Method and loom for improving flatness of weaving cloth

A flatness and cloth surface technology, applied in the direction of looms, weaving auxiliary equipment, textiles, etc., can solve the problem that the speed of the winding roller and the speed of the weaving are prone to deviation, the collection process is prone to deviation, and the winding efficiency is affected and other problems, to improve heating efficiency and production efficiency, prevent cloth offset, and achieve good product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

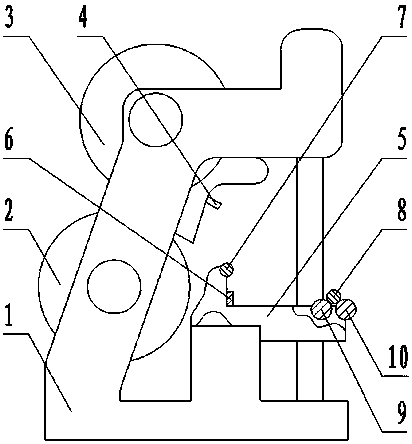

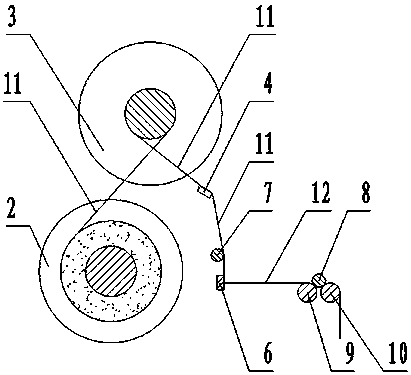

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

[0013] Example. Such as figure 1 , 2 As shown, a method for improving the flatness of the weaving is to perform secondary tension on the yarn 11 by setting the tension wheel 3 and the tension roller 7 to make the yarn 11 straight; and then by setting the heating roller 9 Heat the woven cloth 12 to eliminate wrinkles on the surface of the cloth 12 and improve the flatness; at the same time, limit and tension the cloth 12 through the limit roller 8 to improve heating efficiency and production efficiency and further eliminate wrinkles on the surface of the cloth 12 , to improve the flatness; finally, the guide roller 10 is used for cooling and shaping to ensure high flatness.

[0014] The loom constructed according to the aforementioned method for improving the flatness of the weaving cloth is compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com