Modularized track tensioning mechanism and mounting and dismounting method thereof

A tensioning mechanism and modular technology, applied in the direction of tracked vehicles, motor vehicles, transportation and packaging, etc., can solve the problems of increased wear, easy deformation, inconvenient use, maintenance, loading and unloading, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

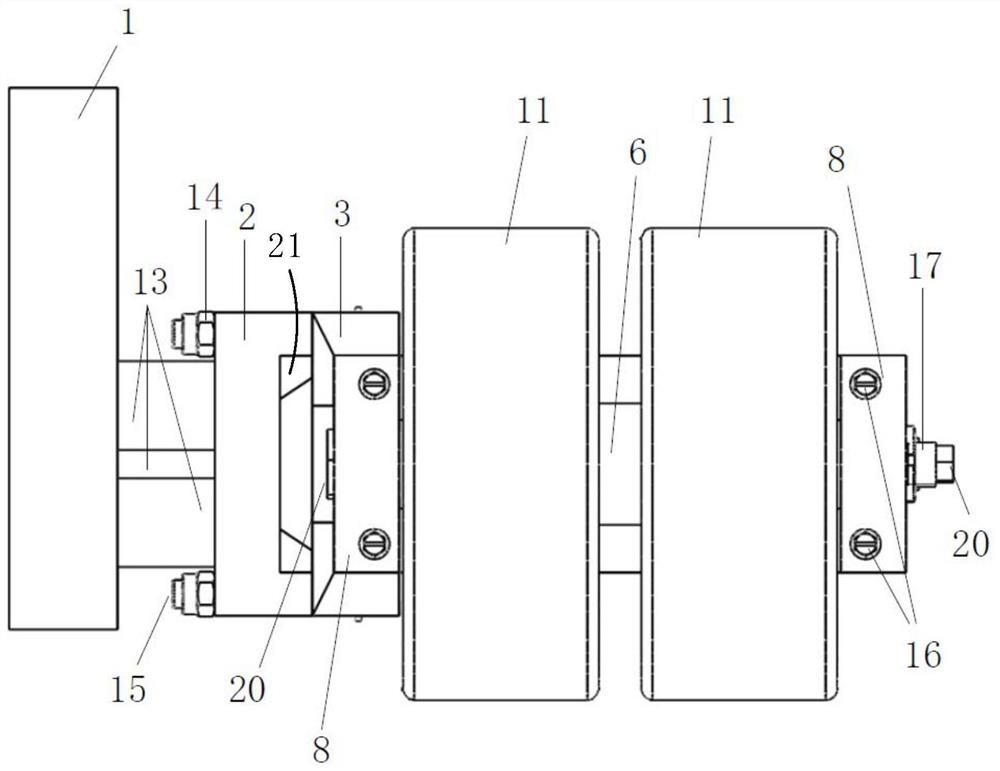

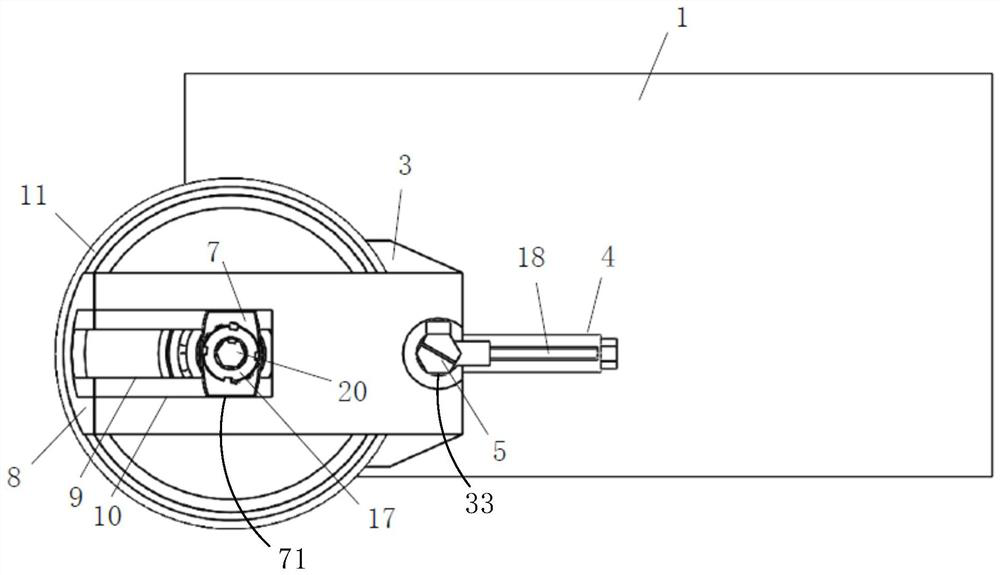

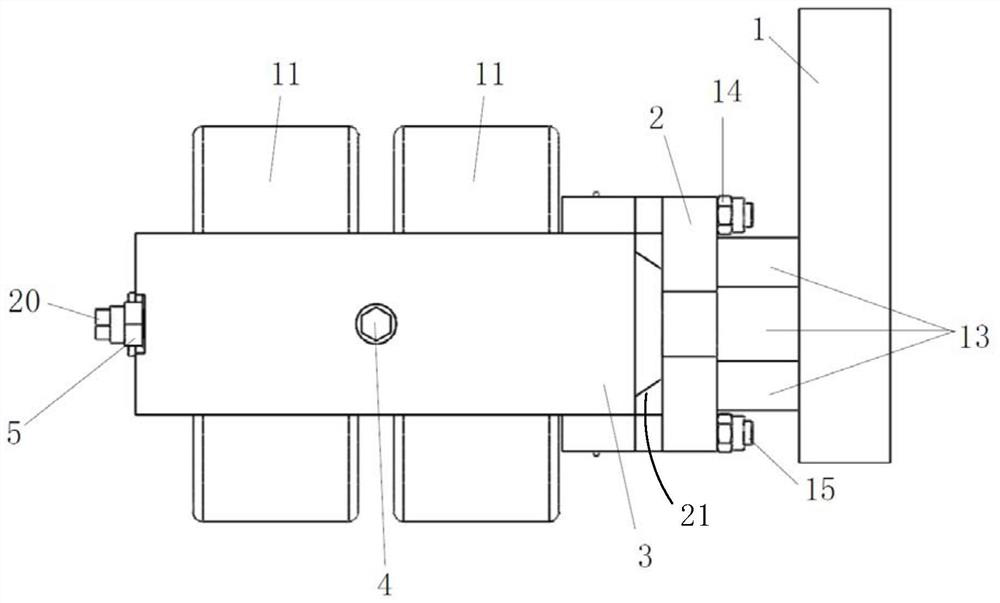

[0034] Such as Figure 1 to Figure 8 As shown, the modular track tensioning mechanism of the present invention includes a U-shaped outer frame 3, one side of the outer frame 3 is fixedly connected with the fixed frame 2 through a fixed stud 15 and a fixed nut, and the fixed frame 2 is connected to the vehicle body through a fixed column 13 1 (the vehicle body 1 is schematically shown in the figure) fixed connection, wherein: the outer frame 3 includes two side frames 31, and the two side frames 31 are connected by a coupling frame 32; The tensioning shaft assembly, the tensioning wheel 11 is rotatably mounted on the tensioning shaft assembly and is surrounded by the outer frame 3 on three sides. 31 can do sliding movement in the sliding groove; the connecting frame 32 is threaded through the movable screw 4, and the end of the screw 4 extending into the outer frame 3 is detachably connected with the tensioning shaft assembly; when the tensioning shaft assembly slides along Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com