Full-automatic numerical control multifunctional electronic thread-regulation jacquard purl round weft knitting machine

A multifunctional, fully automatic technology, applied to circular knitting machines with separate action needles for weft knitting, weft knitting, textiles and paper making, etc. The speed of the cylinder and the lower needle cylinder and the speed of the ordinary motor are not adjustable, so as to achieve the effect of small swing angle, short length and stable action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

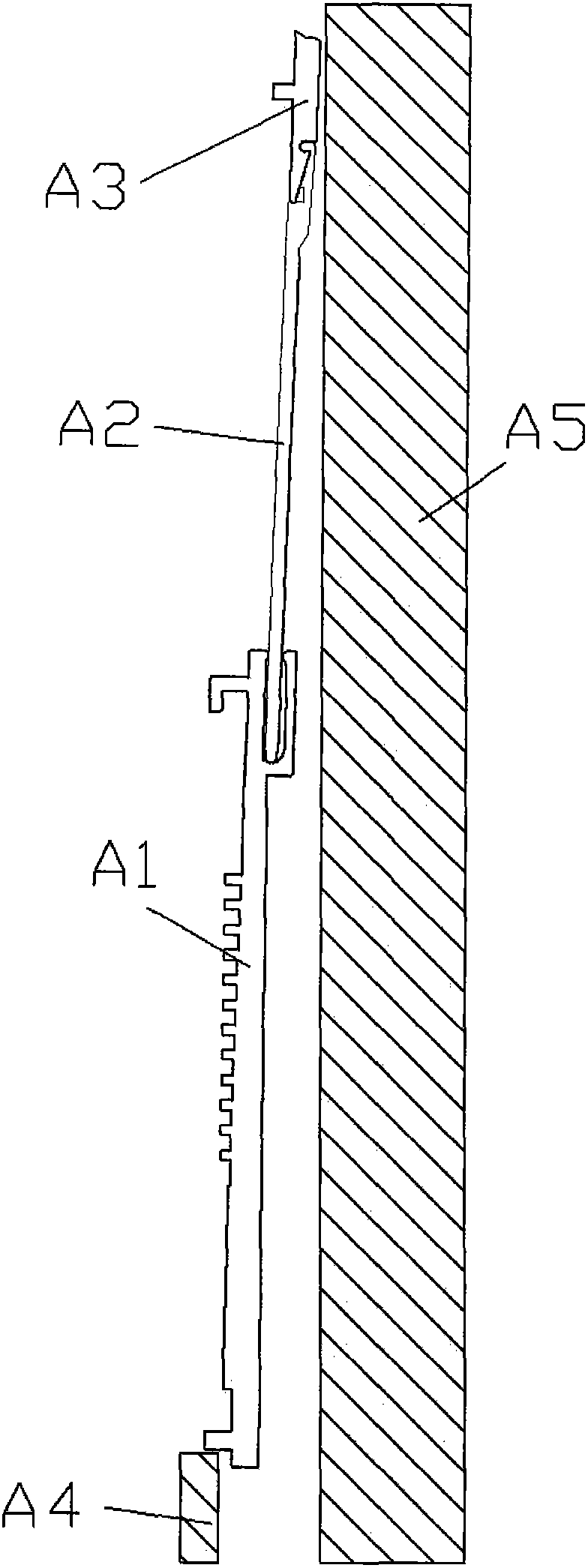

[0047] Example: see Figure 1-11 As shown in the figure, the fully automatic numerical control multi-functional electronic thread adjustment jacquard double-back circular weft knitting machine includes a frame 1, a triangle mechanism 2, a jacquard device 3, a fabric winding mechanism 4 and a needle cylinder driving device 5,

