Filtering device of sewage treatment vehicle

A filter device and sewage treatment technology, applied in the direction of filtration and separation, fixed filter elements, chemical instruments and methods, etc., can solve the problems of incomplete methods, large layout space, cumbersome process, etc., and achieve convenient and reliable operation and save installation Space, the effect of increasing the filter area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

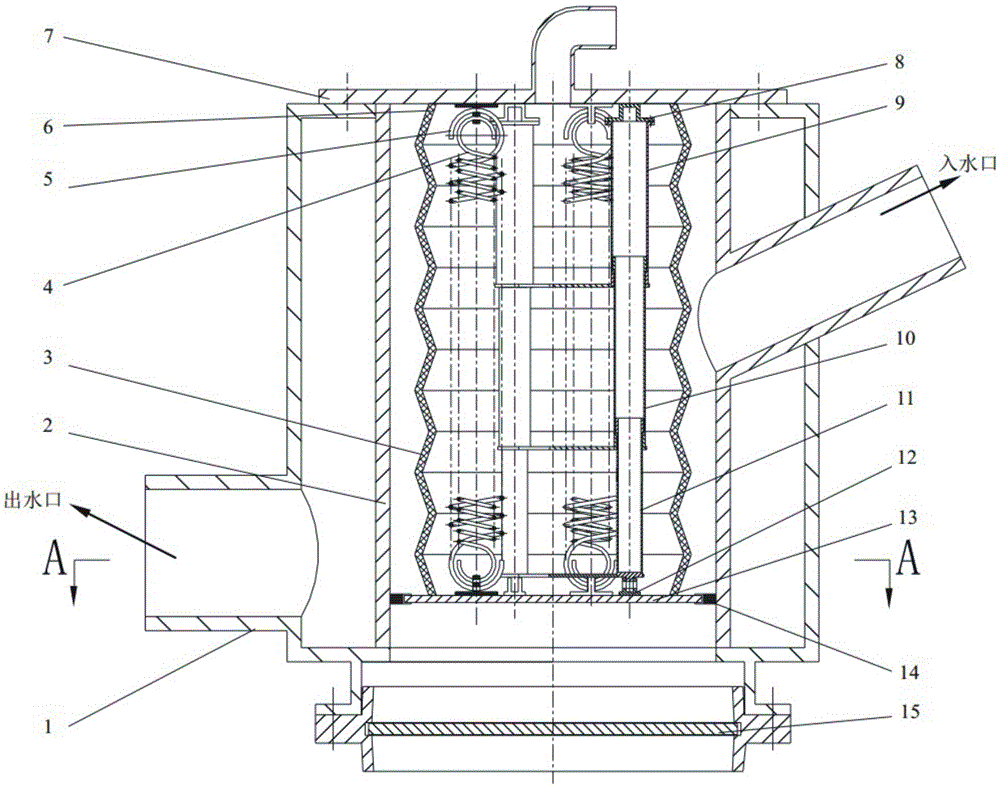

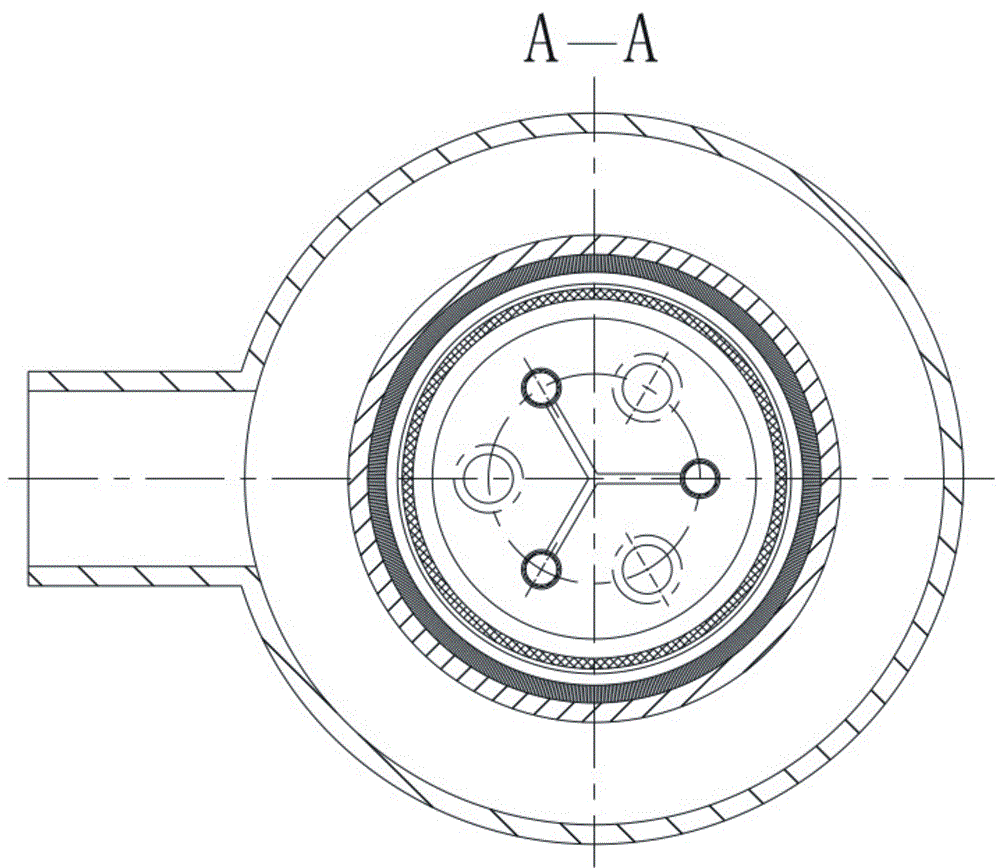

[0027] Such as Figure 1 to 9 As shown, it is a schematic structural diagram of an embodiment provided by the present invention. It can be seen from the figure that it includes a filter cartridge 1, which is open at both ends, and a filter screen 2 and a filter screen 2 are provided in the filter cartridge 1 The two ends of the airbag are connected with the two ends of the filter cartridge 1, and an airbag extrusion mechanism is provided in the filter screen 2. The airbag extrusion mechanism includes an airbag 3, an airbag cover 7, and an airbag bottom plate 13. One end of the airbag 3 and the airbag cover 7 is connected, the airbag cover 7 is fixedly connected with one end of the filter cartridge 1, and the other end of the airbag 3 is connected with the