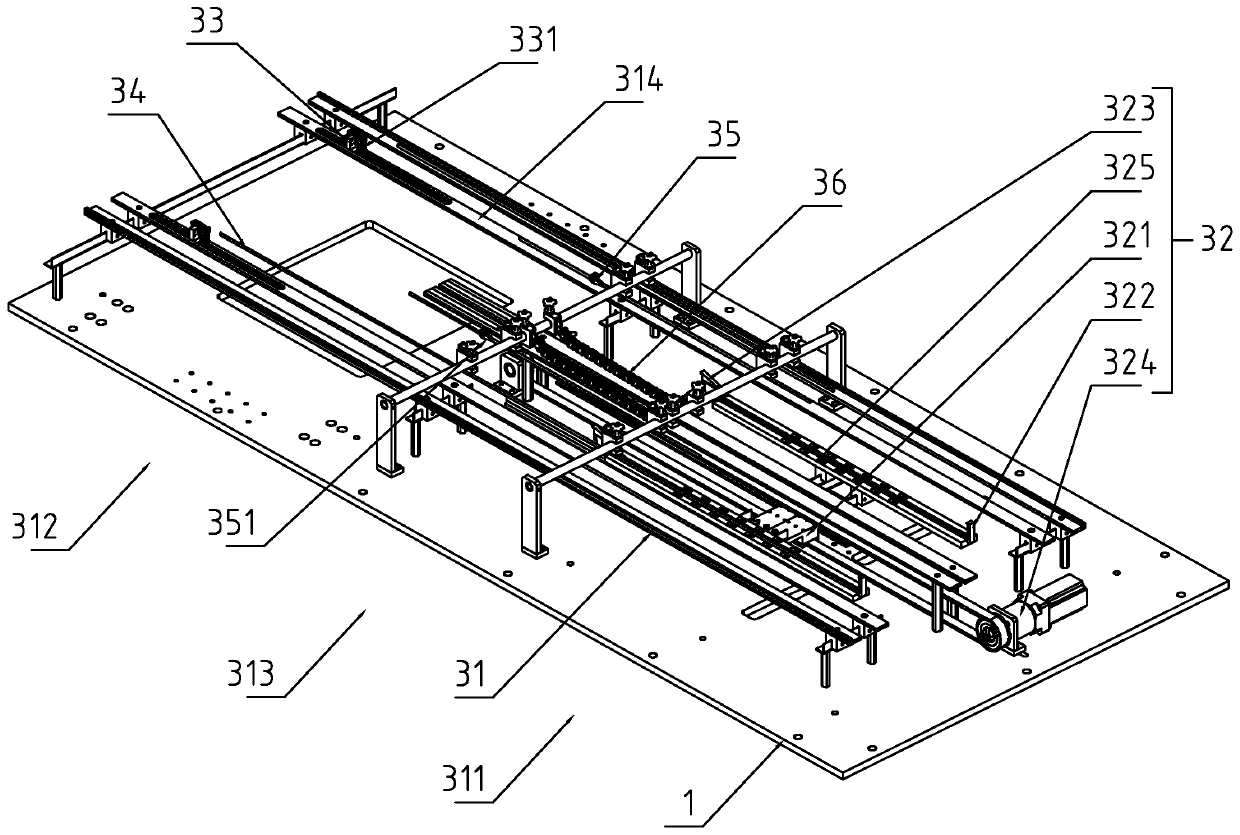

Spreading mechanism and spreading method for organic matter solid waste treatment device

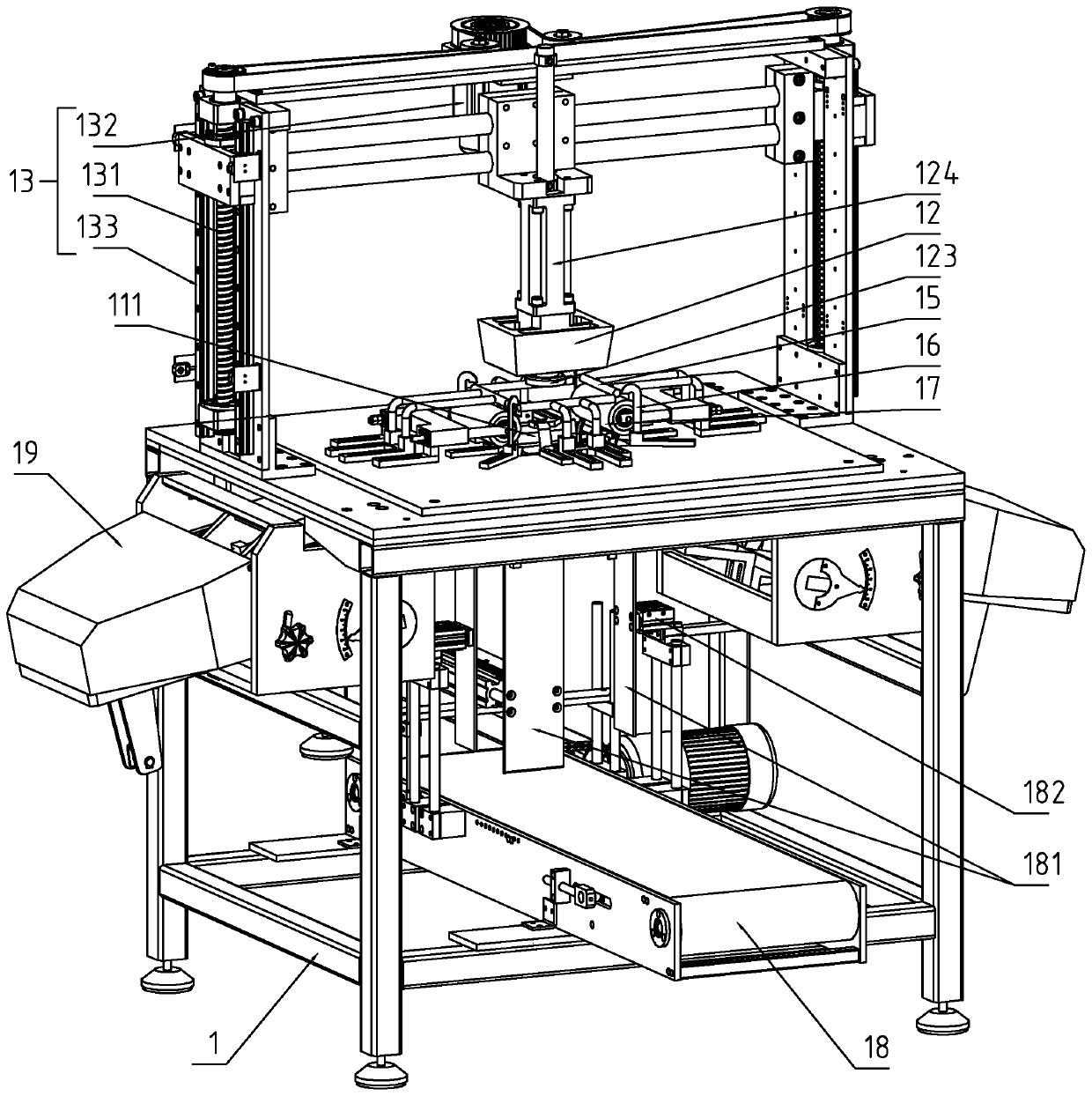

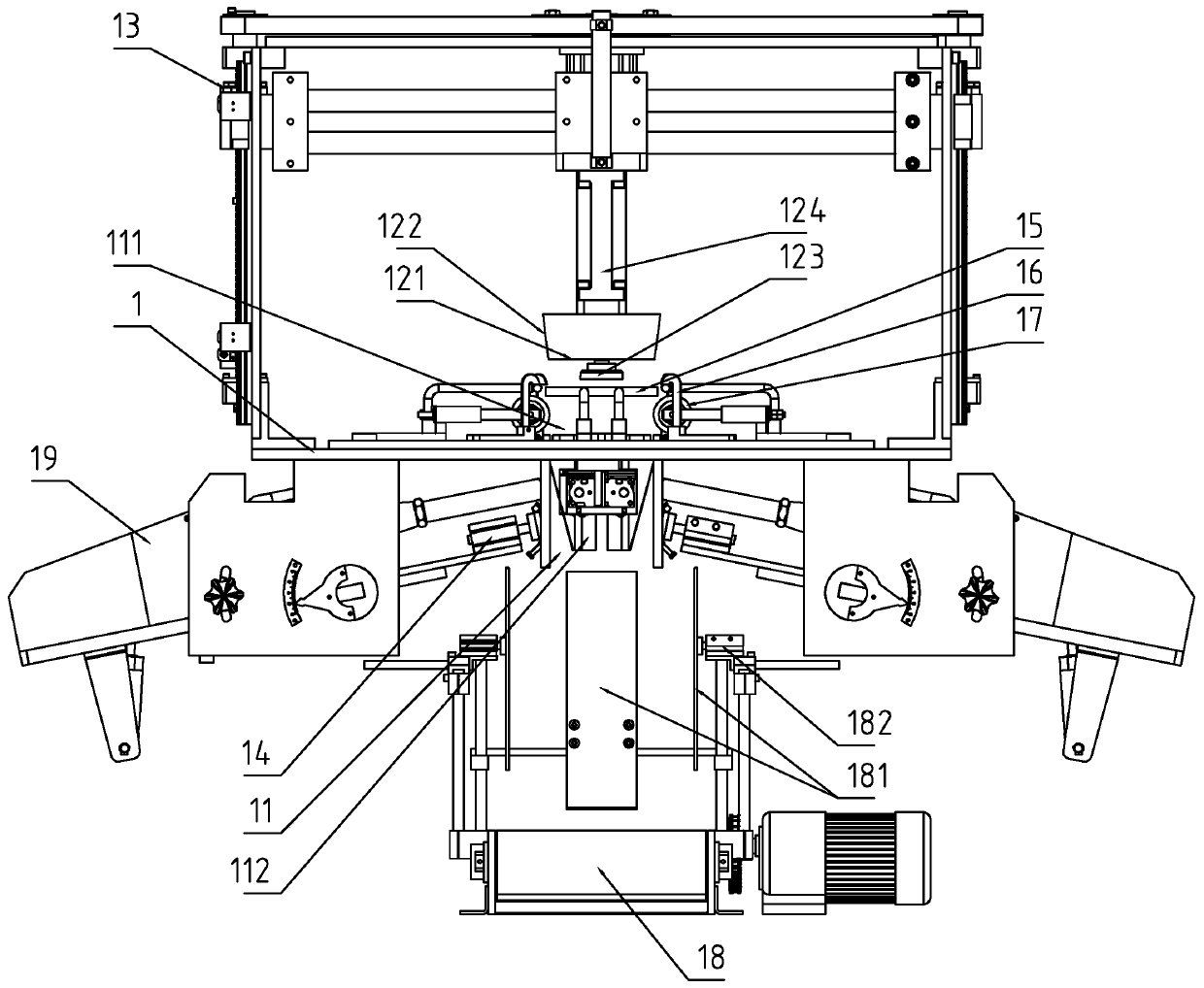

PendingCN110803847AImprove laying qualityImprove laying efficiencySludge treatmentPressesProcess engineeringOrganic matter

The invention provides a spreading mechanism and a spreading method for an organic matter solid waste treatment device. The spreading mechanism comprises a filter cloth filter pressing chamber, a spreading bed and a cloth rolling frame used for providing a filter cloth, a tray capable of moving up and down is arranged in the filter cloth filter pressing chamber, the spreading bed comprises a spreading part capable of moving back and forth, and the cloth rolling frame is arranged between the spreading bed and the filter cloth filter pressing chamber; and the moving direction towards the filtercloth filter pressing chamber is taken as the advancing direction, the spreading part is in a filter cloth spreading state when advancing, and the spreading part is in a material spreading state whenretreating. The single-layer filter cloth is folded and then laid in the filter cloth filter pressing chamber layer by layer when moving back and forth, and material laying is conducted between the two folded layers of the filter cloth, so that the filter cloth spreading quality and the dehydration efficiency are effectively improved.

Owner:中合清源(济南)生态科技有限公司

Processing method for turndown and stand collar

The invention relates to a processing method for a turndown and stand collar. The processing method for the turndown and stand collar includes the following steps that firstly, turndown and stand collar tailoring is performed according to yarn-direction threads; fusible interlining and insertion strip treatment is performed: woven interlinings are fused on an under collar and top collars, non-woven straight yarn insertion strips are fused on the bottom edge of an inner collar band, and an outer collar band is double-layer shell fabric; gathering and pushing-aside treatment is performed again; the parts, close to the front ends, of fold lines of the under collar and the top collars are pushed aside, and the remaining parts of the under collar and the top collars are gathered; after stitching, stitching positions are cleaned; top stitching treatment is performed; double stitches are stitched on the outer edge of the collar, and closing threads are stitched on the upper edge of the inner collar band; a collar neckline is fixed; the outer collar band and a clothes body are stitched, the inner collar band, a front facing and a collar support are stitched, wide slanted strips are fastened at the seam allowance position of the outer collar band and the collar neckline and at the seam allowance position of the inner collar band and the collar neckline respectively, and the edges of the two slanted strips are aligned and fixed through large-needle-distance hand stitching; finished product hooks are sewn, and hand needle blind stitching is performed on the front edges of the collar bands to finally process the needed turndown and stand collar. The processing method has the advantages that fitness and comfort of the turndown and stand collar are improved, and the effect that a person moves without moving the collar is achieved; the turndown and stand collar is more stereoscopic and tall and straight and beautiful in appearance.

Owner:SHANDONG SHOW LONG GARMENT

Dry-modified activated carbon fiber GACF composite and preparation method thereof

ActiveCN110302755AEasy to stretchImprove adsorption capacityOther chemical processesAlkali metal oxides/hydroxidesActivated carbonFiber

The invention relates to a dry-modified activated carbon fiber GACF composite and a preparation method thereof. The dry-modified activated carbon fiber GACF composite is prepared from the raw materials in percentage by weight: 50%-65% of activated carbon fibers, 25%-35% of a shaping carrier and 10%-20% of a bonding agent. According to the dry-modified activated carbon fiber GACF composite, continuous fibers serve as the shaping carrier of the dry-modified activated carbon fiber GACF composite, and after the activated carbon fibers and the continuous fibers are bonded together through superfinerubber powder, the continuous fibers can shape the activated carbon fibers and further enable the activated carbon fibers to have good drawing force; and the superfine rubber powder is adopted as thebonding agent, thus the activated carbon fibers and the continuous fibers can be bonded three-dimensionally, it can be guaranteed that ventilation cavities in the formed dry-modified activated carbonfiber GACF composite are similar to sponge air cavities, it is guaranteed that the activated carbon fibers still keep good adsorption performance, and thus the dry-modified activated carbon fiber GACF composite can be applied to civil processing.

