Multi-joint manipulator and mechanical arm

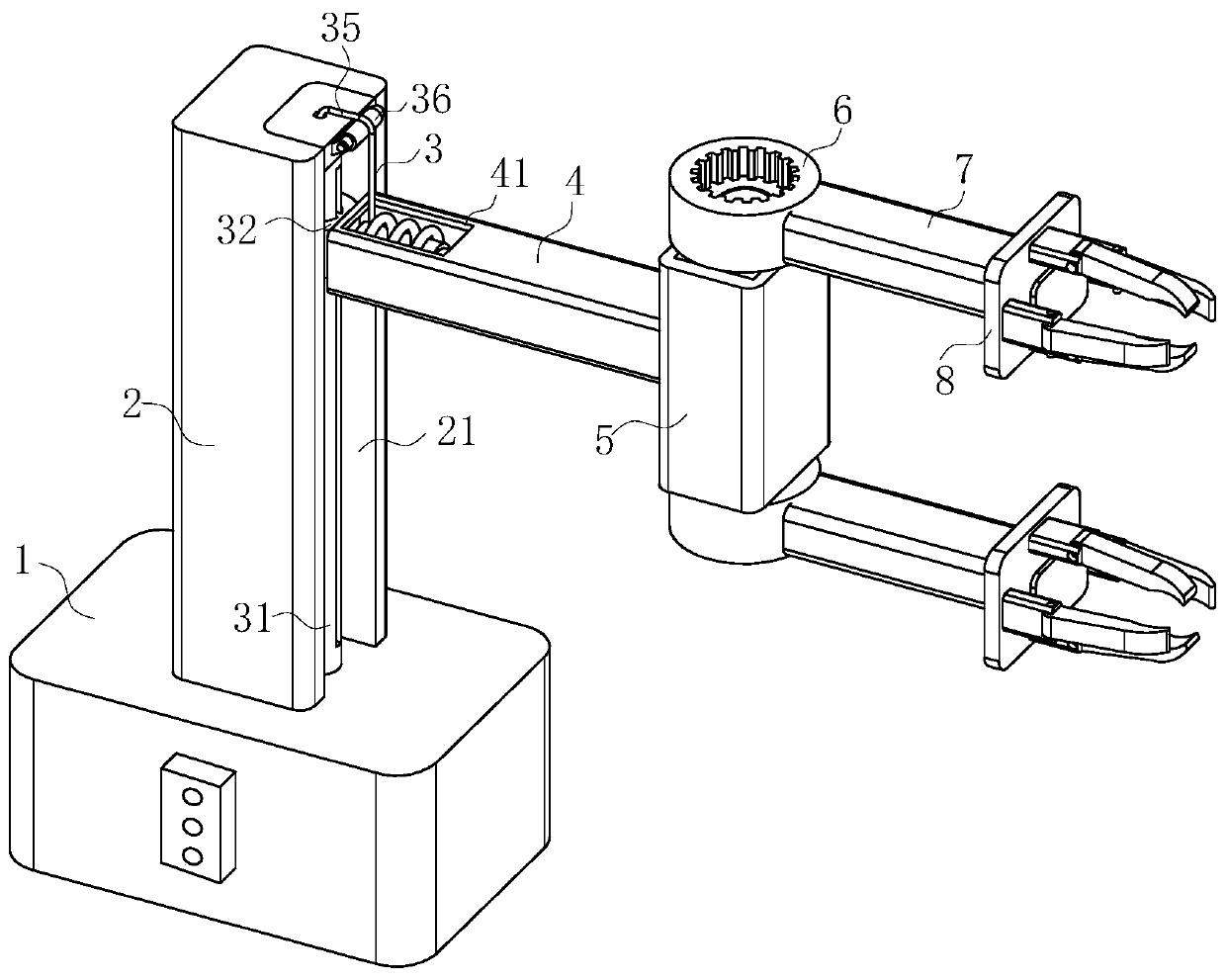

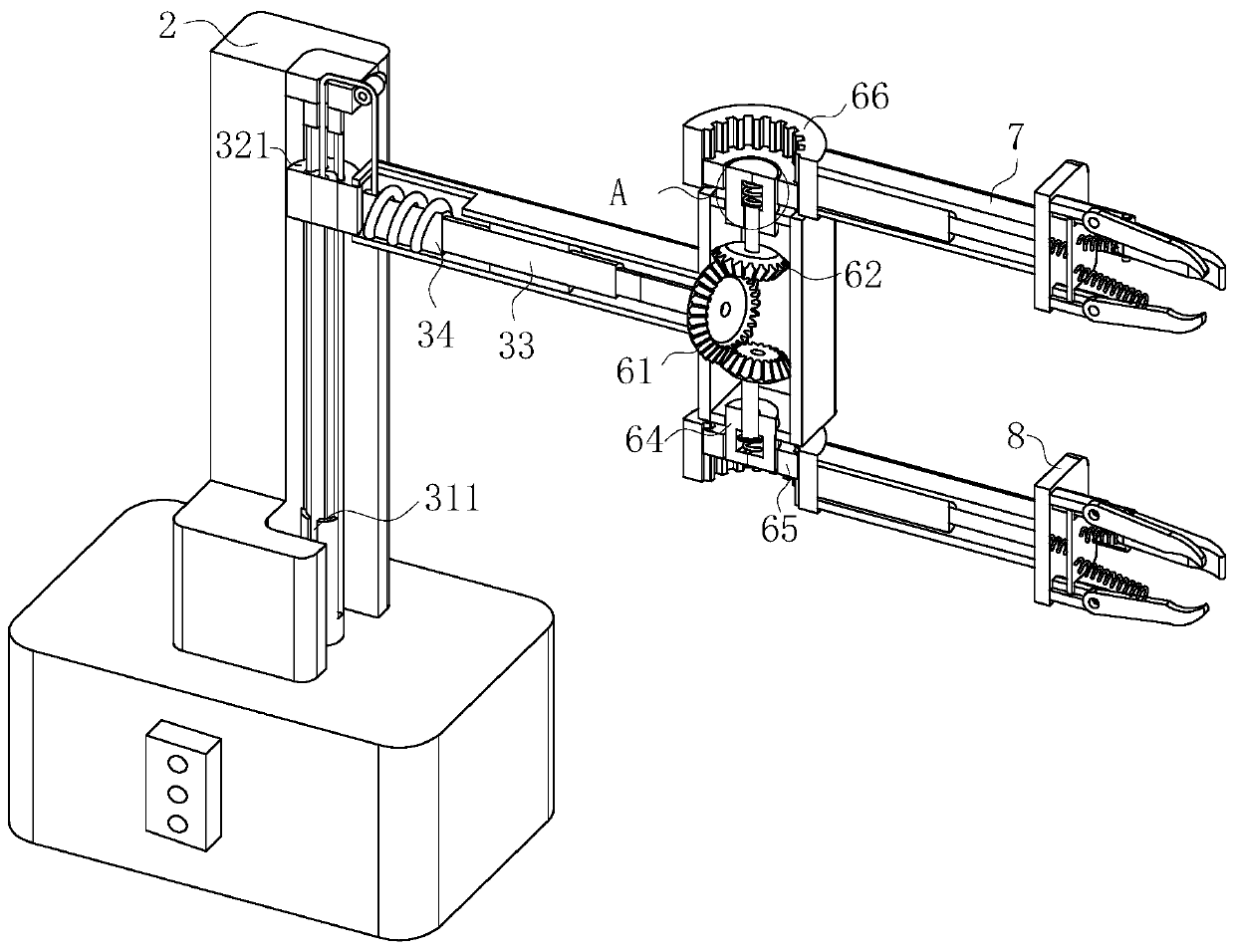

A manipulator and multi-joint technology, applied in the field of manipulators, can solve the problems of difficulty in realizing fast or individual gripping of different objects, affecting the efficient and stable normal operation of multi-joint manipulators, affecting the safe grasping effect of manipulators, etc. The effect of the opposite grasping operation of the angle, realizing the object grasping operation, and improving the ability to grasp the object

