Patents

Literature

47results about How to "Play a tension role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

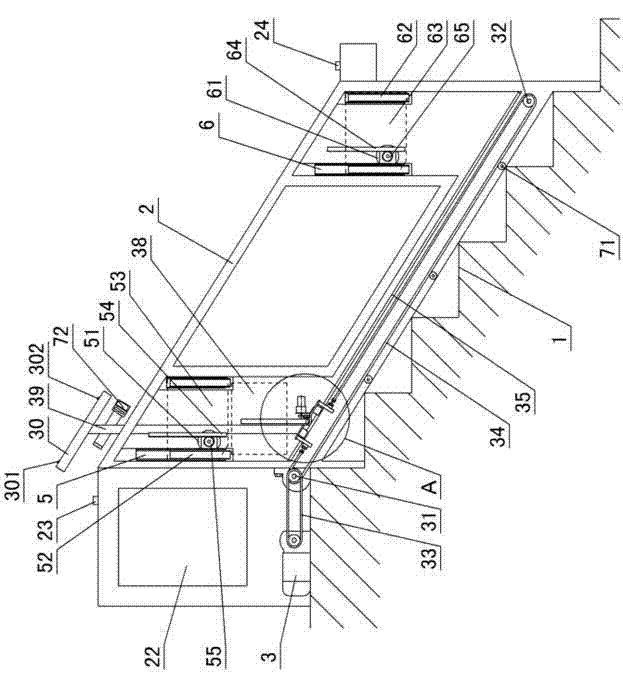

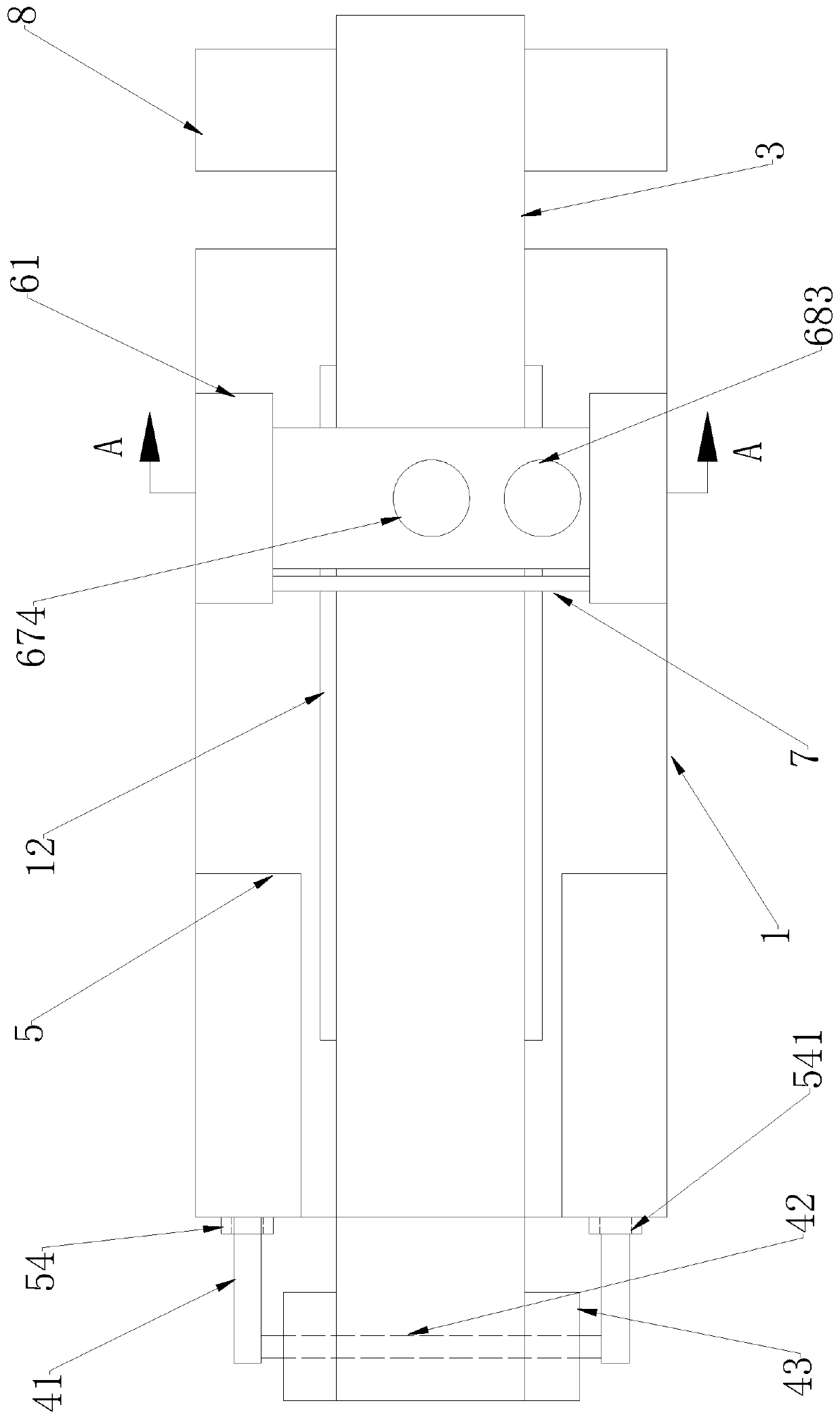

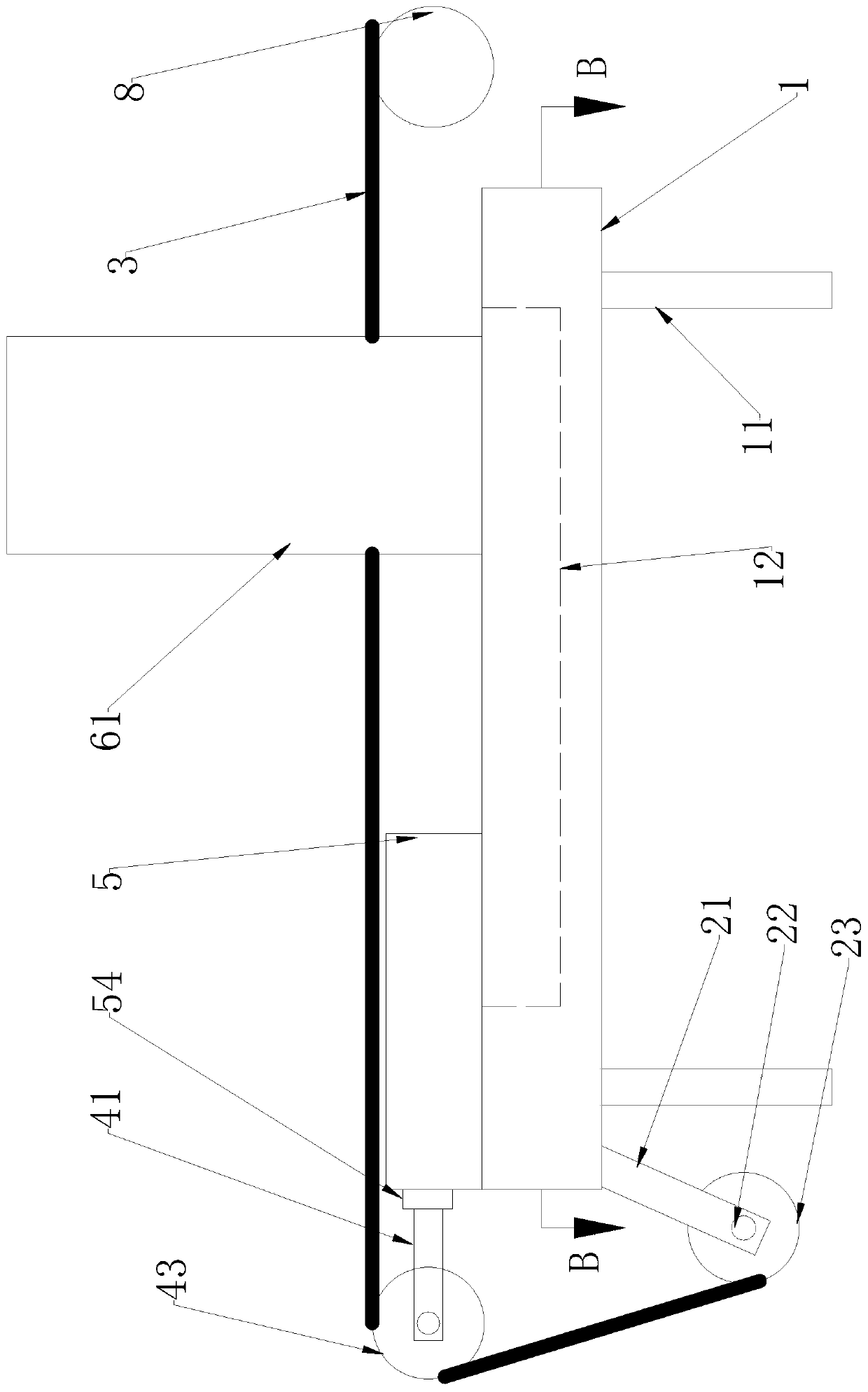

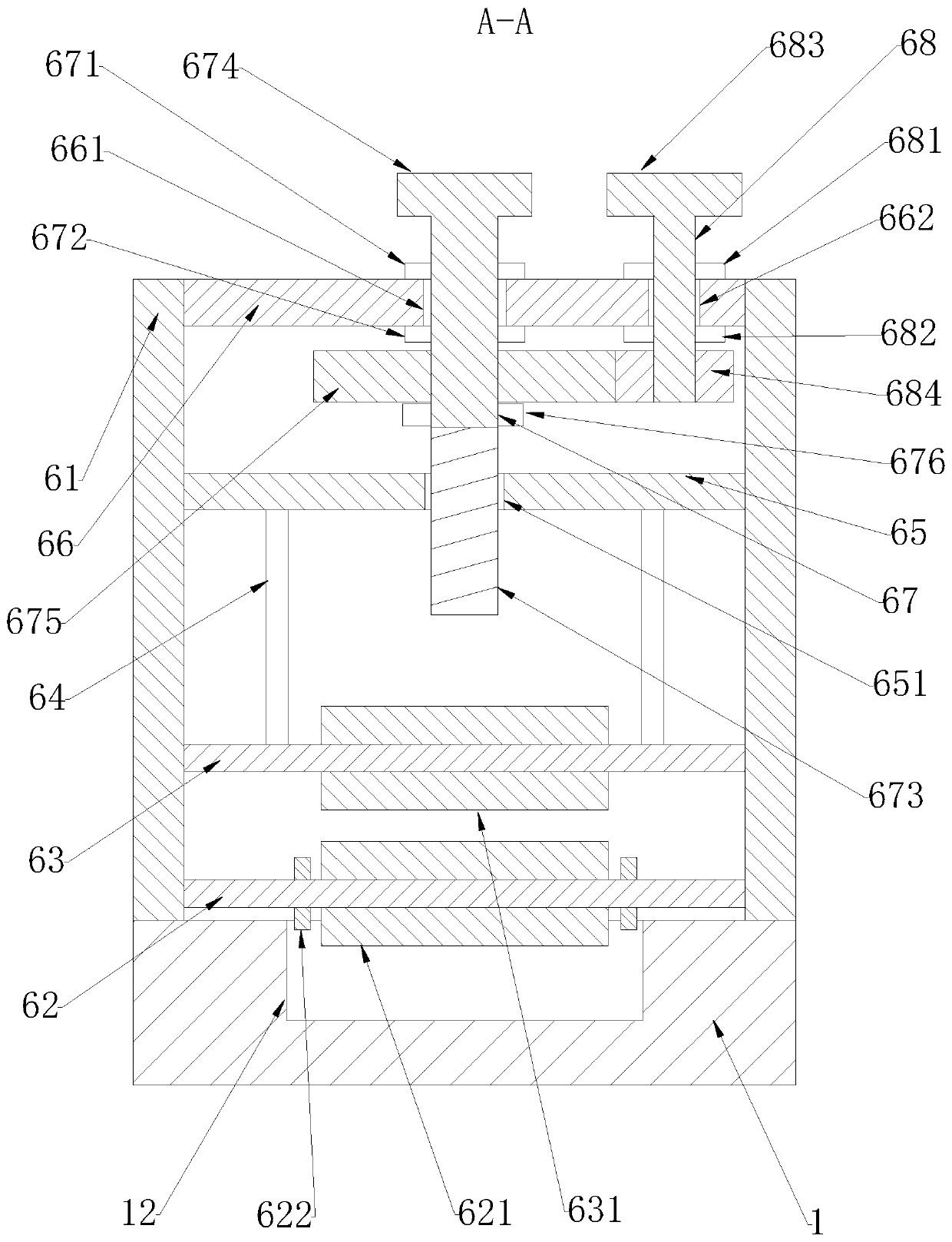

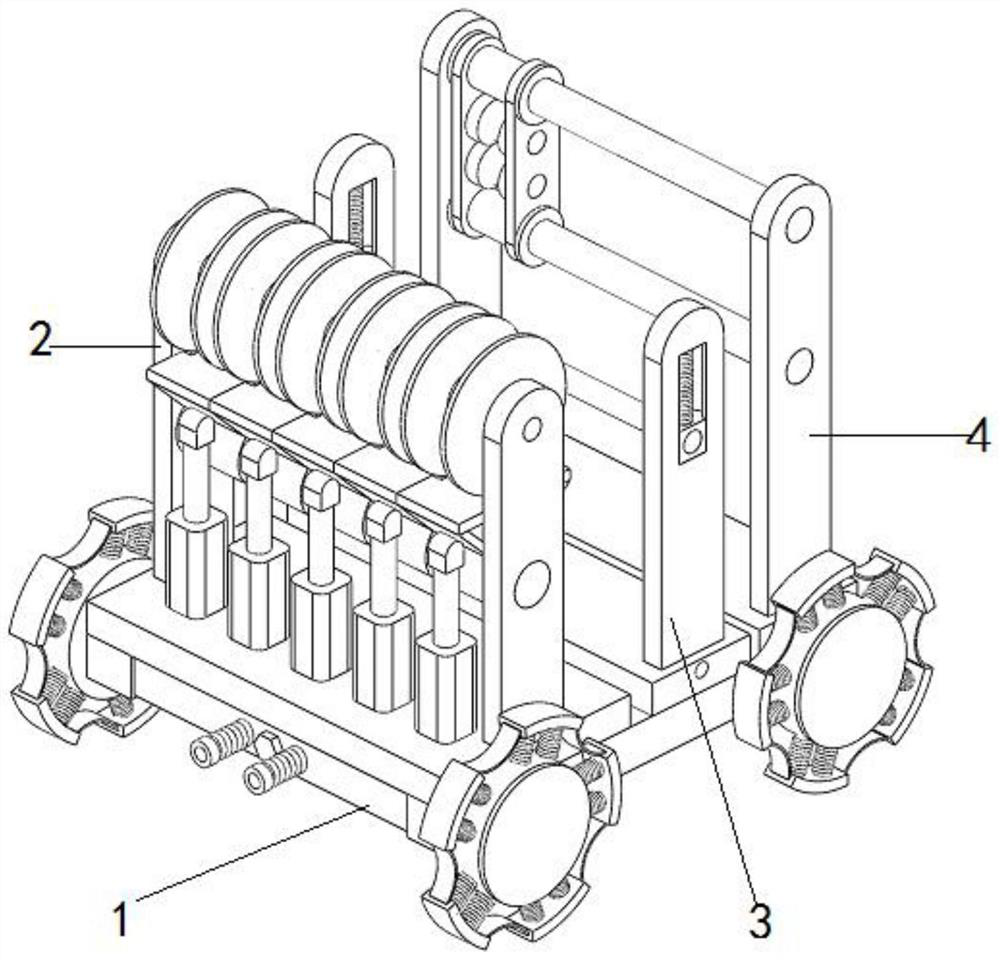

Intelligent stair climbing walking replacing machine

InactiveCN104495573APlay a tension roleGuarantee the safety of useBuilding liftsStairs climbedEngineering

The invention provides an intelligent stair climbing walking replacing machine, which is characterized by comprising a controller, wherein the controller is arranged on a support frame, an automatic stair climbing conveying mechanism, a pedal folding mechanism and an upper and lower box door opening and closing mechanism are arranged in the support frame, the automatic stair climbing conveying mechanism comprises an upper starting switch and a lower starting switch, a chain speed regulating motor, an upper chain shaft and a lower chain shaft are arranged in the support frame, the upper chain shaft and the lower chain shaft are provided with an inclined conveying chain, a slide plate is arranged on a slide rail arranged on the support frame, a slide block is arranged under the slide rail arranged on the support frame, a pedal and an armrest rod are arranged on the slide plate, the pedal folding mechanism comprises an installing seat, a rotating rod connected under the pedal is matched with the installing seat through a rotating shaft, a pedal speed regulating motor is arranged on the slide plate and is used for driving the rotating shaft, the upper and lower box door opening and closing mechanism comprises a support frame upper guide rail and an upper box door speed regulating motor, an upper guide rod is connected onto the upper guide rail, an upper box door is arranged on the upper guide rod, an upper rack is arranged on the inner wall of the upper box door, an upper box door gear is connected onto the upper box door speed regulating motor and is engaged with the upper rack, the support frame is provided with a lower guide rail and a lower box door speed regulating motor, a lower guide rod is connected onto the lower guide rail, a lower box door is arranged on the lower guide rod, a lower rack is arranged on the inner wall of the lower box door, and a lower box door gear connected with the lower box door speed regulating motor is engaged with the lower rack.