Owner:江苏申杰活性炭纤维应用科技有限公司

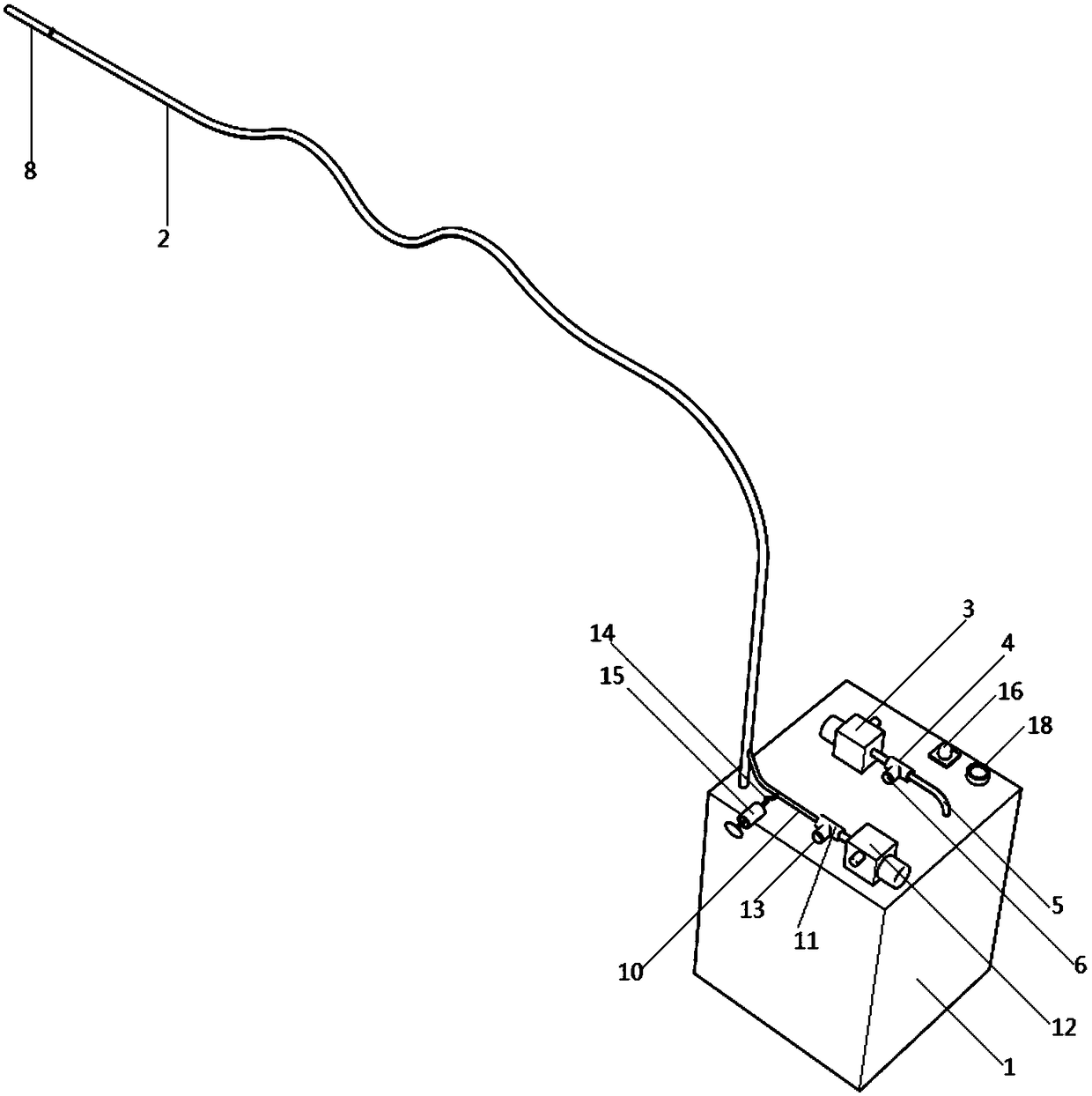

Rapid drainage device for ICU nursing

InactiveCN108525028AGood sealingAvoid cloggingIntravenous devicesSuction drainage systemsIntensive careEngineering

The invention discloses a rapid drainage device for ICU nursing, and relates to the technical field of ICU intensive care. The device comprises a collecting box. A drainage tube is connected to the upper end of the collecting box; a pulse anti-blocking device is arranged on the drainage tube; the upper end of the collecting box is provided with a pulse negative pressure device; the pulse negativepressure device comprises a negative pressure pump installed at the upper end of the collecting box; and the pumping end of the negative pressure pump is connected with a B three-way tube; a pressuresensor module is mounted on a top end of the collection box; the pulse anti-blocking device includes a tube head communicating with a top end of the drainage tube; an annular elastic airbag is fixedlymounted on the left side of the tube head; the elastic airbag is connected with an air guiding tube; the end of the air guiding tube is connected with an A tee tube; the end of the air guiding tube is connected with a branch tube; the other end of the branch is in communication with the output port of a syringe. The device has the beneficial effects that the anti-blocking of the inlet of the drainage end is effectively achieved, and the drainage is facilitated quickly and efficiently, and the sealing of the end portion can be conveniently achieved to avoid backflow.

Owner:张琪芳

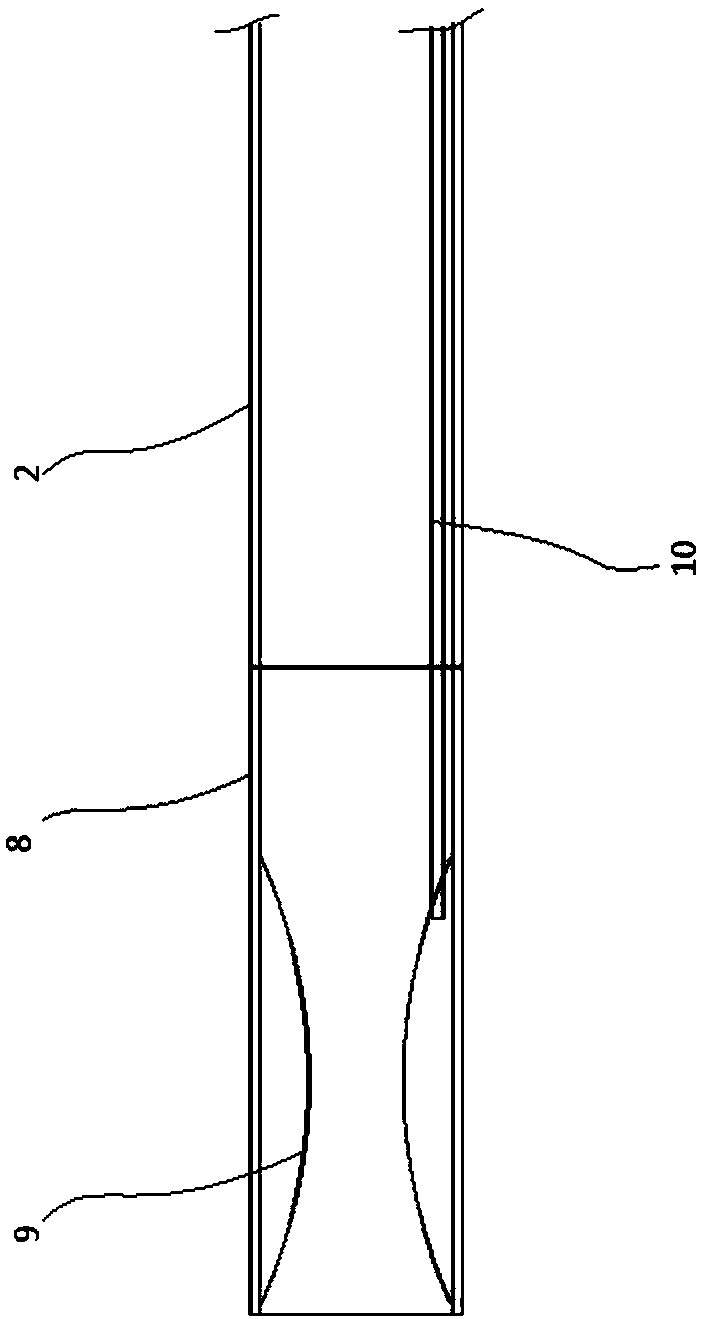

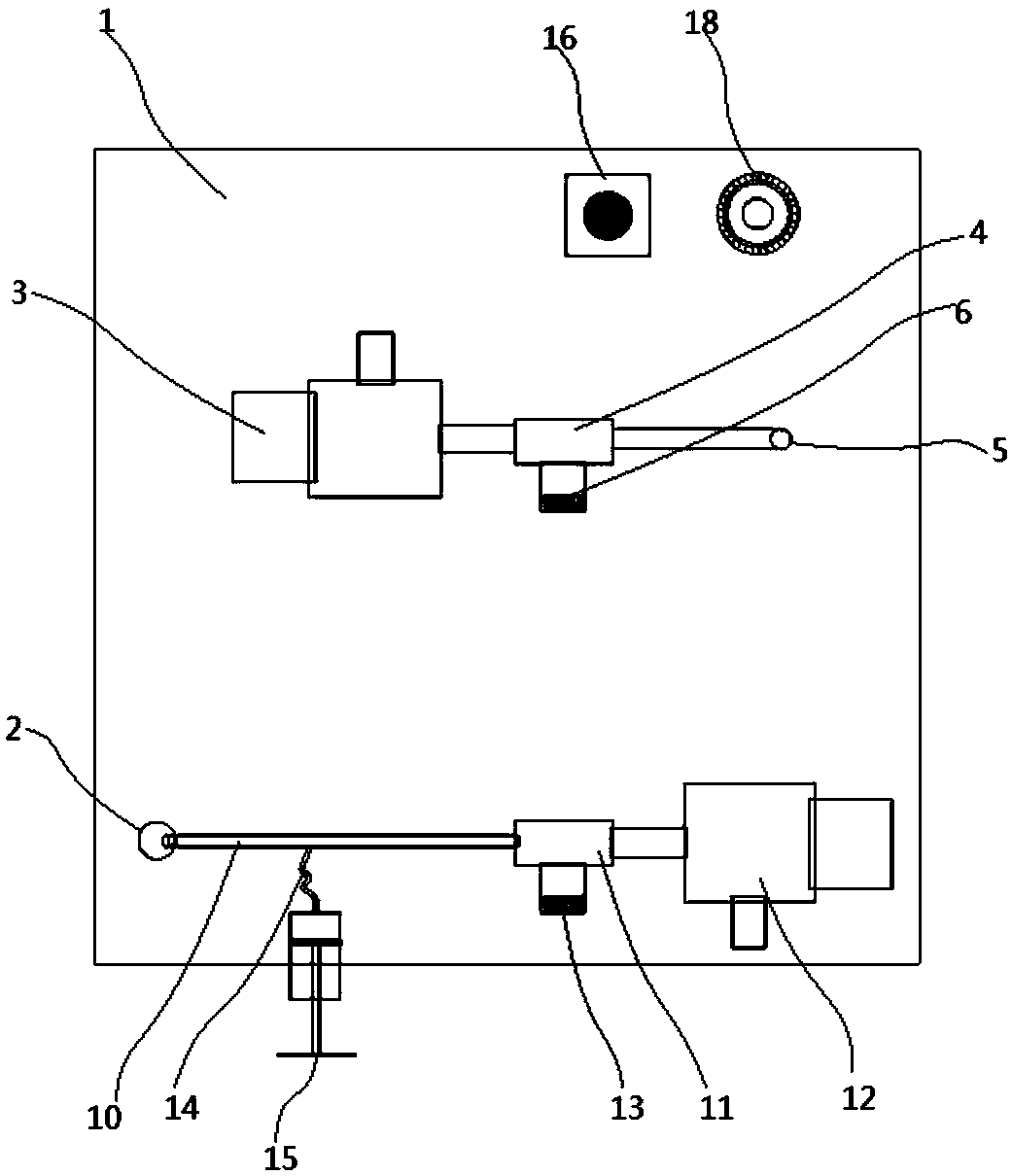

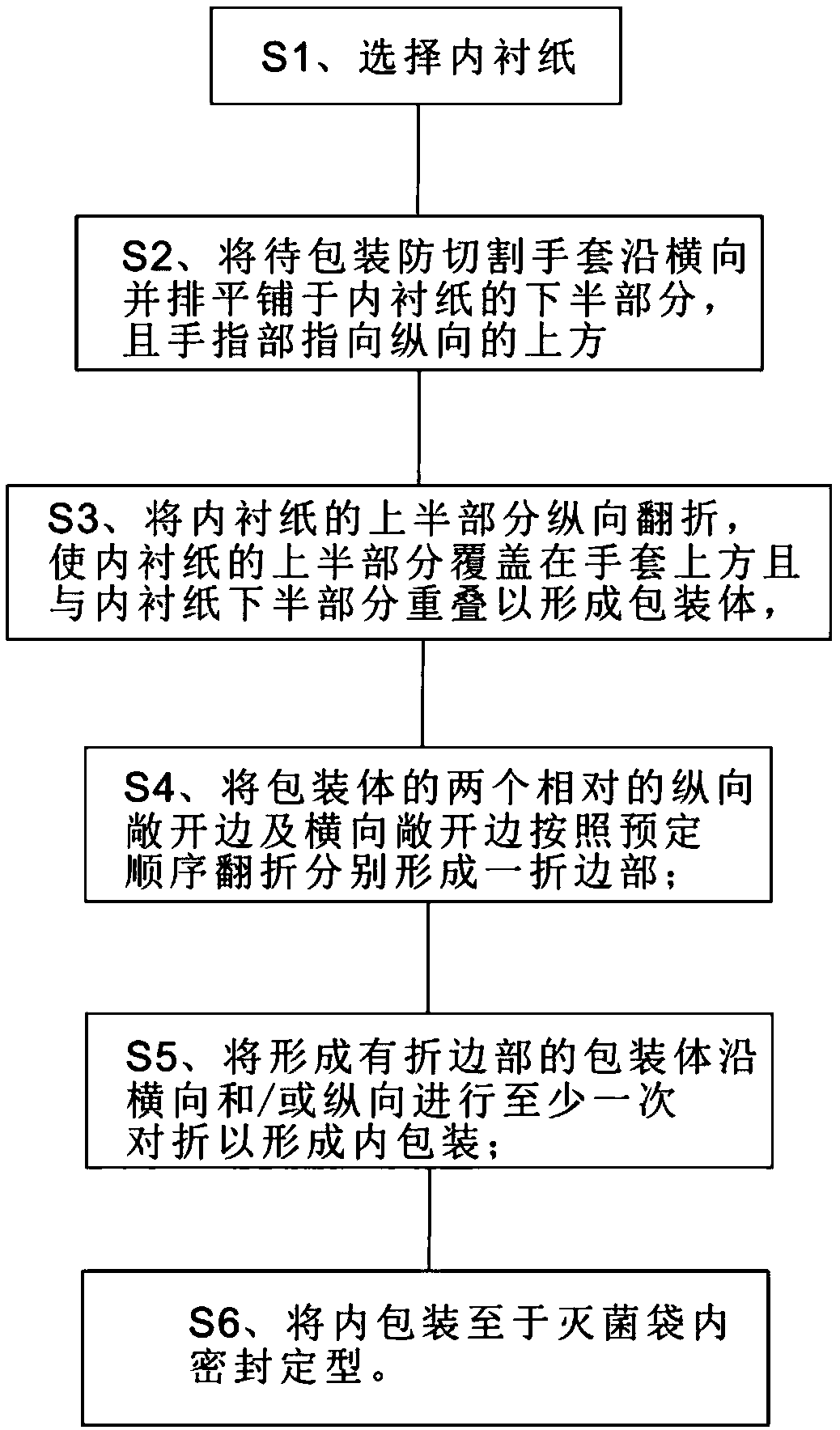

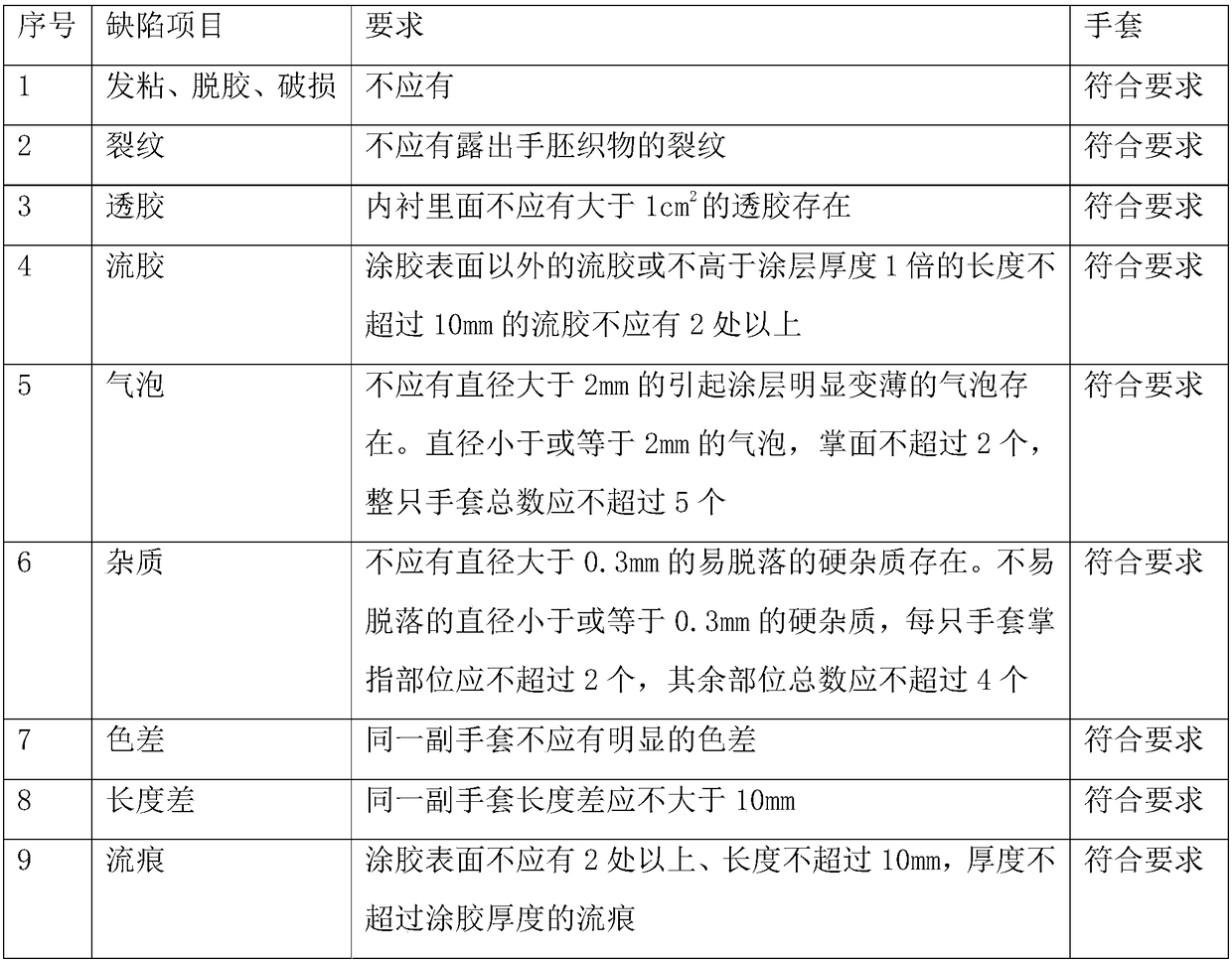

Anti-cutting glove and packaging method thereof

InactiveCN108978013AImprove cut resistanceWon't failWeft knittingWrapper folding/bending apparatusYarnPolyvinyl chloride

The invention discloses an anti-cutting glove and a packaging method thereof and belongs to the technical field of work gloves. The anti-cutting glove is made by knitting yarns which are one or any ofpolyethylene / aramid fiber, polyethylene / aramid fiber / steel wire, PVC-coated (polyvinyl chloride-coated glass fiber spandex yarn, and steel wire; the yarns are knitted into a glove core by an automatic glove knitter; the outside of the glove core is provided with a polymer coating by dipping; the polymer coating is one or a combination of butyronitrile rubber latex, polyurethane and rubber. The anti-cutting glove has excellent cutting protection which is far higher than provisions of national standard of China and European Union standards, has good flame retardance and excellent thermal protection, is light in weight and flexible to wear, and is good in wear resistance, low in production cost and high in batch production efficiency.