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

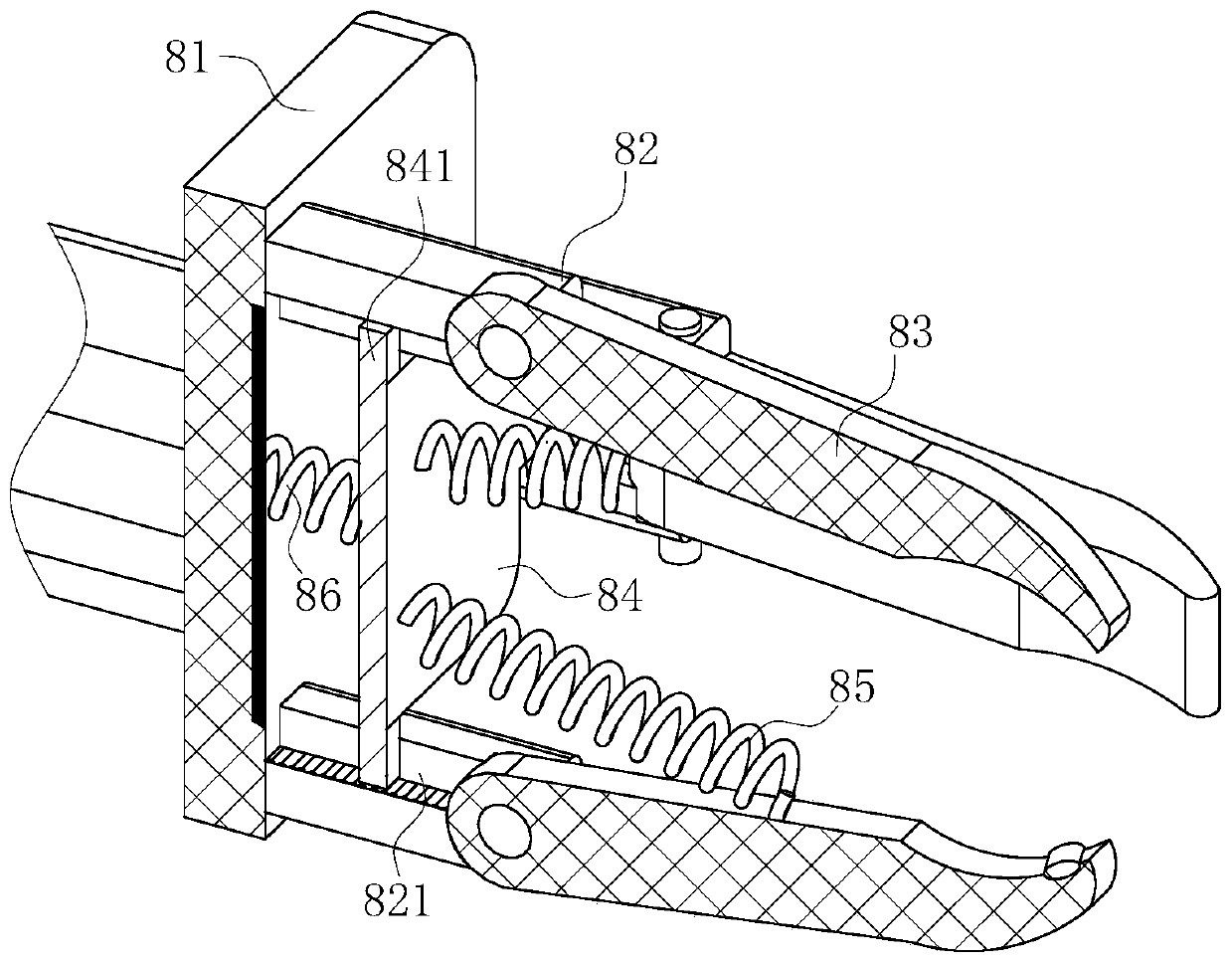

[0029] As an embodiment of the present invention, the mechanical gripper 8 includes a support plate 81, a support column 82, a clamping arm 83, a metal slide plate 84, a rubber connection spring 85 and a rubber limit spring 86; the support plate 81 Installed on the telescopic end of the guide cylinder, and the support plate 81 is provided with an electromagnet; the support plate 81 is equipped with a plurality of support columns 82, and the plurality of support columns 82 are connected to the clamping arm 83 through the rotation column 64; The inner wall of the support column 82 is in sliding contact with a metal slide plate 84, and one side wall of the metal slide plate 84 is connected to the support plate 81 by a rubber limit spring 86, and the other side wall of the metal slide plate 84 is connected by a rubber spring 85 Connected to the clamping wall; the support plate 81, the support column 82 and the clamping arm 83 are all set to rubber materials; during work, when the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com