Owner:浙江省黄岩服装机械厂

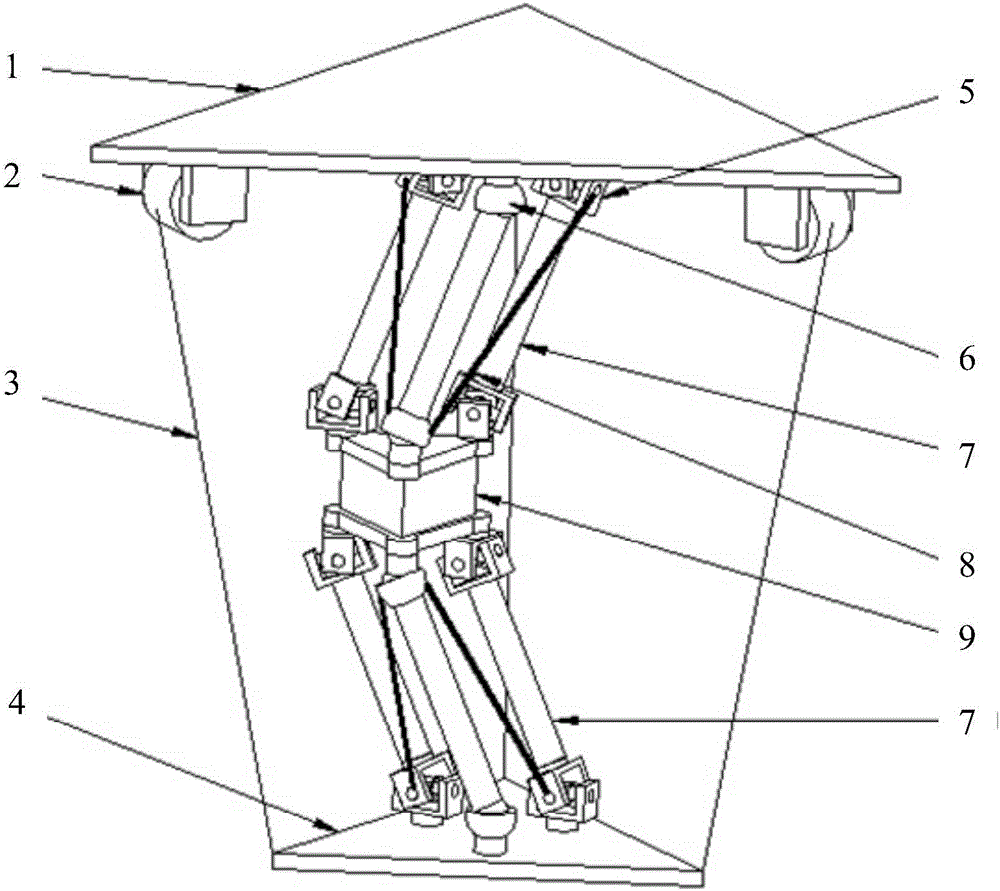

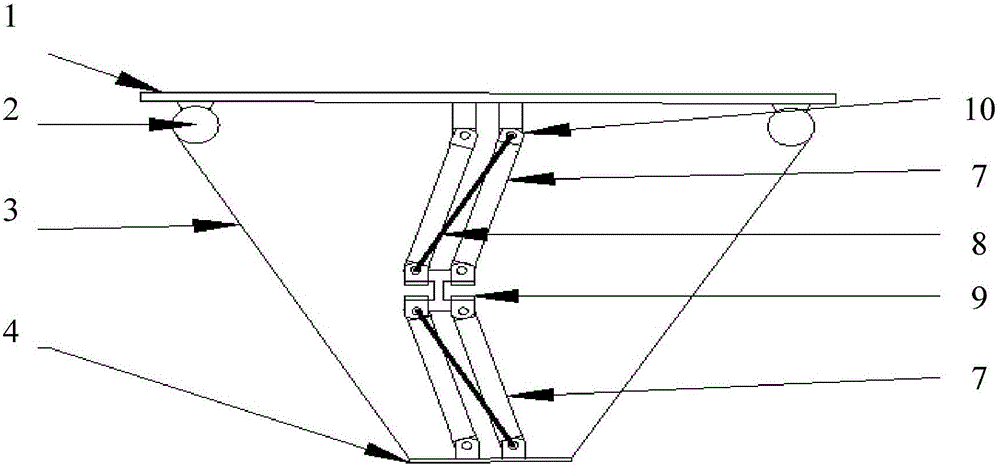

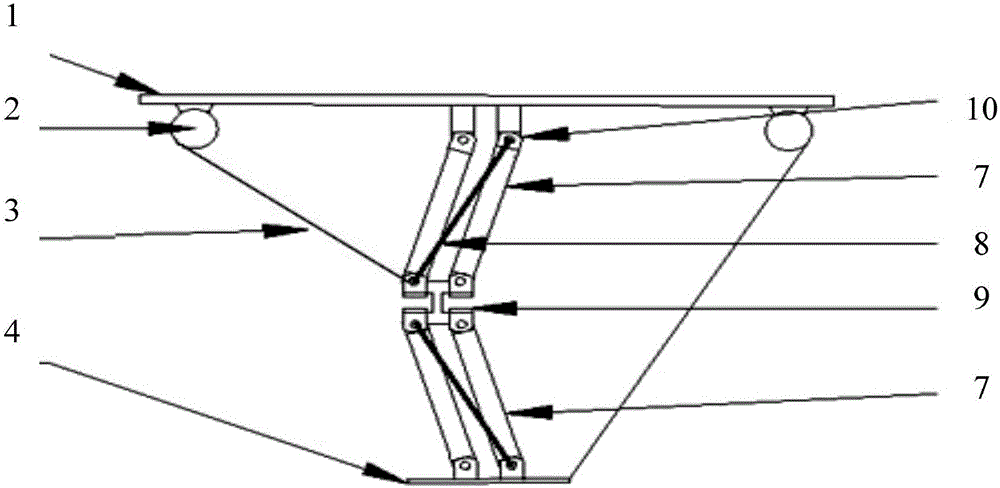

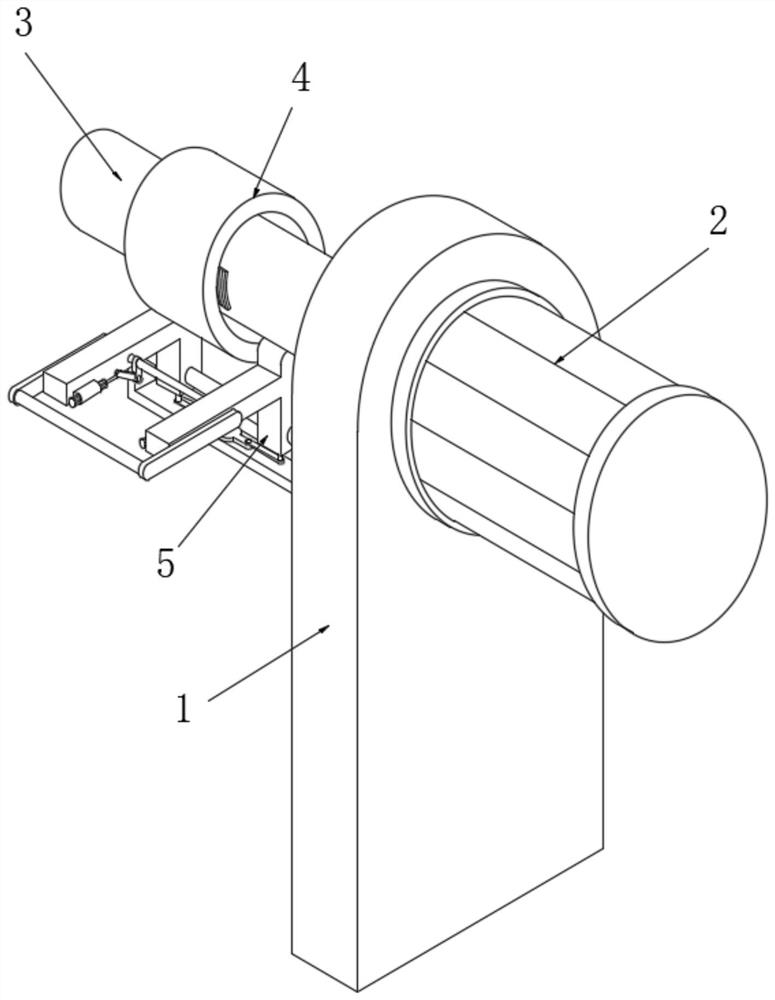

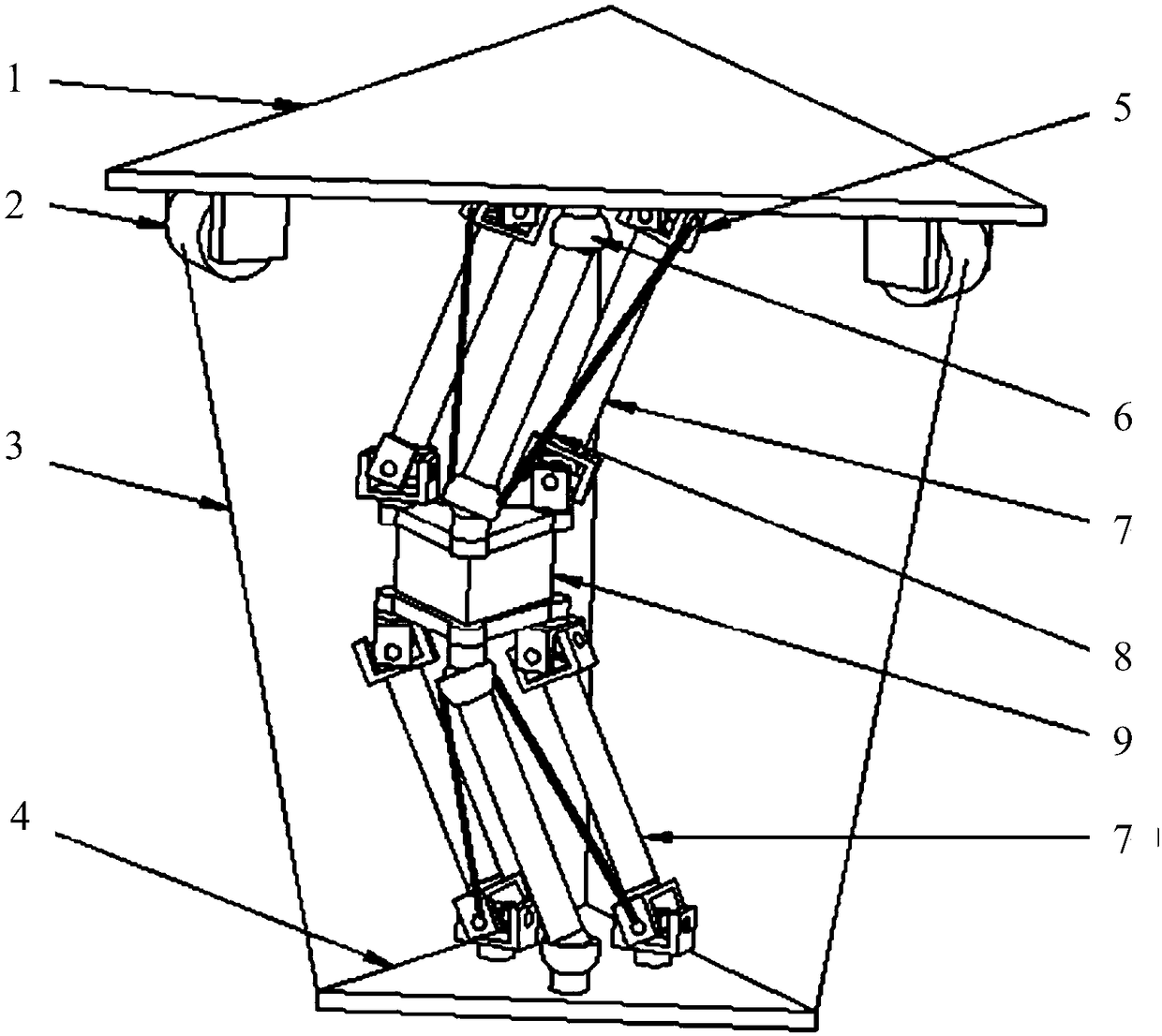

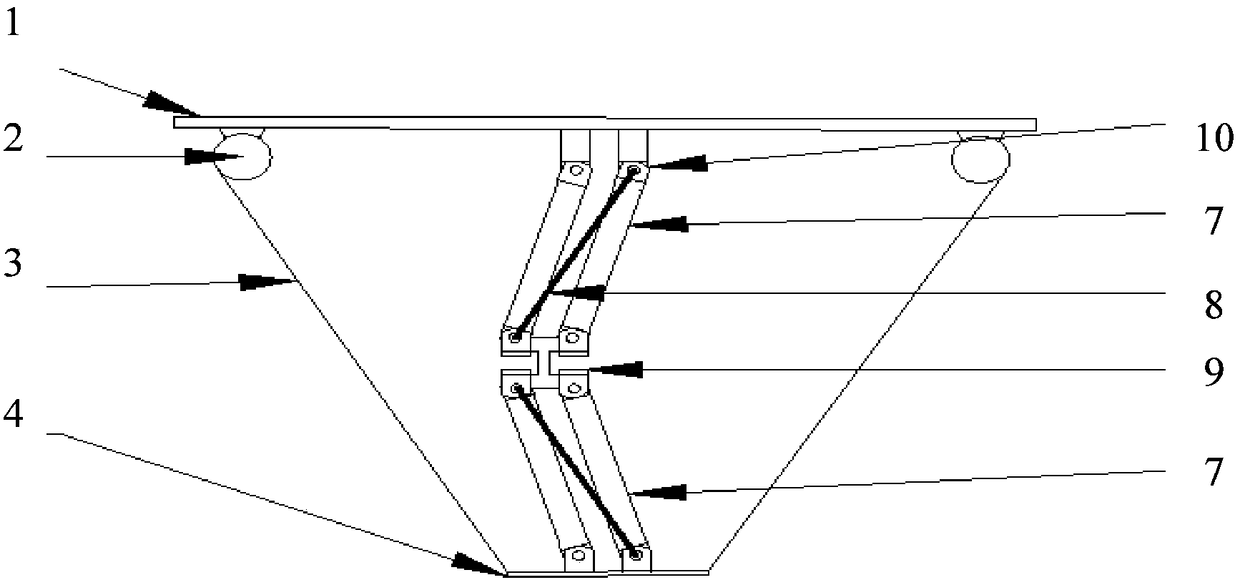

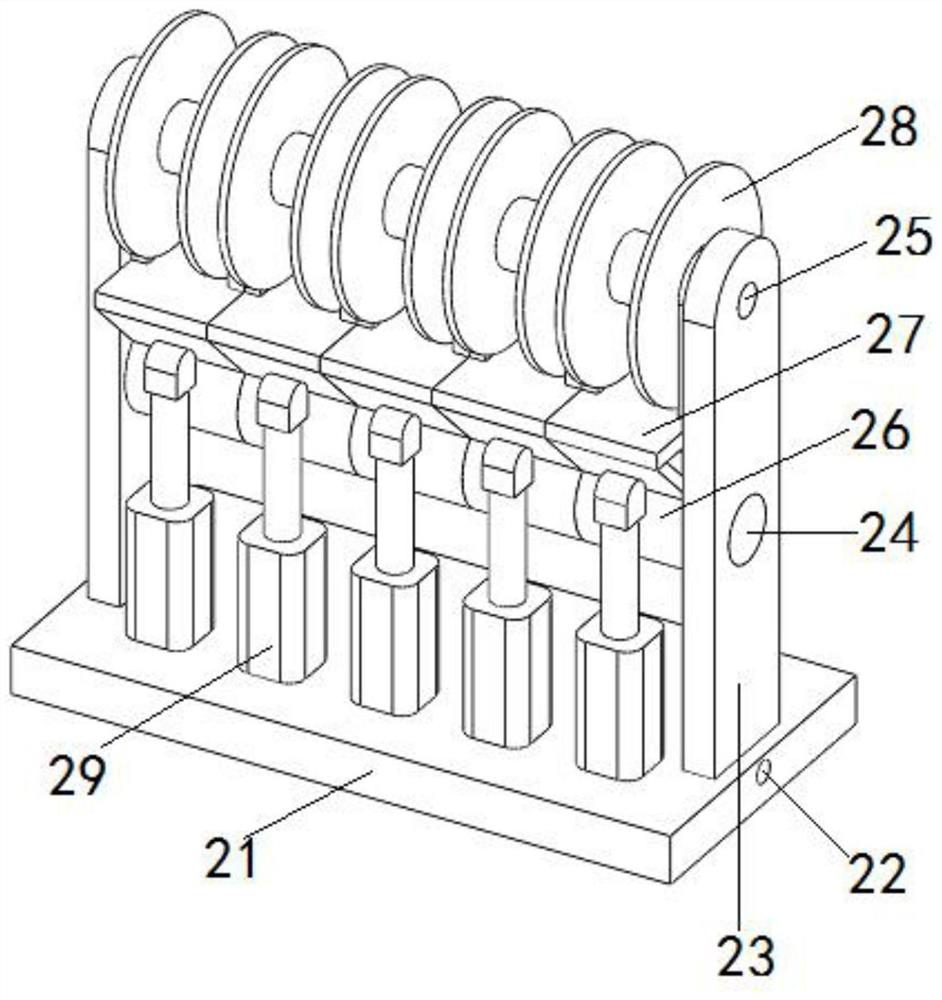

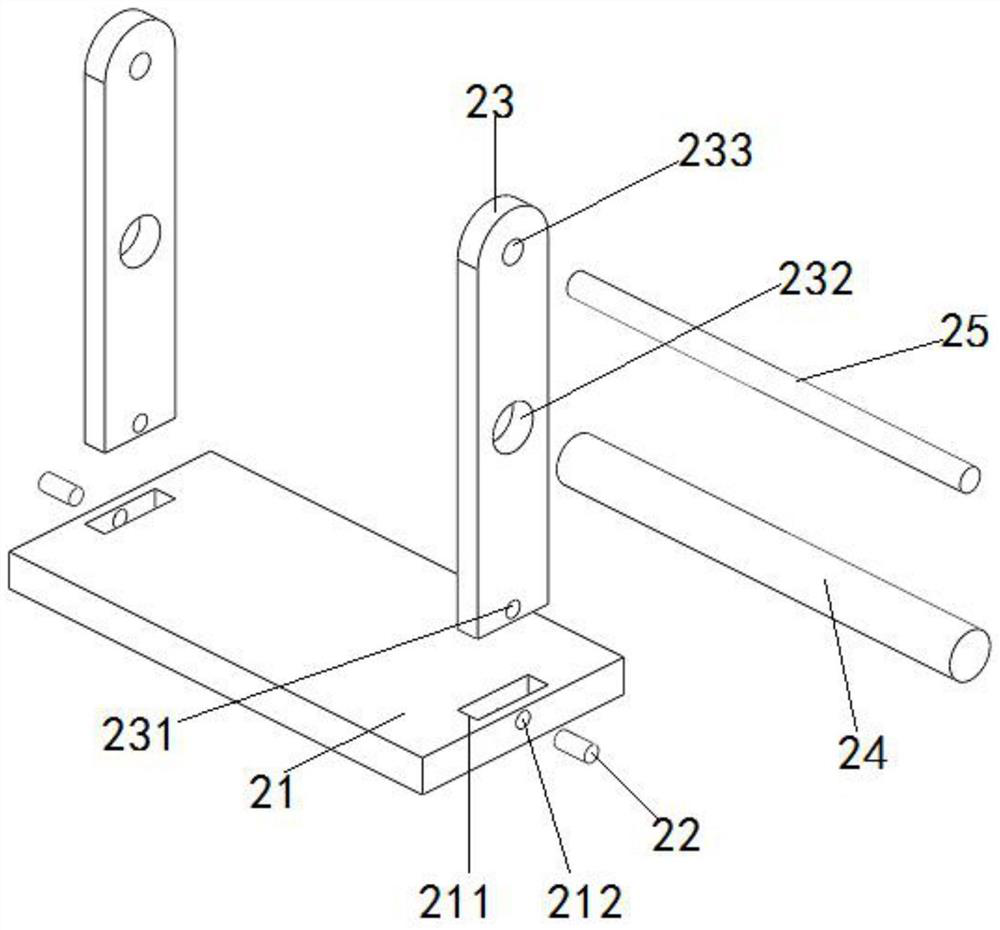

Rope parallel device based on translation constraint structure

ActiveCN105945915AEasy to arrange flexiblyEasy and flexible applicationProgramme-controlled manipulatorCarrying capacityEngineering

The invention discloses a rope parallel device based on a translation constraint structure. The device comprises a static platform, an intermediate platform and a moving platform, wherein rollers and driving units are arranged on the static platform; ropes wind around the rollers and the driving units and are connected with the moving platform; the intermediate platform is connected with the static platform and the moving platform by the aid of rigid rod pieces, each rigid rod piece comprises rigid rods and hinge devices at two ends, and the rigid rods which are equal in length and are parallel constitute parallelogram mechanisms; and springs are connected on diagonal lines of the parallelogram mechanisms and are in the stretched state to provide tension for the ropes. The terminal degree of freedom of a rope parallel mechanism is constrained by the aid of a translation mechanism, and the device inherits the advantages of simple structure, high carrying capacity, easy mounting and dismounting and the like of the rope parallel mechanism and effectively avoids terminal attitude errors, so that the terminal trajectory accuracy is improved.

Owner:TSINGHUA UNIV

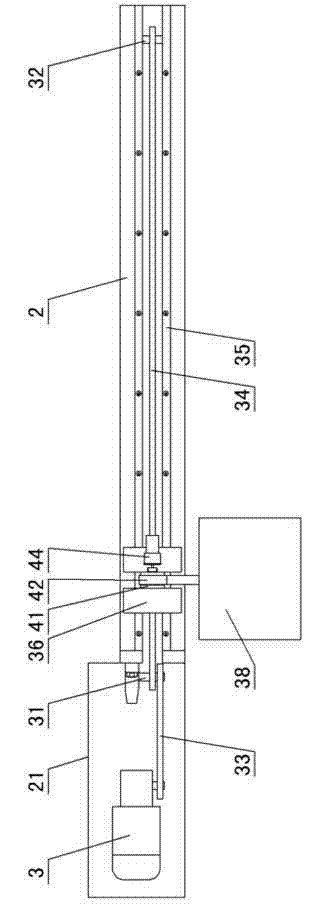

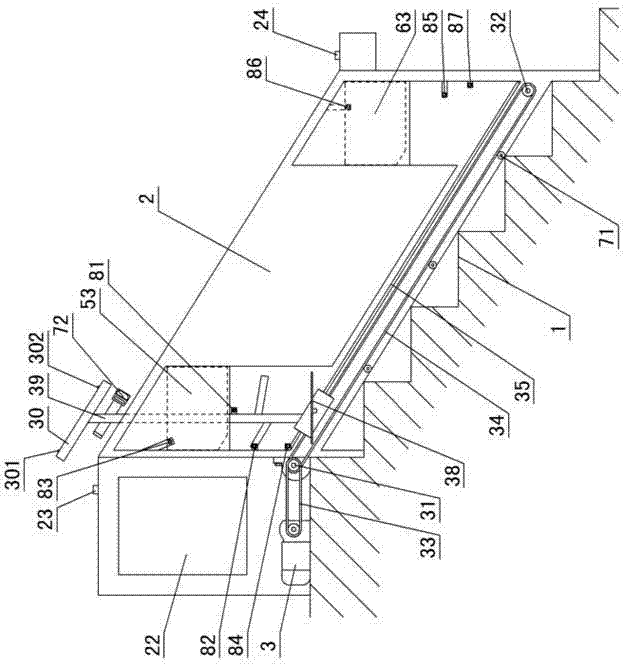

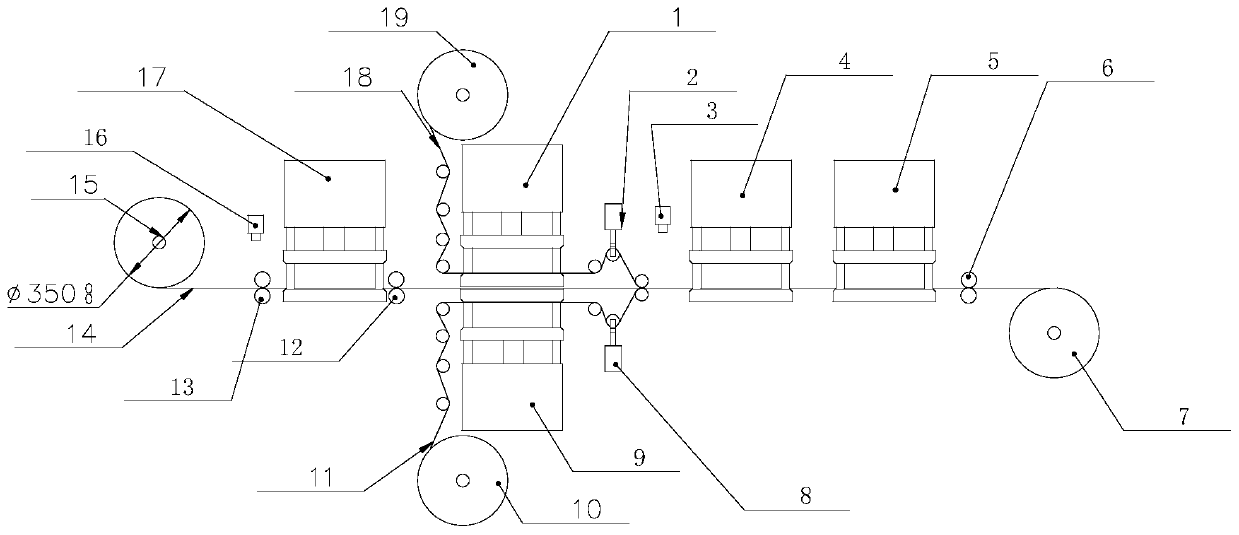

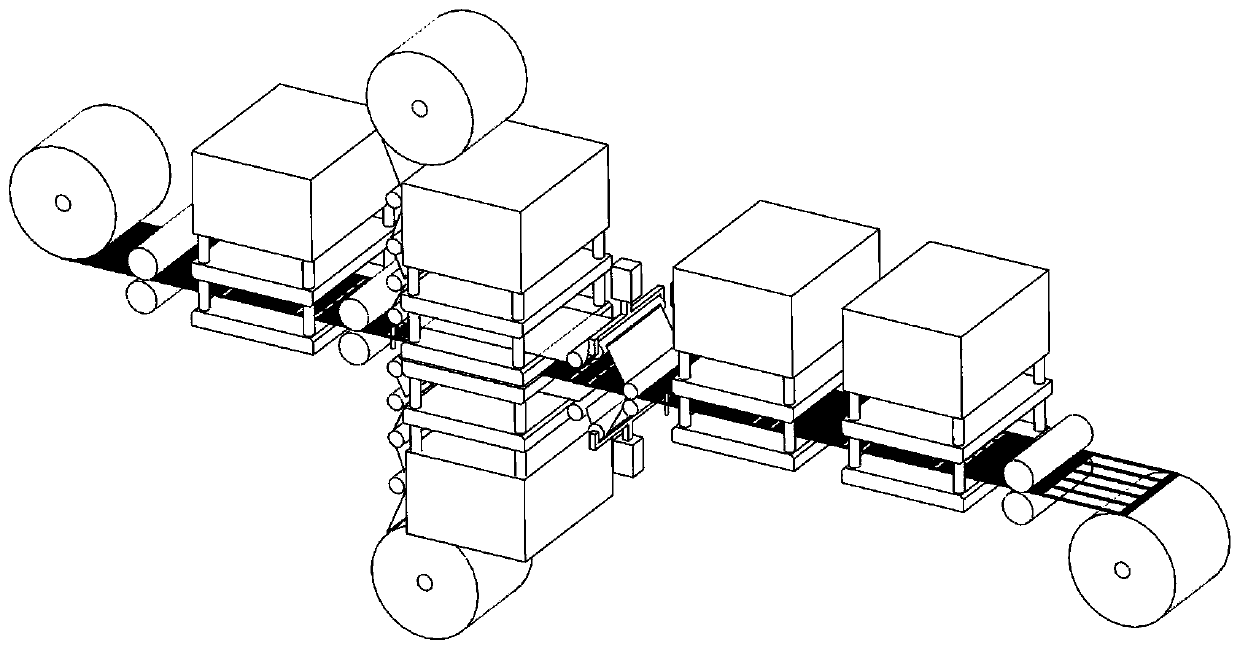

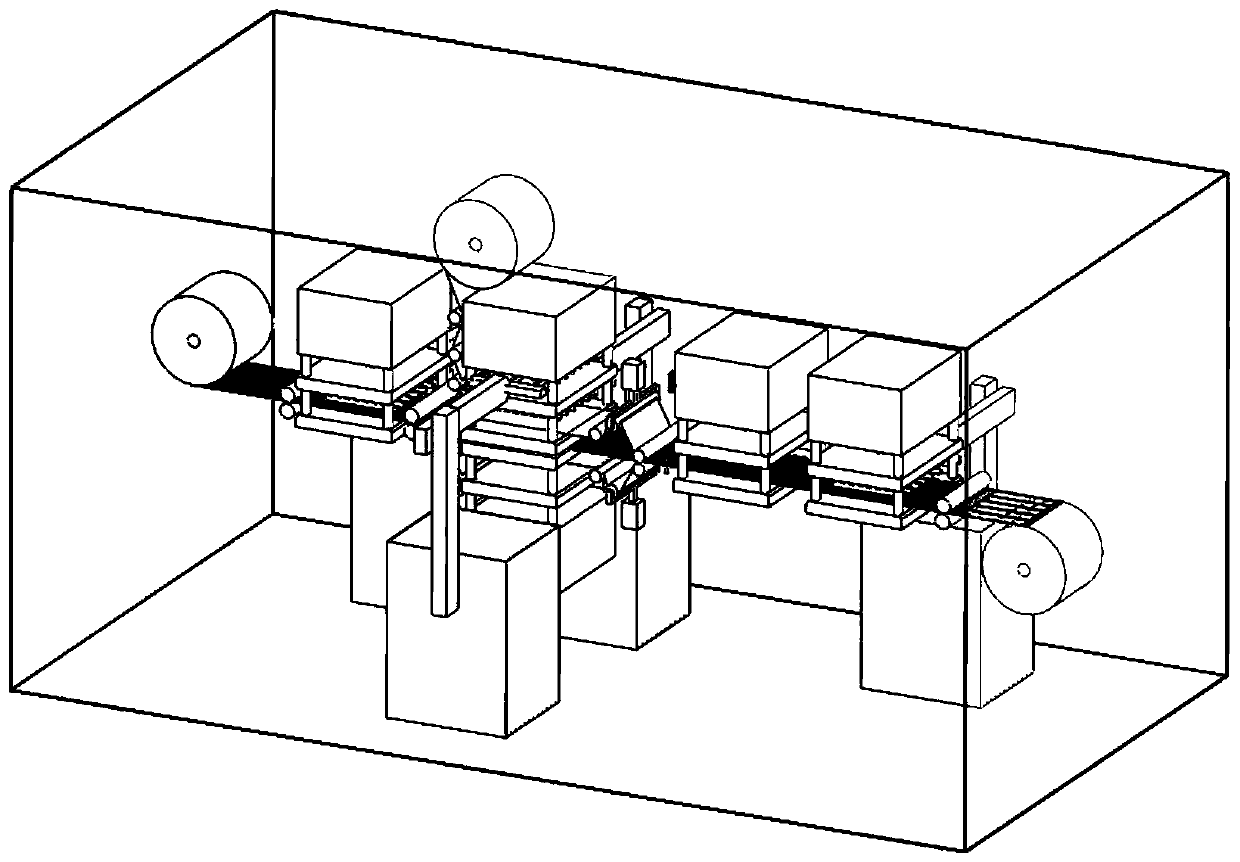

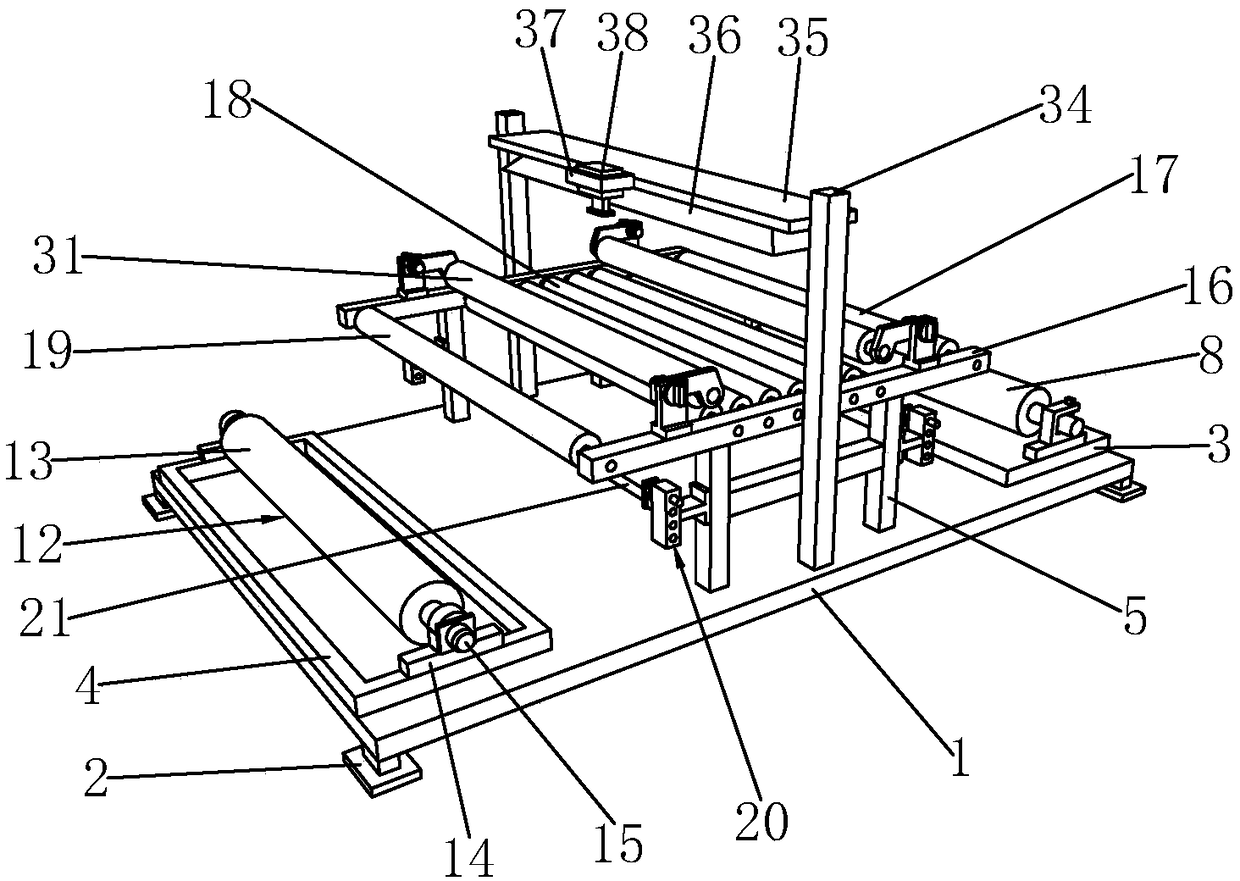

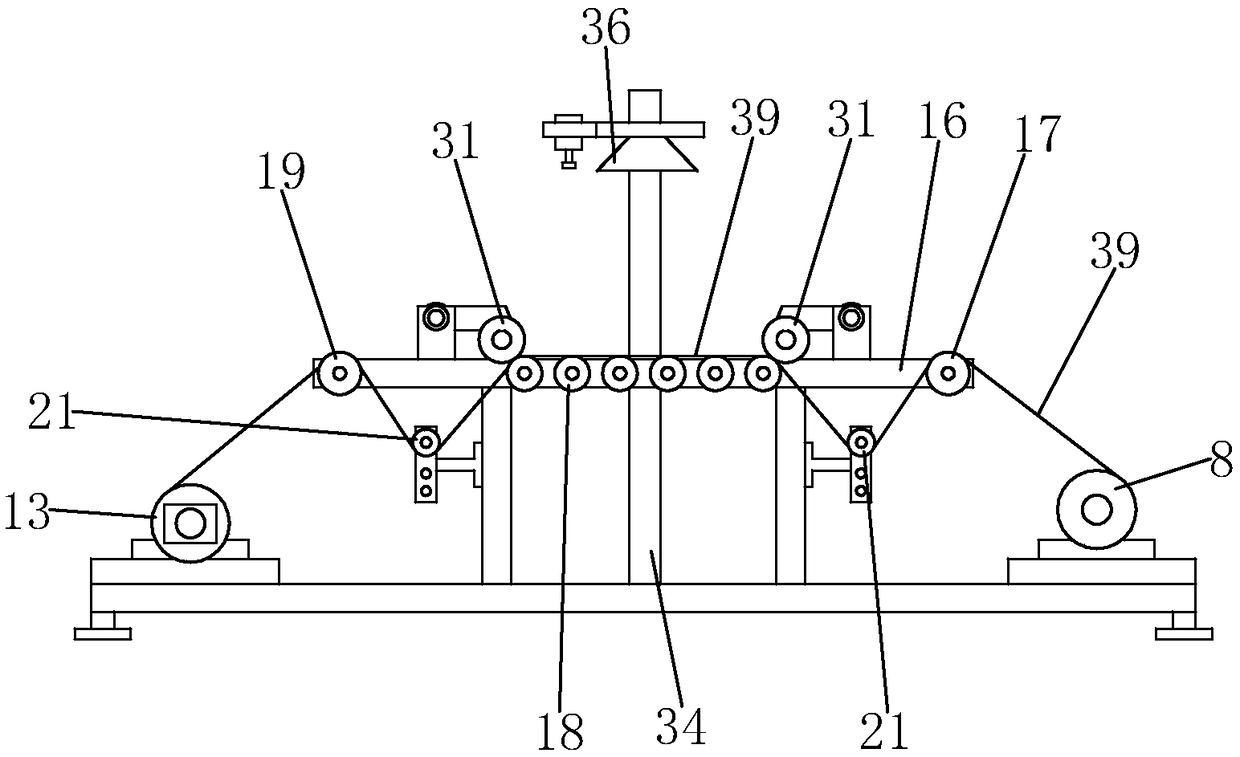

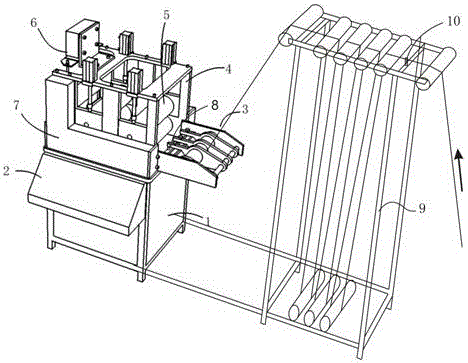

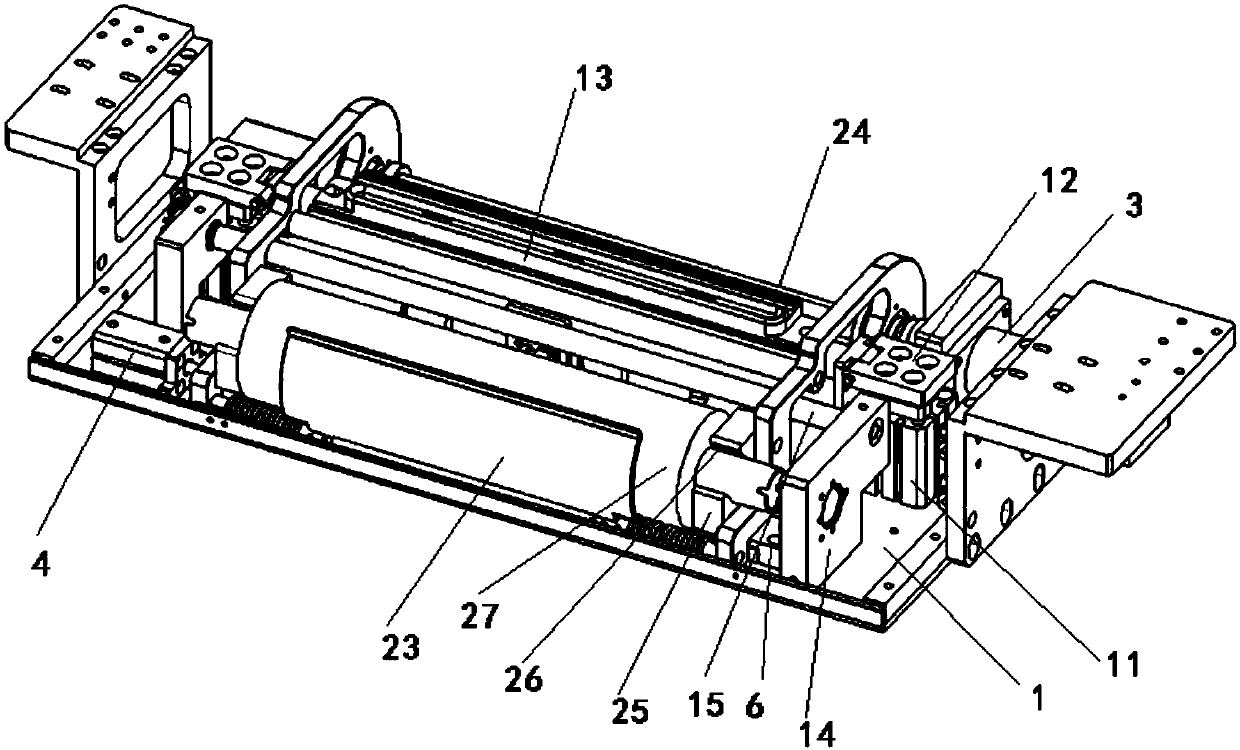

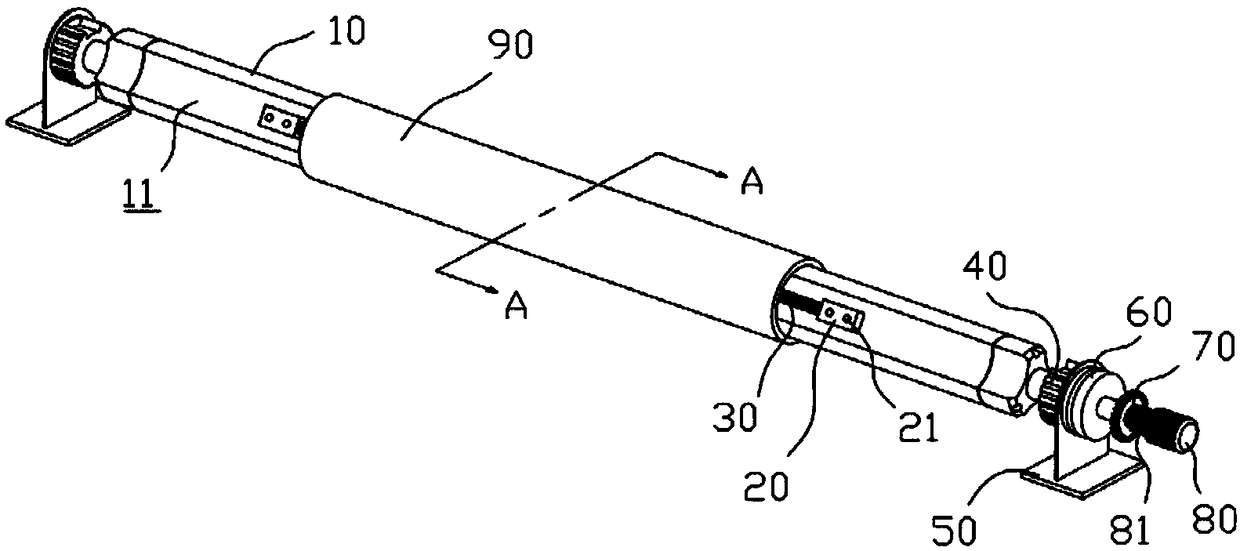

Continuous preparation device and method for membrane electrode

The invention provides a continuous preparation device and method for a membrane electrode, and the method comprises the steps: enabling a CCM material roll to release a CCM membrane under the drivingof a driving roller, conveying the CCM membrane on a conveying belt, carrying out the pre-blanking of the CCM membrane through a CCM membrane pre-blanking machine to remove a redundant part, and conveying the CCM membrane to a PET membrane punching area; respectively arranging a PET material coil and a PET membrane blanking machine above and below the conveying belt, enabling each PET material coil to release a PET membrane under the driving of a driving roller, conveying the PET membrane on the conveying belt, and performing the blanking of the PET membrane by the PET film blanking machine at the corresponding position; and employing a hot press for carrying out overall hot pressing on a three-layer film structure formed by the conveyed CCM film and the conveyed PET film, and then employing an overall blanking machine for carrying out the overall punching on the film structure subjected to hot pressing, so that a final MEA membrane electrode structure is formed. The CCM is pre-blanked, and the blanked CCM membrane and the blanked PET film are subjected to hot pressing and then are integrally blanked, so that the continuity and integrity of the conveying process are ensured, and the efficiency is greatly improved.