Owner:花春丽

Car seat cover fabric fluffing machine

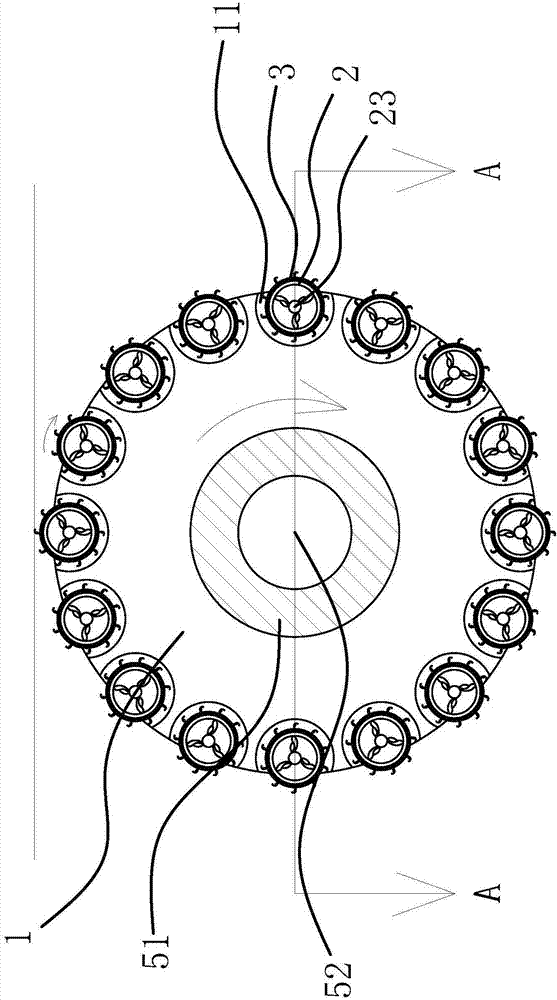

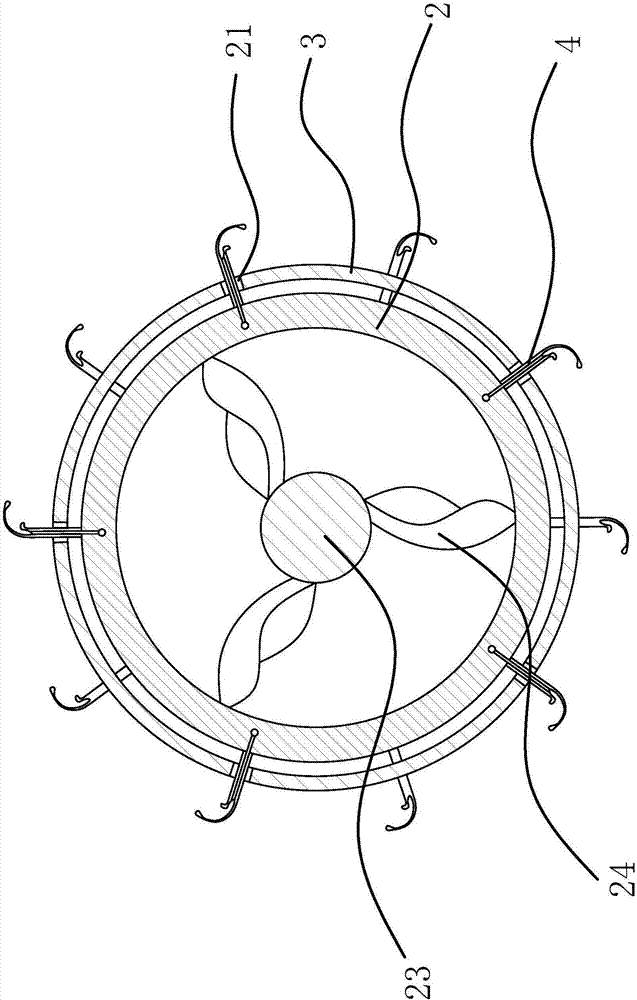

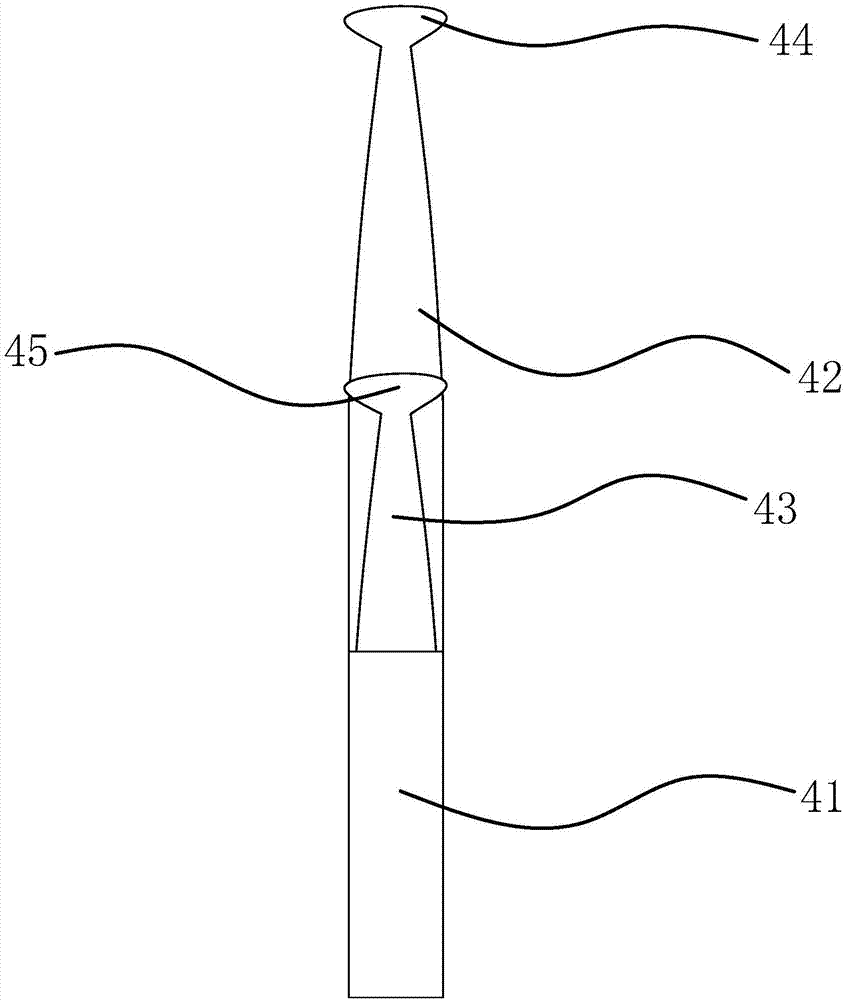

The invention provides a car seat cover fabric fluffing machine and belongs to the technical field of weaving. The car seat cover fabric fluffing machine solves the technical problem that the existing fluffing machine has low fluffing efficiency. The fluffing machine comprises a main roller, a plurality of fluffing rollers, guide sleeves corresponding to the fluffing rollers and a blower. The main roller is provided with avoiding ports corresponding to the fluffing rollers one by one. The fluffing rollers are arranged in the corresponding avoiding ports. A part of each one of the fluffing rollers stretches out of the avoiding port. The fluffing roller is uniformly provided with fluffing needles. A guide sleeve is provided with multiple guide grooves on the peripheral surface of the guide sleeve. The guide grooves are arranged in a corrugate way. The guide sleeve is fixedly connected to the main roller. The fluffing needles are inserted into the guide grooves. A ventilation chamber is arranged in each one of the fluffing rollers. The ventilation chamber is provided with a rotation shaft. The rotation shaft is fixedly provided with an impeller. The impeller is fixedly connected to the interior of the fluffing roller. The rotation shaft is rotatablely connected to the main roller. The car seat cover fabric fluffing machine has high fluffing efficiency.

Owner:李梦颖

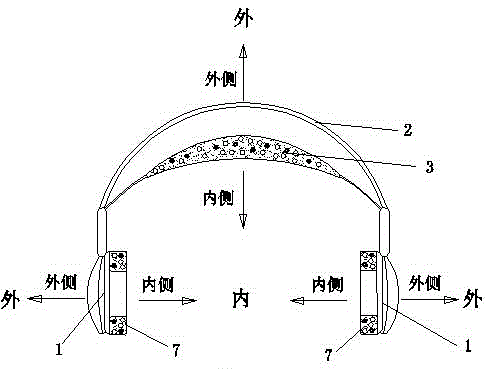

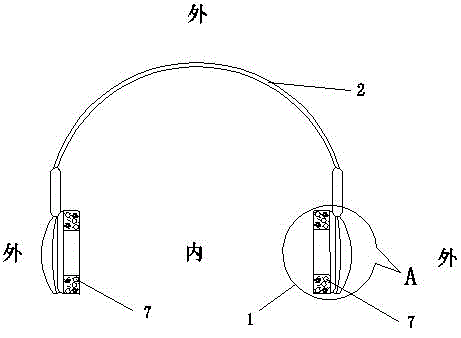

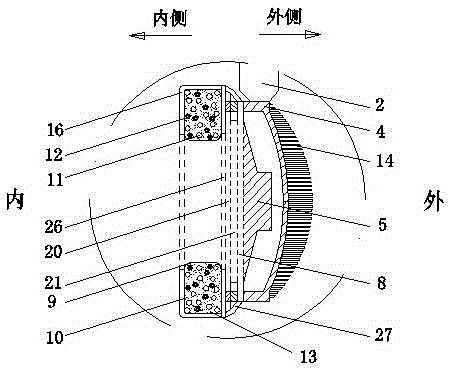

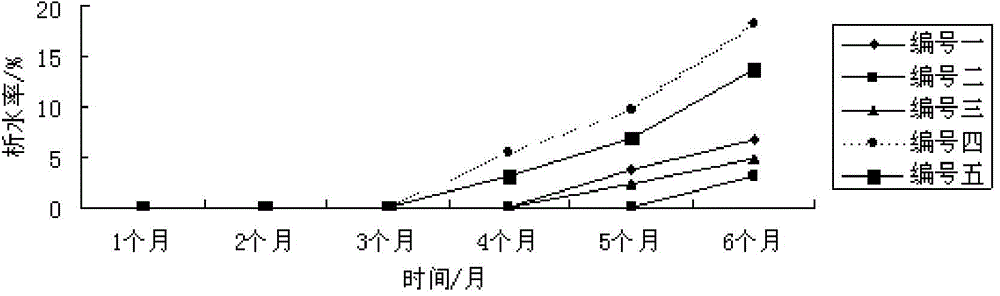

Headset with liquid bags arranged on ear pads and head beam

InactiveCN105635886ASimple structure evolutionPlay the role of heat dissipationMicrophonesLoudspeakersColloidEngineering

The invention provides a headset with liquid bags arranged on ear pads and a head beam. The headset has the advantages of rapid heat dissipation, little possibility of temperature rise, better vocal cavities and easiness in replacing the ear pads and the head beam. According to the technical schemes of the invention, each ear pad is structurally provided with an annular liquid bag ear pillow, a detachable connection fixing device and a sound-transmitting mesh fabric from inside to outside, wherein the annular liquid bag ear pillow comprises an annular shaping ring; the outer sides of ear cover shells are provided with heat dissipation devices; the thermal conductivity of supporting mesh plates, the ear cover shells and the heat dissipation device is high; the inner side or / and outer side of an elastic head frame is provided with one or more cooling liquid bag; the annular shaping rings and the cooling liquid bags are filled with liquid or / and colloid, a plurality of spherical particles and / or a granular decorative composite material body; the detachable connection fixing devices can be devices such as magnets or / and Velcro or / and annular elastic skirts, which can be removed manually or removed by using a manual tool.

Owner:张清华

Nutrition stewing sauce and preparation method thereof

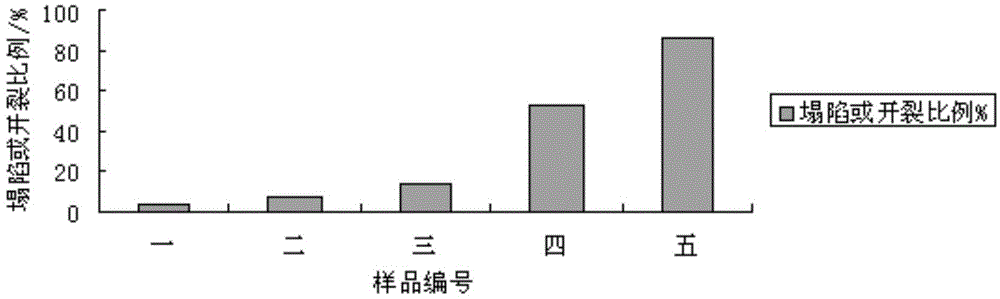

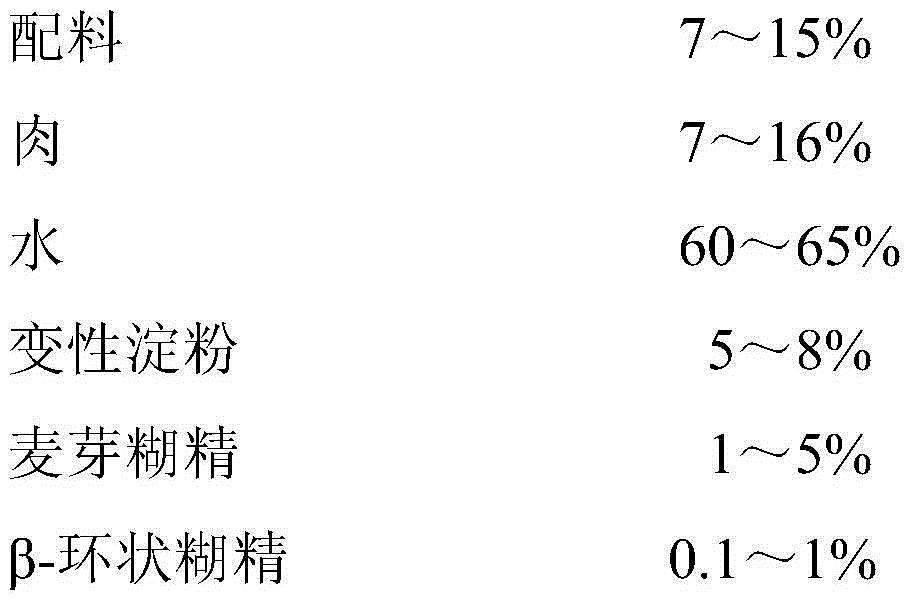

InactiveCN104012942ASolve easy collapseAddresses technical deficiencies of variantsFood ingredientsFood preparationBeta-CaroteneAdditive ingredient

The invention belongs to the technical field of food processing, and discloses a nutrition stewing sauce and a preparation method thereof. The nutrition stewing sauce is prepared from the following raw materials by weight: 7-15% of ingredients, 7-16% of meat, 60-65% of water, 5-8% of modified starch, 1-5% of maltodextrin, 0.1-1% of beta-cyclodextrine, 0.1-2% of guar gum, 1-3% of xanthan gum, 0.01-0.02% of L-Ascorbyl palmitate, 0.4-1.0% of phospholipid, 0-0.3% of beta-carotene, 0.3-0.5% of salt, 0.01-0.05% of disodium nucleotide, 0.3-1.0% of aginomoto and 0.01-0.05% of sodium dehydroacete. The traditional nutrition stewing technology of slowly stewing by small fire at south of the five ridges is combined with the modern food processing technology to prepare the sauce special for baked food stuffing, and the traditional technology and the modern technology are perfectly combined.

