Spreading mechanism and spreading method for organic matter solid waste treatment device

A treatment device and organic matter technology, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems that affect the normal use of the device, and the sludge cannot be evenly laid, and achieve improvement The effect of laying efficiency, improving laying quality and laying efficiency, improving laying quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

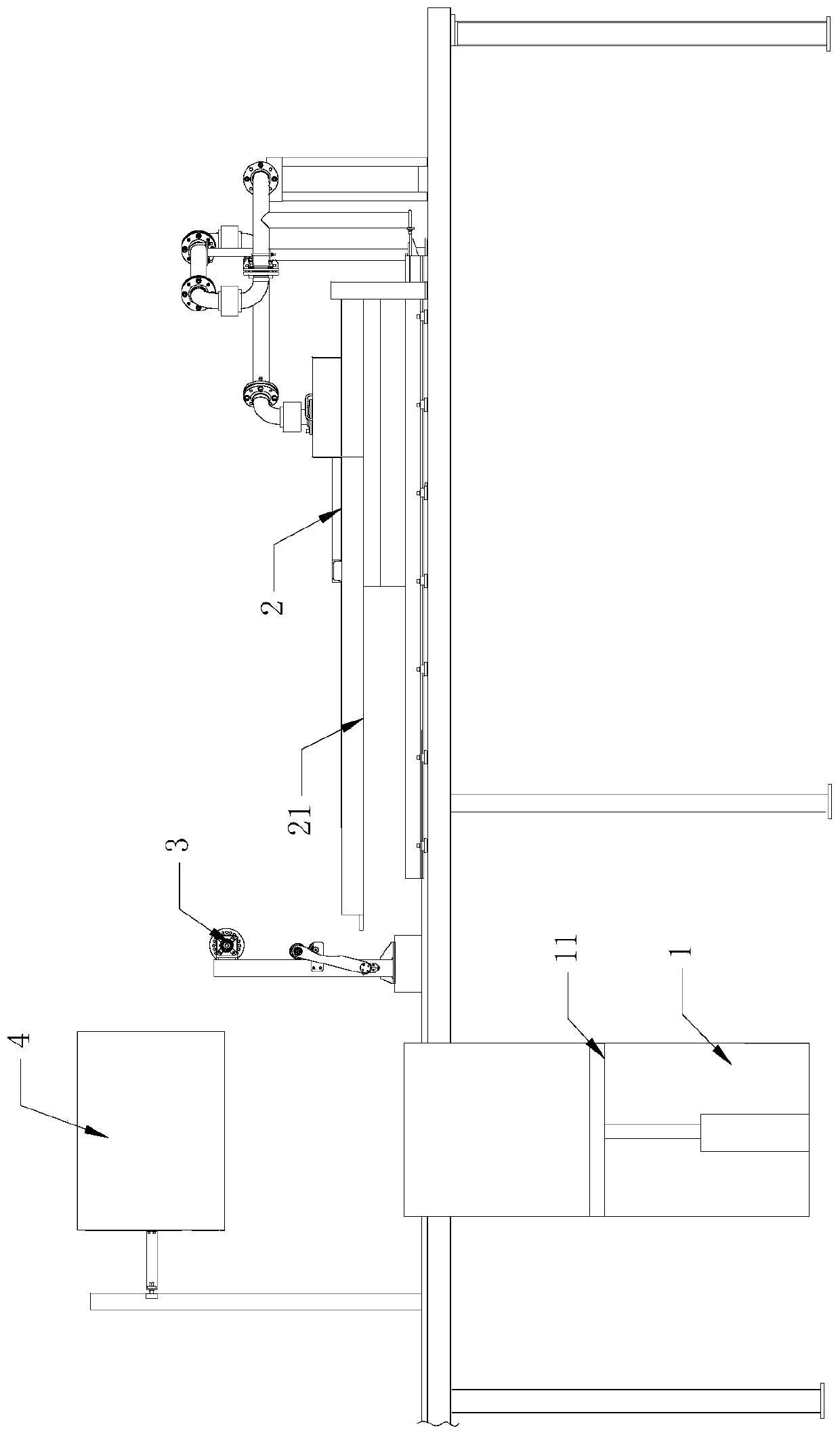

[0042] A material spreading mechanism for an organic solid waste treatment device, such as figure 1 As shown, it includes a filter cloth press chamber 1, a material bed 2, and a cloth roll frame 3 for providing filter cloth, wherein a pallet 11 that can be lifted and moved is arranged in the filter cloth press chamber 1, and the material bed 2 includes The reciprocating material spreading part 21 and the cloth rolling frame 3 are arranged between the material spreading bed 2 and the filter cloth pressure filter chamber 1 .