Owner:珞石(北京)科技有限公司

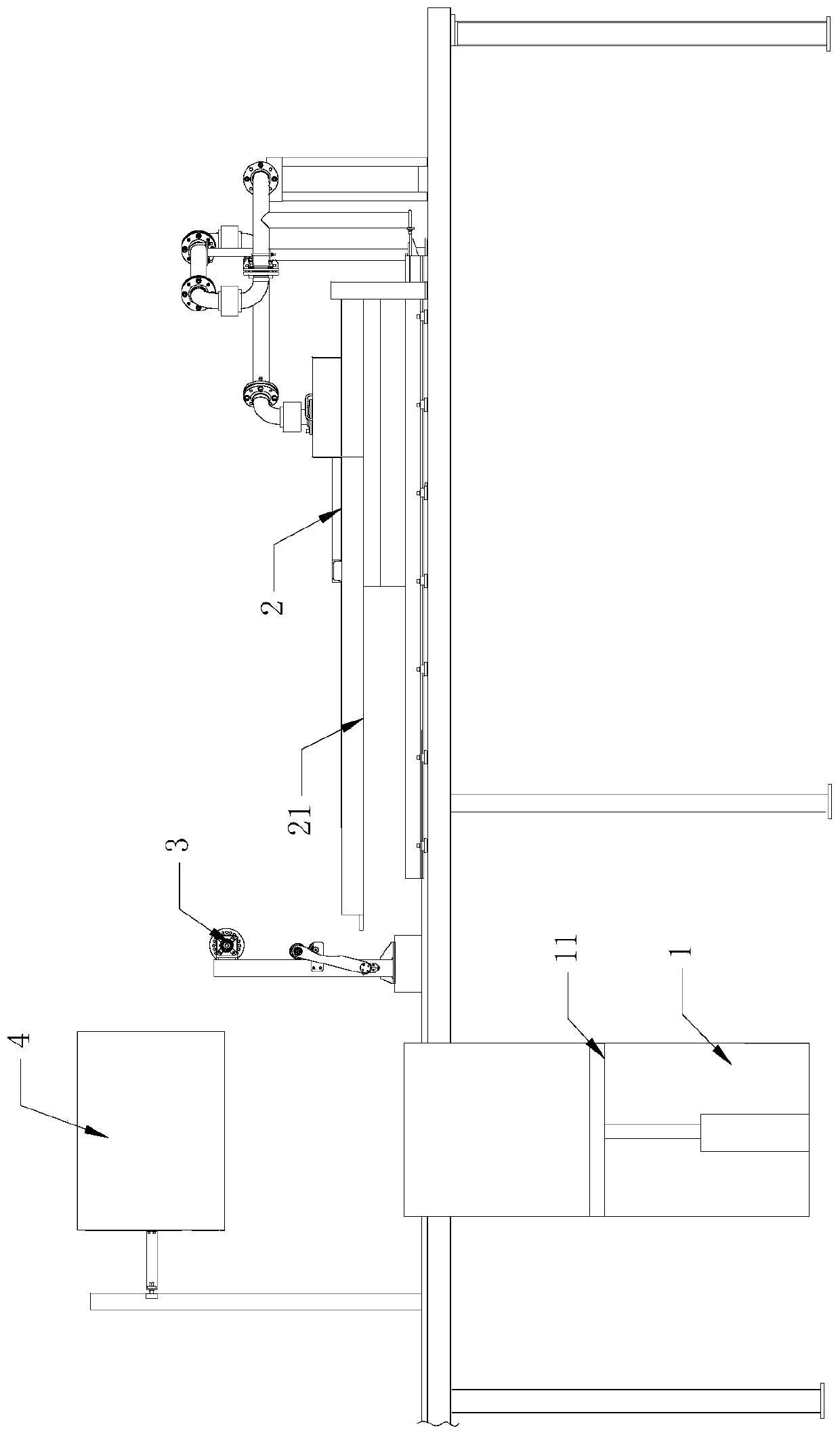

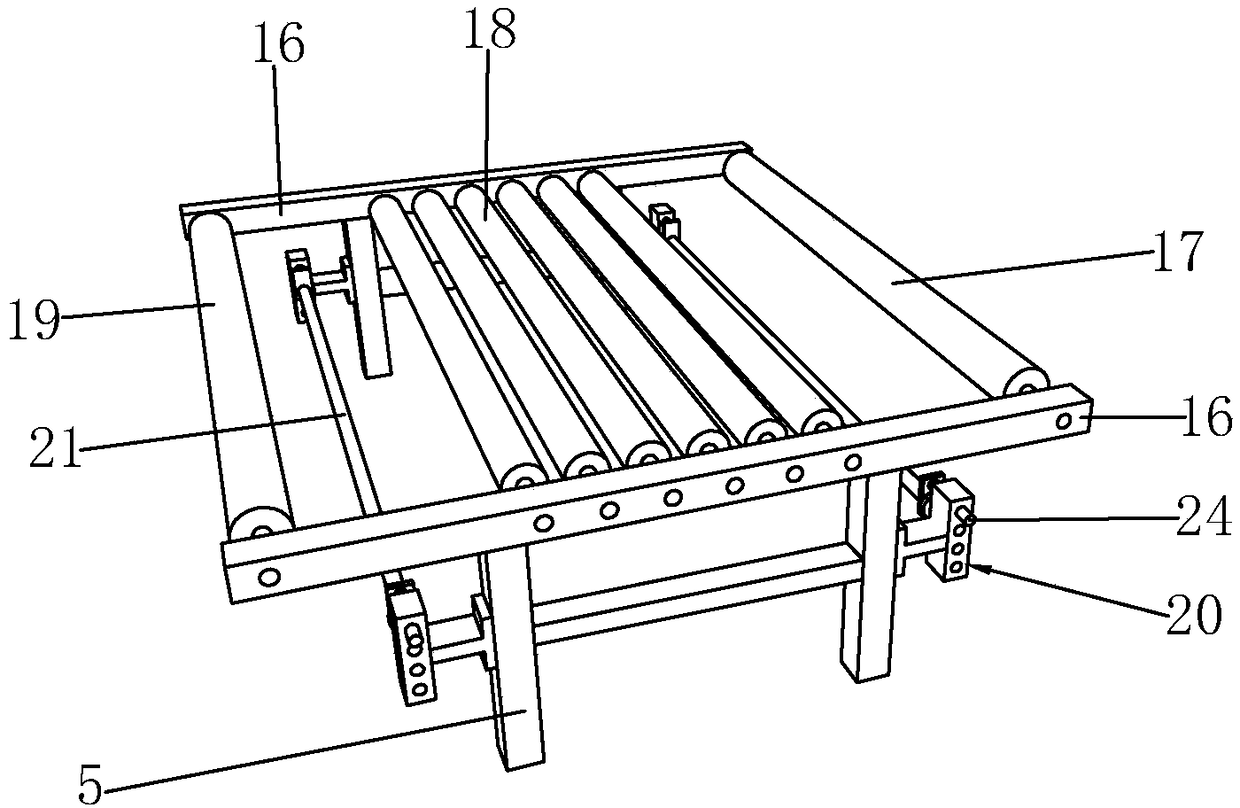

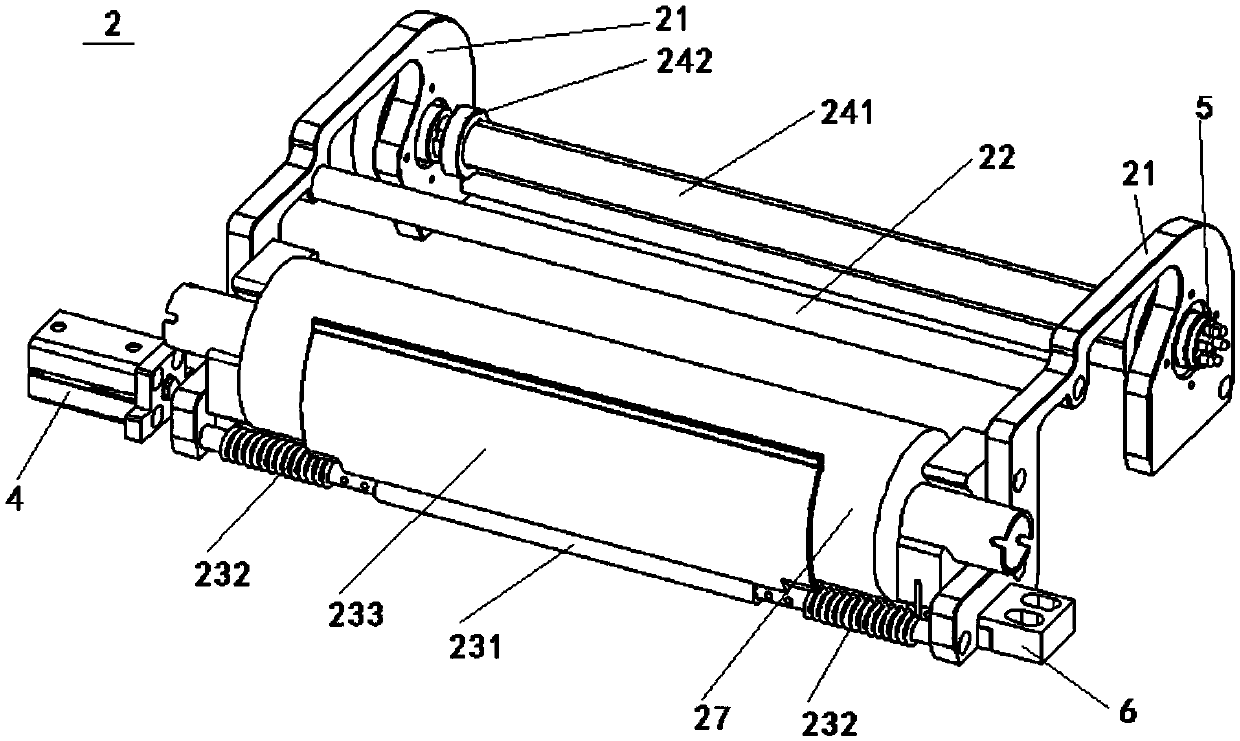

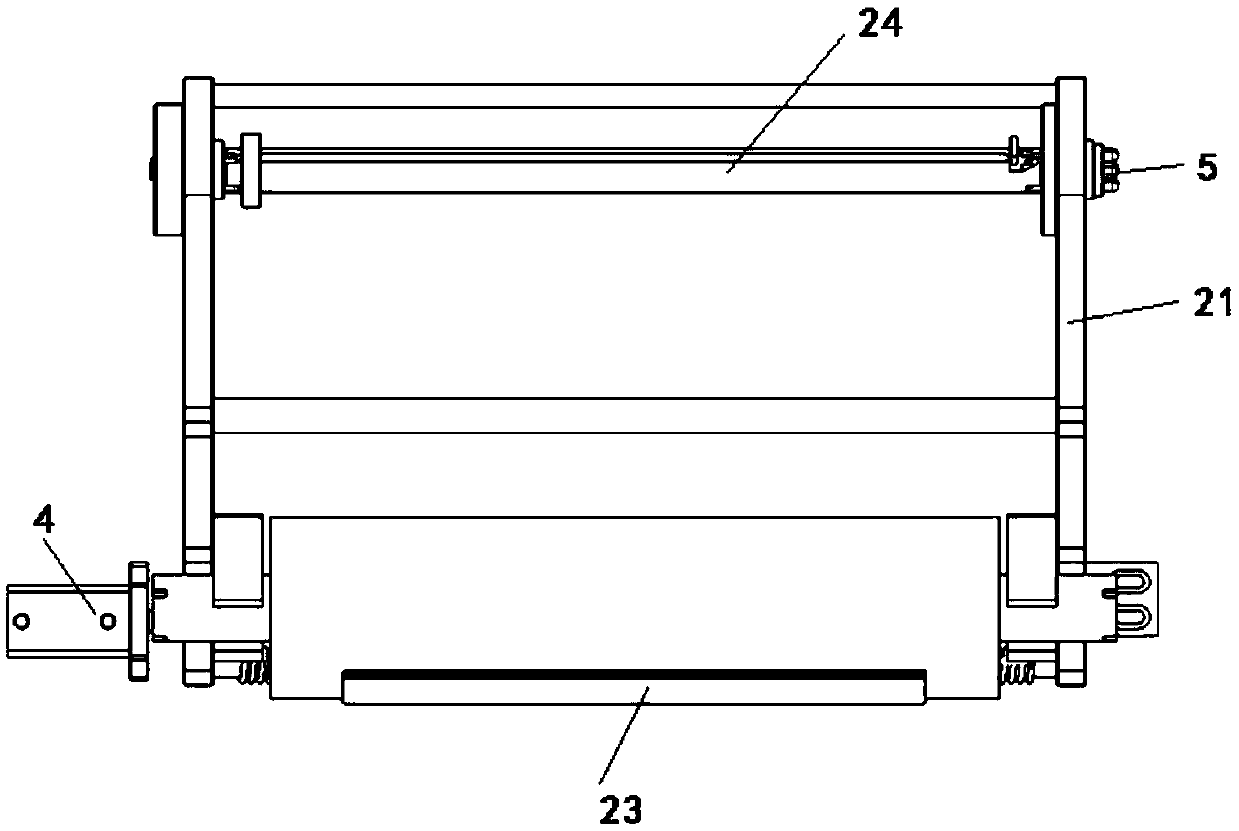

Spreading mechanism and spreading method for organic matter solid waste treatment device

PendingCN110803847AImprove laying qualityImprove laying efficiencySludge treatmentPressesProcess engineeringOrganic matter

The invention provides a spreading mechanism and a spreading method for an organic matter solid waste treatment device. The spreading mechanism comprises a filter cloth filter pressing chamber, a spreading bed and a cloth rolling frame used for providing a filter cloth, a tray capable of moving up and down is arranged in the filter cloth filter pressing chamber, the spreading bed comprises a spreading part capable of moving back and forth, and the cloth rolling frame is arranged between the spreading bed and the filter cloth filter pressing chamber; and the moving direction towards the filtercloth filter pressing chamber is taken as the advancing direction, the spreading part is in a filter cloth spreading state when advancing, and the spreading part is in a material spreading state whenretreating. The single-layer filter cloth is folded and then laid in the filter cloth filter pressing chamber layer by layer when moving back and forth, and material laying is conducted between the two folded layers of the filter cloth, so that the filter cloth spreading quality and the dehydration efficiency are effectively improved.

Owner:中合清源(济南)生态科技有限公司

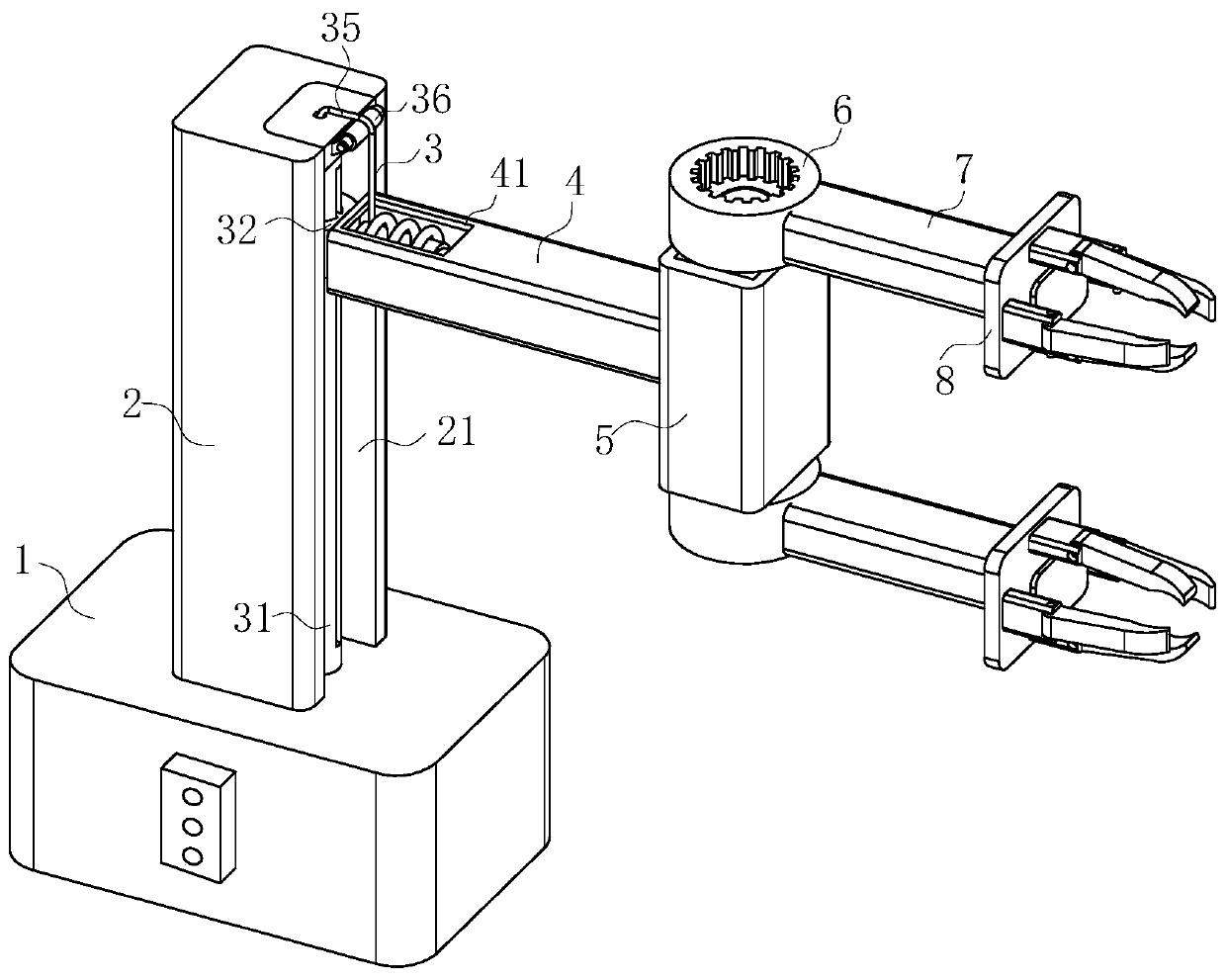

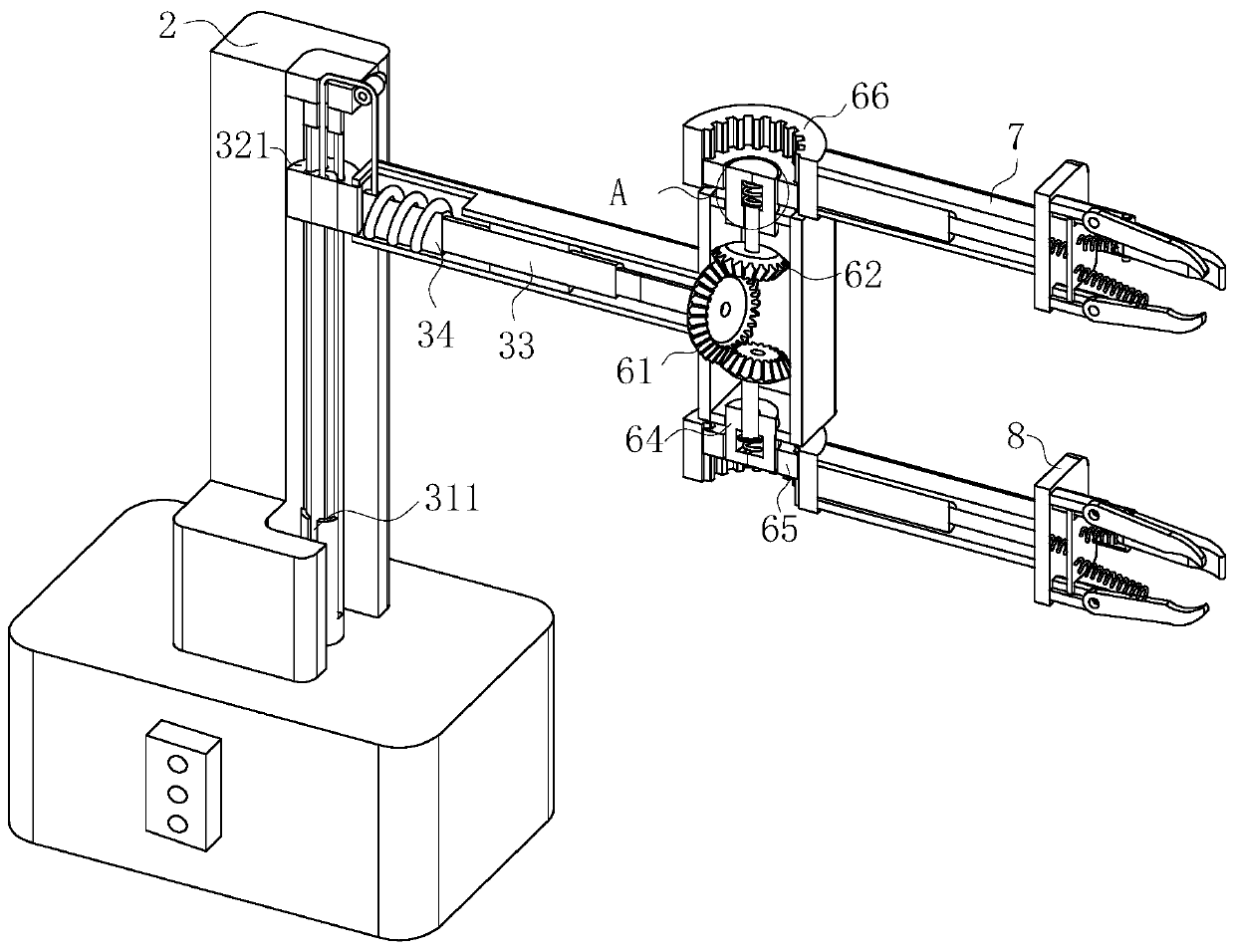

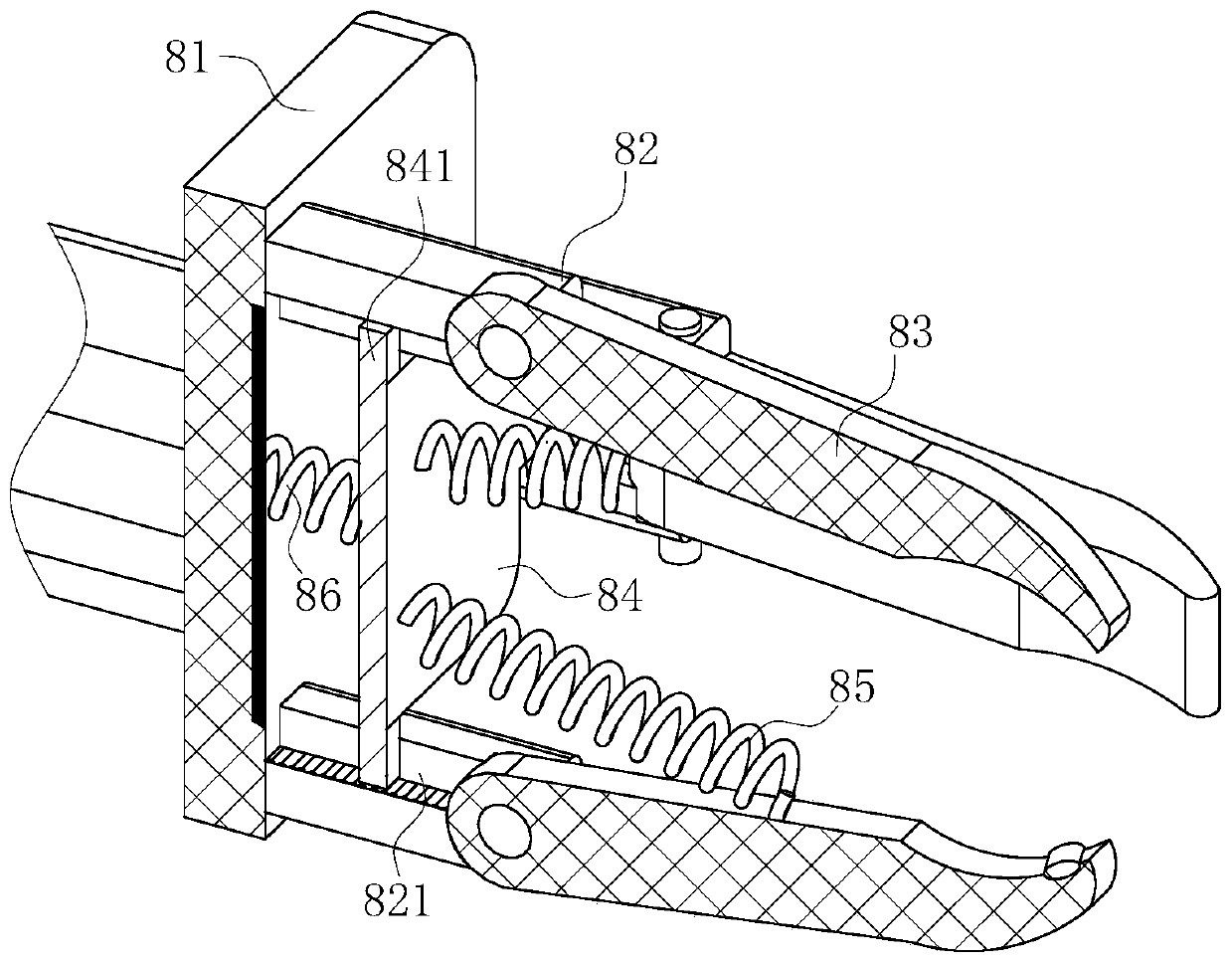

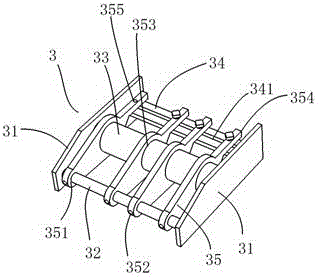

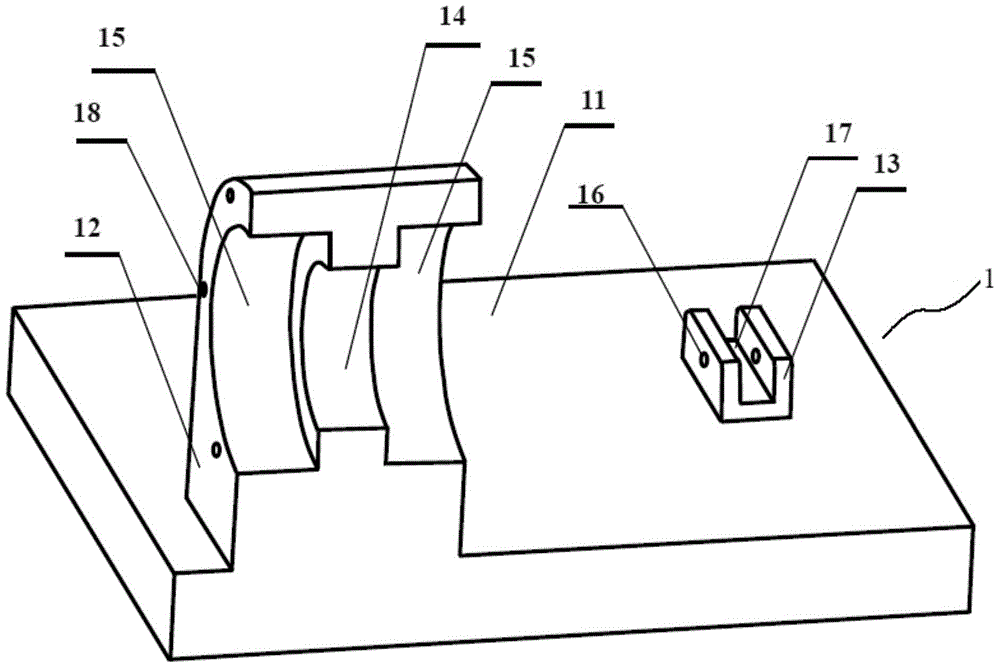

Multi-joint manipulator and mechanical arm

InactiveCN110978030ARealize mobile workRealize opposite grabbing operationsGripping headsArmsRobotic armGear wheel

The invention belongs to the technical field of manipulators, and particularly relates to a multi-joint manipulator and a mechanical arm. The multi-joint manipulator comprises a workbench, a supporting arm is installed on the workbench, a moving arm is connected on the supporting arm through a mobile regulating mechanism, rotating arms are symmetrically connected on a cavity connecting wall, mechanical clamping claws are installed on the rotating arms through guide air cylinders, a guide sliding rod is installed in the supporting arm, the guide sliding rod is slidably sleeved with a guide slide block, a movable arm is arranged on the side face of the guide sliding block; a first bevel gear is connected on another output end of a two-way motor through a coupling, the first bevel gear is symmetrically meshed with second bevel gears; an outer gear is located at the outer end of a cavity connecting arm, the outer gear is meshed with an inner toothed disc in a rotating manner; and the rotating arms are installed on the side wall of the inner toothed disc. According to the multi-joint manipulator and the mechanical arm, through the mutual cooperation of the symmetrically-arranged mechanical clamping claws, the rotating arms and the moving arm, not only the multi-directional and multi-angle opposite grasping operation for objects is realized, but also various object clamping operationis realized.