Owner:GUANGZHOU FOOD IND RES INST

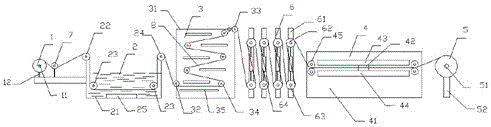

Calendaring device for label tape

InactiveCN106185419AExtended service lifeNo damageCalendersDrying machines with progressive movementsWinding machineEngineering

The invention discloses a calendaring device for a label tape. The calendaring device comprises an unwinding mechanism, a water washing mechanism, a drying mechanism, a calendaring machine and a winding machine, wherein according to the motion direction of the label tape, the water washing mechanism is in front of the drying mechanism; the drying mechanism is in front of the calendaring machine; and the winding mechanism is at the back of the calendaring machine. According to the calendaring device, the label tape calendaring efficiency is high, the surface is flat after calendaring, and the calendaring cost is reduced.

Owner:湖州领先丝带有限公司

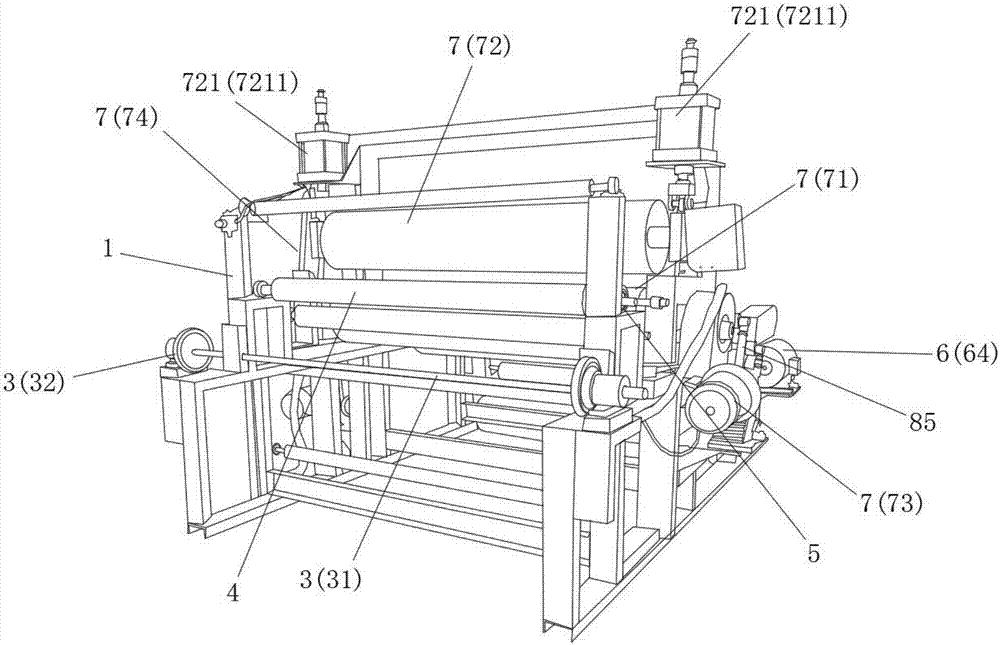

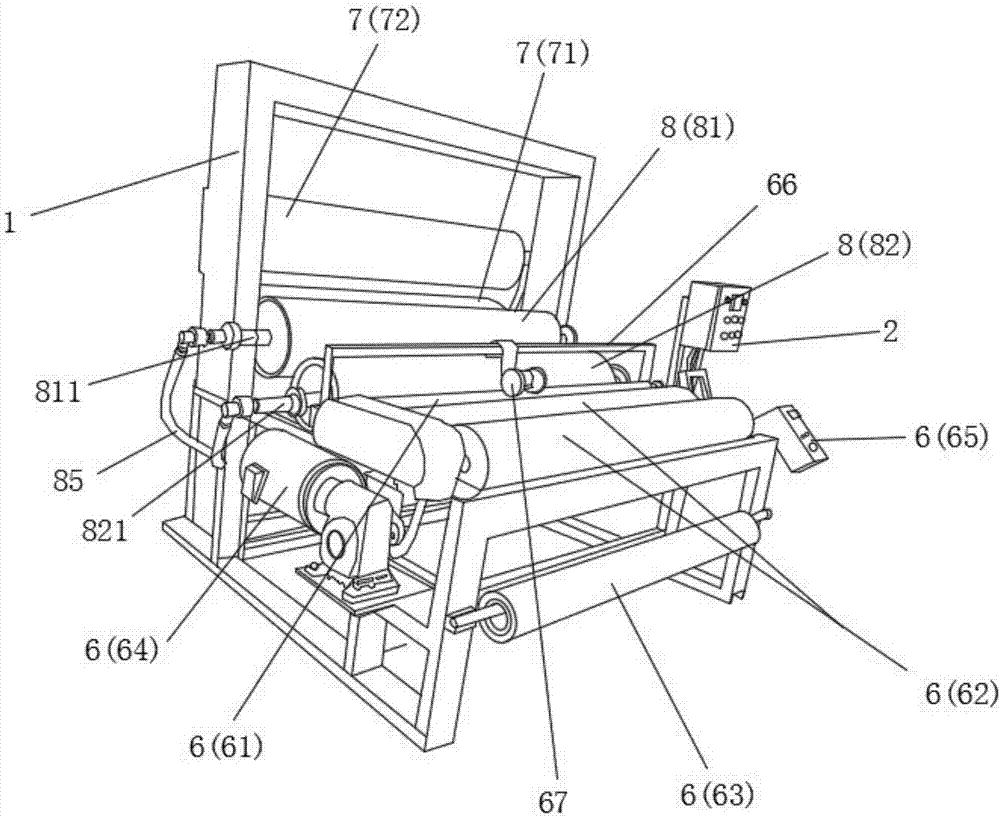

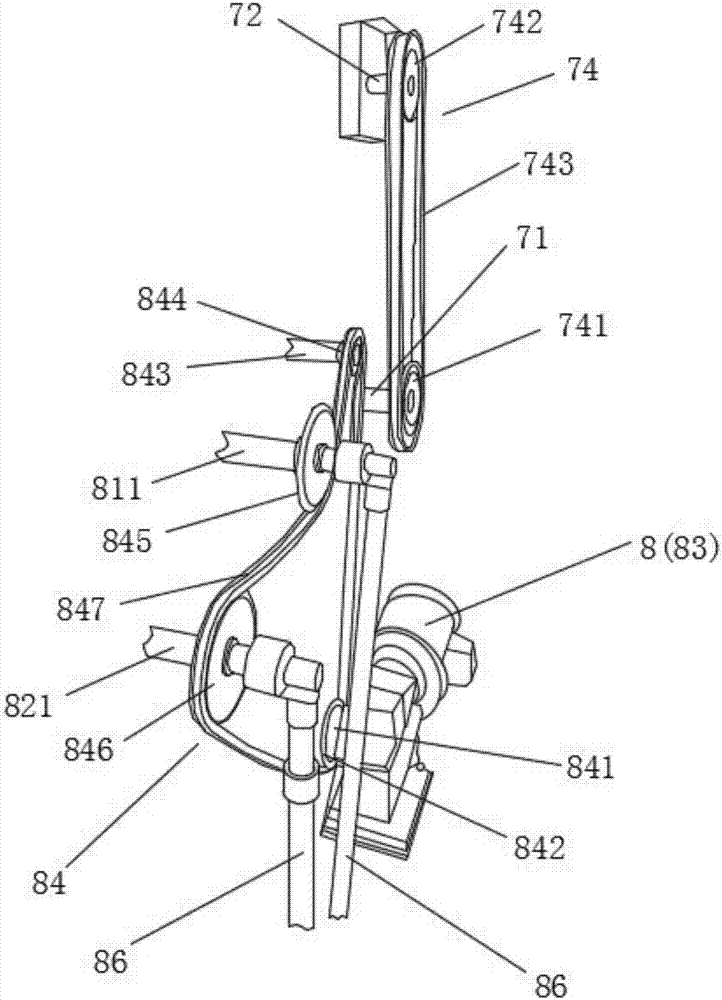

PU film and fabric lamination equipment and method

PendingCN107175879AImprove adhesionImprove bindingSynthetic resin layered productsLaminationElectric machineryDrive motor

The invention discloses PU film and fabric lamination equipment and method. The PU film and fabric lamination equipment comprises a rack, an electric cabinet, a feeding mechanism, a guide roller erected on the rack and located in front of the feeding mechanism, a flattening roller erected on the rack and located in front of the guide roller, a material collecting mechanism as well as a lamination mechanism erected on the rack and located between the flattening roller and the material collecting mechanism, wherein the lamination mechanism comprises a silica gel roller erected on the rack and located in front of the flattening roller, a heating roller erected on the rack and located right above the silica gel roller in parallel, a silica gel roller drive motor connected to the silica gel roller and the electric cabinet as well as a lamination transmission assembly connected between the silica gel roller and the heating roller. The invention further discloses a PU film and fabric lamination method based on the PU film and fabric lamination equipment. By combining the improved and optimized equipment structure and process, a PU film attached to fabric is tightly laminated on the fabric in a hot pressing manner, the adhesion between the PU film and the fabric is stronger, lamination is better, bonding performance is higher, and the overall performance of the fabric is improved.

Owner:东莞市伟欣高分子材料有限公司

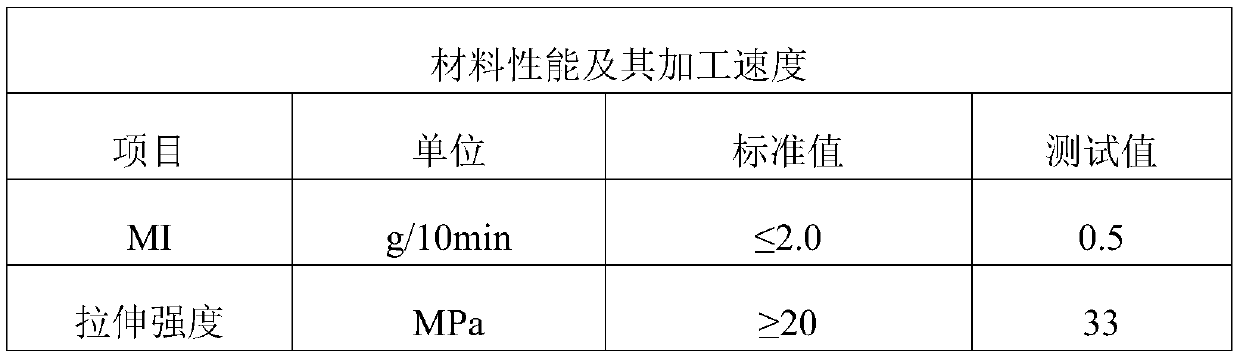

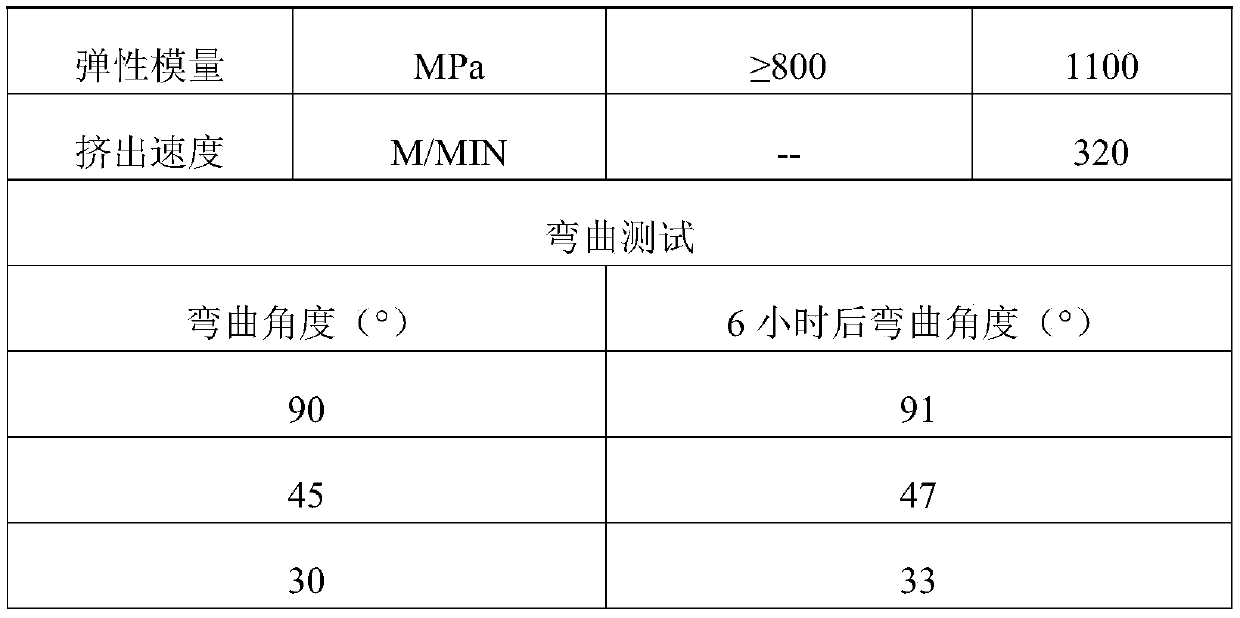

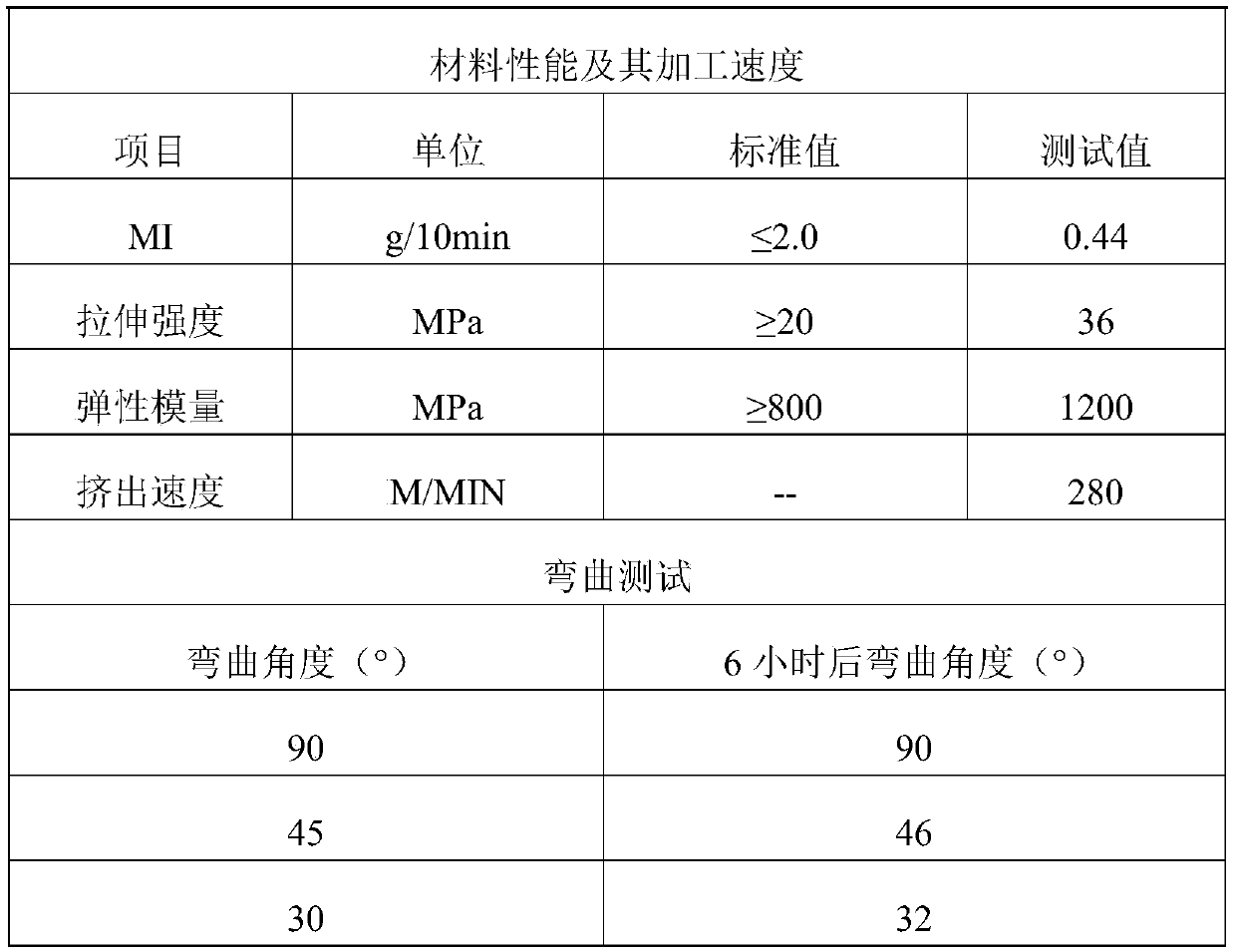

Mask all-plastic nose bridge strip polyolefin modified material and preparation method thereof

PendingCN111393732AEasy to processGood performance of arbitrary bending and settingProtective garmentSpecial outerwear garmentsFiberPolyolefin

The invention discloses a mask all-plastic nose bridge strip polyolefin modified material and a preparation method thereof. The mask all-plastic nose bridge strip polyolefin modified material comprises the following raw materials in parts by weight: 40-75 parts of polyethylene, 5-10 parts of polypropylene, 1-3 parts of a softening agent, 5-20 parts of fibers, 1-2 parts of an anti-aging agent, 0.5-1 part of a lubricating dispersant, 5-10 parts of talcum powder, 1-2 parts of a processing aid, 1-2 parts of a coupling agent and 5-10 parts of a compatilizer. The raw materials of the polyolefin modified material prepared by the preparation process provided by the invention are uniformly dispersed; the polyolefin modified material provided by the invention has excellent physical and chemical properties, has good processability and arbitrary bending and shaping properties after being extruded and processed into a nose bridge strip, is easy to compact and good in shaping effect, has convenientrecoverability and relatively high cost performance, meets the requirements of the current market on the nose bridge strip of the mask, and has good economic benefits.