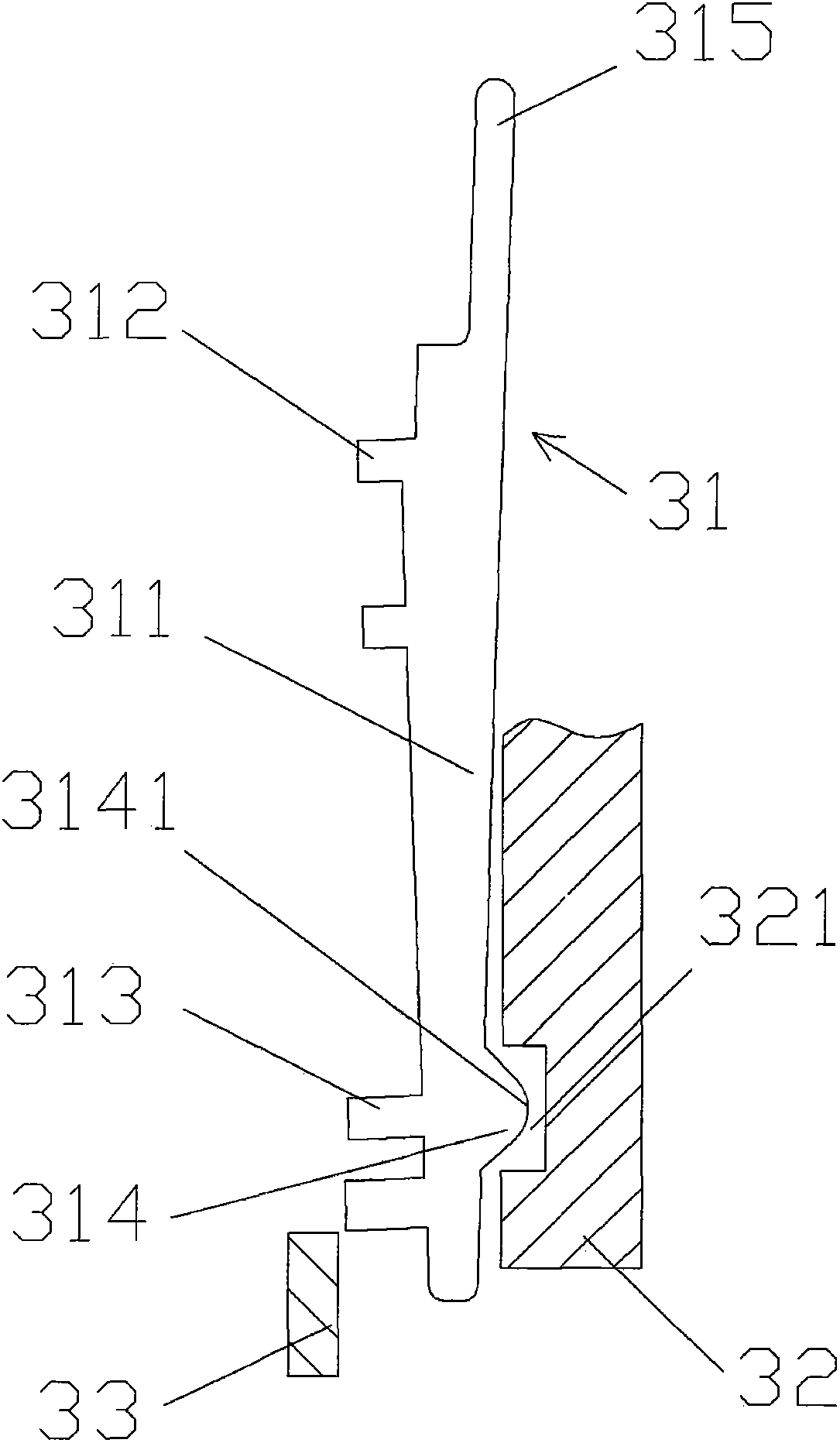

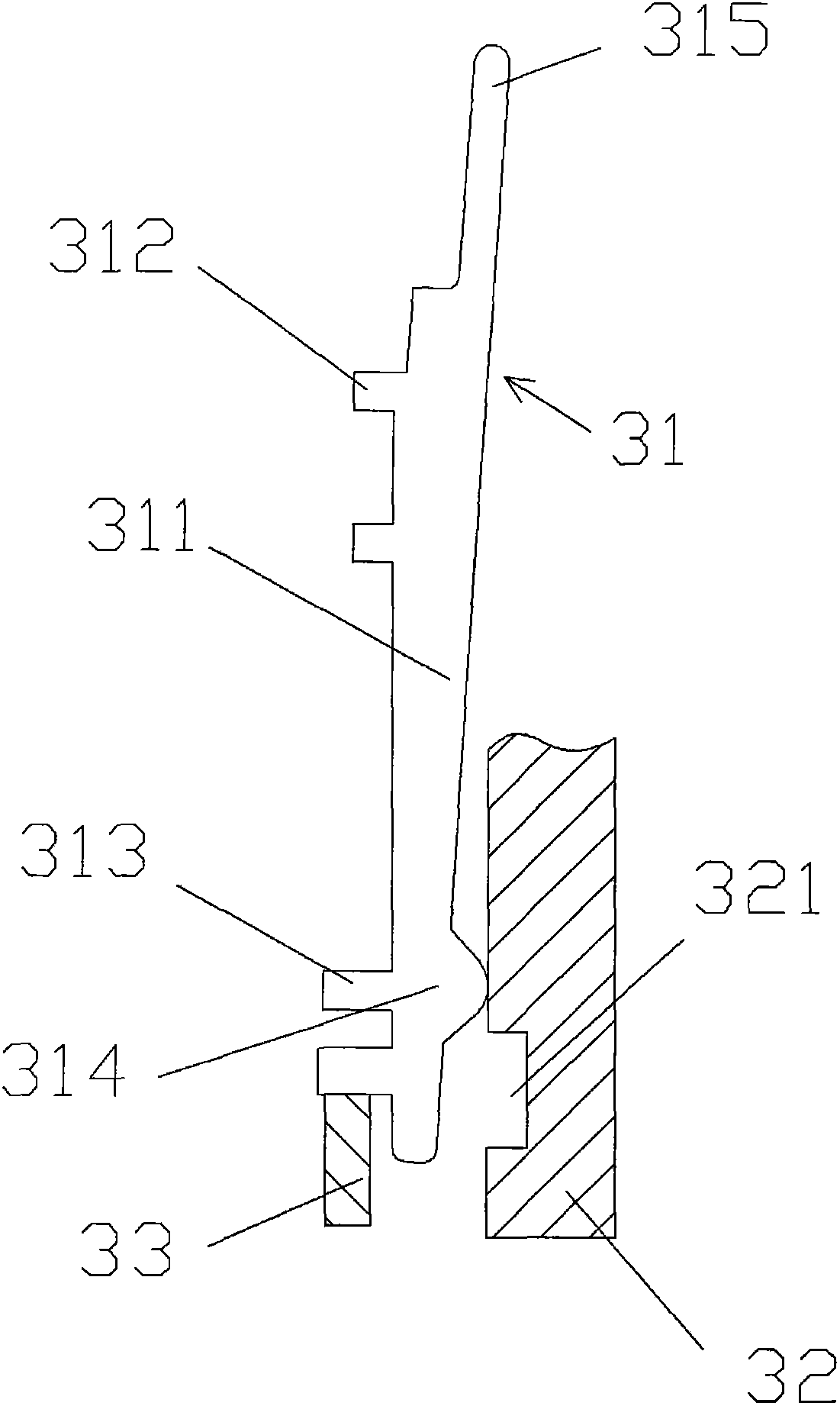

[0048] The triangular mechanism 2 includes a triangular block 21 and a triangular seat 22, the triangular seat 22 is formed with a triangular seat through hole 221, the fixed block 23 is inserted in the through hole 221, and the limit plate 24 is fixed on the lower part of the triangular seat 21;

[0049] The fixed block 23 is formed with a fixed block through hole 231 for the triangular block 21 to be inserted; the limit plate 24 is formed with a limit plate through hole 241 through which the chassis 25 passes; the front part of the chassis 25 is fixed on the triangular block 21; the return spring 26 is sleeved on the mounting handle 25, one end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com