Owner:TONGLING ZHAOLIN IND & TRADE CO LTD

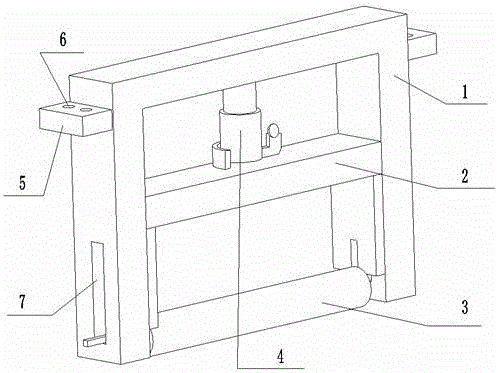

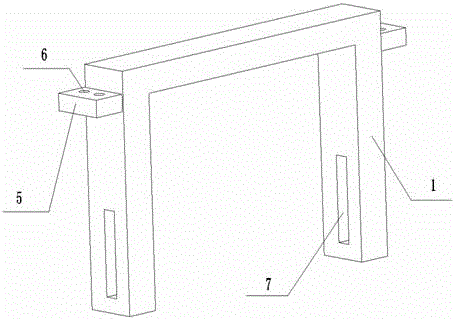

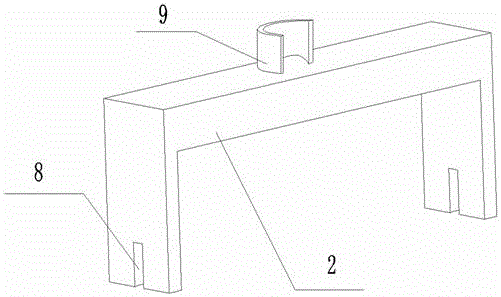

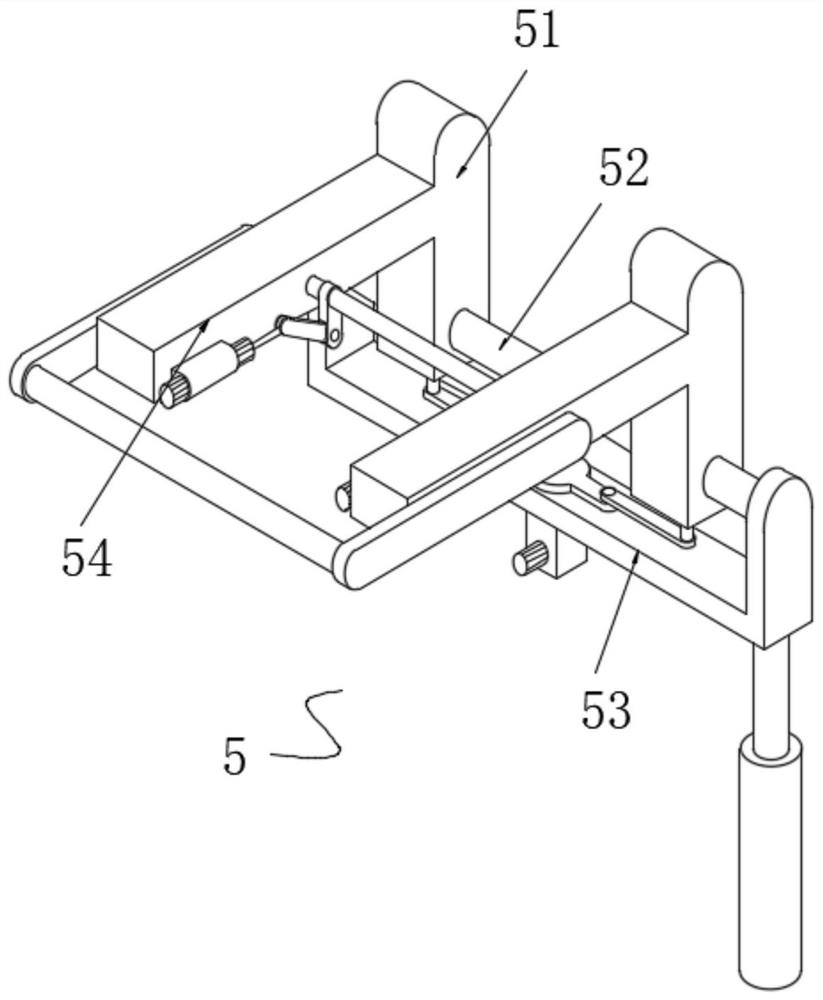

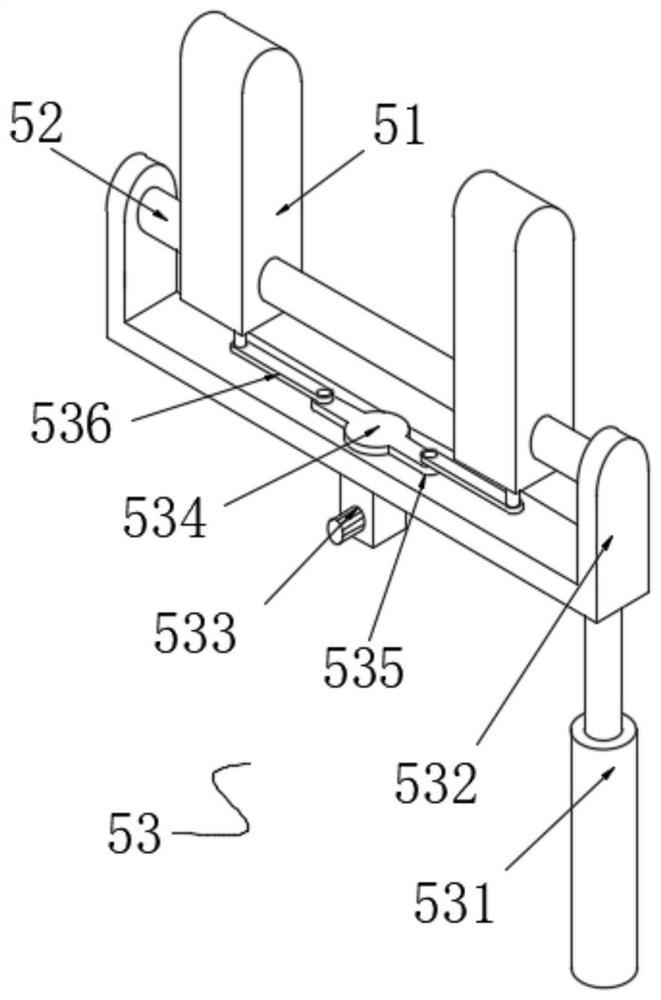

Tensioner for belt conveyor

The invention discloses a tensioner for a belt conveyor. The tensioner comprises a support body, a tensioning body, a tensioning shaft and a telescopic adjustor. The support body and the tensioning body are of an n-shaped frame structure, the tensioning body is embedded in the inner side of the support body of the n-shaped frame structure, the tensioning shaft is located at the bottom of the tensioning body and contacts with a conveying belt, the telescopic adjustor is arranged between the support body and the tensioning body, and the distance between the support body and the tensioning body is adjusted through the telescopic adjustor. By adoption of the tensioner, the distance between the support body and the tensioning body can be adjusted through the telescopic adjustor, so that the contact distance between the tensioning shaft and the conveying belt is changed through downward movement of the tensioning body, and thus a tensioning effect is achieved. The tensioner is simple in integral structure, convenient to operate, low in cost, simple to produce and machine and reliable in quality, the service life of the belt conveyor can be prolonged, and the popularization and application of the tensioner to the belt conveyor are also promoted.

Owner:杜尔明

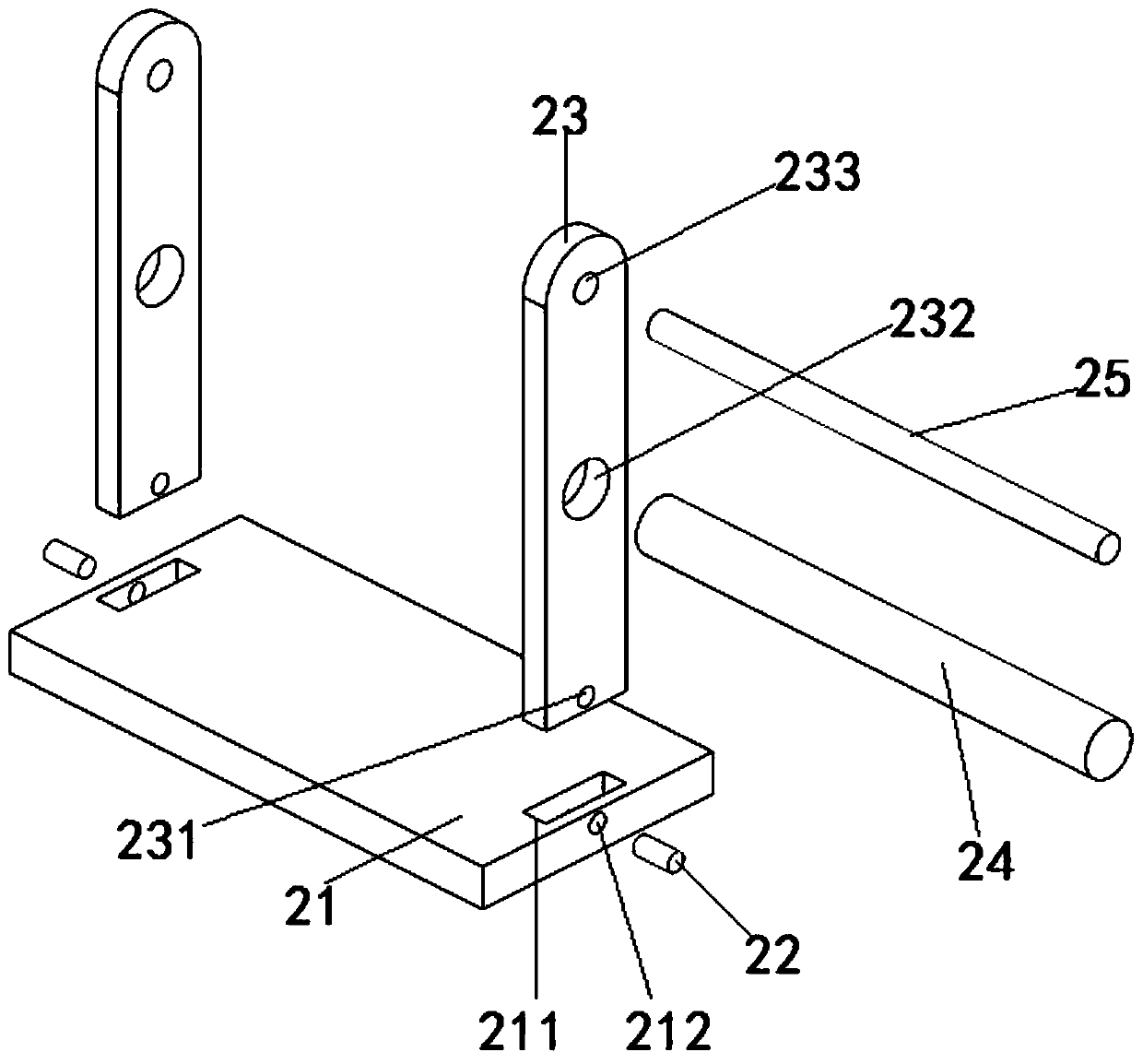

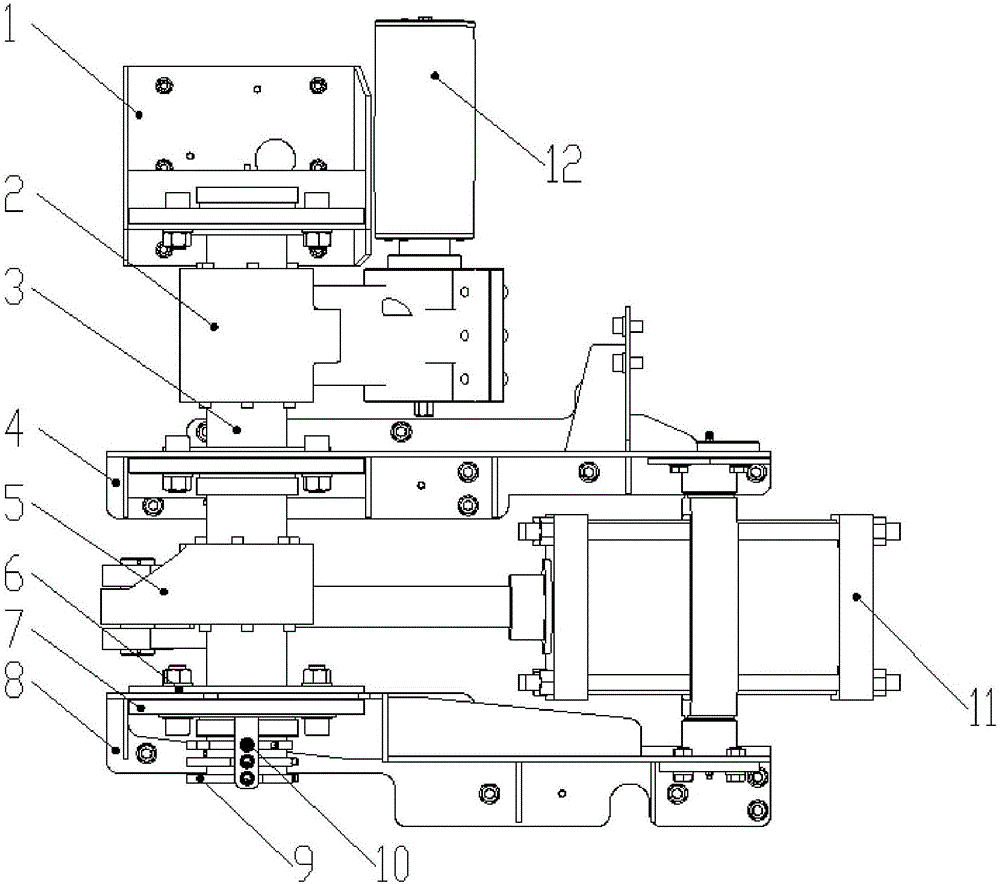

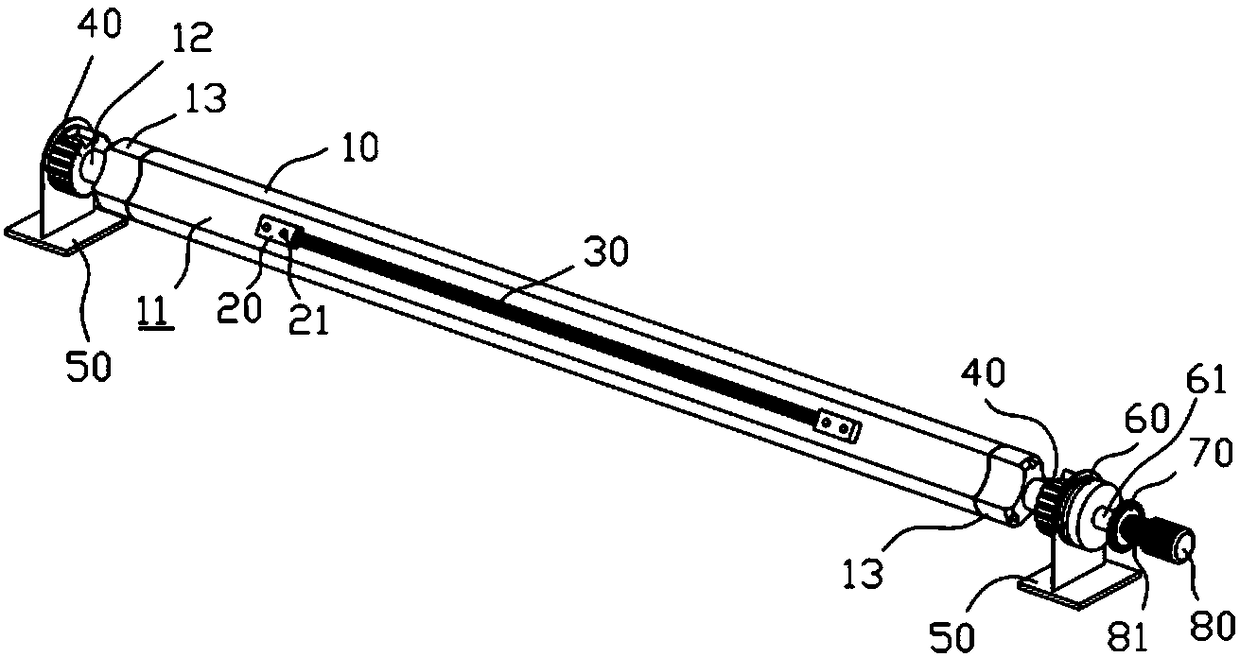

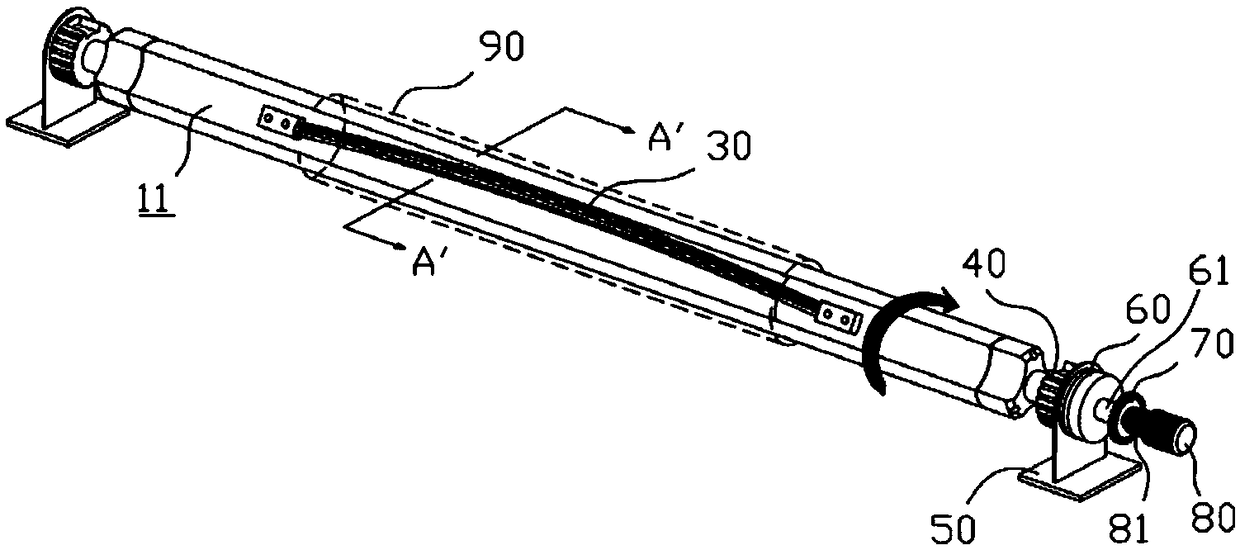

Cable winding and unwinding adjusting mechanism

ActiveCN110562798APlay a tension roleGuaranteed to be verticalFilament handlingApparatus for laying cablesEngineeringConductor Coil

The invention discloses a cable winding and unwinding adjusting mechanism. The cable winding and unwinding adjusting mechanism comprises a horizontally distributed movable supporting mechanism, wherein a cable reel mounting mechanism, a tensioning connecting mechanism and a guide limiting mechanism are sequentially mounted above the movable supporting mechanism from left to right. According to thecable winding and unwinding adjusting mechanism, the abrasion winding of a cable is reduced; through the design of a tensioning connecting shaft, a lifting sliding block and a tensioning limiting spring, the cable can be tensioned to a certain extent, and meanwhile damage caused by rigid connection is avoided; by rotating and adjusting a limit adjusting bolt, a driving limit groove is matched with or separated from a driving limit protrusion, so that the free rotation or fixing state of a driving shaft is changed; through a supporting spring and a concave elastic sheet, a rolling buffering mechanism can play a good buffering and supporting role on the cable in the moving and supporting process, the influence of vibration impact on the service life of a cable reel is avoided, the working efficiency is effectively improved by mounting and using the multi-cable reel, and good practical and popularization values are achieved.

Owner:安徽伟光电缆股份有限公司

Textile defect detecting device

ActiveCN109374641AImprove flatnessEliminate wrinklesOptically investigating flaws/contaminationFixed frameEngineering

The invention discloses a textile defect detecting device which comprises a working platform and supporting legs. The working platform is provided with a supporting plate, a fixing frame and a supporting frame. The supporting frame is located between the supporting plate and the fixing frame. The supporting plate is provided with a cloth release mechanism. The fixing frame is provided with a clothcollecting mechanism, and supporting rods are arranged on the top of the supporting frame. A feeding roller, a guiding roller and a delivery roller are respectively movably connected between the supporting rods. Adjusting seats are arranged on both sides of the supporting frame. A tension roller is arranged between the adjusting seats, pillars are arranged on two sides of the working platform, amounting plate is arranged between the pillars, and a lighting device is arranged on the bottom surface of the mounting plate. The textile defect detecting device has the advantages of being compact in structure, flexible to connect and simple to adjust, convenient detection of defects, being clear and intuitive, being capable of adapting to gray cloth with different qualities, and wide applicablerange.

Owner:宝鸡金联纺织有限公司

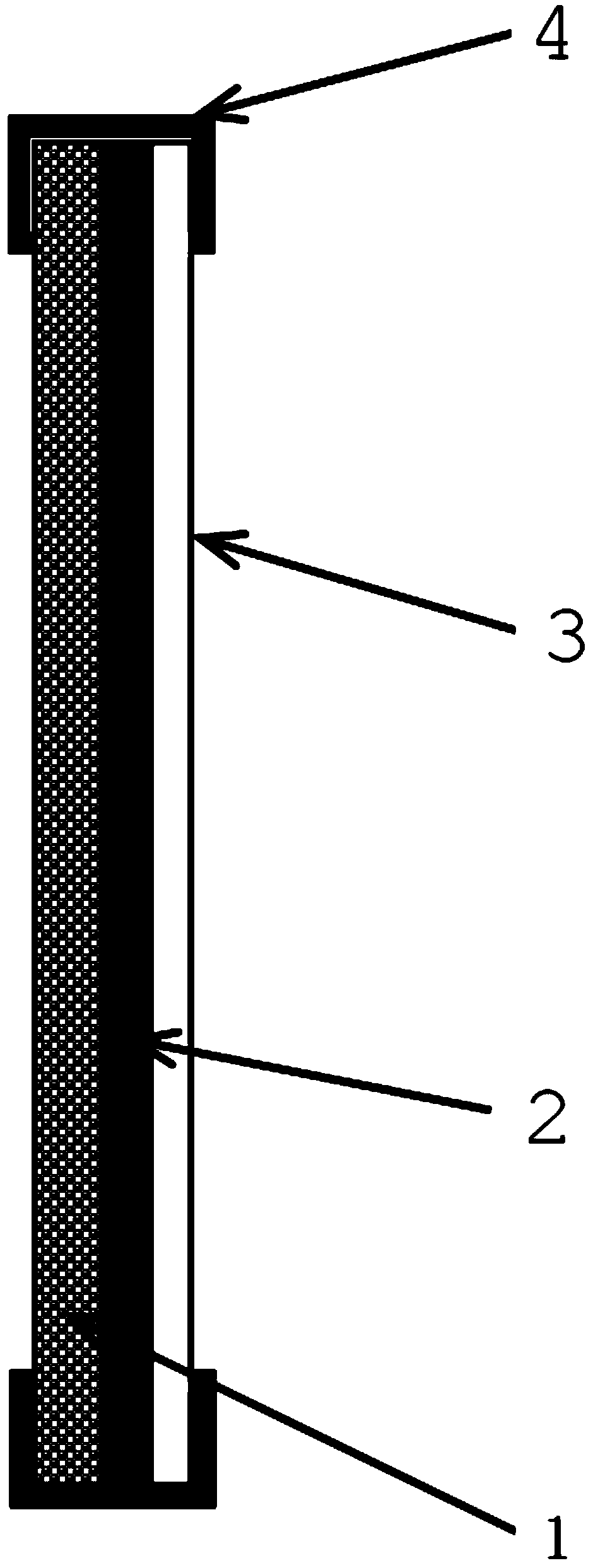

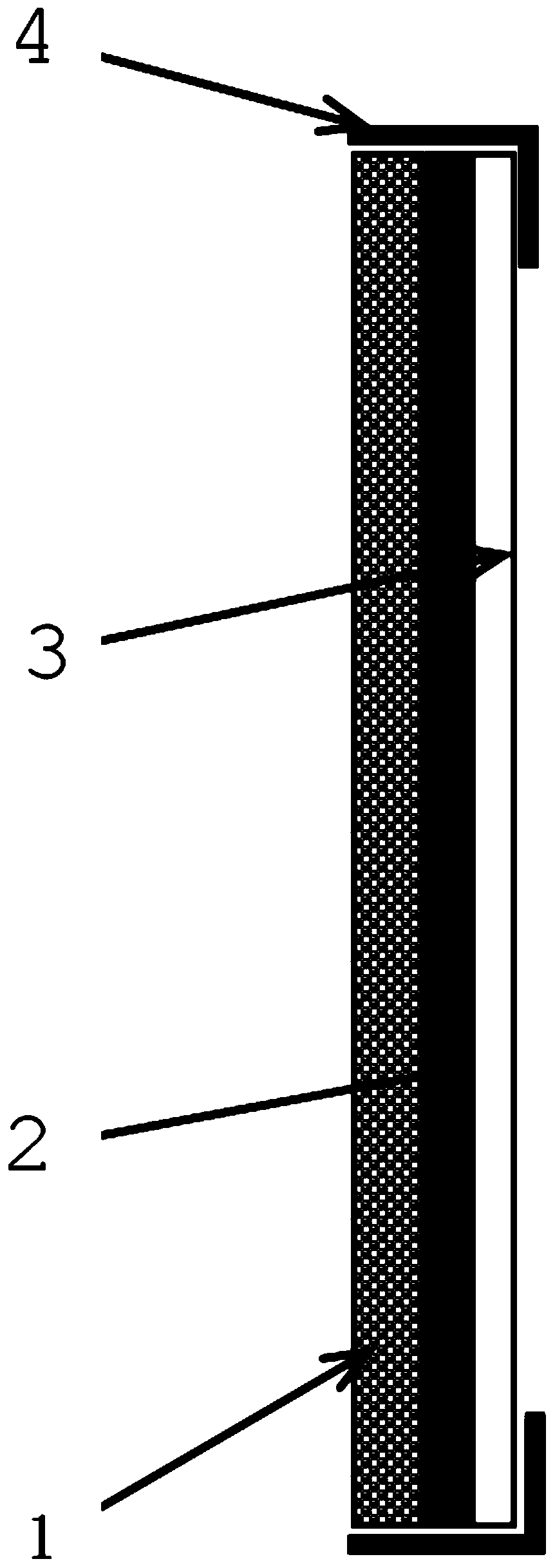

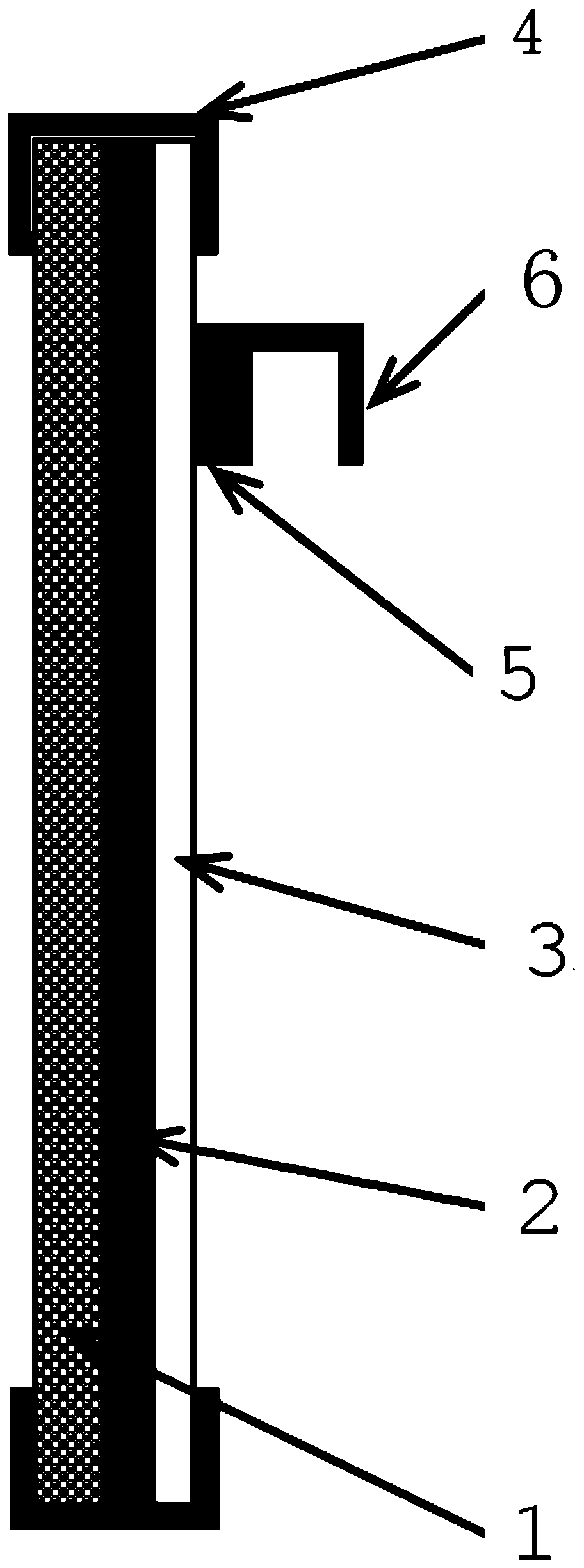

The invention discloses an optical screen structure of an ultrathin laser television