Owner:广州敬信高聚物科技有限公司

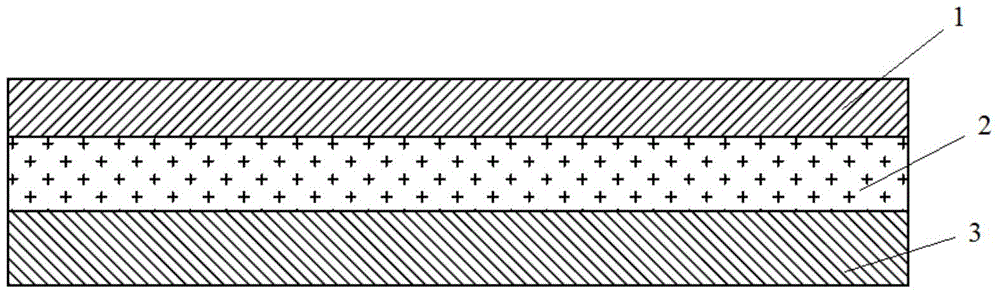

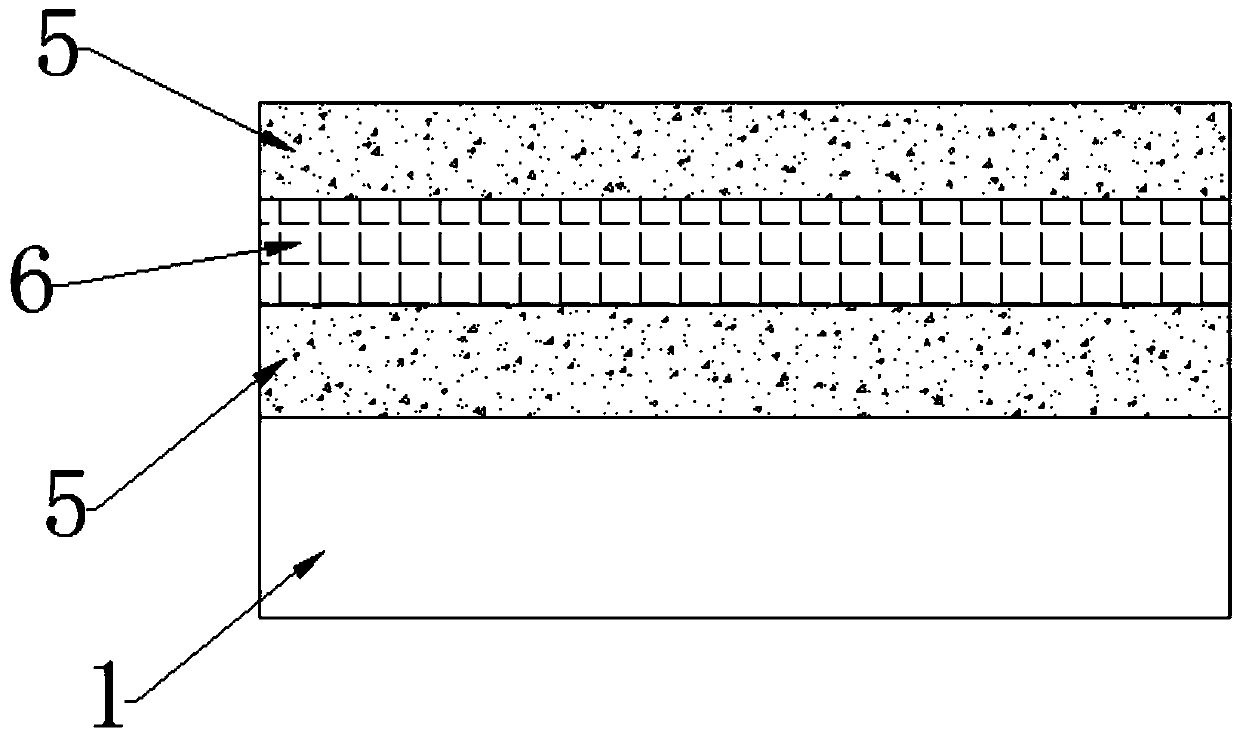

Composite fireproof material

InactiveCN105774115APlay a stereotyped roleGood heat insulationLayered productsThermal insulationFiber layer

The invention provides a composite fireproof material, which comprises a quartz sand layer (1), a fireproof rock wool layer (2), and an aluminum silicate fiber layer (3). The quartz sand layer (1) is arranged above the fireproof rock wool layer (2), the aluminum silicate fiber layer (3) is arranged under the fireproof rock wool layer (2), and the quartz sand layer (1), the fireproof rock wool layer (2), and the aluminum silicate fiber layer (3) are tightly laminated together. The fireproof rock wool layer is clamped by an upper quartz sand layer and a lower aluminum silicate layer so as to fix the fireproof rock wool layer to a certain degree; at the same time, the external quartz sand layer has a good thermal insulation effect, the fireproof load of the center layer and inner layer is relieved in a certain degree; the composite fireproof material has the advantages of simple structure and low cost, and a good fireproof function can be realized through simple structural improvement.

Owner:TIANJIN KANGKAI PIPELINE ENG CO LTD

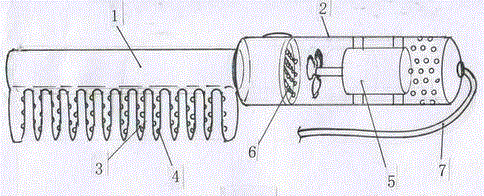

Electric hair drier comb

InactiveCN104414103AAccelerateGood effectHair dryingElectrical and Electronics engineeringTubes types

The invention provides an electric hair drier comb. A plurality of hollow comb teeth are connected to the lateral side of an air tube type comb body; an integral hollow handle is connected to the tail end of the air tube type comb body; and an electric hair drier device capable of blowing out hot air through the hollow comb teeth is installed in the hollow handle. When the electric hair drier comb is used, the electric hair drier device of the hollow handle can be started to blow out the hot air through the hollow comb teeth, so that wet hairs can be dried directly when the hairs are combed. As the hot air is blown out through the hollow comb teeth directly, the electric hair drier comb has the beneficial effects of being rapid and good in effect.

Owner:XIANGYANG VOCATIONAL & TECHN COLLEGE

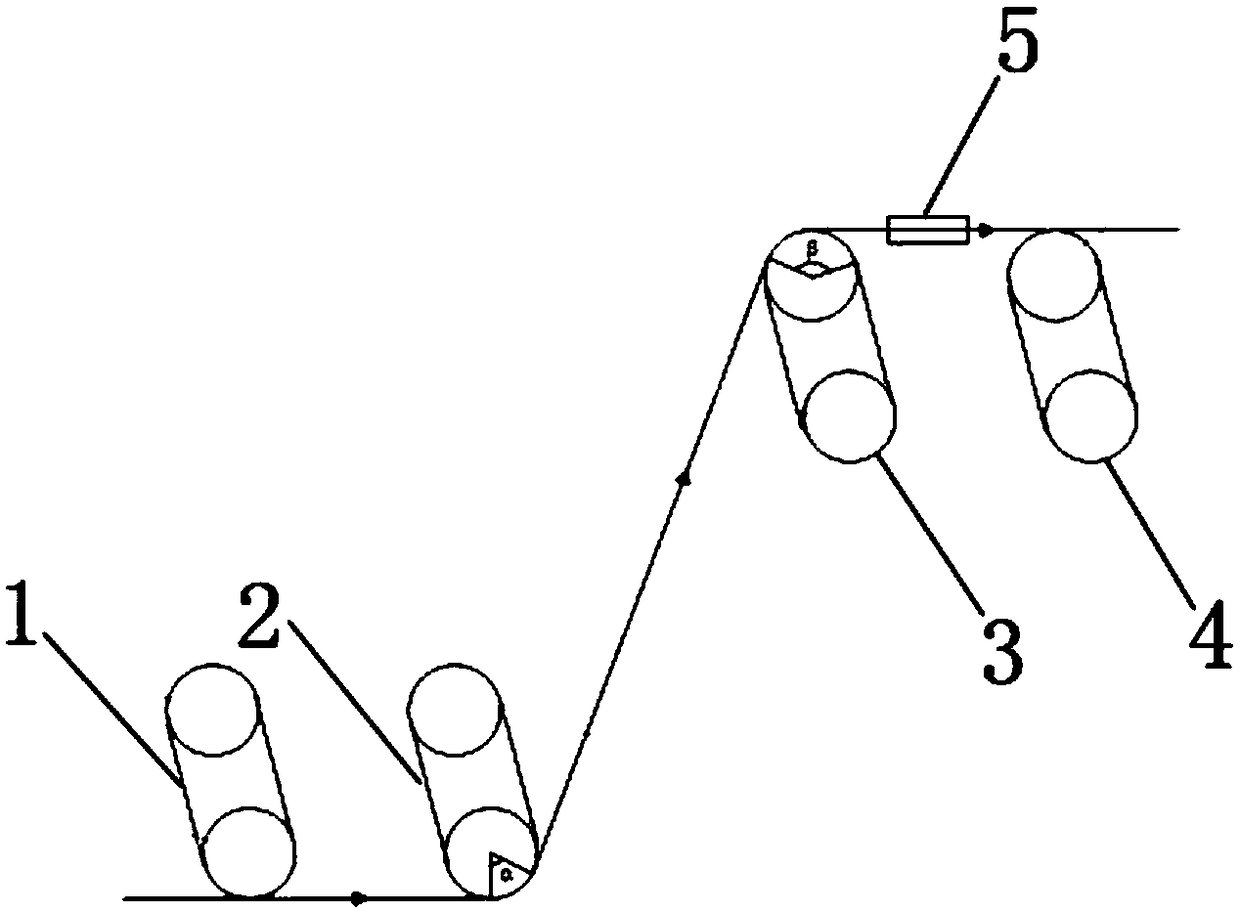

Multi-stage drafting device and method for nylon 6 high-strength yarn

The invention relates to a multi-stage drafting device and method for nylon 6 high-strength yarn, wherein the drafting device comprises a first drafting hot roller, a second drafting hot roller, a third drafting hot roller and a drafting cold roller which are sequentially arranged in parallel, the first drafting hot roller and the second drafting hot roller are horizontally arranged, and the thirddrafting hot roller and the drafting cold roller are horizontally arranged, the third drafting hot roller is positioned to the upper right of the second drafting hot roller, and a hot plate is arranged between the third drafting hot roller and the drafting cold roller. The drafting method includes: the temperature of the first drafting hot roller is set to be 50-70 DEG C, the temperature of the second drafting hot roller is set to be 100-120 DEG C, the temperature of the third drafting hot roller is set to be 160-180 DEG C, the temperature of the hot plate is set to be 180-190 DEG C, and thedrafting multiple between the first drafting hot roller and the second drafting hot roller is 1.90-2.60, the drafting multiple between the second drafting hot roller and the third drafting hot rolleris 1.40-1.80, and the drafting multiple between the third drafting hot roller and the drafting cold roller is 1.05-1.25. The device can enhanced the shaping effect of the nylon 6 filament, improve thetenacity of the filament, and enhance the strength of the filament by raising the orientation degree of the filament.