[0043] When this embodiment is working, such as Figure 7 As shown, the tray 11 rises to the top of the filter cloth pressure filter chamber 1, and the material spreading part 21 moves forward to the cloth rolling frame 3. Since the filter cloth 7 is in front of the material spreading part 21, the front end of the material spreading part 21 is at the top. As the middle part of the filter cloth 7 moves forward, the upper and lower parts of the filter cloth...

Embodiment 2

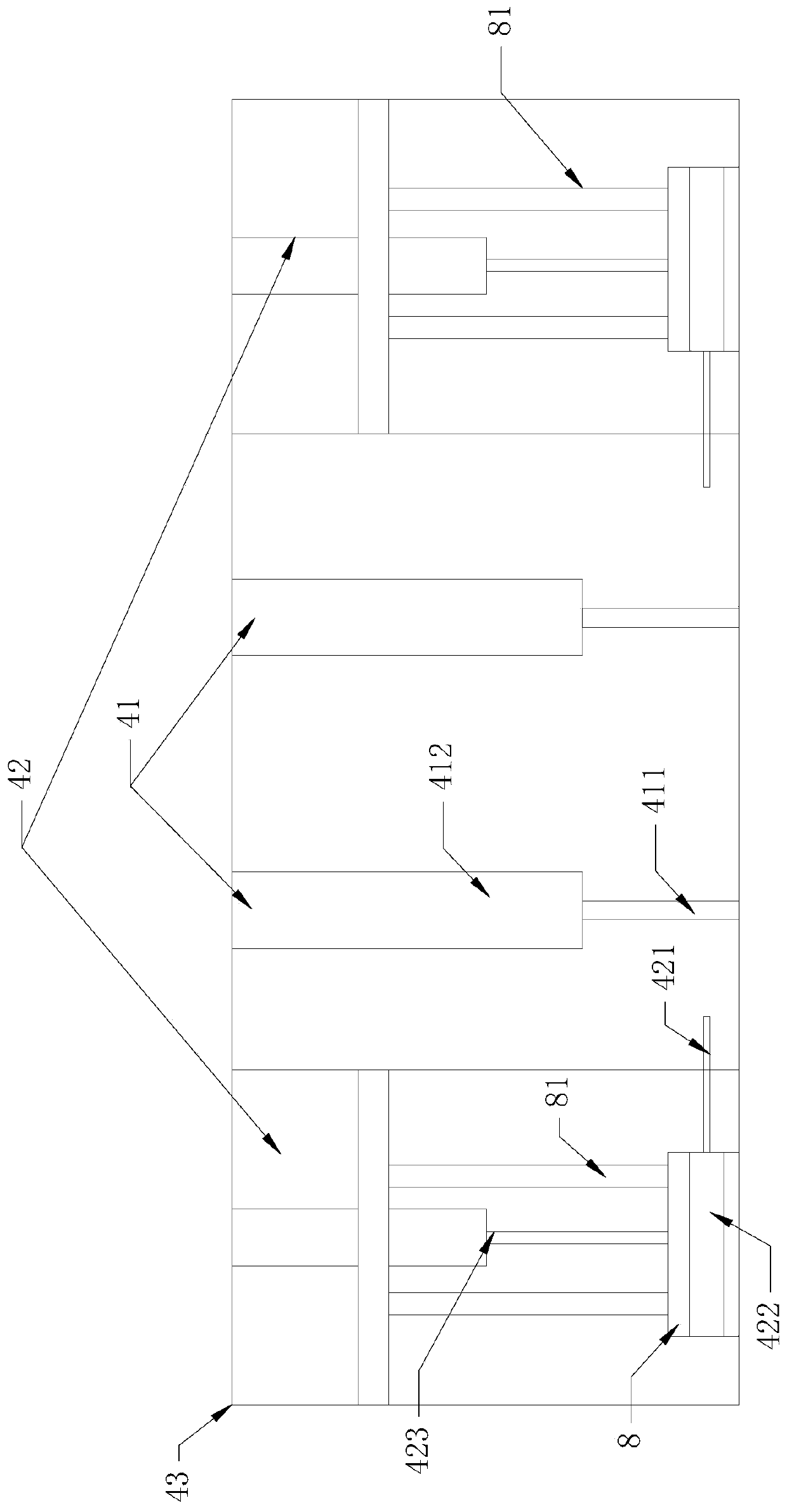

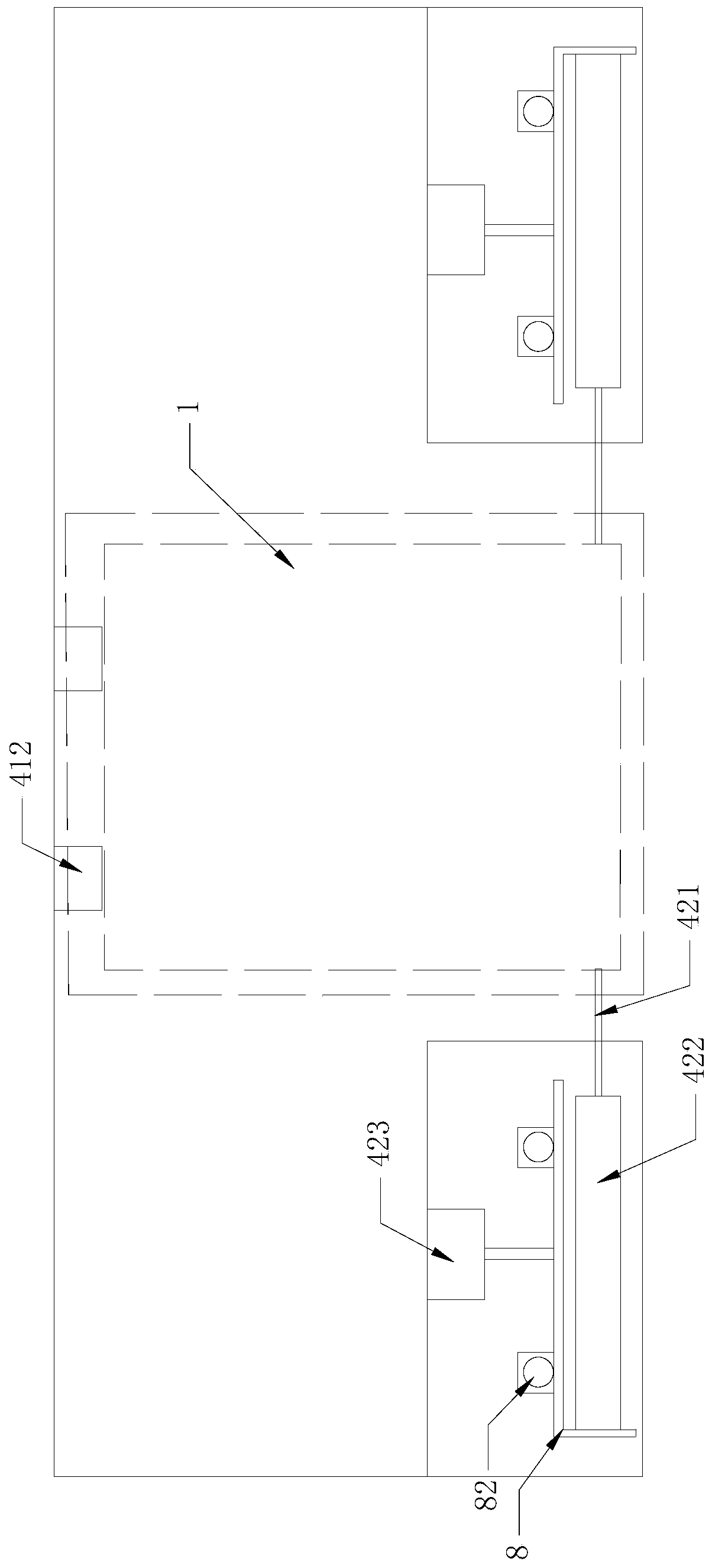

[0046] On the basis of Embodiment 1, a material laying mechanism for an organic solid waste treatment device in this embodiment further includes a filter cloth stopper 4 , and the filter cloth stopper 4 is arranged above the filter cloth pressure filter chamber 1 . Such as figure 1 with figure 2 As shown, the filter cloth limiting part 4 includes a first limiting part 41 and a second limiting part 42, the first limiting part 41 is arranged on the side of the filter cloth pressure filter chamber 1 away from the cloth rolling frame 3, and the second The limiting portion 42 is arranged on a side of the filter cloth press chamber 1 close to the cloth roll frame 3 .

[0047] Wherein, the first limiting portion 41 includes several first pressing members 411, one end of the first pressing members 411 is connected with the piston rod of the first cylinder 412, and the first pressing members 411 and the first cylinder 412 are arranged vertically;

[0048] The second limiting part 42...

Embodiment 3

[0057] The present embodiment describes the specific structure of the material bed 2 on the basis of embodiment 1, as Image 6 As shown, according to the conveying direction of organic solid waste, the material spreading part 21 includes a main pipeline 211, a material distribution part 212 and a number of material spreading pipelines 213 connected in sequence. one end.

[0058] The material spreading bed 2 also includes a base 22, the material spreading portion 21 is arranged on the base 22, the base 22 is provided with a telescopic mechanism for the material spreading portion 21 to reciprocate, and the base 22 is also provided for the material spreading portion 21 to reciprocate slide.

[0059] A positioning plate 5 is also provided on the end of the material spreading portion 21 close to the fabric rolling frame 3 , and a groove 51 is provided on the positioning plate 5 to cooperate with the first pressing member 411 .

[0060] When this embodiment is in use, the material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com