InactiveCN109831633AImprove assembly efficiencyReduced screen thicknessTelevision system detailsPicture reproducers using projection devicesBackplaneTelevision screen

The invention discloses an optical screen structure of an ultrathin laser television. The optical screen structure comprises a projection optical film, a supporting back plate, a first adhesive and ahanging frame assembly, The projection optical film is bonded to the front face of the supporting back plate through a first adhesive, and the hanger assembly is fixed to the back face of the supporting back plate. According to the optical screen structure of the ultra-thin laser television, the thicknesses of the ultra-large-size screen main body and the frame can be reduced to be within 6mm, andthe ultra-large-size, ultra-narrow-frame and ultra-thin full-screen design of the laser television screen is realized while the flatness of the screen main body is ensured.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

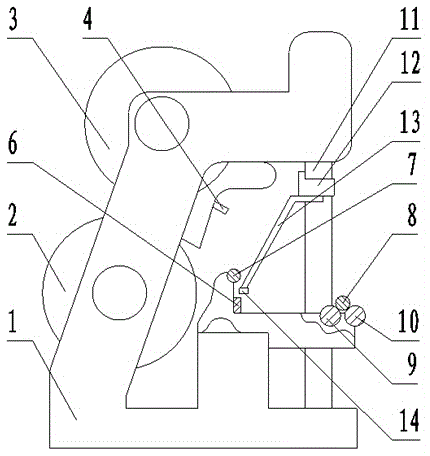

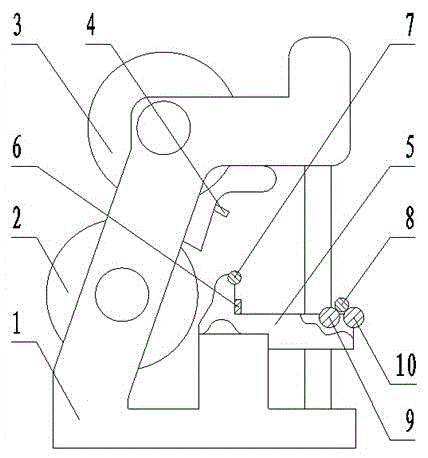

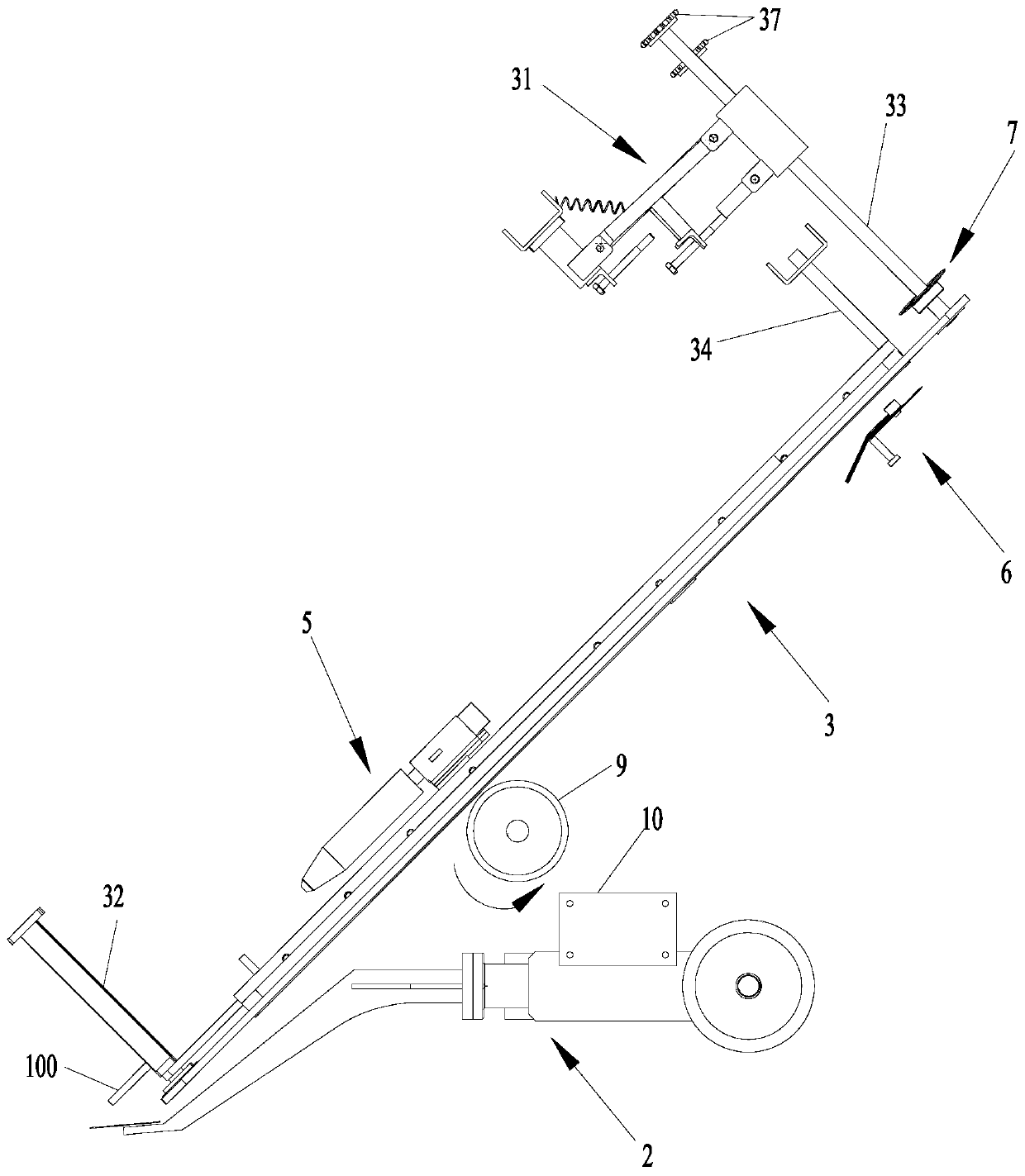

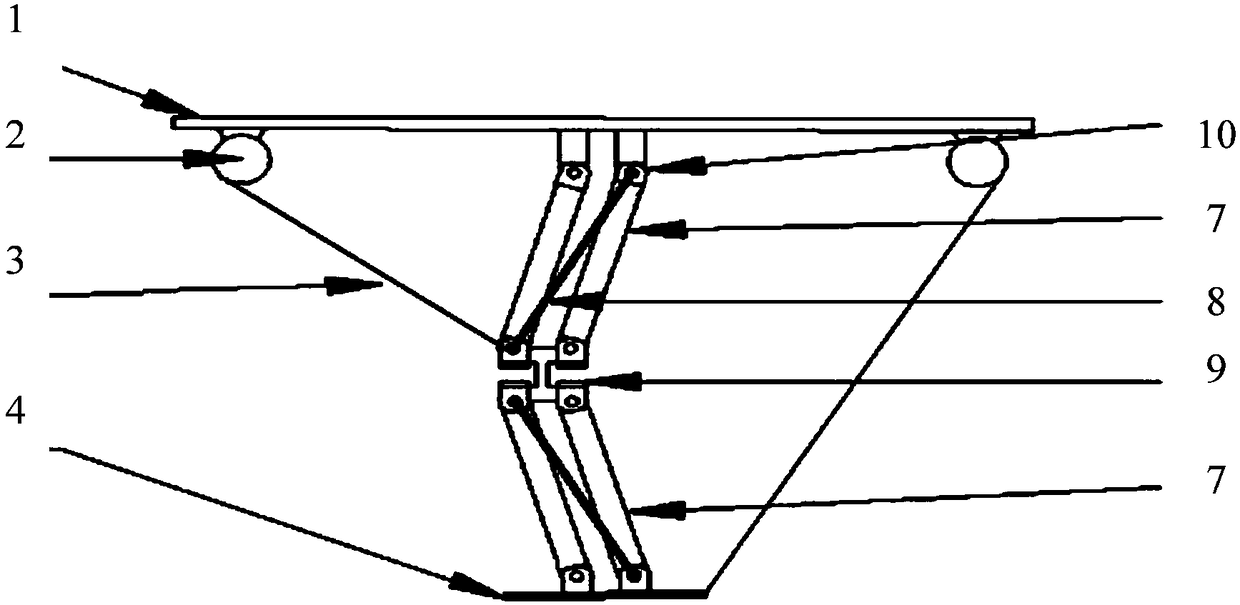

Method for lowering defective rate of woven fabric and loom

InactiveCN104947297AAvoid wrinklesEliminate wrinklesLoomsHeating/cooling textile fabricsYarnStructural engineering

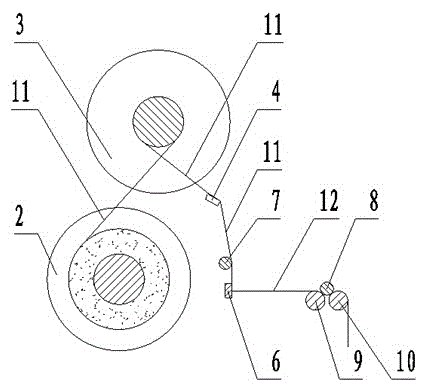

The invention discloses a method for lowering the defective rate of woven fabric and a loom. According to the method, an infrared probe is used for scanning, a motor is controlled by a controller to stop suddenly, secondary tensioning is conducted on yarn through a tensioning wheel and a tensioning roller, and woven fabric is heated through a heating roller so that wrinkles can be eliminated. The loom manufactured through the method comprises a machine frame (1), wherein a yarn wheel (2) and the tensioning wheel (3) are arranged on the machine frame (1), a distributor plate (4) and a working table (5) are arranged below the tensioning wheel (3), knitting needles (6) and the tensioning roller (7) are arranged at one end of the working table (5), a limiting roller (8), the heating roller (9) and a guiding roller (10) are arranged at the other end of the working table (5), a sliding rail (11) is arranged above the working table (5), and the infrared probe (14) is connected to the sliding rail (11) through a sliding block (12) and a suspension frame (13). The method for lowering the defective rate of woven fabric and the loom can improve the quality of products and lower the defective rate and further have the advantages that the production efficiency is high and the surface smoothness is good.

Owner:HUZHOU JIESHENG GAOKE TEXTILE

Automatic belt cutting machine

ActiveCN106743925AAvoid slackSlack won't show upArticle deliveryWebs handlingEngineeringMechanical engineering

The invention discloses an automatic belt cutting machine which comprises a power distribution box, a control console, a positioning migration preventing frame, a feeding roller rack, feeding roller devices, a cutter device and a transmission box. The positioning migration preventing frame is mounted and fixed at a feeding end of the feeding roller frame and comprises a shaft fixing side plate, a fastening shaft, a tensioning shaft, a fastening transverse plate and a positioning plate, the feeding roller devices are mounted on the feeding roller frame and include a first feeding roller device and a second feeding roller device, upper pressing rollers of the first feeding roller device and the second feeding roller device are liftable and adjustable, the cutter device is mounted at a discharging end of the feeding roller frame, and an upper cutter of the cutter device is directly driven by a cutter lifting cylinder to go up and down for cutting. The automatic belt cutting machine has the advantages of compact structure, small occupied space, freeness of loosening during woven belt conveying, wide application range, high cutting efficiency, high accuracy and capability of automatically detecting broken weft and cutting off woven belt sections with the broken weft.

Owner:福建锦特新材料科技有限公司

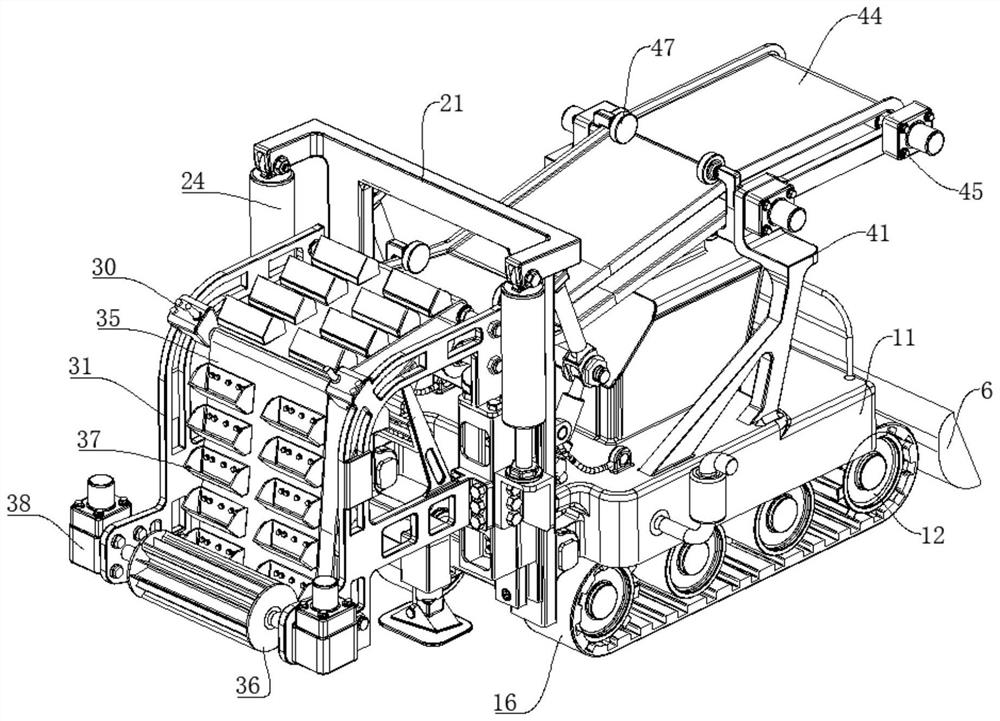

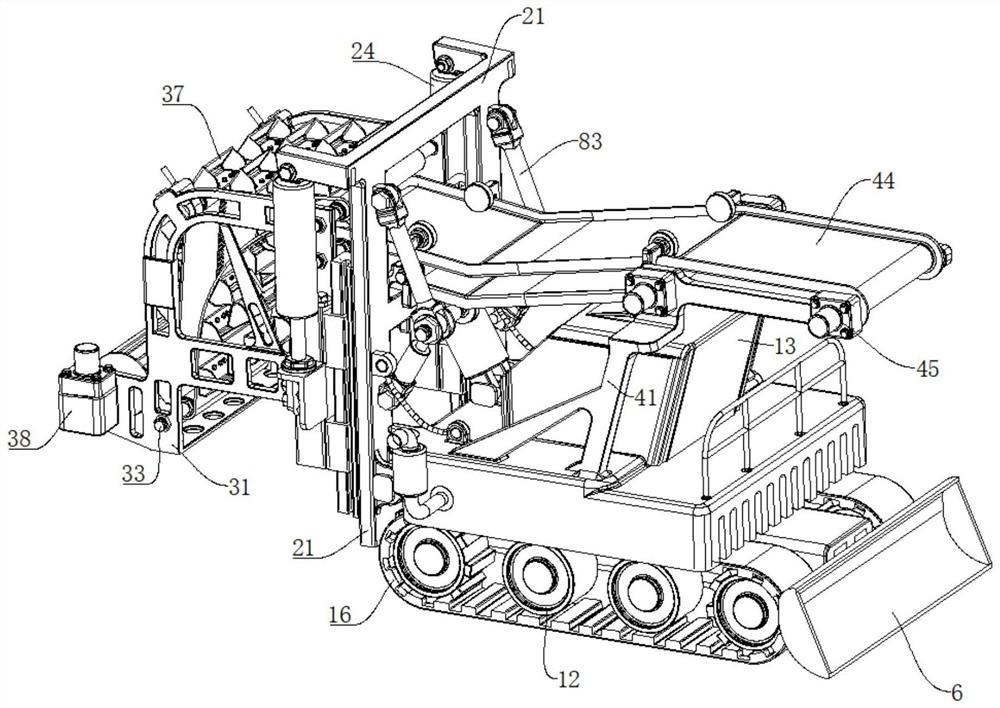

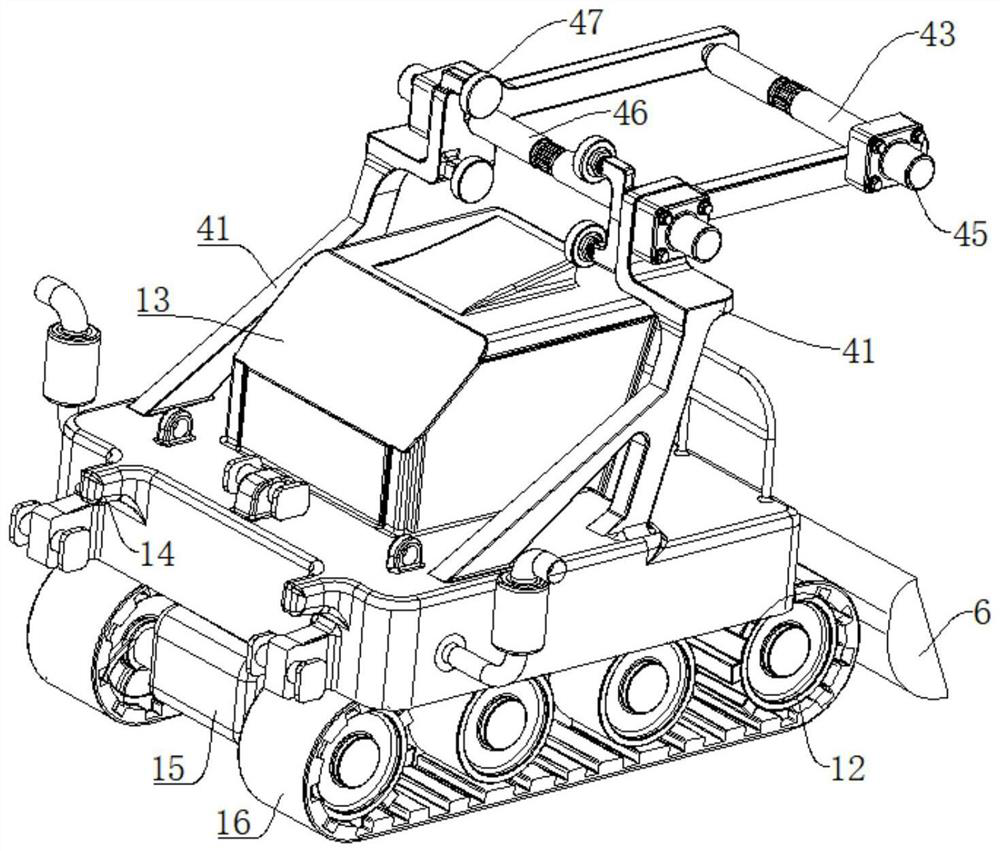

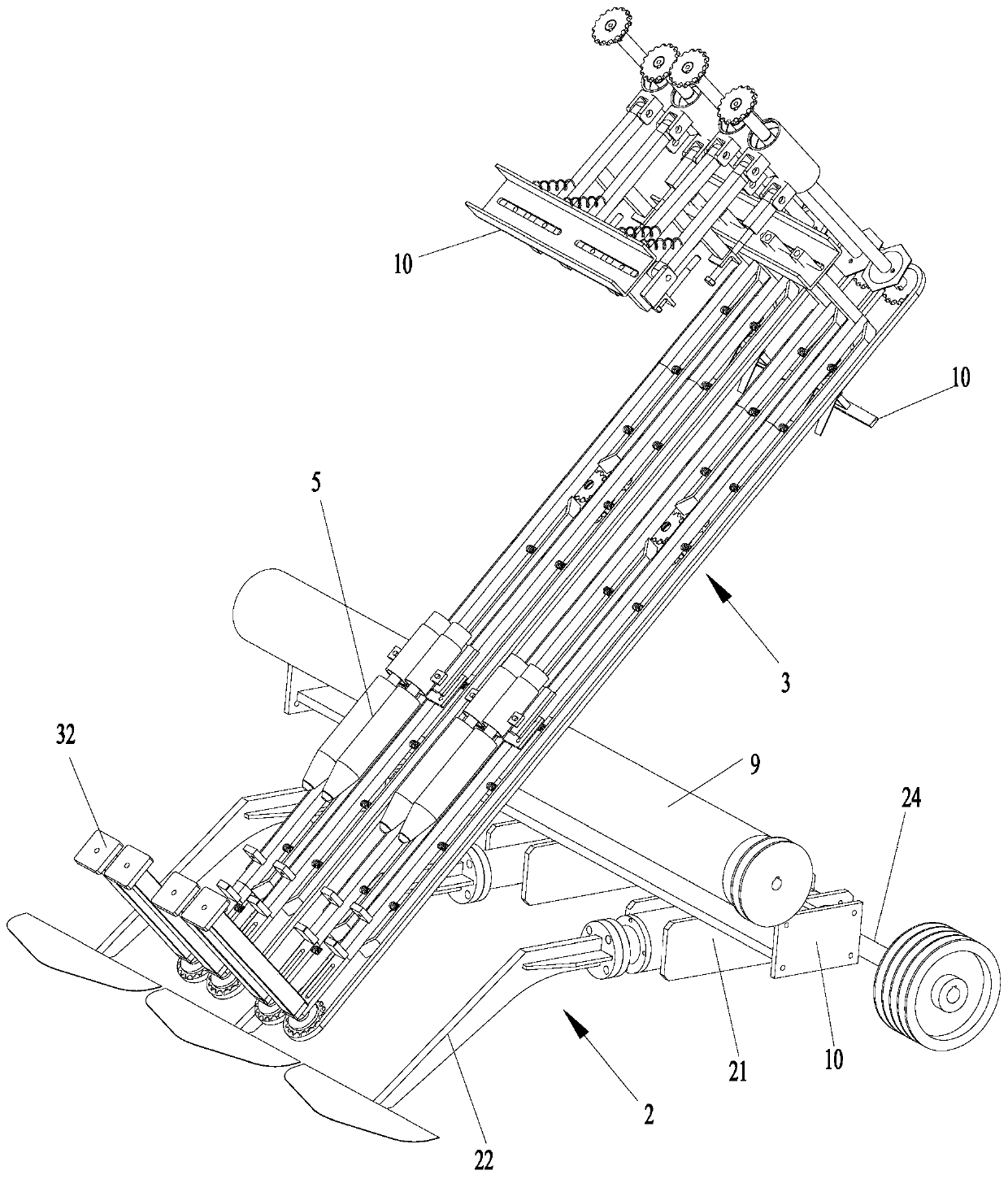

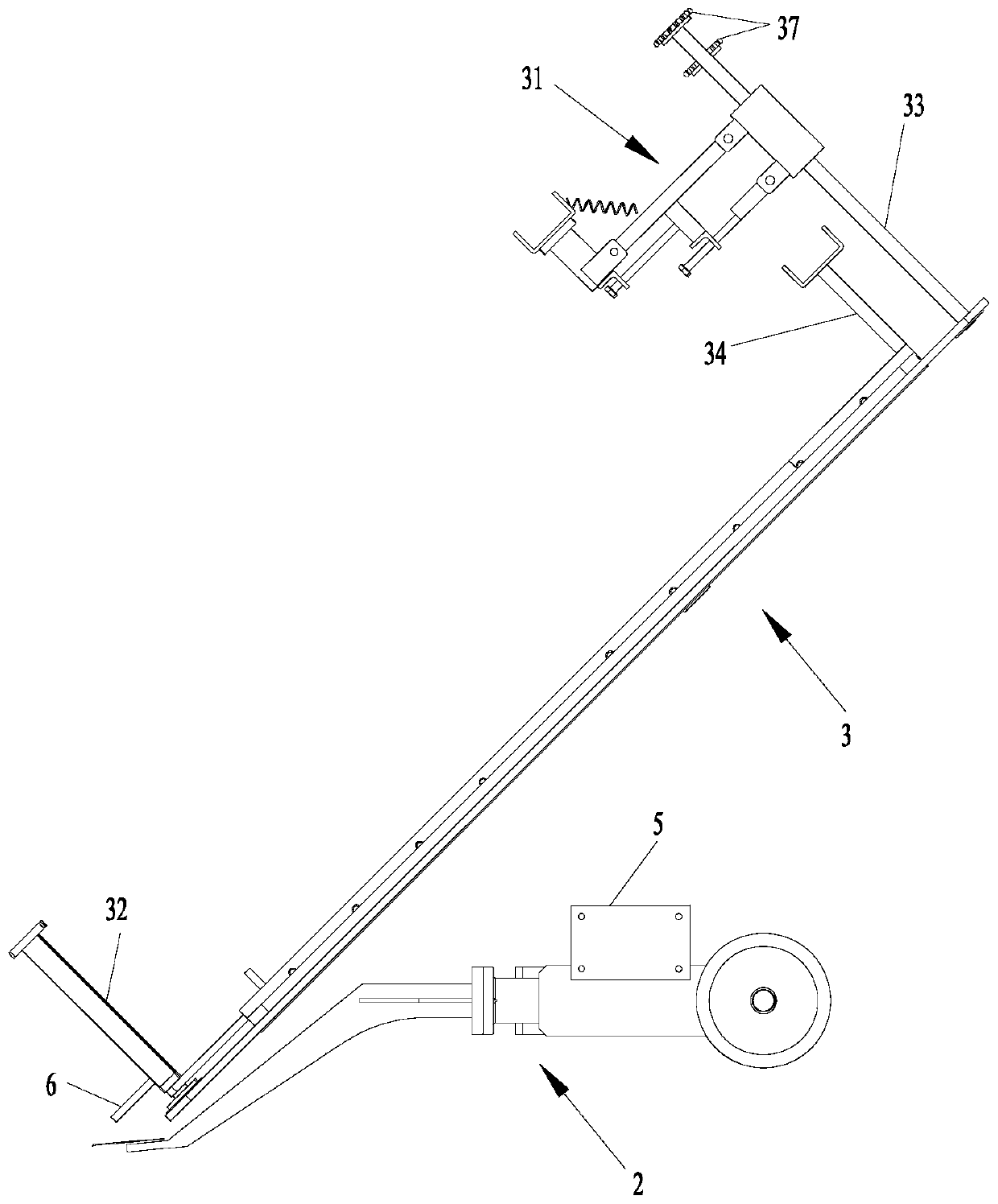

Loading machine with rotary feeding hoppers

PendingCN111977395AImprove work efficiencyShorten the timeConveyorsLoading/unloadingTransmission beltControl engineering

The invention provides a loading machine with rotary feeding hoppers. The loading machine comprises a walking device, a feeding device, a belt conveying device and a tensioning mechanism. The feedingdevice comprises a feeding frame, a first rolling shaft, a second rolling shaft, a third rolling shaft, conveying belts, a first drive device, a second drive device and a feeding roller. The conveyingbelts are installed on the first rolling shaft, the second rolling shaft and the third rolling shaft. The first drive device is connected with the first rolling shaft in a transmission manner. The feeding frame is installed ahead of the walking device. The outer side wall of each conveying belt is provided with a plurality of feeding hoppers distributed at equal intervals. The tensioning mechanism is installed between the conveying belts and the feeding frame. A feeding roller is installed on the portion, ahead of the conveying belts, of the bottom of the feeding frame in a rotating manner. The second drive device is used for driving the feeding roller to rotate. The belt conveying device is installed on the walking device. The loading machine can solve the technical problems that when atraditional loading machine or transferring machine carries out loading or transferring operation, needed space is large, and the loading efficiency is low.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

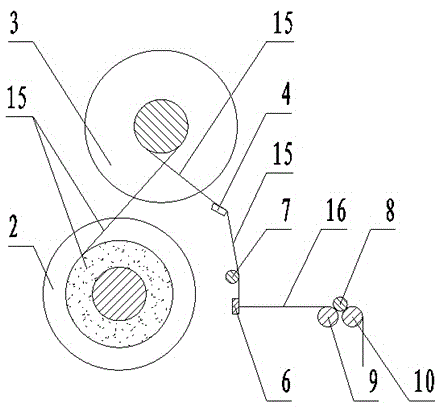

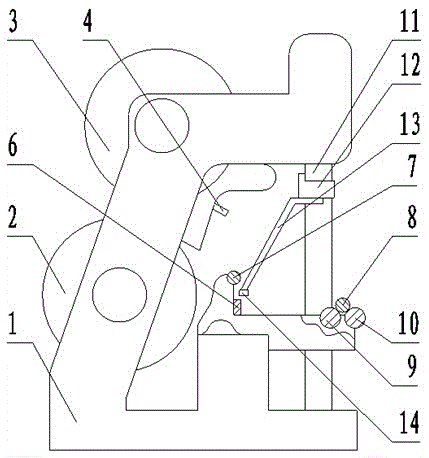

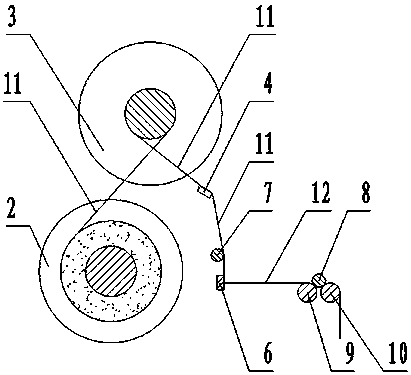

Method for improving weaving flatness and loom

The invention discloses a method for improving weaving flatness and a loom. According to the method, yarns are tensioned twice through a tensioning wheel and a tensioning roller, and woven cloth is heated through a heating roller, is limited and tensioned through a limiting roller, and is cooled and sized through a guide roller. The loom constructed according to the method comprises a machine frame (1), wherein a yarn wheel (2) is arranged on the machine frame (1); the tensioning wheel (3) is arranged above the yarn wheel (2); a yarn separating plate (4) is arranged on the lower side of the tensioning wheel (3); a working table (5) is arranged below the yarn separating plate (4); a weaving needle (6) is arranged at one end of the working table (5); the tensioning roller (7) is arranged above the weaving needle (6); the limiting roller (8) is arranged at the other end of the working table (5); the heating roller (9) and the guide roller (10) are arranged on two sides below the limiting roller (8) respectively. The heating efficiency and the production efficiency can be improved, and the method and the loom also have the advantages of high flatness and high product quality.