Owner:DONGHUA UNIV +1

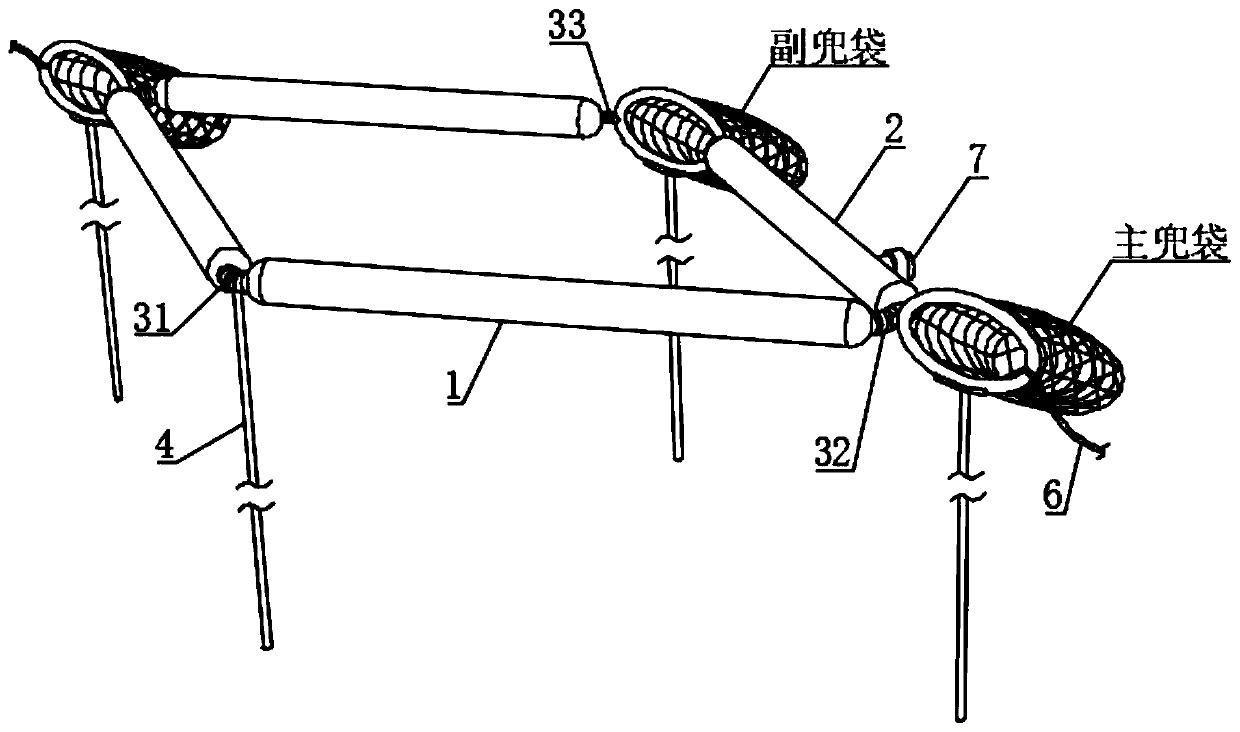

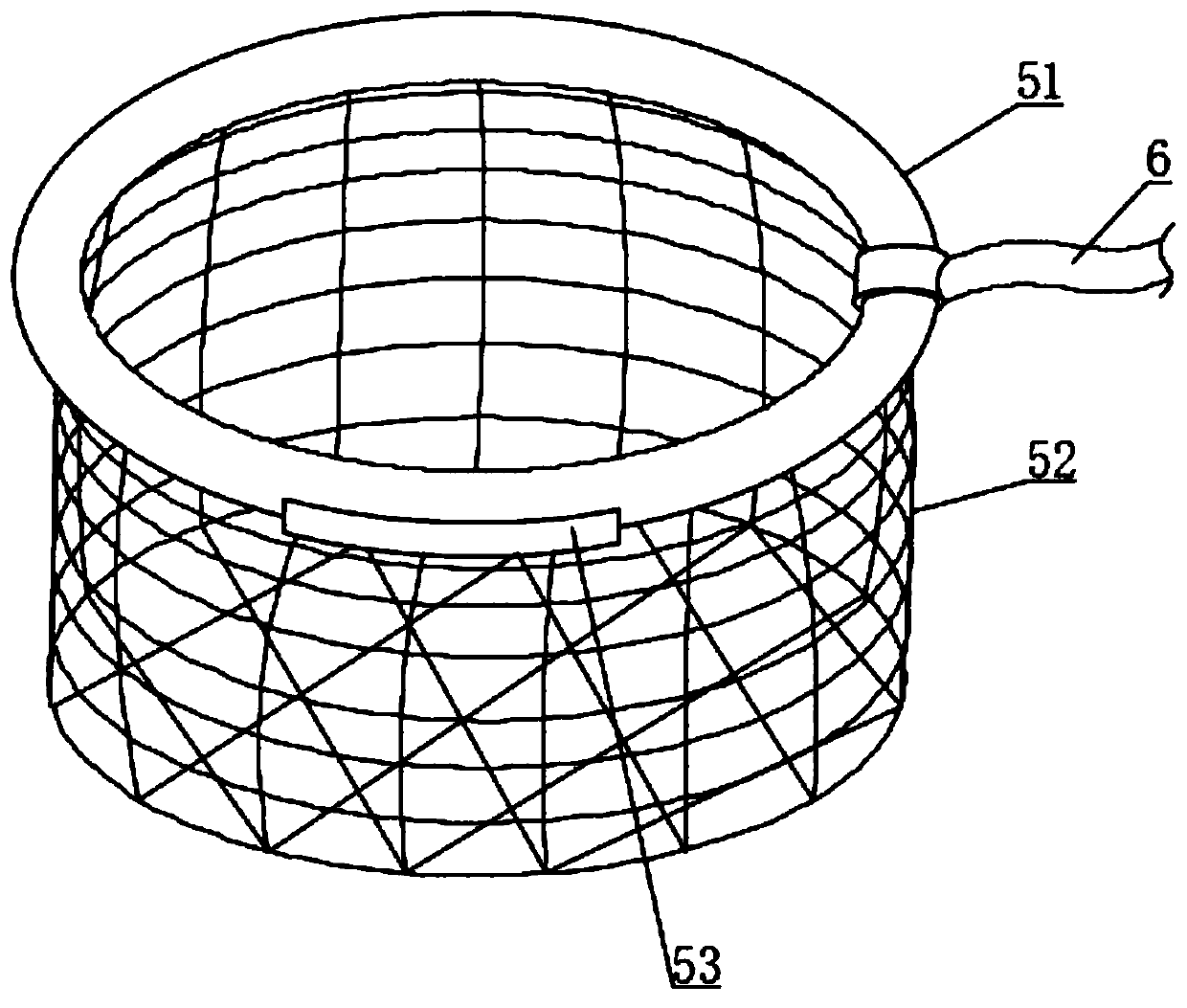

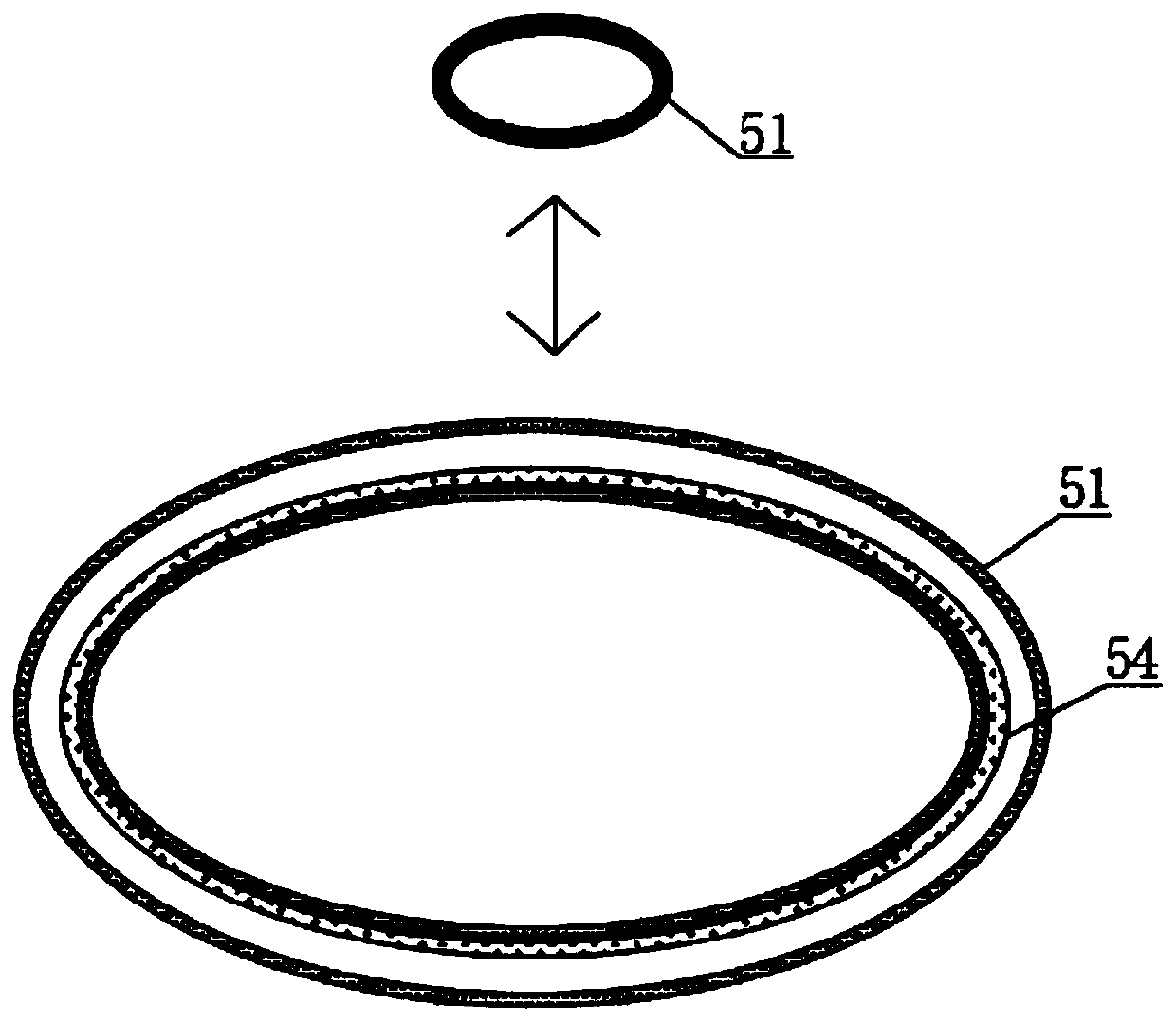

Adaptive deformation multi-effect intercepting device for riverway floating garbage

ActiveCN111501700AStrong environmental adaptabilityNot easy to intercept and missWater cleaningMeteorologyEngineering

The invention discloses an adaptive deformation multi-effect intercepting device for riverway floating garbage, and belongs to the field of riverway garbage intercepting devices. The device is characterized in that firstly, the device can deform according to the width of a riverway and adjust the length of the whole device, so that the device has good environmental adaptability; then, double interception on the floating garbage is realized through main floating rings and auxiliary floating rings, so that interception omission is not prone to occurring, and the interception effect is comprehensive; in addition, through cooperative use among the main floating rings and main pockets, the garbage intercepted for the first time is collected, and through cooperative use among the auxiliary floating rings and an auxiliary pocket, the garbage intercepted for the second time is collected, so that unnecessary manual collection stage is reduced, and the condition of secondary loss of the garbageis reduced; and when the main floating rings, the auxiliary floating rings or net opening annular bags leak air, under the elastic contraction of elastic rings, the net opening annular bags are drivento gather inwards, so that the openings in the main pockets and the auxiliary pocket are tightened inwards, and the garbage is not prone to flying out.

Owner:江苏中兴水务有限公司

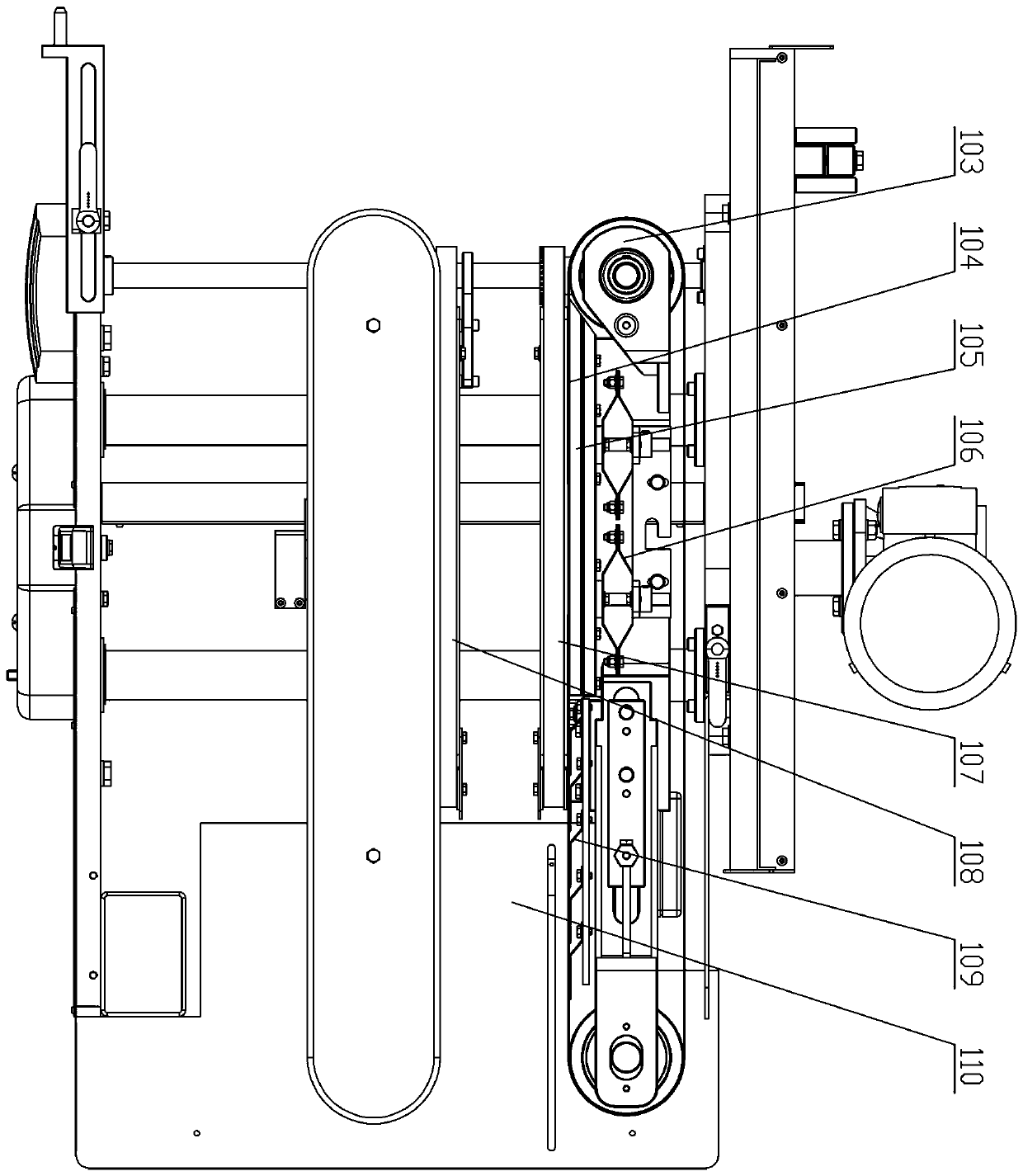

Side sealing mechanism

PendingCN111547314AAvoid stickingPlay a stereotyped roleWrapper twisting/gatheringTransmission beltEngineering

The invention discloses a side sealing mechanism. The side sealing mechanism comprises a rack, a left heat sealing component and a right heat sealing component, a side sealing channel is formed between the left heat sealing component and the right heat sealing component, and the side sealing mechanism is characterized in that the side sealing channel is divided into a heat sealing part and a shaping part; the left heat sealing component and the right heat sealing component each comprise a transmission wheel, a transmission belt arranged on the transmission wheel, a heating assembly and a buffer shaping assembly, the heating assembly and the buffer shaping assembly are arranged in the transmission belt, the transmission belt is vertically arranged, and the heating assembly is arranged behind the buffer shaping assembly. The left heat sealing component and the right heat sealing component convey products during heat sealing, the products enter the shaping part after heat sealing and extrude the heat sealing part to achieve a shaping effect, so that the sealing effect is improved until the products are conveyed out through the transmission belt, the products are conveyed out in time instead of staying at a heat sealing station, film adhesion of the front products and the rear products is avoided, and the product is not influenced by heat radiation, so that the packaging quality isgreatly improved.