airbag bottom plate 13. A wiper is installed on the outer peripheral edge of the airbag bottom plate 13, and the wiper is connected to the filter cartridge The inner wall of 1 is in contact with each other, so that the outer p...

Embodiment 2

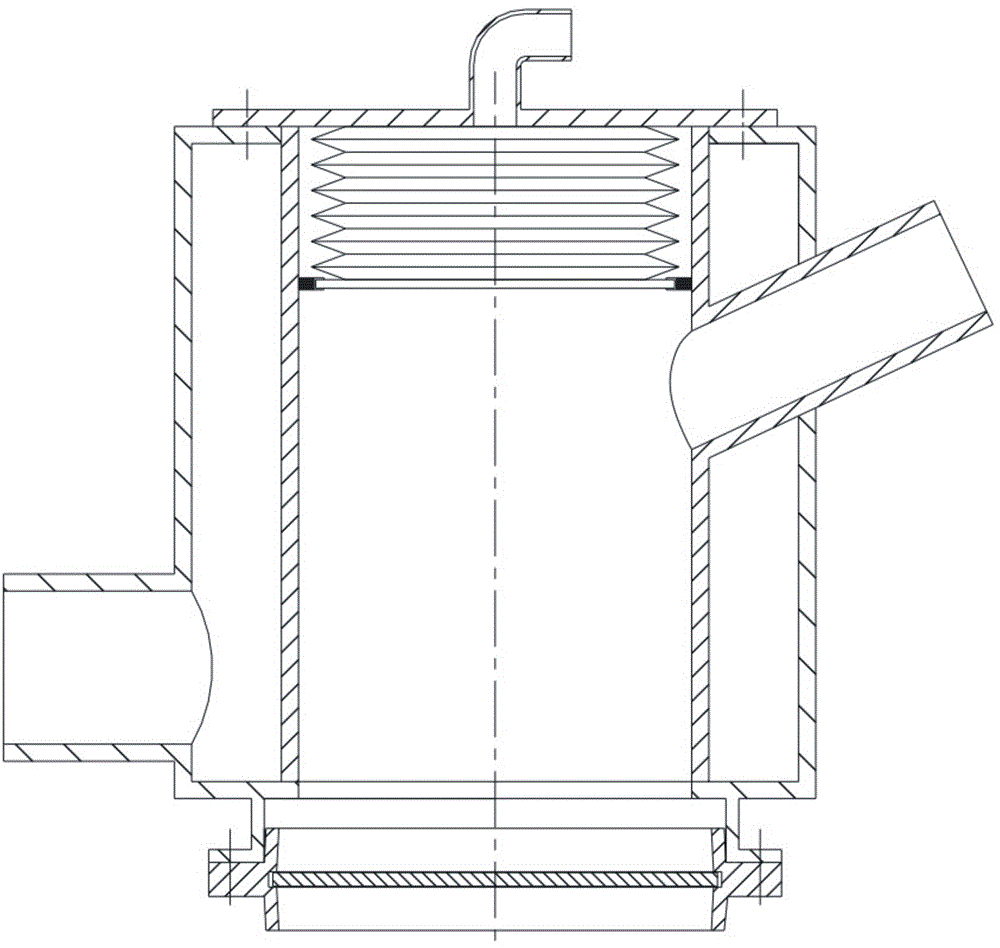

[0034] Such as Picture 10 As shown, it is a schematic structural diagram of another embodiment of the guide mechanism and the spring provided by the present invention. The structure of this embodiment is basically the same as that of the first embodiment. The difference is that the airbag cover 7 and the airbag bottom plate 13 A set of guide rods and three tension springs 5 are connected in between, of which there is only one set of guide rods, consisting of three upper, middle and lower guide rods 9, 10 and 11, and the three springs 5 are evenly arranged around the guide rods. In this embodiment, the spring base and the upper and lower bases of the guide rod are eliminated, and they are directly processed on the airbag cover 7 and the airbag bottom plate 13, wherein the upper guide rod 9 in the guide rod is fixedly connected to the airbag cover 7, and the lower part of the guide rod The guide rod 11 is fixedly connected to the airbag bottom plate 13. This embodiment has s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com