Owner:山东贝斯特信息科技有限公司

Strip billet tensioning device of V-shaped belt cloth wrapping machine

The invention discloses a strip billet tensioning device of a V-shaped belt cloth wrapping machine. The strip billet tensioning device comprises a rack, wherein one side of the rack is fixedly connected with a first rotary motor and a second rotary motor; the output end of the first rotary motor is fixedly connected with a first connecting rod; the first connecting rod passes through the rack; oneend of the first connecting rod is rotatably connected with a drive wheel through a rotary shaft; one side of the drive wheel is equipped with a driven wheel; the center of one side of the driven wheel is fixedly connected with a connecting block; a second connecting rod is arranged on the inner cavity of the connecting block in a sleeving mode; strip billets are arranged on the drive wheel and the driven wheel; one side of the driven wheel is equipped with a gear; the gear is rotatably connected with a third connecting rod through a rotary shaft; and the third connecting rod passes through the rack. The strip billet tensioning device of the V-shaped belt cloth wrapping machine is simple in structure, is easy in operation, is relatively low in manufacturing cost, is easily popularized, and has a wide application prospect.

Owner:阿雷法(苏州)汽车部件有限公司

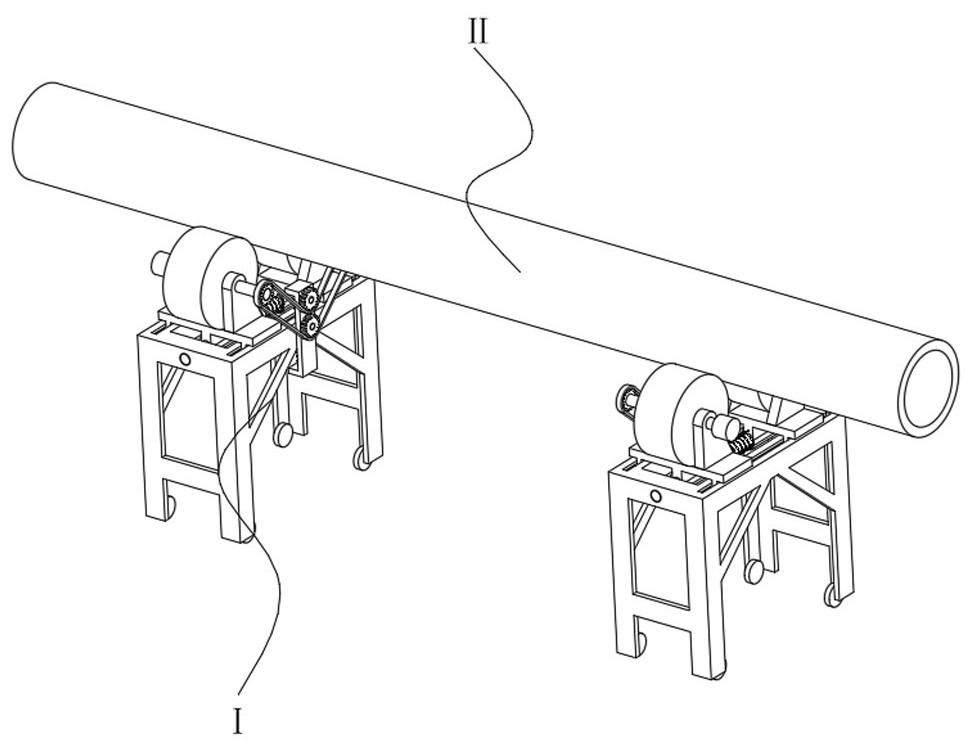

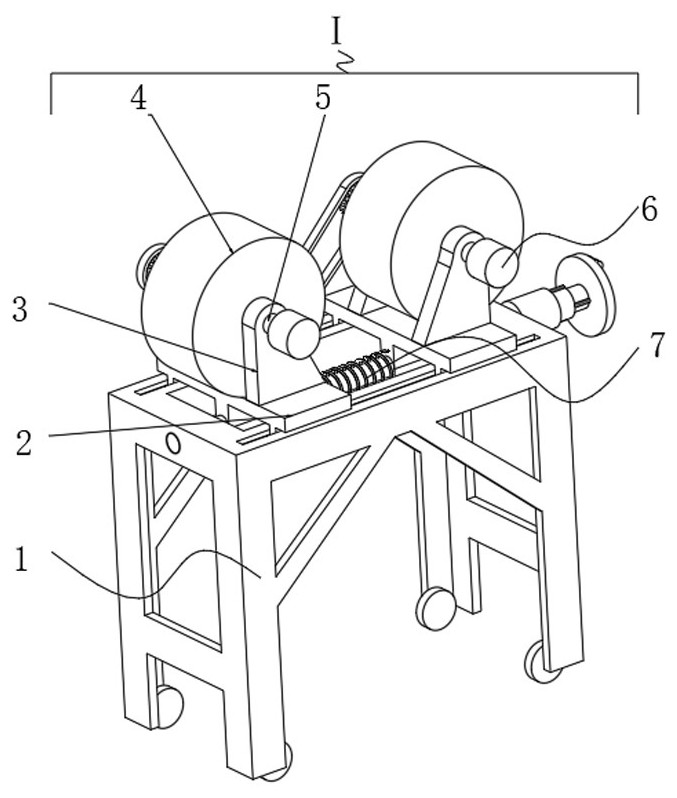

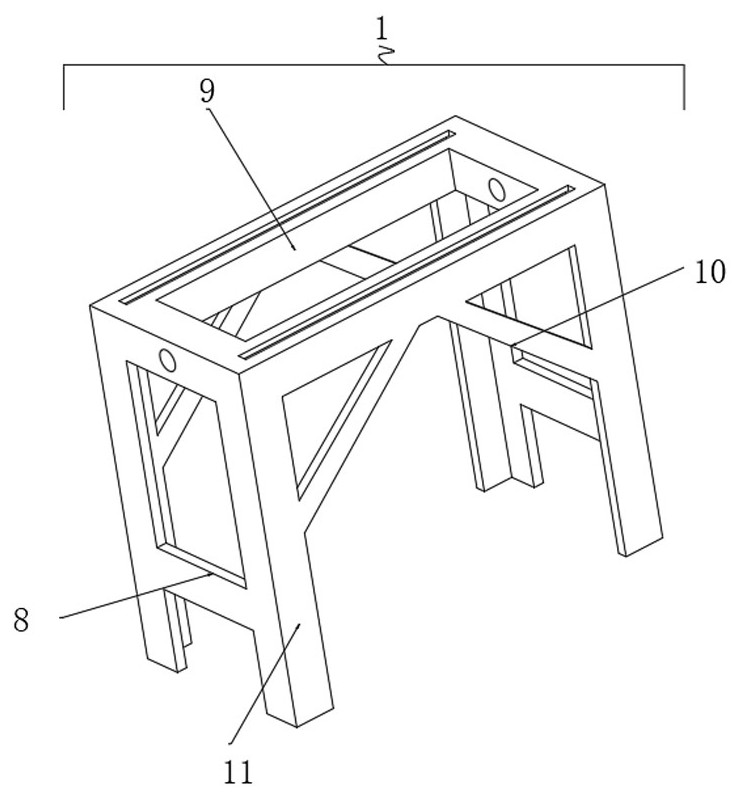

Simple construction pedestal for steel pipe painting and using method thereof

ActiveCN113578586AMeet the convenience of manual brushingChange distanceSpraying apparatusClassical mechanicsEngineering

The invention discloses a simple construction pedestal for steel pipe painting and a using method thereof, and relates to the technical field of pipeline protection. In order to solve the problem that manual painting operation is difficult, the simple construction pedestal comprises two sets of pedestal modules used for supporting a steel pipe to be painted, each pedestal module comprises a support structure and two supports symmetrically arranged at the top of the support structure, and a supporting plate is welded to the outer wall of the top of each support. The using method comprises the steps that the supporting distance between the two sets of pedestal modules is determined according to the length of the steel pipe, and the two sets of pedestal modules are placed at the distance; according to the diameter and the supporting height of the steel pipe, the distance between two rubber roller assemblies is adjusted by rotating a lead screw, and the steel pipe is hoisted to the position between the two sets of rubber roller assemblies; and reversing rubber wheels make contact with the side wall of the steel pipe, and the supporting point positions of the two sets of pedestal modules are finely adjusted. According to the simple construction pedestal for steel pipe painting and the using method thereof, 360-degree dead-angle-free painting can be achieved while the manual painting convenience is met.

Owner:中国建筑土木建设有限公司

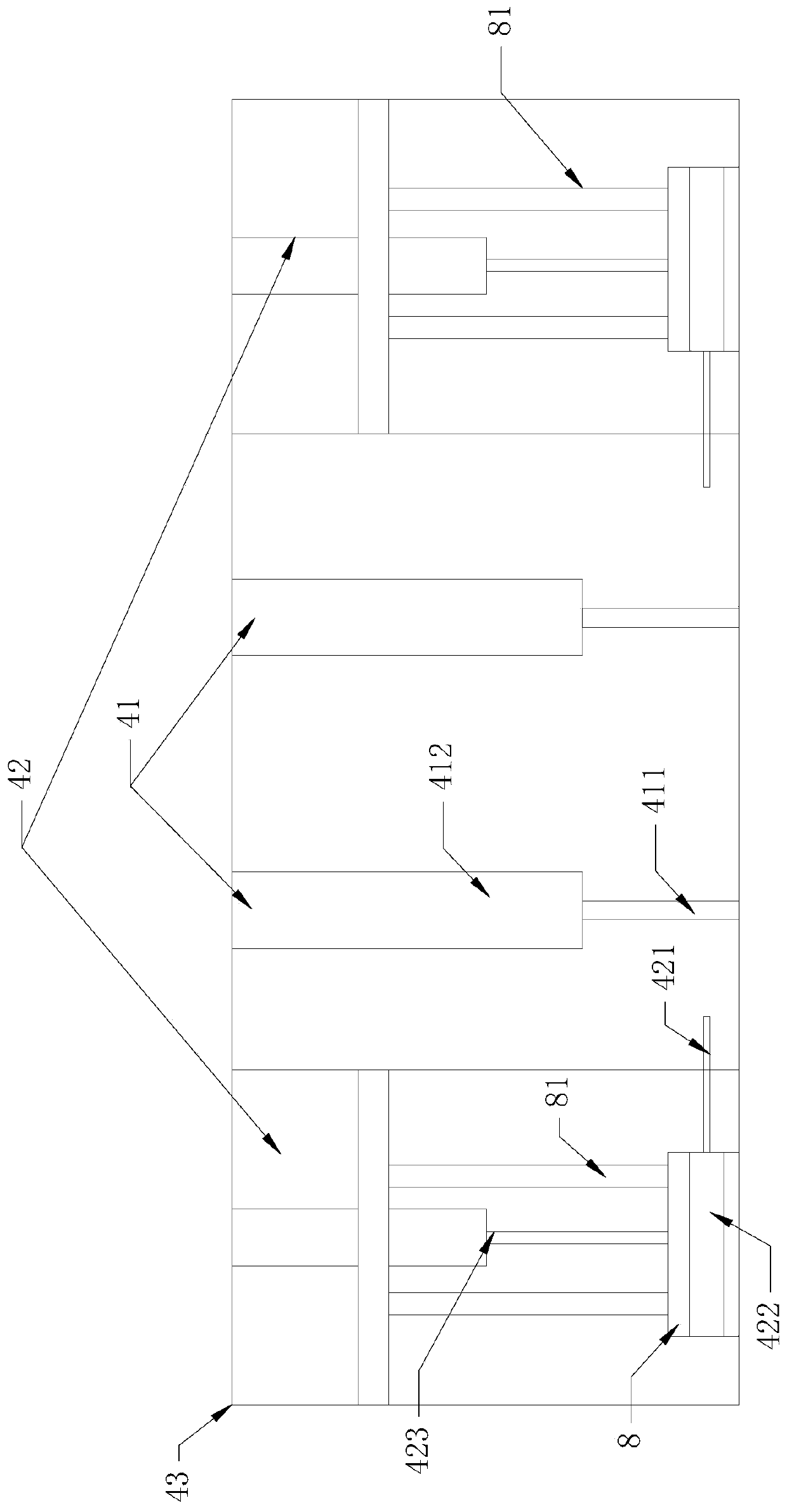

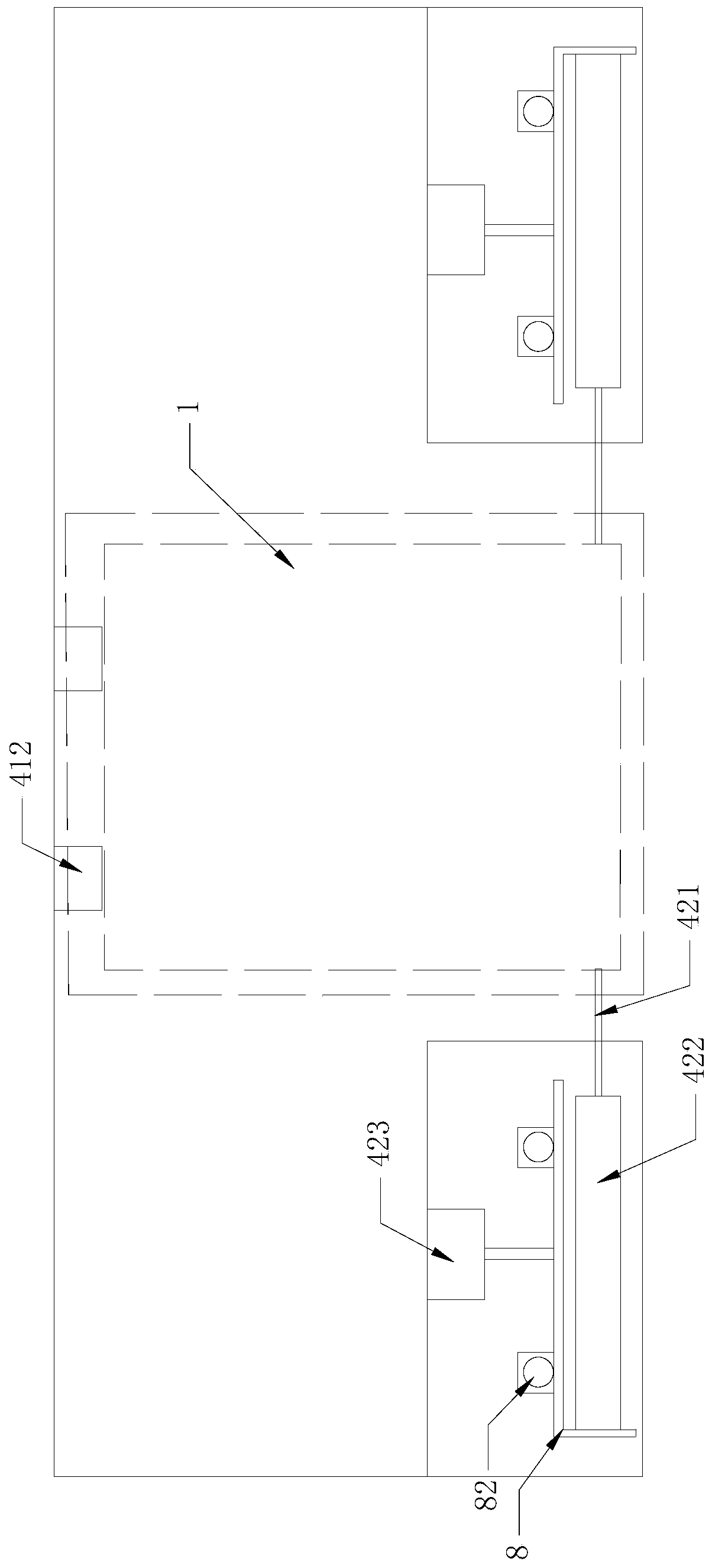

Quick-replacing device and method for cleaning paper

ActiveCN109572250AShorten the timeIncrease productivityOther printing apparatusWebs handlingButt jointGas cylinder

The invention discloses a quick-replacing device for cleaning paper. The quick-replacing device comprises a cleaning mechanism and quick paper replacing mechanisms, wherein a paper rolling motor and alimiting gas cylinder are mounted on the cleaning mechanism; connecting shafts which are in the shape of a semi-circular head are arranged on the quick paper replacing mechanisms; when the connectingshafts are separated from the paper rolling motor, the quick paper replacing mechanisms can be integrally taken out from the cleaning mechanism; and when the limiting gas cylinder extends out to abutagainst the quick paper replacing mechanisms, the connecting shafts can be in 360-degree no-dead-angle butt-joint with the paper rolling motor. Two groups of same quick paper-replacing mechanisms arereserved on each piece of equipment, and the two quick paper-replacing mechanisms are alternatively replaced for use, so that middle paper replacing time, and starting-up and closing-down time is reduced, production efficiency is improved, and production cost is reduced.

Owner:GKG PRECISION MACHINE

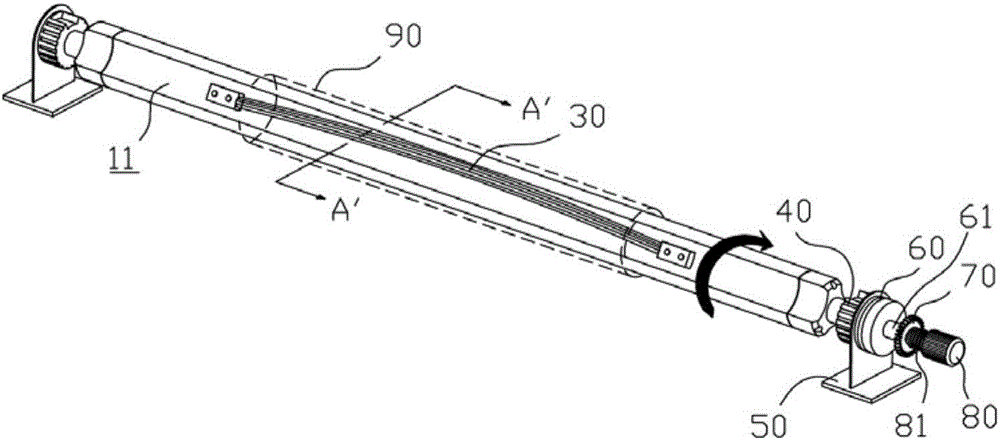

Tensioning mechanism of film-pasted coiled tube core

The invention discloses a tensioning mechanism of a film-pasted coiled tube core. The tensioning mechanism comprises a spindle, wherein two locking blocks are arranged at two ends of the spindle respectively and are fixed to the spindle through a plurality of bolts, the middle of the spindle is a central shaft, the central shaft penetrates through the locking blocks for installation, the central shaft penetrates an installing block to be fixed in a base, and the base is installed on a rack of a film-pasted machining machine tool. The spindle is provided with three large gaps, the gaps are circular-arc-shaped and are arranged peripherally, two fixing blocks are arranged in each large gap, and a tensioning strip is arranged between the two fixing blocks. The tensioning mechanism of an existing film-pasted coiled tube core is improved in design, the plastic tensioning strip is designed and installed in the large gaps, so that the tube core firmly attaches to the tensioning strip during rotation, and a tensioning effect is played on the tube core.

Owner:苏州威仕薄膜科技有限公司

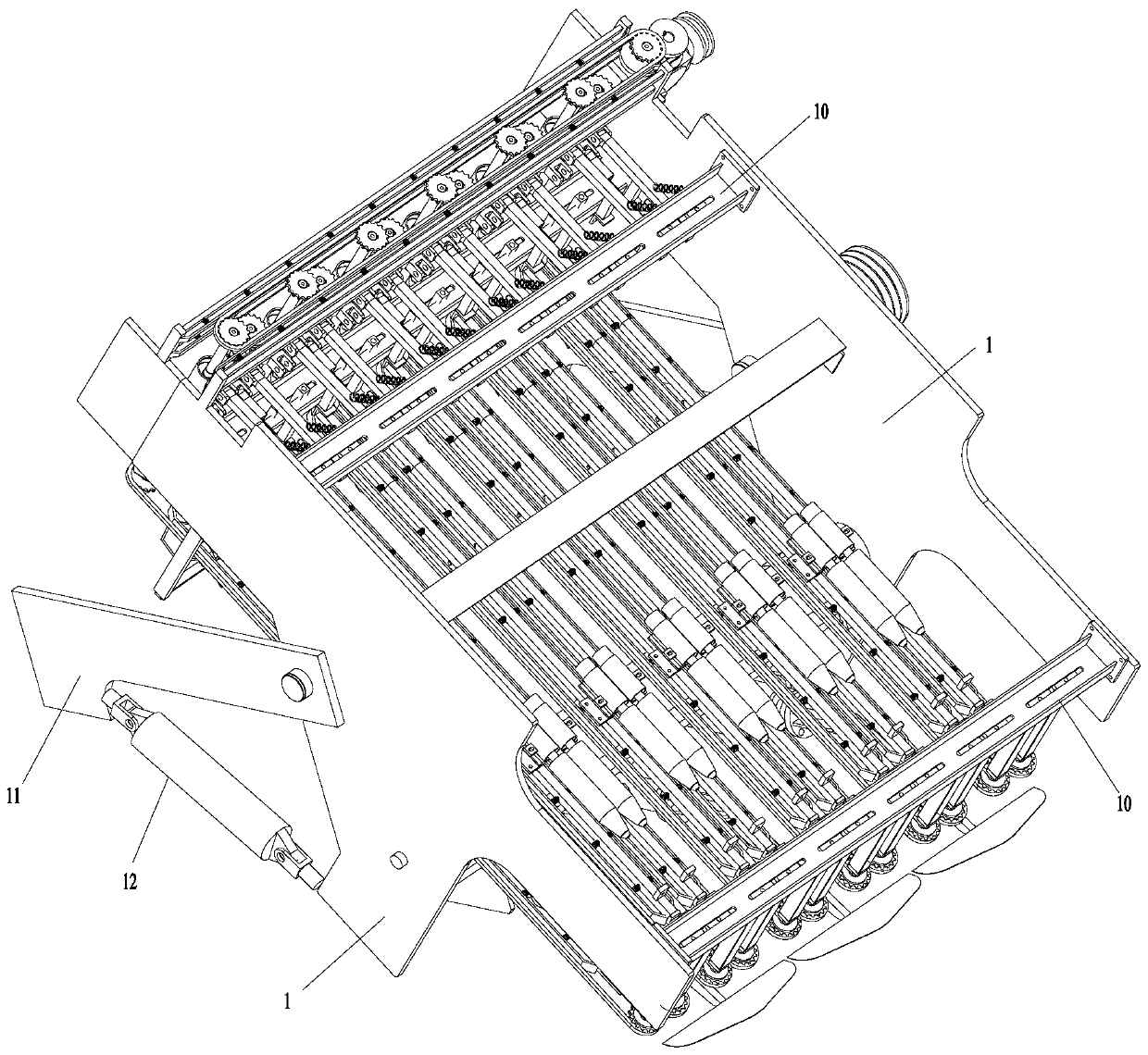

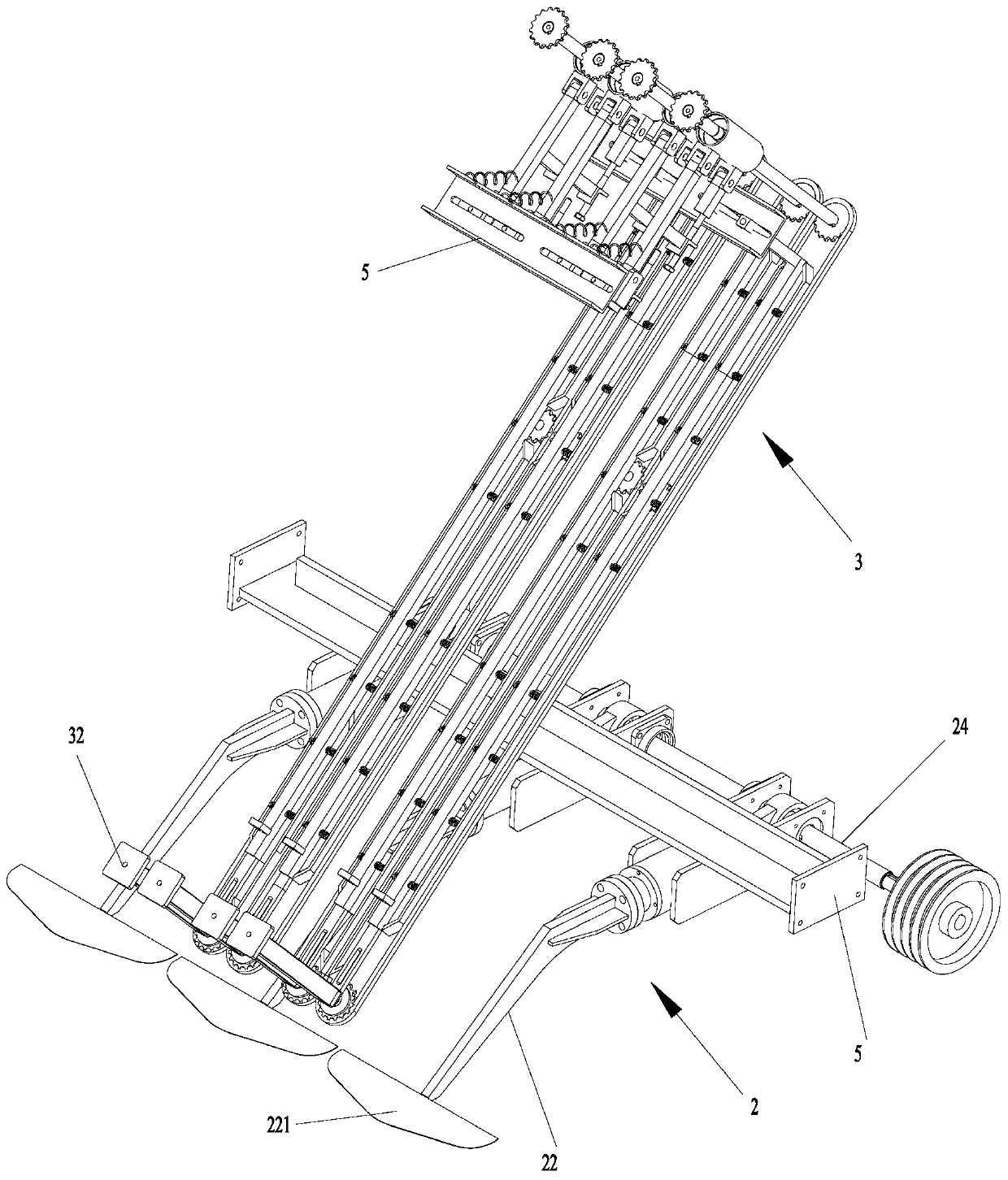

Shearing device of garlic harvester

PendingCN111436273AStable clampingReduce impactDigger harvestersFood treatmentAgricultural engineeringStructural engineering

The invention discloses a shearing device of a garlic harvester. The shearing device comprises a soil and garlic separation mechanism arranged on two symmetric side plates; the soil and garlic separation mechanism is provided with positioning mechanisms, stigma shearing mechanisms and stem shearing mechanisms; the soil and garlic separation mechanism comprises chain lifting units used for clampinggarlics to be conveyed; the soil and garlic separation mechanism is mounted on a tractor by the two symmetrically arranged side plates; the positioning mechanisms are used for carrying out positioning in a garlic lifting process; each stigma shearing mechanism comprises a guide frame and a blade arranged on the guide frame; and each stem shearing mechanism comprises two blades which are overlapped together, and the two overlapped blades are opposite in rotational direction. By utilizing a structure that one end of each chain lifting unit is fixed and the other end of the chain lifting unit issuspended, garlic clamping is more stable on one hand, and the change of the garlic size can be adapted by combination with the stigma shearing mechanisms on the other hand, so that the stigma shearing mechanisms can capture garlic stigmas more accurately.

Owner:徐州腾尔盛机械设备科技有限公司

Double roller glue application device of solvent-free compound machine

PendingCN111299064APlay a tension rolePrevent looseningLiquid surface applicatorsCoatingsSolvent freeEngineering

The invention discloses a double roller glue application device of a solvent-free compound machine. The double roller glue application device includes a worktable, a base material, fourth connecting rods, a third supporting plate, first rotating rods and glue scraping plates; a glue groove is formed in the upper end surface of the worktable, and two sets of first supporting plates are arranged onthe worktable; a heating tube is arranged at the groove bottom of the glue groove; third connecting rods are arranged at the bottoms of the two sets of first supporting plates; glue application rollers sleeve the third connecting rods; the glue scraping plates are in contact with the glue application rollers; the fourth connecting rods are located above the third connecting rods, edge pressing rollers sleeve the fourth connecting rods; connecting plates are arranged on the two sides of the fourth connecting rods; second supporting plates are arranged at the tops of the two sets of connecting plates; the bottoms of the first rotating rods penetrate through first through holes to extend into the upper parts of the second supporting plates, first limiting rings and second limiting rings sleeve the first rotating rods, and screws are arranged at the bottoms of the first rotating rods; and the screws are matched with thread holes. The glue application work of the base materials with different thicknesses can be satisfied; and meanwhile, the arrangement of guiding rollers can play a tensioning role and prevent the material from loosening during the glue application process.

Owner:江苏万喜至工业设计有限公司

Adhesive tape processing system and adhesive tape processing method

The invention discloses an adhesive tape processing system and an adhesive tape processing method, and relates to the technical field of adhesive tape processing.The adhesive tape processing system comprises a base plate, a winding motor is installed on one side of the upper portion of the base plate, an output shaft of the winding motor is connected with a winding drum, and the winding drum is sleeved with an adhesive tape drum; an adhesive tape adjusting assembly is arranged at the position, below the adhesive tape barrel, of the other side face of the base plate. According to the adhesive tape processing system and the adhesive tape processing method, when the adhesive tape is wound, under the work of the speed reduction servo motor and the electric push rod, the two limiting strips can play a role in limiting the adhesive tape barrel, in this way, after the adhesive tape is wound around the adhesive tape barrel, the dislocation situation is avoided, and under the work of the hydraulic cylinder, the adhesive tape can be wound around the adhesive tape barrel. The bottom of the adhesive tape can be propped by the guide shaft, the adhesive tape is tensioned, and meanwhile, the tensioning force can be adjusted, so that the adhesive tape cannot be loosened, and the adhesive tape is tidily wound on an adhesive tape barrel.