Owner:温州优博特机械有限公司

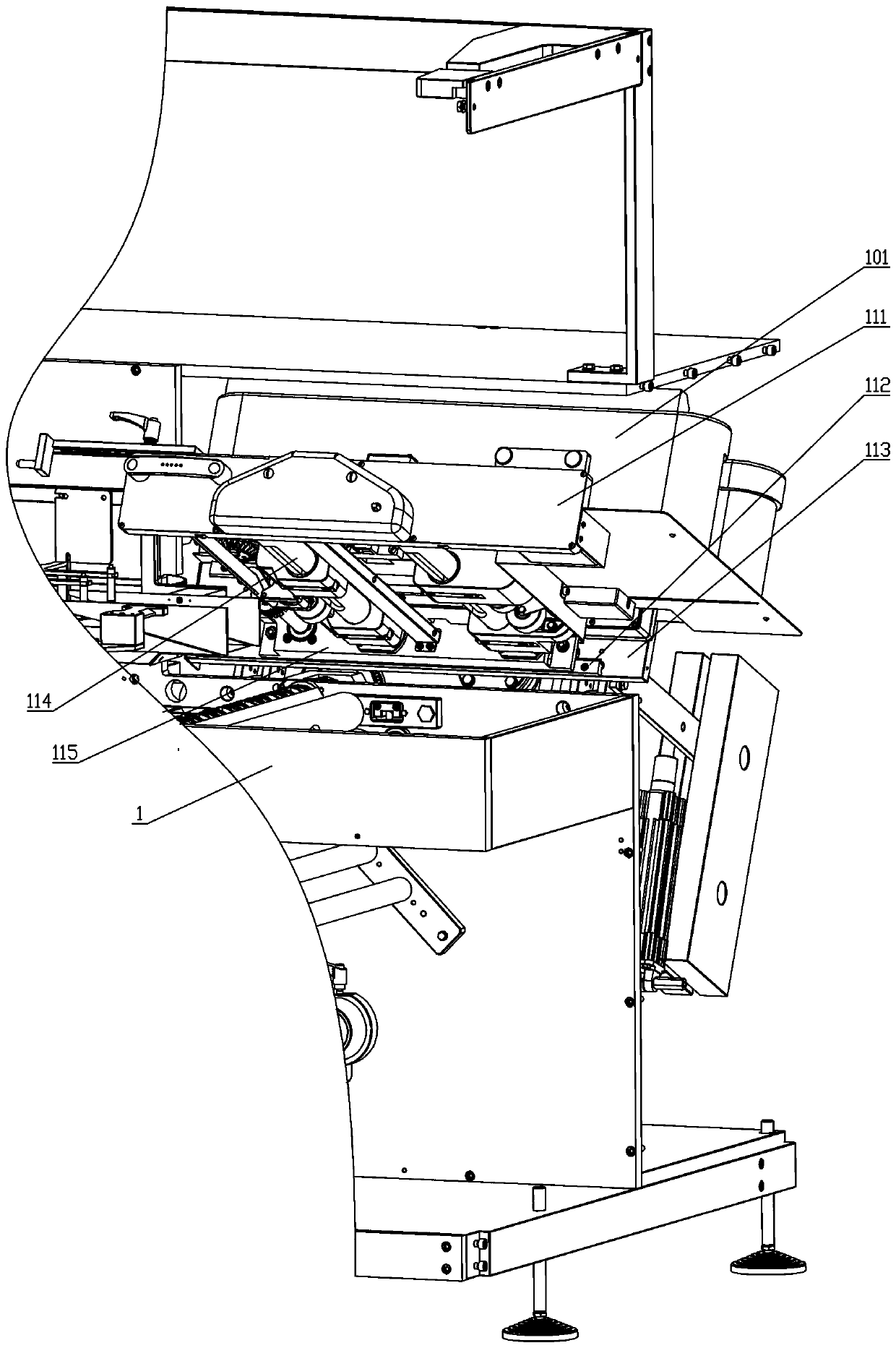

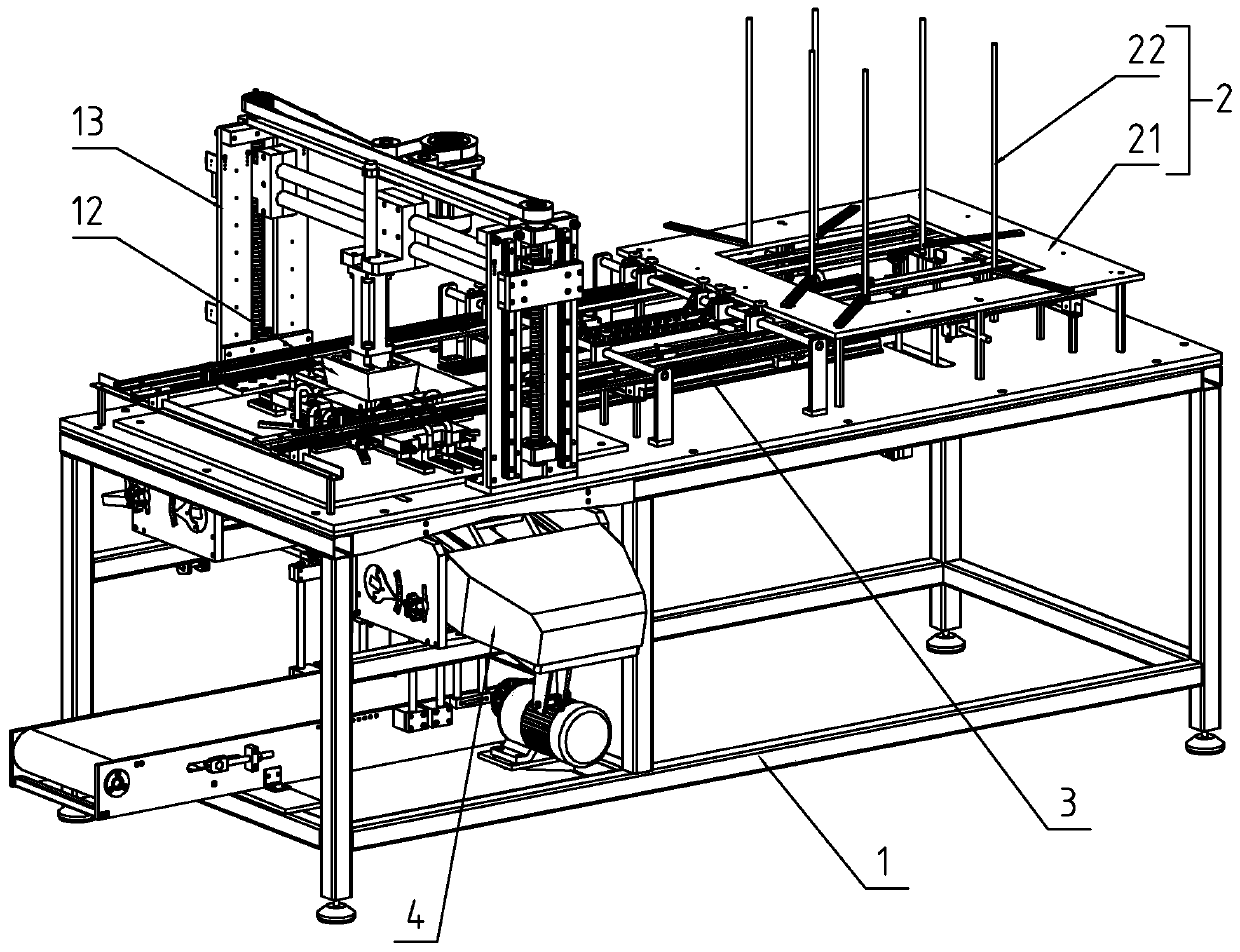

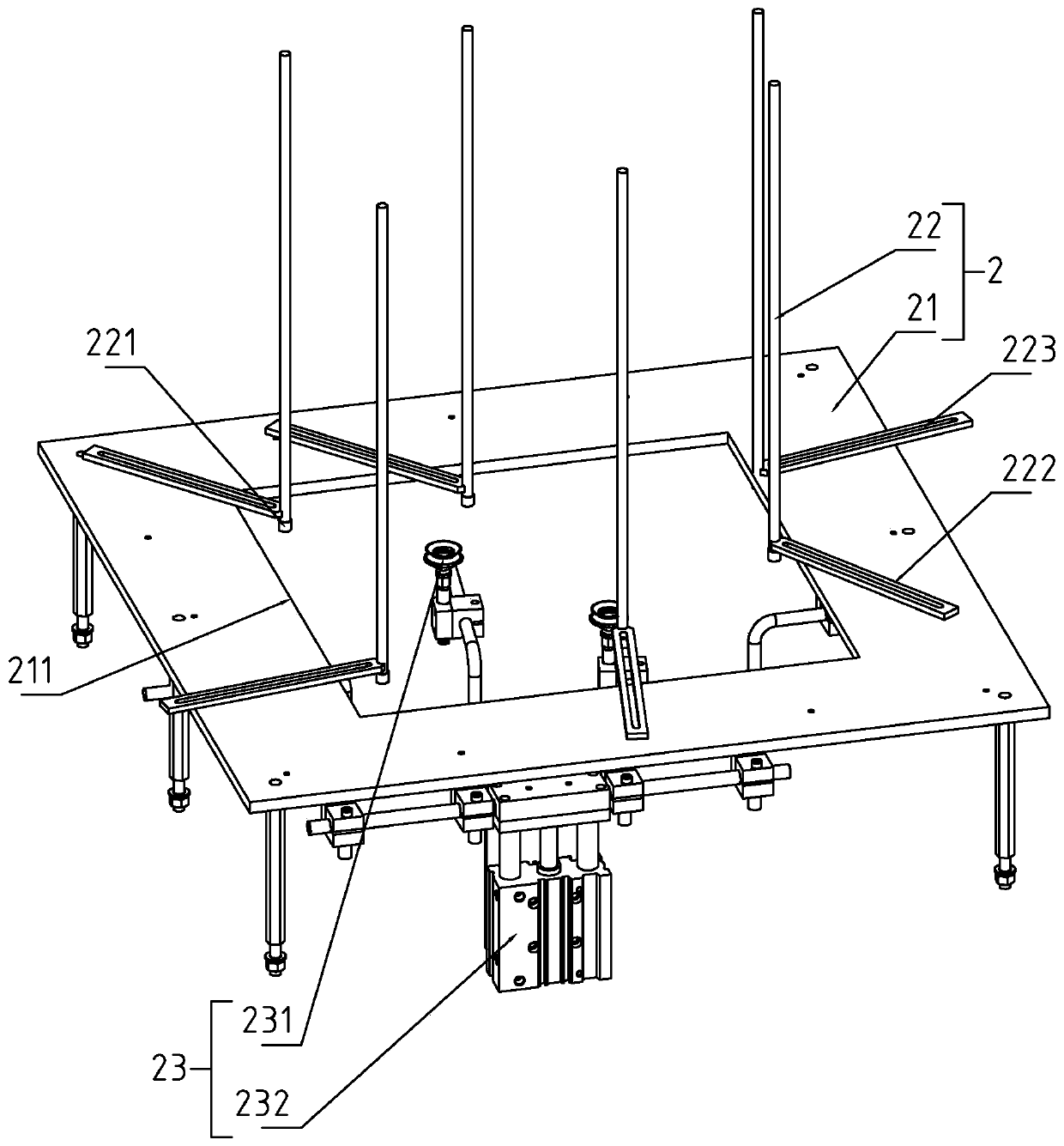

Packaging box forming machine

PendingCN109719994ARealize automatic feedingImprove the flexibility of usePaper-makingBox making operationsMolding machinePaperboard

The invention discloses a packaging box forming machine. The main points of the technical scheme of the packaging box forming machine include a machine frame, a feeding platform, a feeding device andan ultrasonic generator; the feeding platform includes a feeding bottom plate and a feeding rod, wherein the feeding rod is rotatably connected to the feeding bottom plate in a slippage mode, a material falling outlet is formed in the feeding bottom plate, the feeding rod is provided with a limiting material falling structure, and a feeding mechanical arm is arranged under the feeding platform; the machine frame is provided with a paperboard passage, and a sending board mechanism is arranged at a feeding inlet position of the paperboard passage; the sending board mechanism includes a sending board push head and a sending board driving device, and the sending board push head includes a pushing and sending surface and a butting surface; bearing boards are arranged on the periphery of the paperboard passage; a bearing driving device for driving the bearing boards to move close to or away from the paperboard passage is arranged on the machine frame; and the sending board push head can be matched with the bearing boards to clamp and shape paperboards into packaging box shapes in the process of pushing and sending the paperboards into the paperboard passage. The packaging box forming machine can improve the automation degree and the application scope of packaging box processing, and is beneficial to improving the production efficiency.

Owner:浙江国豪机械有限公司

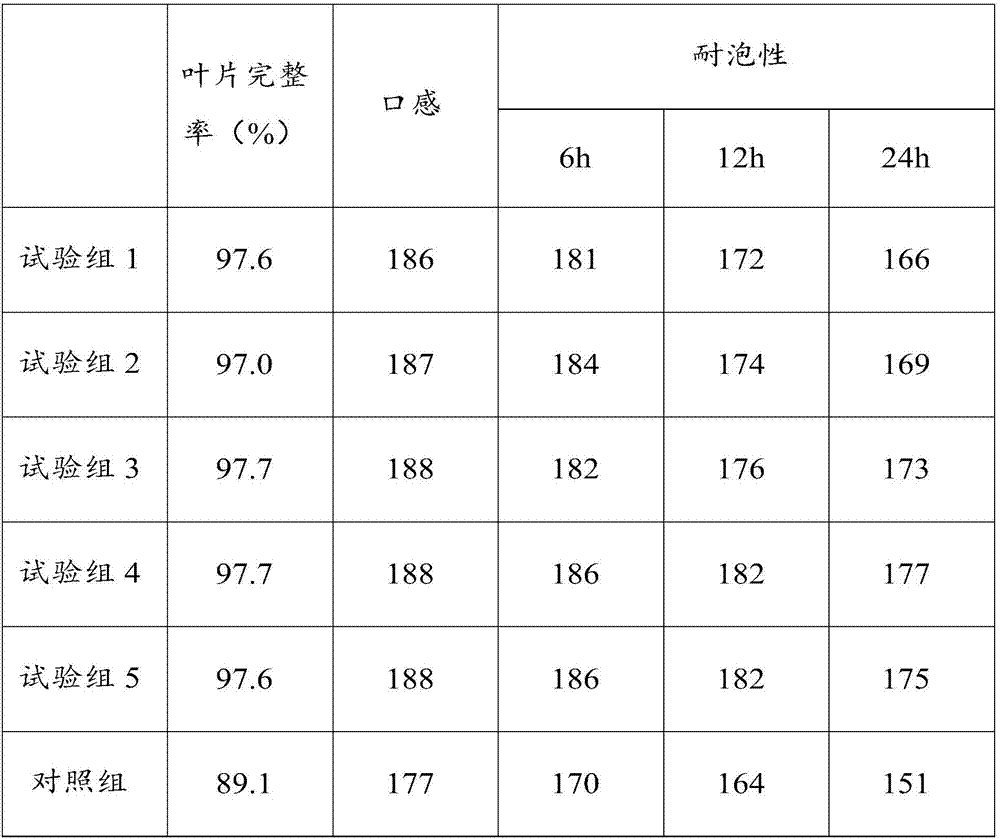

Disc-flower-shaped granular cyclocarya tea and processing method thereof

The invention relates to disc-flower-shaped granular cyclocarya tea and a processing method thereof, and belongs to the field of food processing. The processing method comprises the following steps of using cyclocarya leaves as raw materials, performing tedding under the condition of 15-25 DEG C until the water content of the raw materials is 78-82%, and performing fixation, resurgence, twisting, dehydration and fermentation so as to obtain primary products; and frying the primary products, so as to obtain disc-flower-shaped granular cyclocarya tea. The processing method is simple and easy to operate, the cost is low, and the time consumption is low. The disc-flower-shaped granular cyclocarya tea processed by the method is not liable to break, the complete percentage of leaves is high, and the disc-flower-shaped granular cyclocarya tea is easy to store and transport. In addition, the infusing extract of the disc-flower-shaped granular cyclocarya tea processed by the method disclosed by the invention is high, and the disc-flower-shaped granular cyclocarya tea is sweet and refreshing in taste, and high in soaking resistance.

Owner:QIANDONGNAN SENLINWANG TAXUS CHINENSIS DEV CO LTD

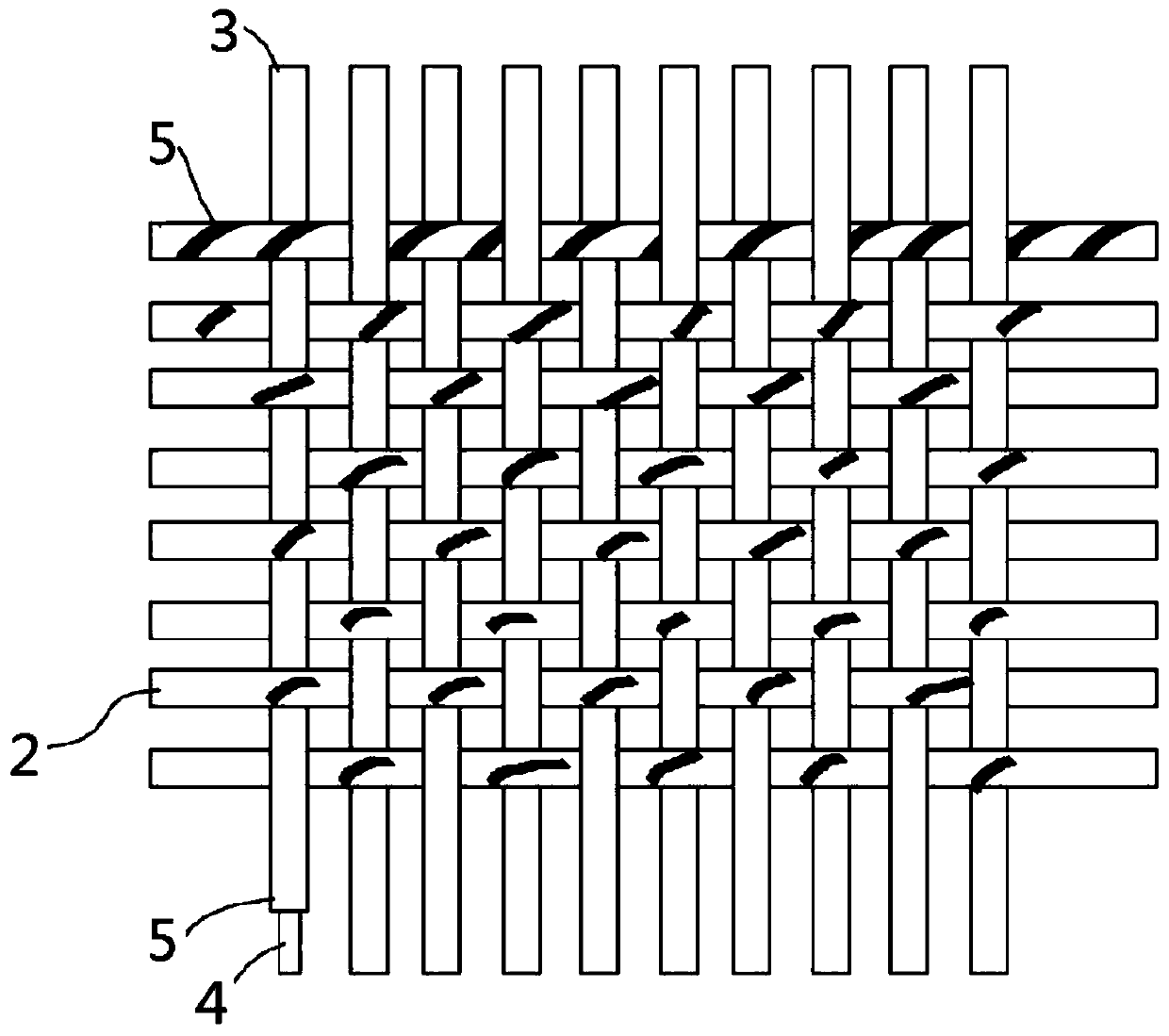

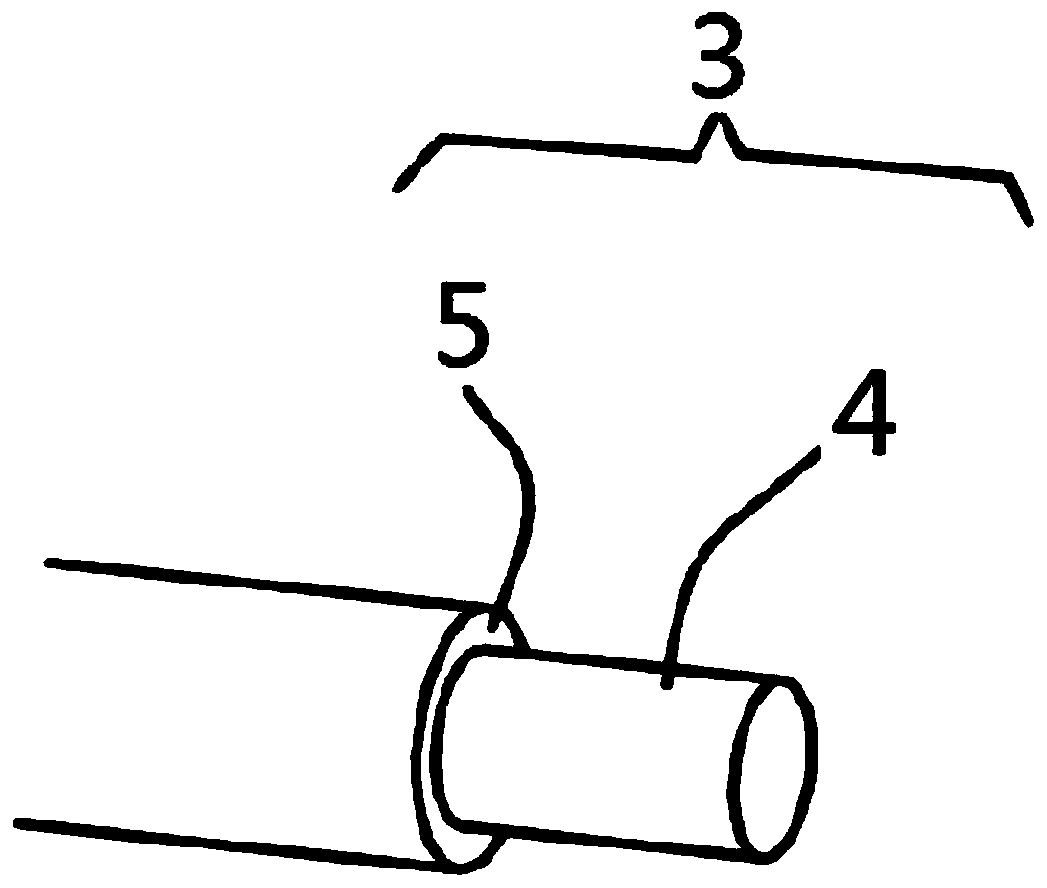

Safety lining cloth with excellent moisture transferring and heat conducting performance and production process thereof

InactiveCN110284333AImprove cooling effectGuaranteed breathabilityGarment special featuresFibre typesSurface layerHeat conducting

The invention discloses safety lining cloth with excellent moisture transferring and heat conducting performance and a production process thereof. The safety lining cloth comprises base layer safety lining cloth, wherein the base layer safety lining cloth is formed through plain weave of warp and weft yarns, the weft yarn is an elastic monofilament, the outer surface of the monofilament is also covered with a composite adhesive layer, and the composite adhesive layer comprises 70-80 parts of a hot melt adhesive, 5-10 parts of Teflon and 3-5 parts of nano-graphene oxide; the safety lining cloth also comprises hygroscopic fiber cloth arranged at the upper side face of the base layer safety lining cloth, wherein the lower side face of the hygroscopic fiber cloth is bonded with the base layer safety lining cloth through the composite adhesive layer on the upper side face of the base layer safety lining cloth, and the upper side face of the hygroscopic fiber cloth is also provided with a point-shaped or strip-shaped or grid-shaped composite adhesive layer. The lining cloth has the excellent moisture transferring, sweat discharging and heat conducting performance, the process comprises preparation of a composite adhesive, yarn making, preparation of the base layer safety lining cloth, improvement of moisture absorbing and transferring and heat conducting performance of the base layer safety lining cloth, preparation of an initial safety lining cloth product and surface layer sizing, the process is simple, and the practicability is strong.