Owner:武汉友发包装科技有限公司

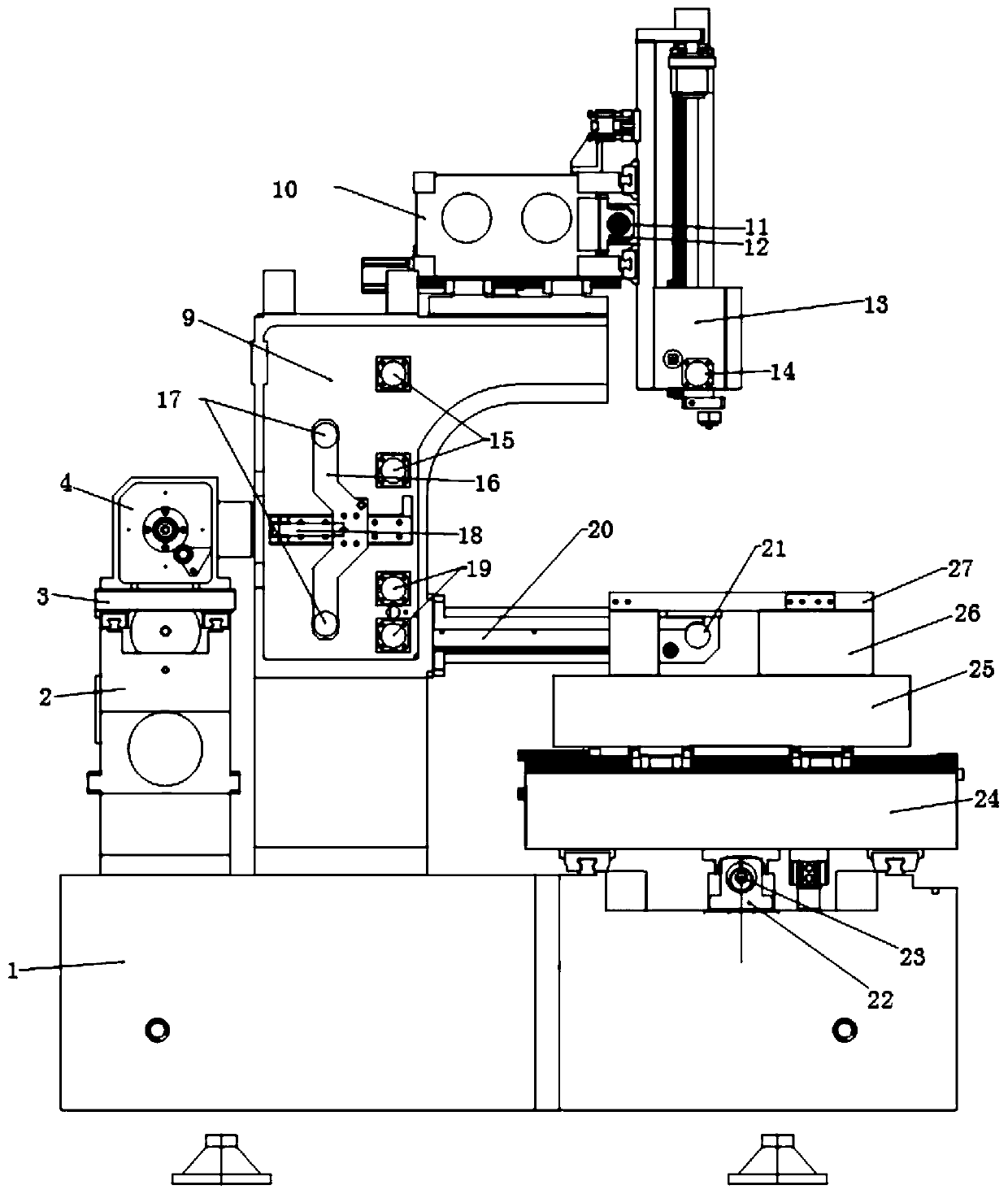

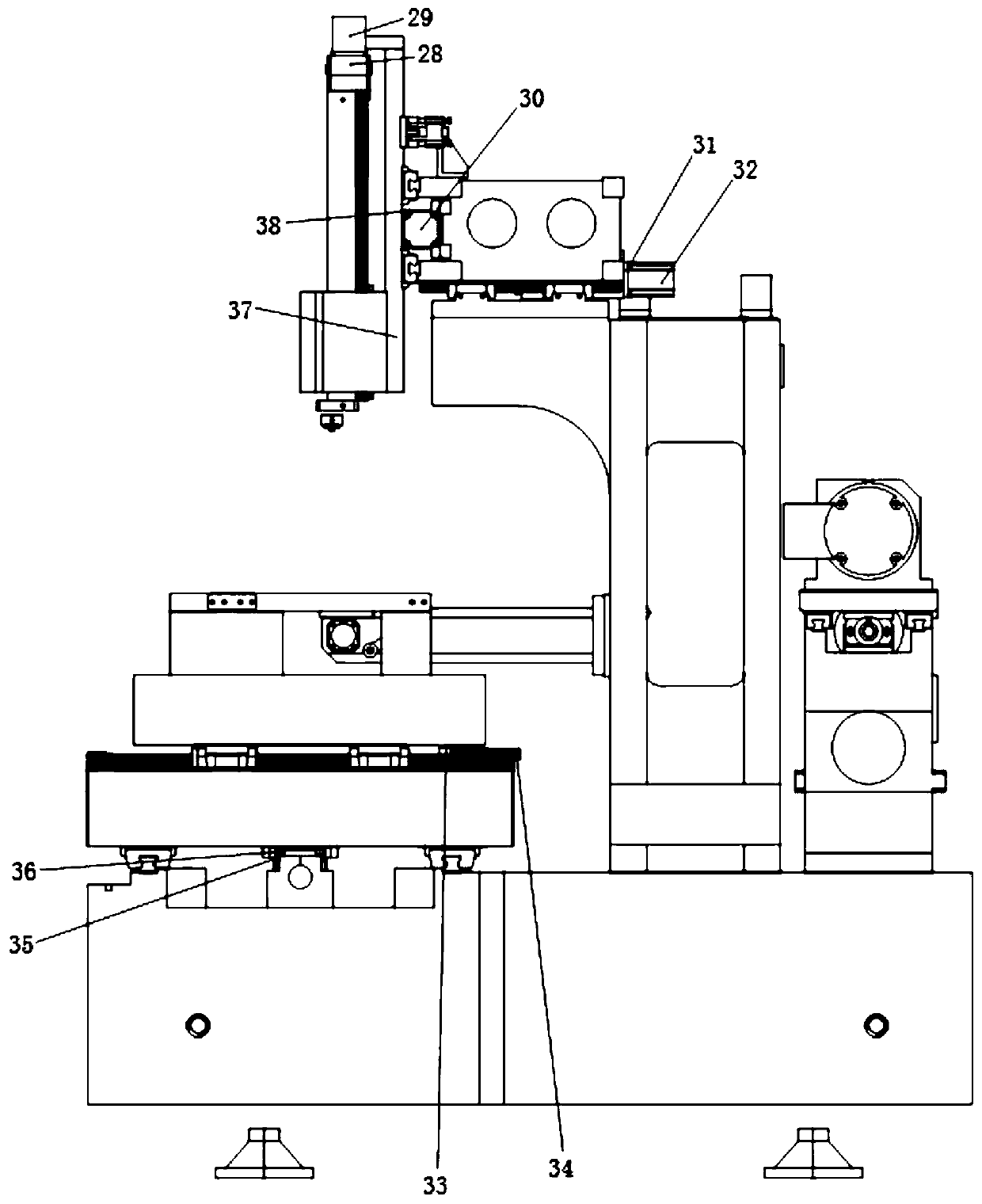

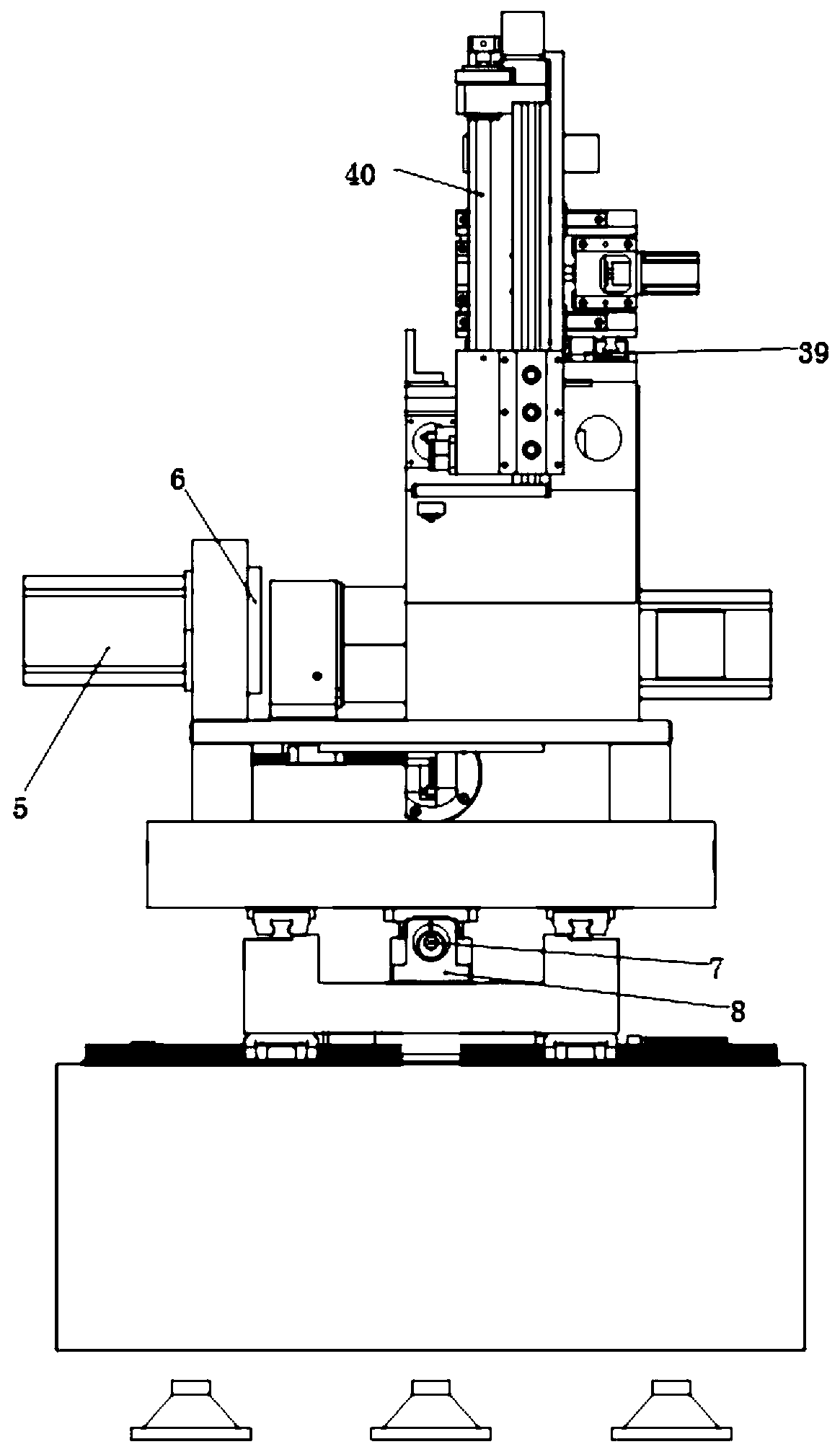

Six-shaft servo control marble lathe bed medium-speed wire cutting machine

InactiveCN111203602AIncrease flexibilityPlay a tension roleElectrical-based machining electrodesControl engineeringWire cutting

The invention discloses a six-shaft servo control marble lathe bed medium-speed wire cutting machine. The machine comprises a marble lathe bed base, wherein a wire conveying base is arranged on one side of the upper end face of the marble lathe bed base, a wire conveying device is arranged on the wire conveying base, a UV-shaft supporting base is arranged on the upper end face of a C-shaped standcolumn, a UV-shaft lead screw is arranged on the UV-shaft supporting base, one end of the UV-shaft lead screw is connected with a UV-shaft servo motor, a Z shaft is arranged on a Z-shaft fixing base,a Z-shaft lead screw is vertically arranged on the Z-shaft fixing base, the Z-shaft lead screw is in threaded connection with and penetrates through the Z shaft, a Z-shaft motor base is arranged on one side of the bottom of the Z-shaft fixing base, a Z-shaft servo motor is installed on the Z-shaft motor base, and the Z-shaft servo motor is in transmission connection with the Z-shaft lead screw. According to the machine, six-shaft servo control is adopted, the control effect is good, the flexibility of the medium-speed wire cutting machine is greatly improved, the working efficiency is improved, enterprise development is facilitated, an A shaft, a U shaft, a V shaft, an X shaft, a Y shaft and the Z shaft which are arranged are controlled by servo motors, the control effect is good, and operation is more accurate.

Owner:桑明焱 +1

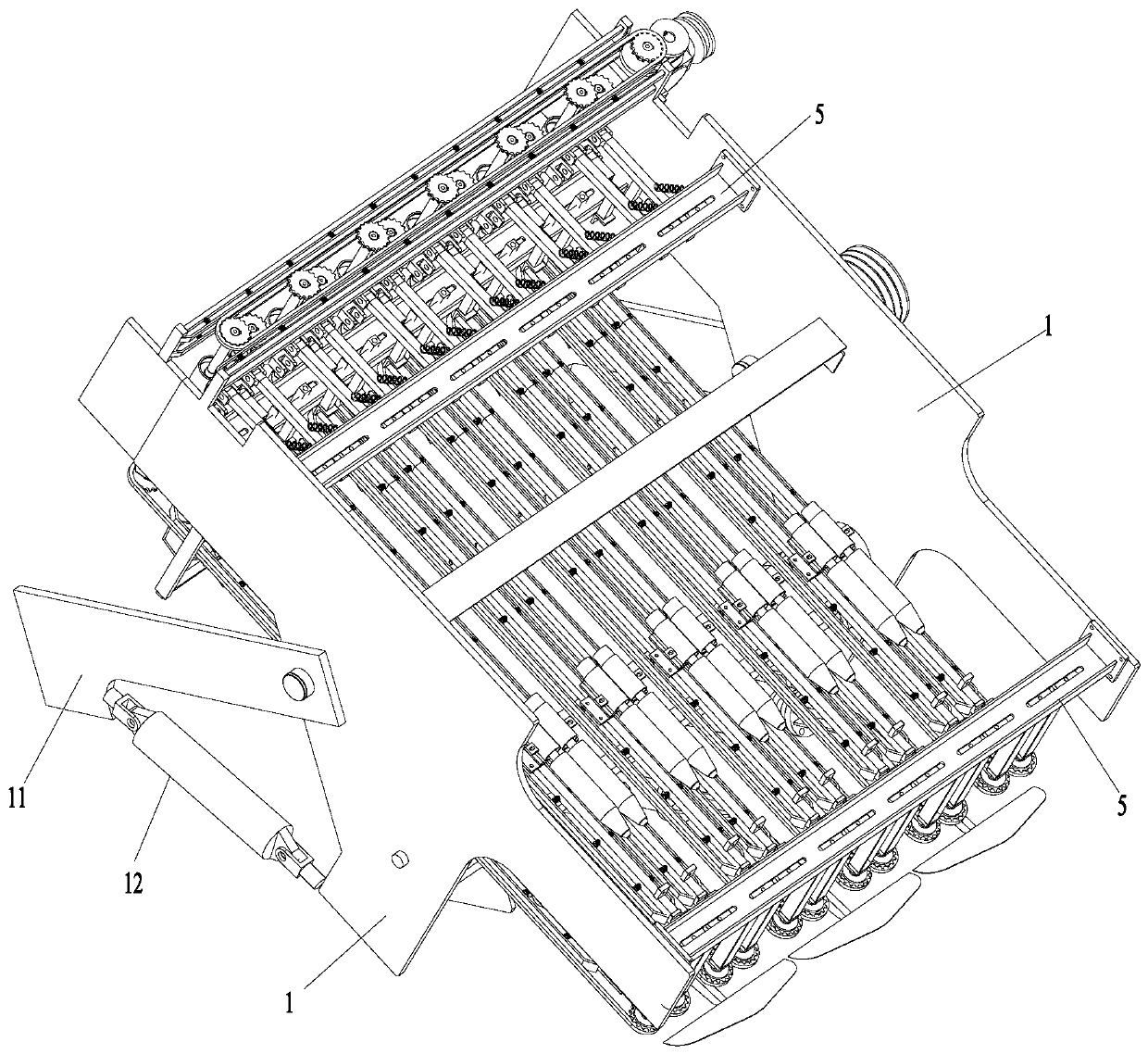

Earth and garlic separating mechanism of garlic harvester

PendingCN111406490AStrong shoveling abilityImprove radial load capacityNon-rotating vibration suppressionDiggersClassical mechanicsAllium sativum

The invention discloses an earth and garlic separating mechanism of a garlic harvester. The earth and garlic separating mechanism is mounted on a tractor through two side plates which are symmetrically arranged; a supporting arm which can rotate is arranged on each side plate; the supporting arms are fixed on the tractor; and a driving cylinder is arranged between each supporting arm and the corresponding side plate. The earth and garlic separating mechanism comprises earth scraping units, a chain elevating unit and a driving unit, wherein the earth scraping units are used for separating garlics from a soil layer; the chain elevating unit is used for transmitting the garlics to a collecting box; and the driving unit is used for providing power for the earth scraping units and the chain elevating unit. According to the earth and garlic separating mechanism disclosed by the invention, the chain elevating unit adopting a structure that one end is fixed, and the other end is suspended, isarranged, so that the earth and garlic separating mechanism is more stable when being used for clamping the garlics; and the flexible clamping can be adapted to impacts caused by that outside road surfaces are uneven, and the probability that the garlics fall down is reduced.