Owner:张家港市杨舍镇美捷配饰设计工作室

Manufacture method of memory metal sheet of circuit breaker for vehicle

ActiveCN101937785AStable stateStable physical propertiesMetal-working apparatusElectric switchesSizingMetal alloy

The invention relates to a manufacture method of a memory metal sheet of a circuit breaker for a vehicle, belonging to the manufacture method of the metal sheet. The memory metal sheet with more stable motion can be obtained. The manufacture method comprises the steps of: 1, preheating, and heating to 20-40 DEG C; 2, punching; 3, blanking, and punching a strip metal alloy into a rectangular metal sheet with length of 16mm, width of 9.5mm and corner radius of 4.75mm; 4, thermally treating, carrying out thermal treatment in a vacuum thermal treatment furnace at a temperature of 20-40 DEG C; 5, welding a connecting sheet; 6, welding a moving contact; 7, pressing for three times: pre-profiling pressing, secondary-profiling pressing and sizing pressing, wherein the pressure of a cylinder in each pressing is 10MPa, and the pressing time is 2s; and 8, cutting to form the memory metal sheets of the circuit breaker for the vehicle, which are symmetrically along the center line. The memory metal sheet of the circuit breaker for the vehicle, which has good stability, can be obtained by adopting the manufacture method.

Owner:AEROSPACE HI TECH HLDG GROUP

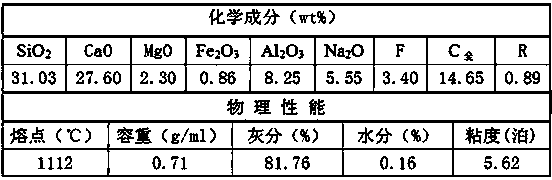

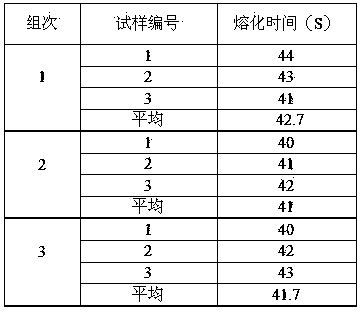

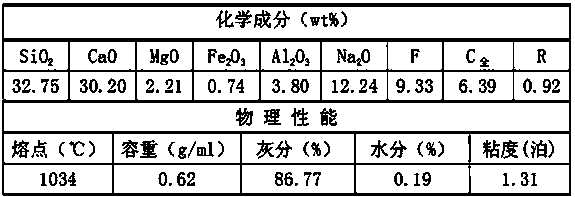

Method for measuring melting rate of covering slag

ActiveCN103792251AThe amount of sand is consistentGood reproducibilityInvestigating phase/state changeSlagMagnesite

The invention discloses a method for measuring the melting rate of covering slag. According to the method, the molten covering slag is absorbed by utilizing magnesite, a measuring end-point is determined based on the complete melting absorption of the covering slag, and the melting rate is judged according to the time period needed from putting of a covering slag sample to complete melting of the sample. The detection end-point time is not needed to be judged according to the melting shape of the covering slag, the influence of subjective factors in a previous slag column test method is overcome, the test phenomenon is intuitive, and the reproducibility is obviously improved. Moreover, the melting rate of the covering slag can be directly and accurately tested without calculation, the operation is rapid and convenient, instruments are not needed to be purchased additionally, a ceramic square boat filled with the magnesite can be repeatedly used, the detection material is saved, and the test cost is reduced.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

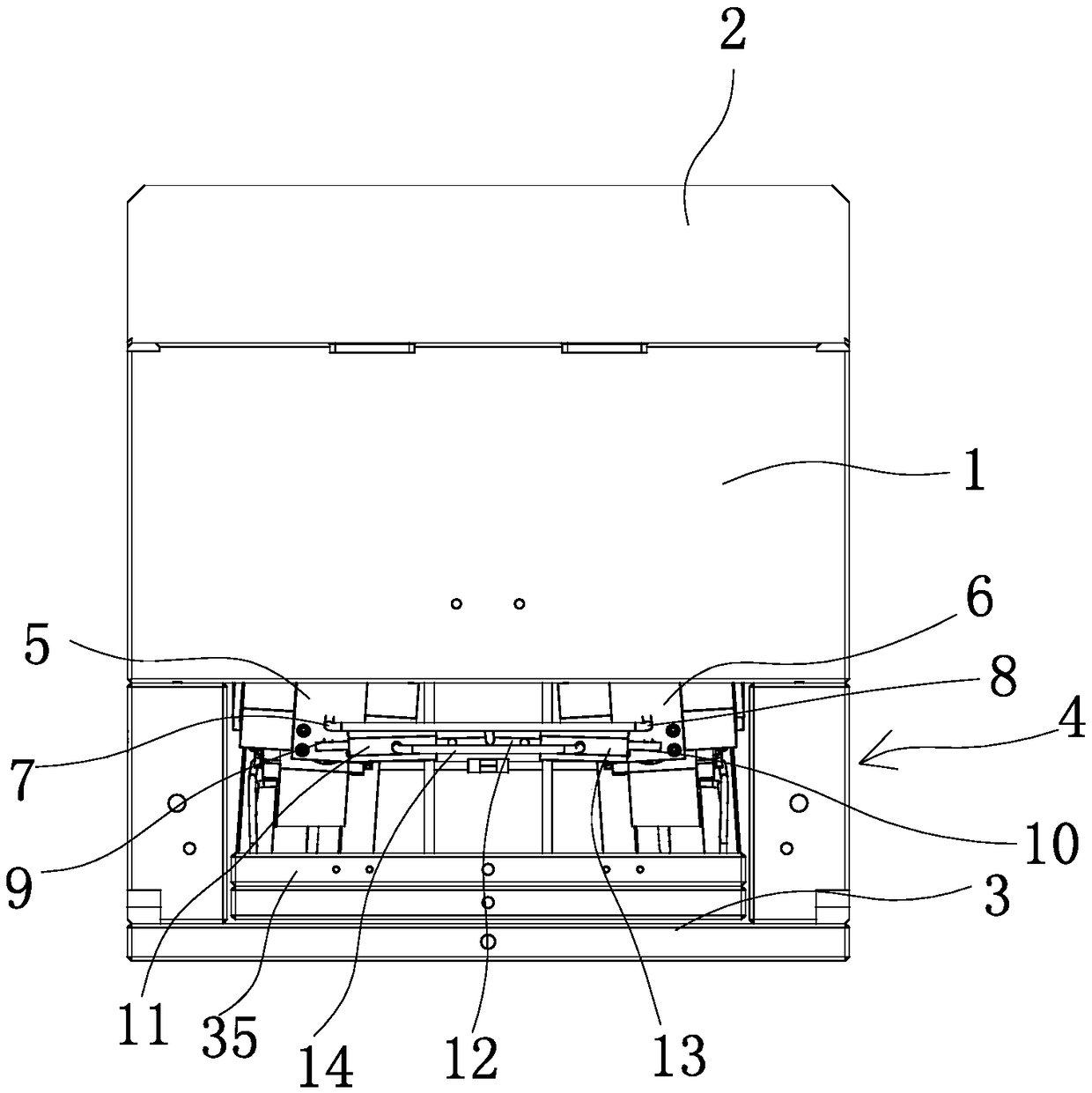

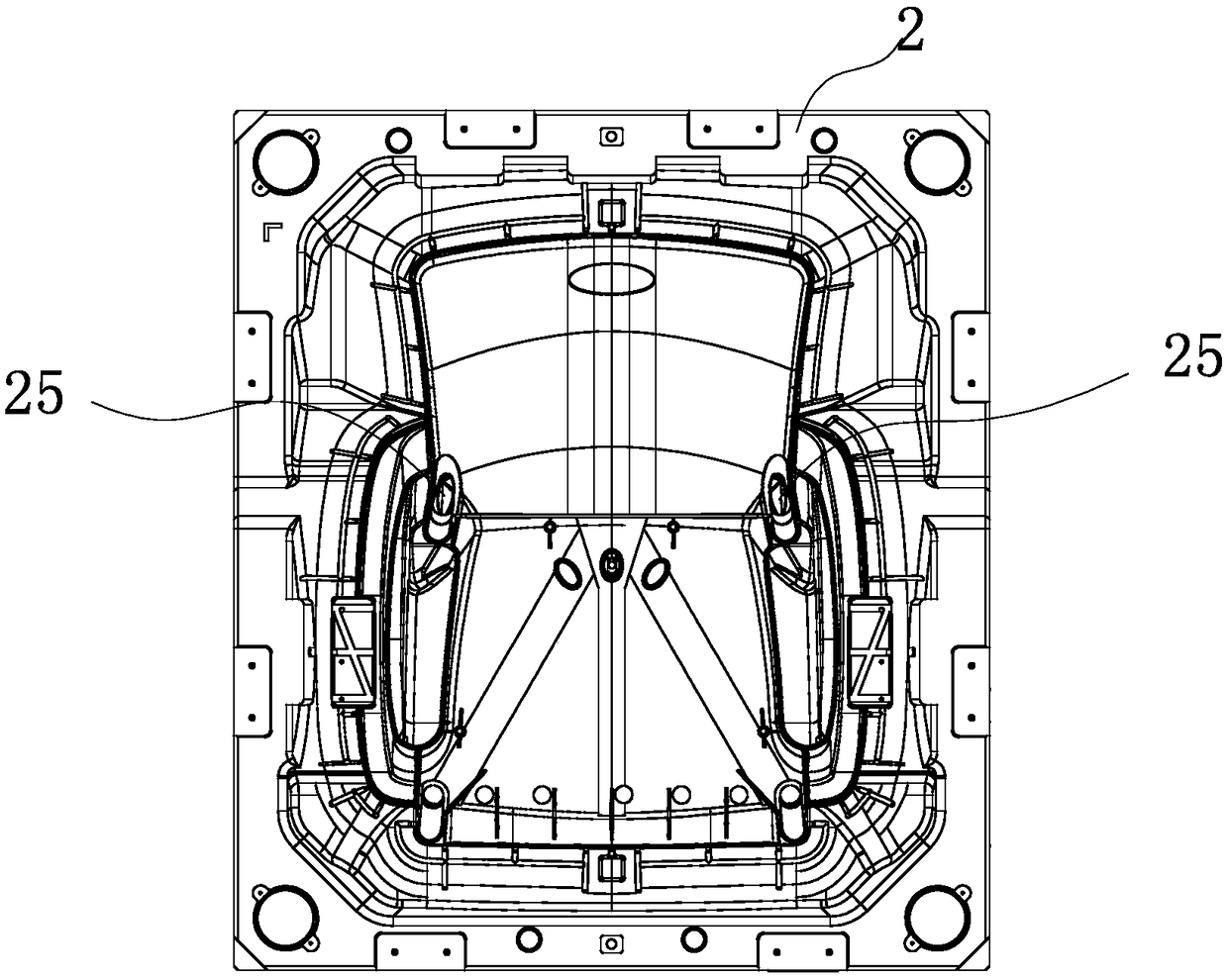

Non-leg plastic chair injection mold with sliding block loose-core mechanism

PendingCN108688083AAvoid deformationPlay a stereotyped roleDomestic articlesEngineeringOil distribution

The invention belongs to the field of injection molds, and relates to a non-leg plastic chair injection mold with a sliding block loose-core mechanism. The technical problems that in the prior art, chair leg inserting holes are poor in suction synchronism and deformation is prone to occur on a no-leg chair are solved by the chair injection mold. The chair injection mold comprises a movable template, a fixed template and a movable mold base plate, two chair leg inserting hole core pulling structures are arranged below the movable template, and first oil distribution plates and second oil distribution plates are arranged on the two chair leg inserting hole core pulling structures, a first oil distribution channel and a second oil distribution channel are formed in the first oil distributionplates, a third oil distribution channel and a fourth oil distribution channel are arranged on the second oil distribution plate, the first oil distribution channel is connected with the third oil distribution channel, and the second oil distribution channel is connected with the fourth oil distribution channel. Compared with the prior art, the non-leg plastic chair injection mold with the slidingblock loose-core mechanism has the advantages that loose cores of the chair leg inserting hole are synchronic, chair leg inserting holes are not prone to be deformed.

Owner:TAIZHOU BONA MOLD

Preparation method of rancidity shaped heat storage material

InactiveCN108841361AImprove lipophilicityPlay a protective effectHeat-exchange elementsMethacrylateFiber

The invention relates to a preparation method of a rancidity shaped heat storage material, and belongs to the technical field of heat storage material preparation. In the heat storage material prepared by the invention, biomass oil and nano-carbon fibers are firstly mixed and in rancidity, the biomass oil is in the rancidity and hydrolyzed by microorganisms under high-temperature and high-humiditysealing conditions to generate a large amount of fatty acids and free ester groups, and monomeric methacrylate is polymerized to form a rigid hard colorless transparent material, thereby being capable of ensuring that a matrix does not deform or melt when the fatty acids are melted, playing a role of protecting the matrix, and further achieving a shaping effect. On the other hand, the free estergroups generated by the rancidity are introduced to the surfaces of the nano-carbon fibers under the action of the microorganisms, and high thermal-conductivity nano-carbon fibers are introduced to the composite shaped heat storage material, so that the thermal conductivity of the composite shaped heat storage material can be enhanced. The rancidity shaped heat storage material prepared with the method is not easy to leak, high in thermal conductivity and broad in application prospects.

Owner:王雪峰

Setting equipment for packaging box forming machine

PendingCN109774238APlay a stereotyped roleHigh degree of automationPaper-makingBox making operationsCardboardMolding machine

The invention discloses setting equipment for a packaging box forming machine. According to the technical scheme, the setting equipment comprises ultrasonic generators and a bracket; the bracket is provided with a paperboard channel, a paperboard pushing mechanism is arranged at a feeding inlet of the paperboard channel and comprises a paperboard pushing head for pushing paperboards, and a paperboard pushing driving device for driving the paperboard pushing head; the paperboard pushing head comprises a pushing surface abutting against the paperboard for forming the bottom of a packaging box, and abutting surfaces which are located on the periphery of the pushing surface and used for abutting against the paperboards for forming the sides of the packaging box; the periphery of the paperboardchannel is provided with a receiving plate which can abut against the outer side walls of the paperboards which are fed into the paperboard channel and used for forming the packaging box; the bracketis provided with a receiving driving device which is used for driving the receiving plate to go close to or go away from the paperboard channel; and the paperboard pushing head can cooperate with thereceiving plate to clamp and set the paperboards into a packaging box shape in the process of pushing the paperboards into the paperboard channel. Through the setting equipment, the automation degreeof the packaging box forming machine can be increased, and the production efficiency is advantageously improved.

Owner:浙江国豪机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com