Owner:徐州腾尔盛机械设备科技有限公司

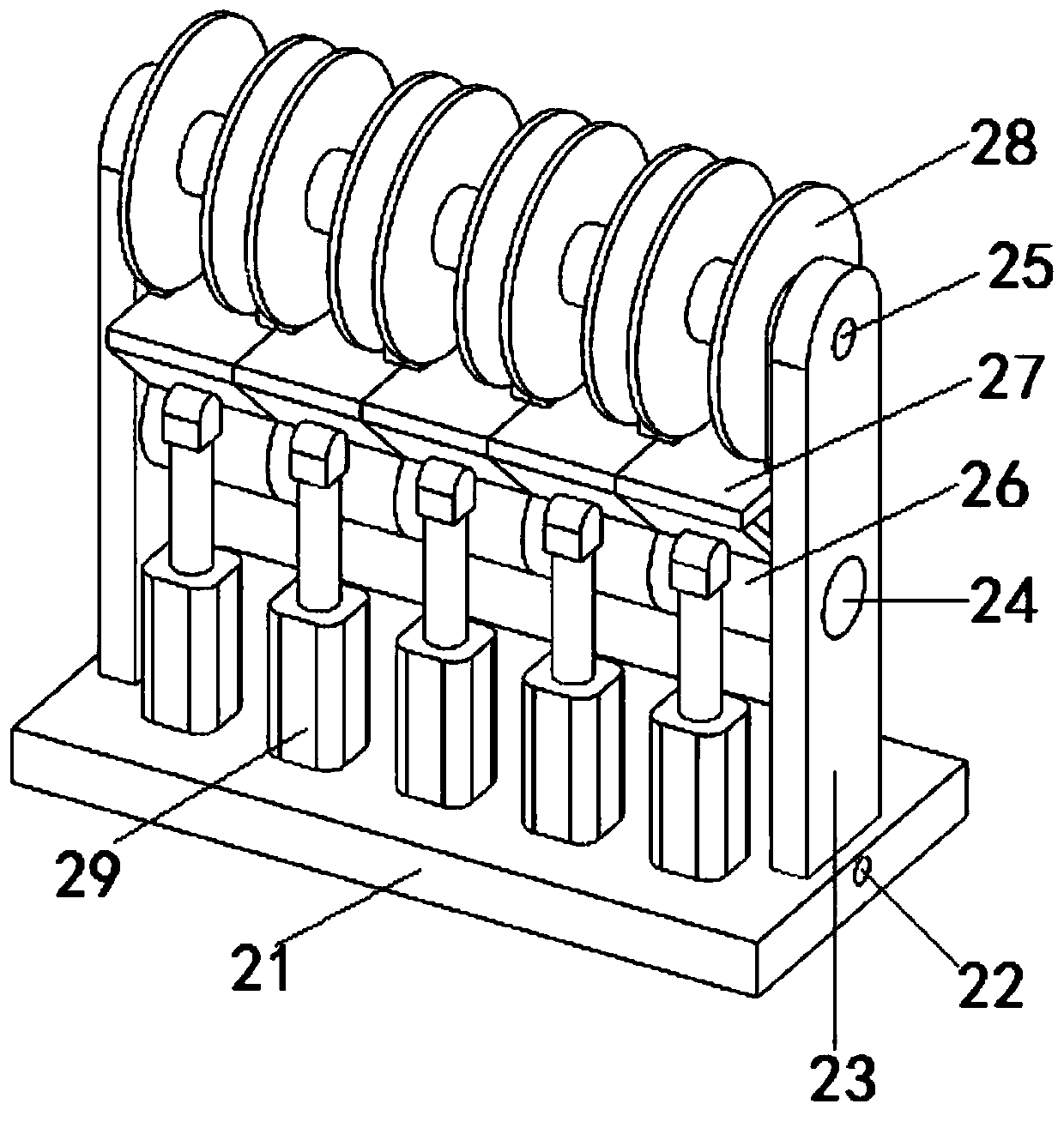

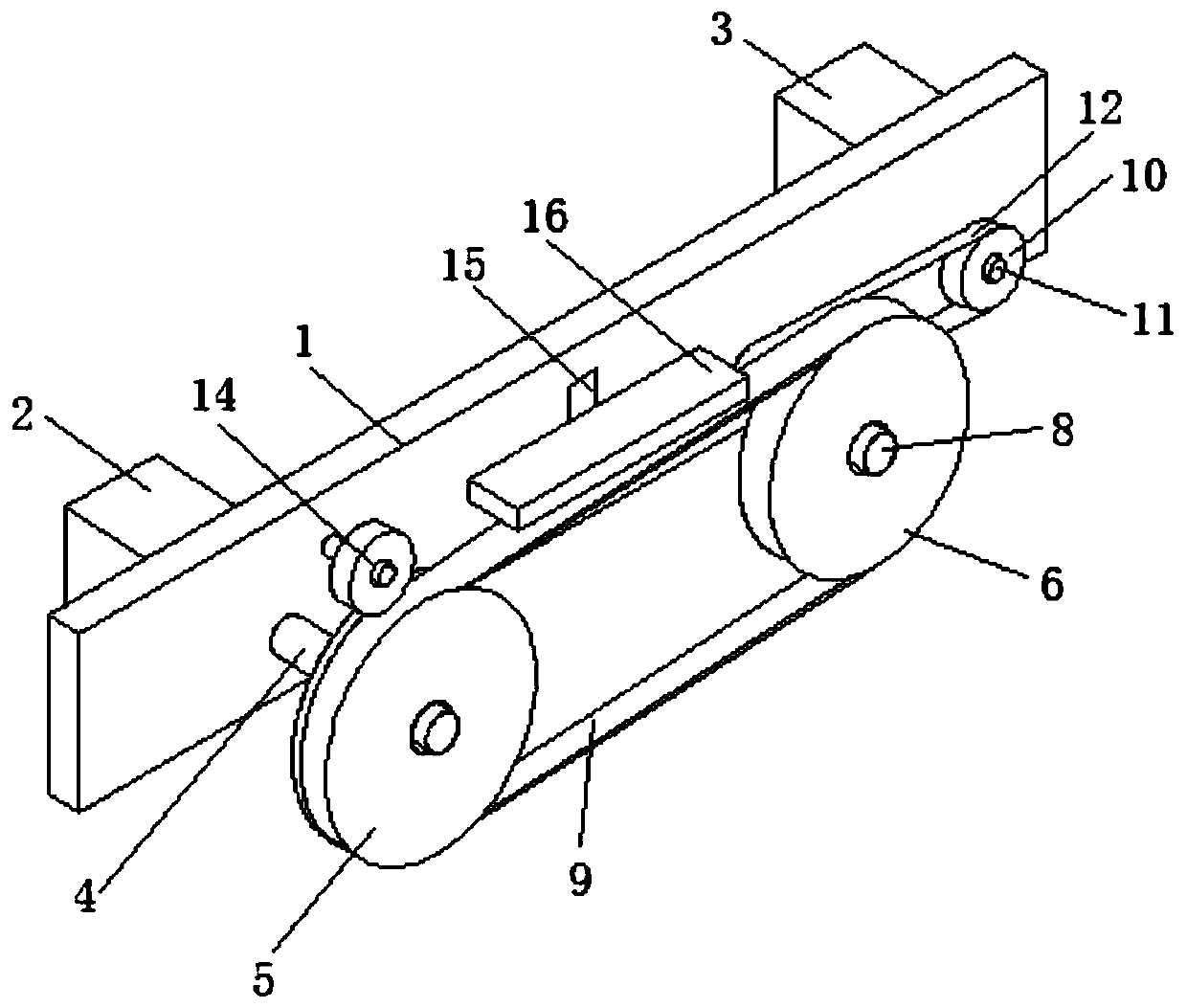

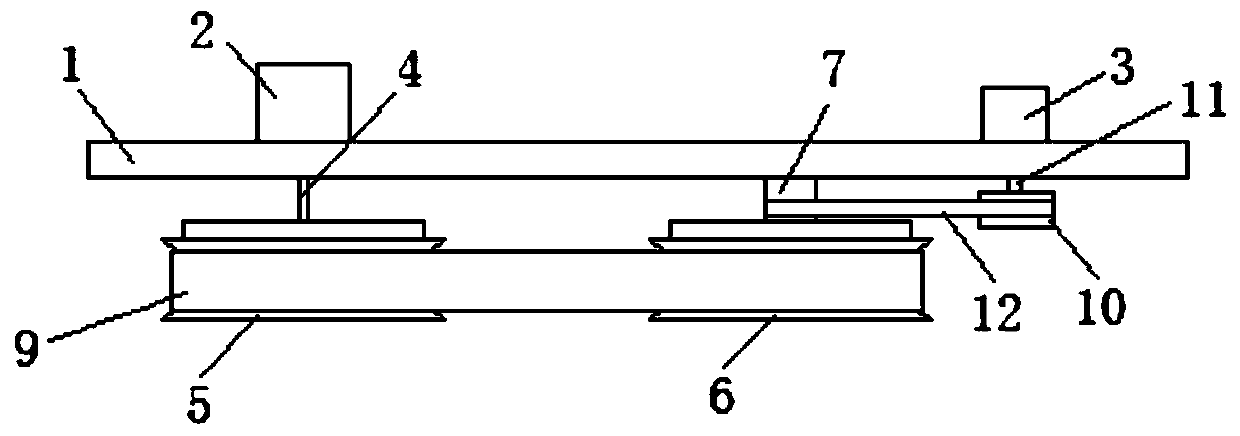

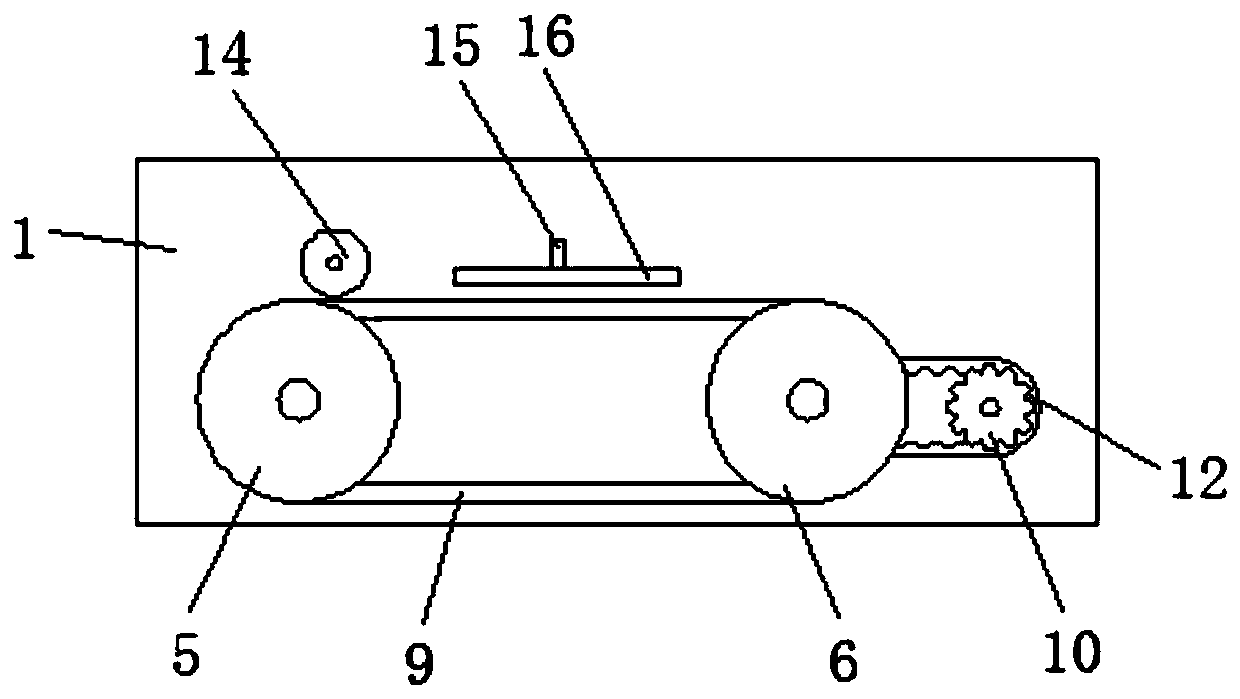

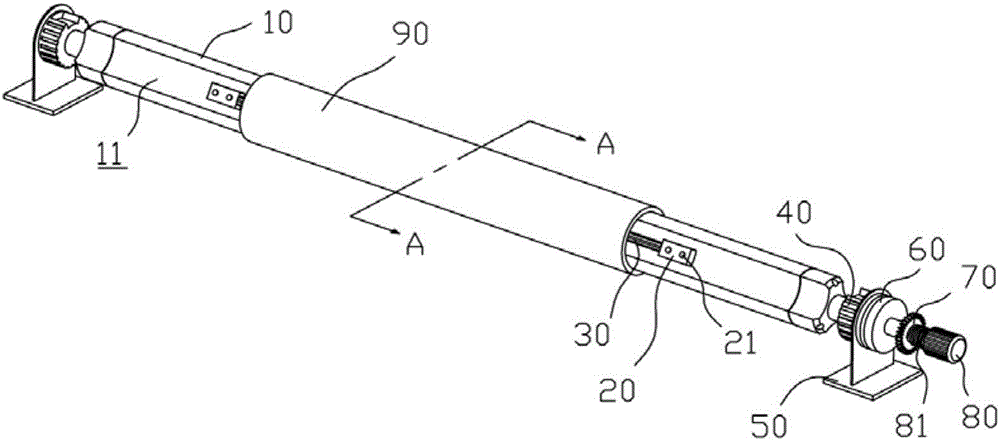

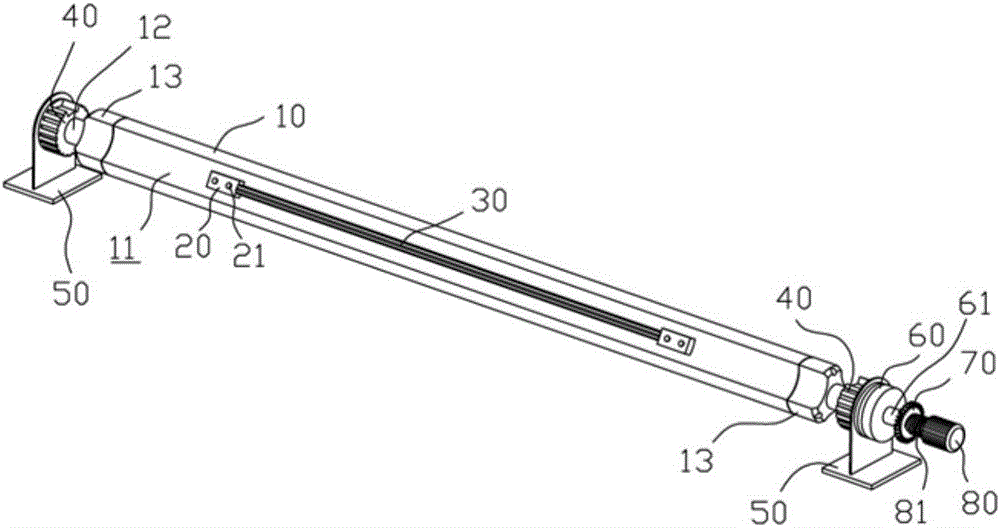

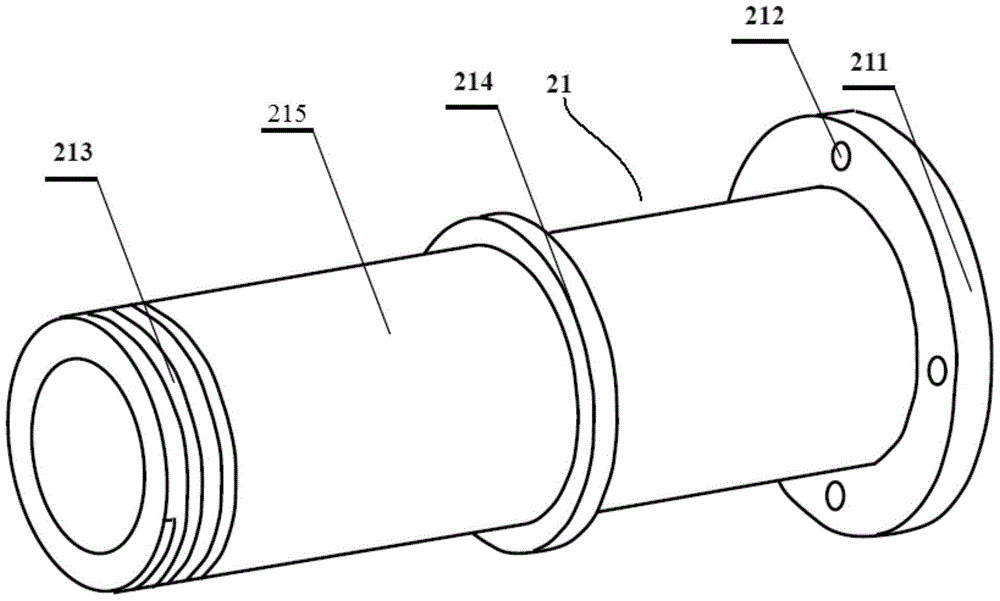

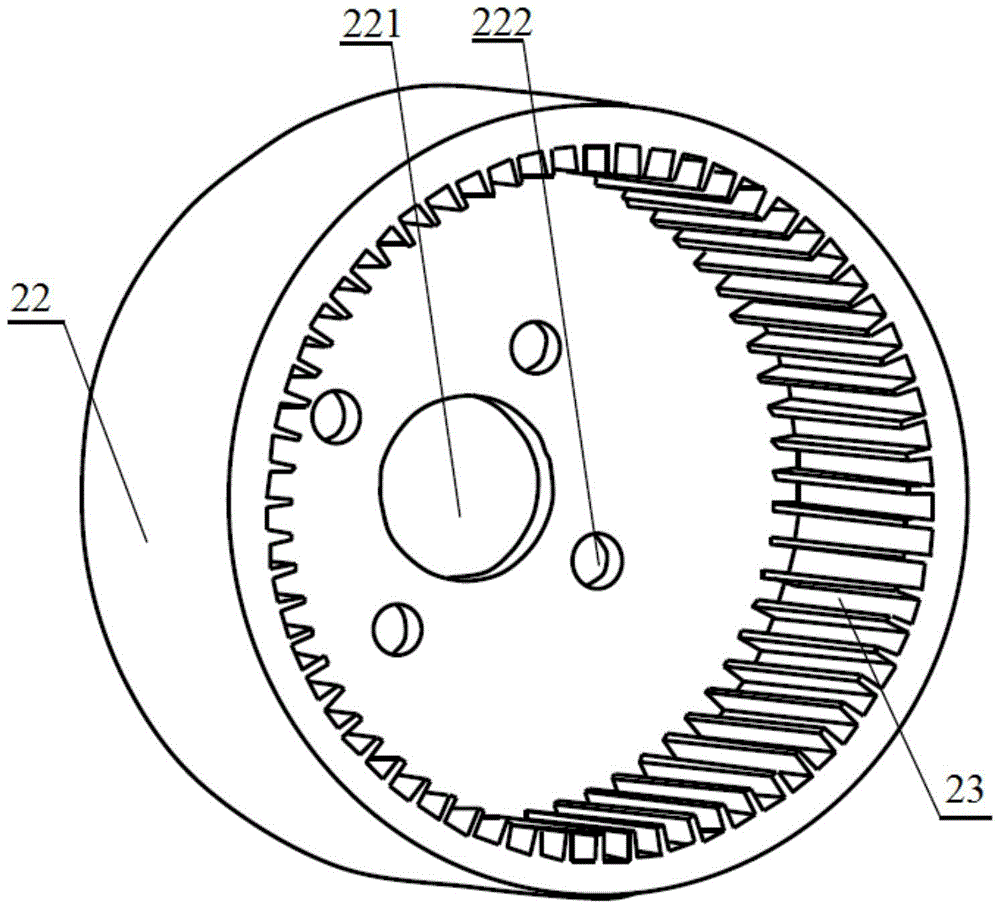

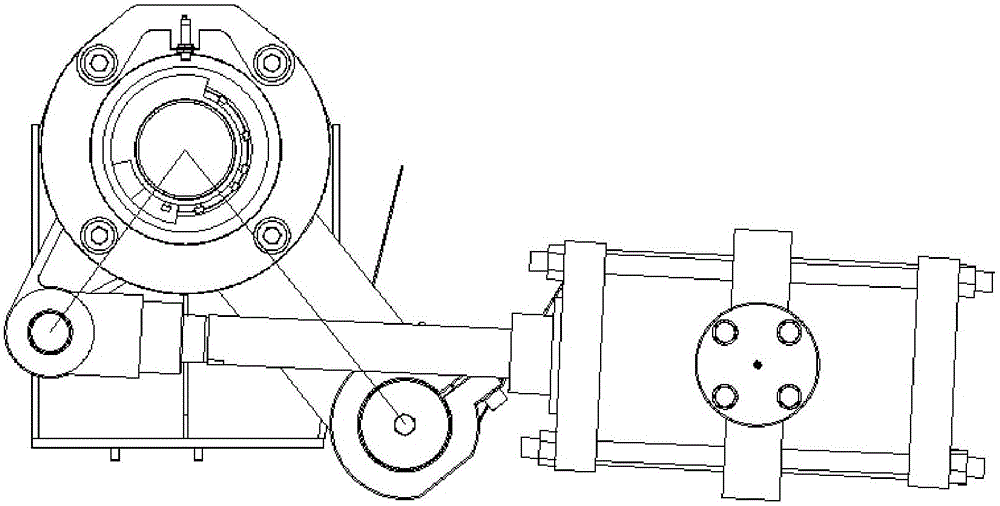

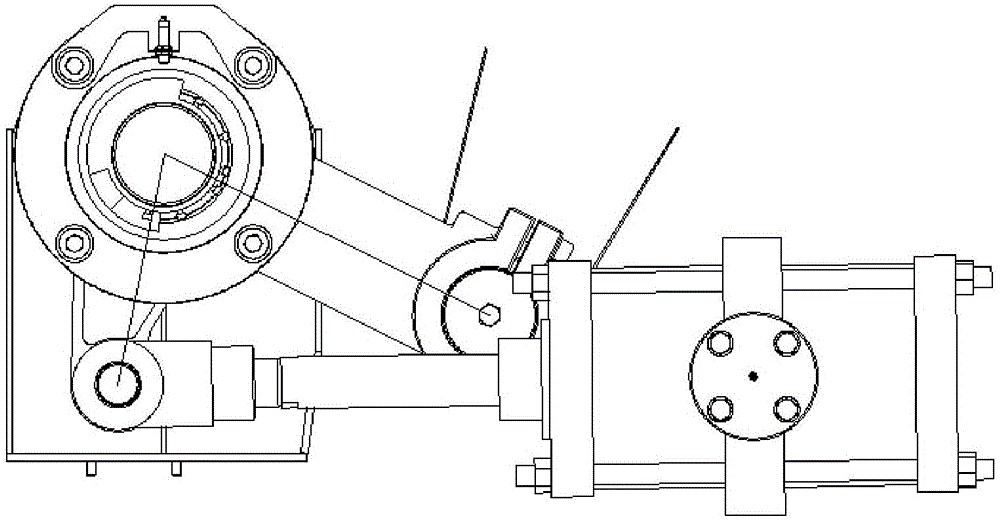

A micro-amplitude low-frequency tensioning device for flexible transmission

ActiveCN104913016BAchieve micro-motionAchieving slight low-frequency tensionGearingElectric power transmissionDrive wheel

The invention discloses a micro-amplitude low-frequency tensioning device for flexible transmission. The micro-amplitude low-frequency tensioning device comprises a machine frame, a planetary gear mechanism, a crank rocker mechanism and a tensioning execution mechanism. A driven wheel axle is of a hollow structure, one end of the driven wheel axle is fixedly connected with a driven wheel through a flange and a bolt, and the other end of the driven wheel axle is supported on the machine frame and can rotate. The planetary gear mechanism is arranged in a cylindrical space of the hollow driven wheel, a tooth ring is arranged on the circumference of the inner side of the driven wheel, a planetary gear is meshed with a center gear and the tooth ring, and the center gear is fixedly connected to the machine frame. A planet frame is provided with a crank pin; the crank rocker mechanism is formed through the hinging of the crank pin, a connecting rod, a rocker bar and the machine frame, and the bar length ratio is set so that the rocker bar performs small oscillating angle movement. A pressing wheel is installed on a guide rod fixedly connected with the rocker bar. The device does not rely on the gravity principle; and when the machine frame performs complex spatial movement or a frequently-used tensioning mode fails in the slight gravity and even weightless environment, the device stills has a tensioning and vibration absorption function.

Owner:安徽英格尔包装科技有限公司

A cable parallel device based on translational restraint structure

ActiveCN105945915BEasy to arrange flexiblyPlay a tension roleProgramme-controlled manipulatorCarrying capacityDegrees of freedom

The invention discloses a rope parallel device based on a translation constraint structure. The device comprises a static platform, an intermediate platform and a moving platform, wherein rollers and driving units are arranged on the static platform; ropes wind around the rollers and the driving units and are connected with the moving platform; the intermediate platform is connected with the static platform and the moving platform by the aid of rigid rod pieces, each rigid rod piece comprises rigid rods and hinge devices at two ends, and the rigid rods which are equal in length and are parallel constitute parallelogram mechanisms; and springs are connected on diagonal lines of the parallelogram mechanisms and are in the stretched state to provide tension for the ropes. The terminal degree of freedom of a rope parallel mechanism is constrained by the aid of a translation mechanism, and the device inherits the advantages of simple structure, high carrying capacity, easy mounting and dismounting and the like of the rope parallel mechanism and effectively avoids terminal attitude errors, so that the terminal trajectory accuracy is improved.

Owner:TSINGHUA UNIV

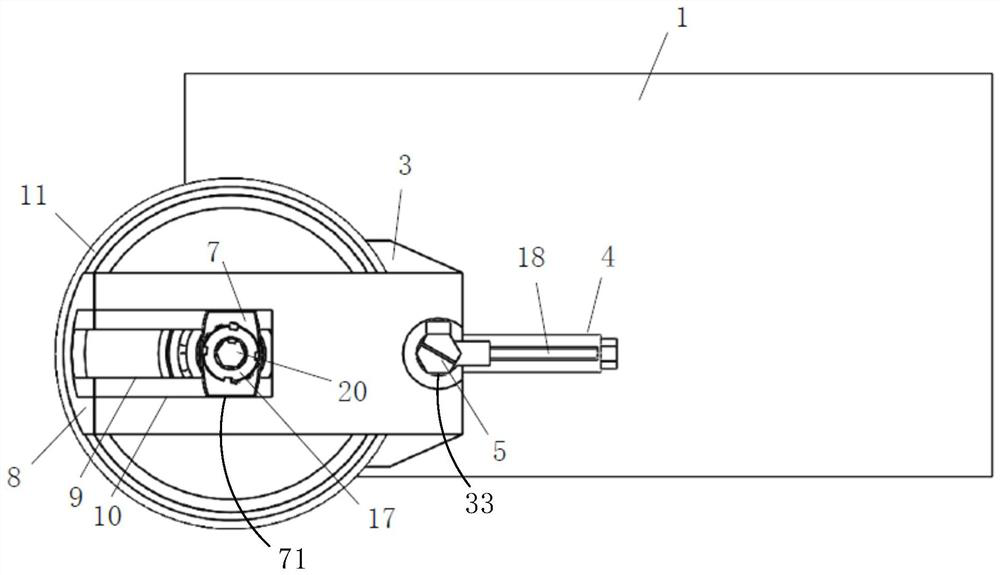

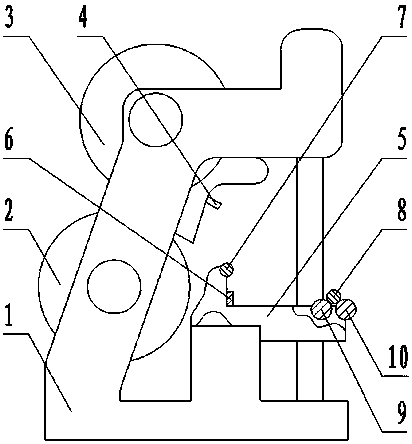

Method and loom for reducing defective rate of weaving

InactiveCN104947297BAvoid wrinklesEliminate wrinklesLoomsHeating/cooling textile fabricsYarnElectric machinery

The invention discloses a method for lowering the defective rate of woven fabric and a loom. According to the method, an infrared probe is used for scanning, a motor is controlled by a controller to stop suddenly, secondary tensioning is conducted on yarn through a tensioning wheel and a tensioning roller, and woven fabric is heated through a heating roller so that wrinkles can be eliminated. The loom manufactured through the method comprises a machine frame (1), wherein a yarn wheel (2) and the tensioning wheel (3) are arranged on the machine frame (1), a distributor plate (4) and a working table (5) are arranged below the tensioning wheel (3), knitting needles (6) and the tensioning roller (7) are arranged at one end of the working table (5), a limiting roller (8), the heating roller (9) and a guiding roller (10) are arranged at the other end of the working table (5), a sliding rail (11) is arranged above the working table (5), and the infrared probe (14) is connected to the sliding rail (11) through a sliding block (12) and a suspension frame (13). The method for lowering the defective rate of woven fabric and the loom can improve the quality of products and lower the defective rate and further have the advantages that the production efficiency is high and the surface smoothness is good.

Owner:HUZHOU JIESHENG GAOKE TEXTILE

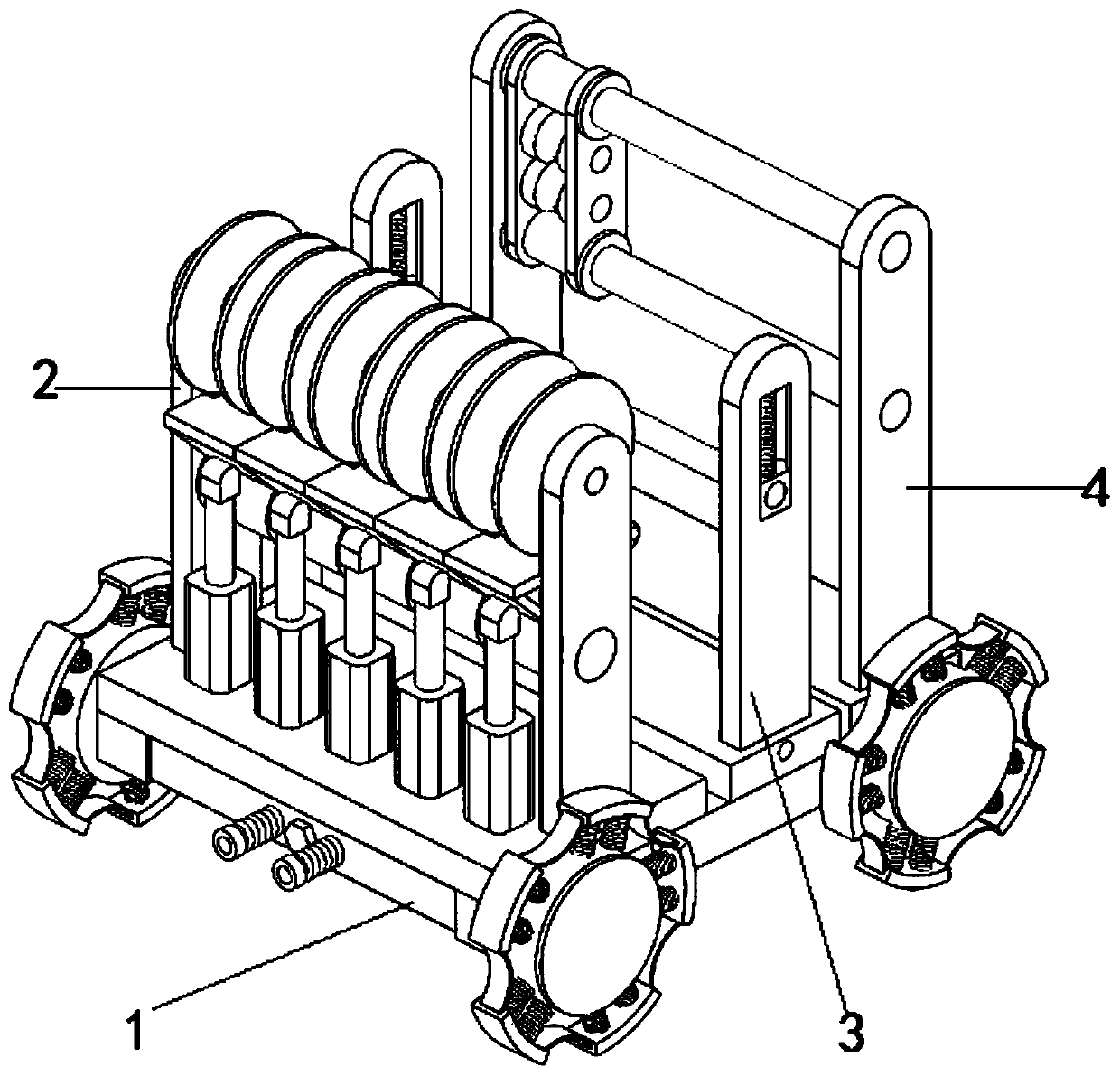

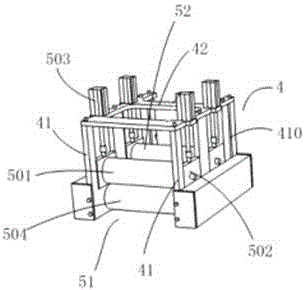

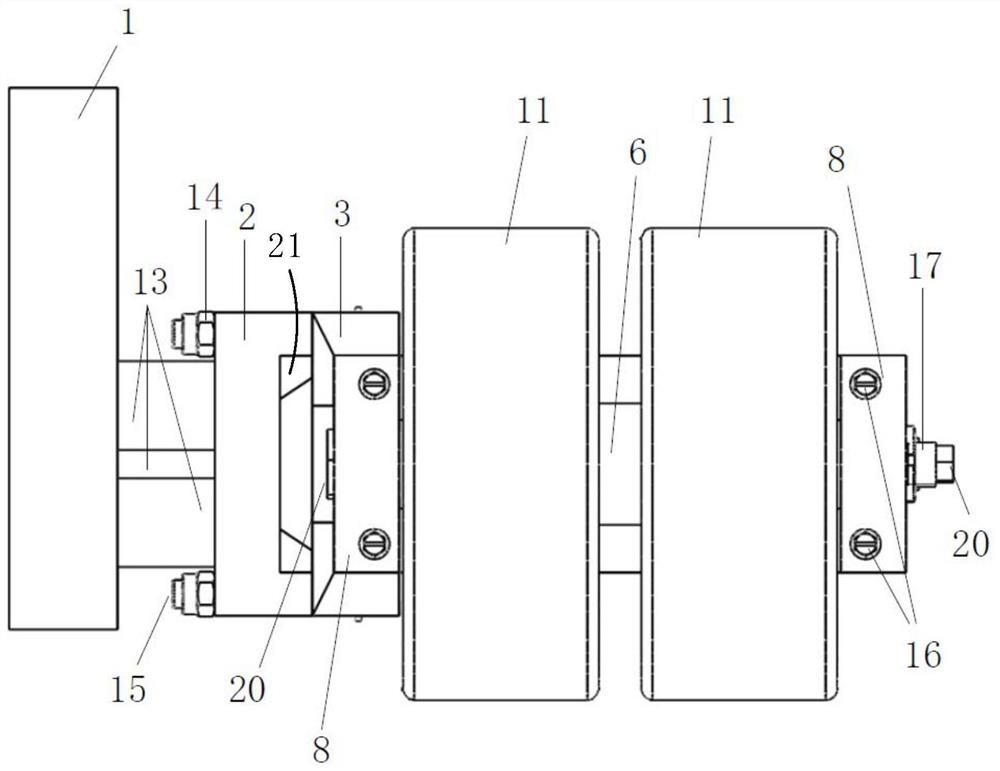

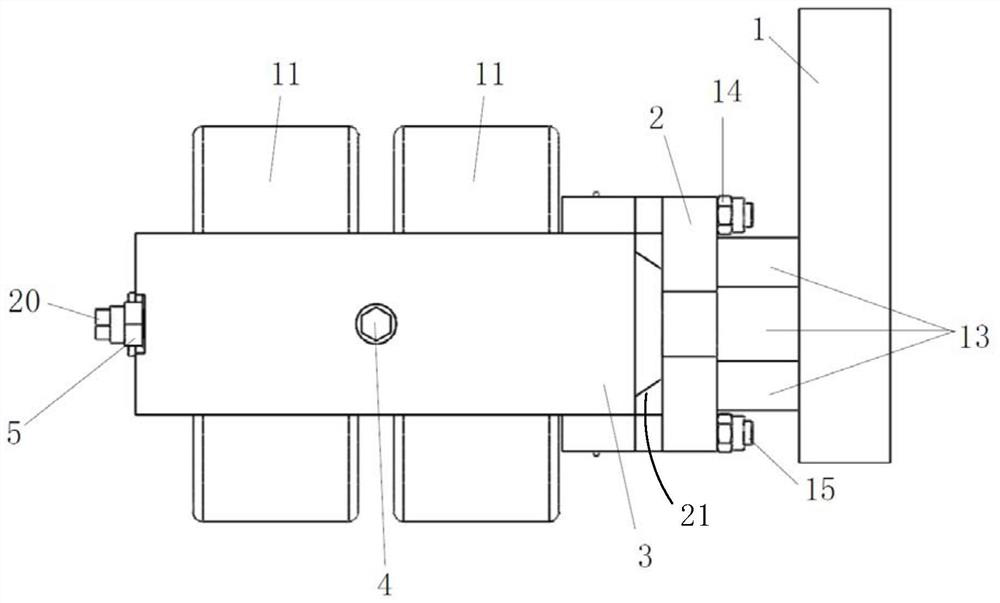

Modularized track tensioning mechanism and mounting and dismounting method thereof

ActiveCN112810715APlay a tension roleGuaranteed not to deformEndless track vehiclesPhotovoltaic energy generationFixed frameEngineering

The invention discloses a modularized track tensioning mechanism and a mounting and dismounting method thereof. The track tensioning mechanism comprises a U-shaped outer frame, the outer frame is fixedly connected with a fixing frame, the outer frame comprises two side frames, and the two side frames are connected through a connecting frame; a tensioning shaft assembly is installed between the two side frames, a tensioning wheel is rotatably installed on a tensioning shaft assembly and surrounded by three surfaces of the outer frame, and the two ends of the tensioning shaft assembly penetrate through and stretch out of the two side frames and can slide in sliding grooves of the two side frames; a screw rod is movably screwed on a connecting frame in a penetrating manner; one end, extending into the outer frame, of the screw rod is detachably connected with the tensioning shaft assembly; and when the tensioning shaft assembly slides to the position needing to be tensioned and is connected with the end, extending into the outer frame, of the screw rod, the screw rod is fixed by a positioning pin installed on the outer frame in a penetrating mode. The mechanism can bear a large load, and is high in strength, simple in structure and convenient to use, maintain, assemble and disassemble.

Owner:ARMOR ACADEMY OF CHINESE PEOPLES LIBERATION ARMY

Method and loom for improving flatness of weaving cloth

ActiveCN105040244BEliminate wrinklesAvoid offsetLoomsAuxillary apparatusYarn tensionHeating efficiency

The invention discloses a method for improving the smoothness of weaving cloth and a loom. In the method, the yarn is tensioned twice through a tension wheel and a tension roller, and the woven cloth is heated through a heating roller. The positioning rollers limit and tension the cloth, and the temperature is cooled and shaped by the guide rollers. The loom constructed according to the aforementioned method includes a frame (1), a yarn wheel (2) is arranged on the frame (1), and a tension wheel (3) is arranged above the yarn wheel (2); the tension wheel ( 3) is provided with a distribution board (4) on the lower side, and a worktable (5) is provided below the distribution board (4); a knitting needle (6) is provided at one end of the worktable (5), and a knitting needle (6) is arranged above the knitting needle (6). A tension roller (7) is provided; a limit roller (8) is arranged at the other end of the workbench (5), and a heating roller (9) and a guide roller (10) are respectively arranged on both sides below the limit roller (8). The invention not only can improve heating efficiency and production efficiency, but also has the advantages of high flatness and good product quality.

Owner:山东贝斯特信息科技有限公司

Cotton lap pressure adjusting device

PendingCN106757566APlay a tension roleGuaranteed uniformityLap-winding devicesSurface layerControl system

The invention discloses a cotton lap pressure adjusting device which comprises a support, an adjusting shaft, an adjusting connection rod, a tension roller, a rotatable driving mechanism and a control system. The adjusting shaft can rotatably mounted on the support, one end of the adjusting connection rod is fixedly mounted on the adjusting shaft, the tension roller is fixedly mounted at the other end of the adjusting connection rod and axially parallel to the adjusting shaft, the rotatable driving mechanism drives the adjusting shaft to rotate, and the control system controls the rotatable driving mechanism to work. According to the cotton lap pressure adjusting device, rotation of the adjusting shaft drives the tension roller to move in a circular-arc upward and circular-arc downward manner, tension action of a winding belt is achieved, the compressing force of the belt on a surface layer is automatically adjusted according to increase of the diameter of a cotton lap, and uniform of the upper winding surface layer of the cotton lap is kept.

Owner:JIANGSU KAIGONG MACHINERY

A cable retractable adjustment mechanism

ActiveCN110562798BPlay a tension roleGuaranteed to be verticalFilament handlingApparatus for laying cablesFree rotationDrive shaft

The invention discloses a cable winding and unwinding adjusting mechanism. The cable winding and unwinding adjusting mechanism comprises a horizontally distributed movable supporting mechanism, wherein a cable reel mounting mechanism, a tensioning connecting mechanism and a guide limiting mechanism are sequentially mounted above the movable supporting mechanism from left to right. According to thecable winding and unwinding adjusting mechanism, the abrasion winding of a cable is reduced; through the design of a tensioning connecting shaft, a lifting sliding block and a tensioning limiting spring, the cable can be tensioned to a certain extent, and meanwhile damage caused by rigid connection is avoided; by rotating and adjusting a limit adjusting bolt, a driving limit groove is matched with or separated from a driving limit protrusion, so that the free rotation or fixing state of a driving shaft is changed; through a supporting spring and a concave elastic sheet, a rolling buffering mechanism can play a good buffering and supporting role on the cable in the moving and supporting process, the influence of vibration impact on the service life of a cable reel is avoided, the working efficiency is effectively improved by mounting and using the multi-cable reel, and good practical and popularization values are achieved.

Owner:安徽伟光电缆股份有限公司

A tensioning mechanism for film-attached winding tube core

The invention discloses a tensioning mechanism of a film-pasted coiled tube core. The tensioning mechanism comprises a spindle, wherein two locking blocks are arranged at two ends of the spindle respectively and are fixed to the spindle through a plurality of bolts, the middle of the spindle is a central shaft, the central shaft penetrates through the locking blocks for installation, the central shaft penetrates an installing block to be fixed in a base, and the base is installed on a rack of a film-pasted machining machine tool. The spindle is provided with three large gaps, the gaps are circular-arc-shaped and are arranged peripherally, two fixing blocks are arranged in each large gap, and a tensioning strip is arranged between the two fixing blocks. The tensioning mechanism of an existing film-pasted coiled tube core is improved in design, the plastic tensioning strip is designed and installed in the large gaps, so that the tube core firmly attaches to the tensioning strip during rotation, and a tensioning effect is played on the tube core.

Owner:苏州威仕薄膜科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com