Patents

Literature

728results about How to "Guaranteed not to deform" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

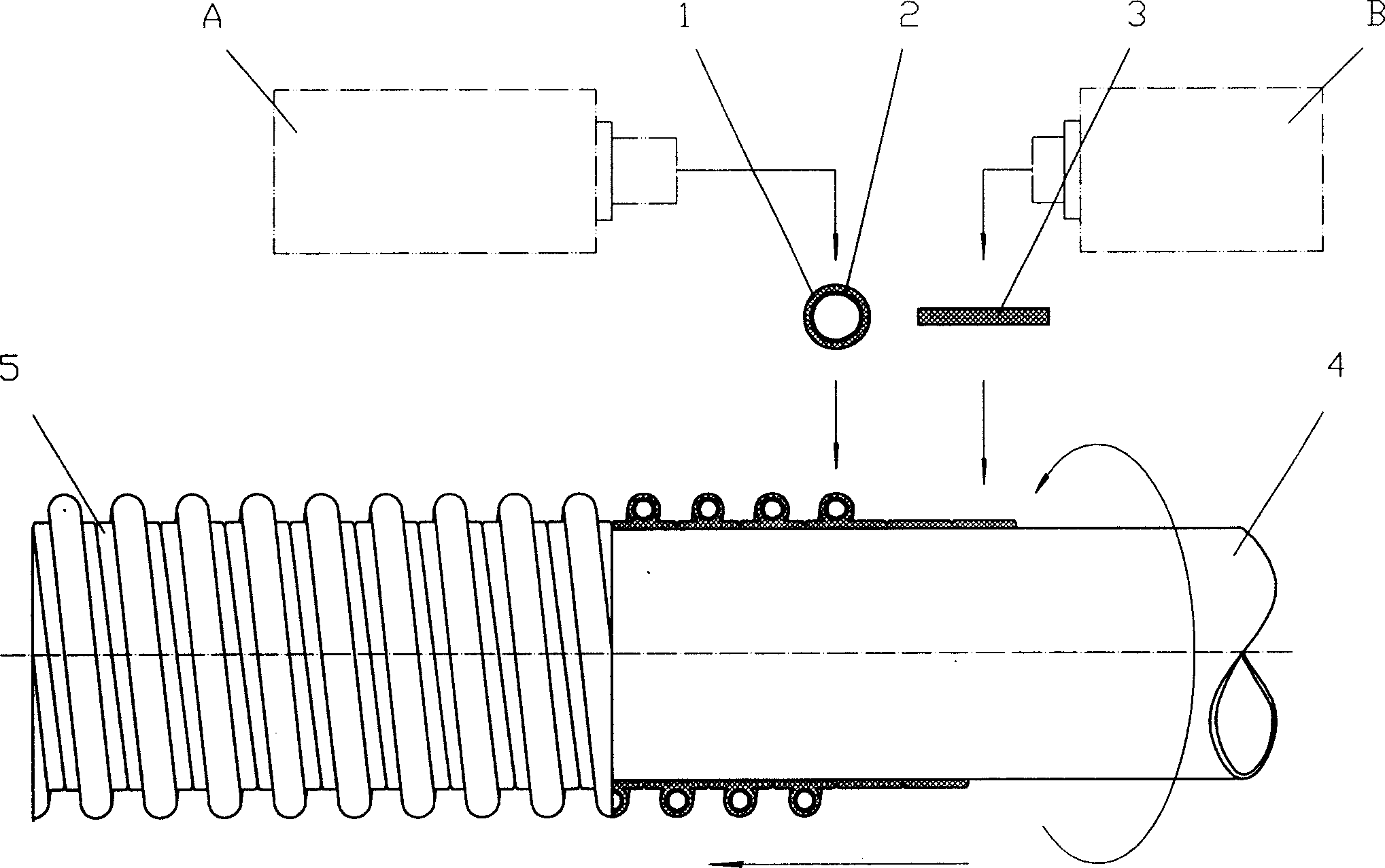

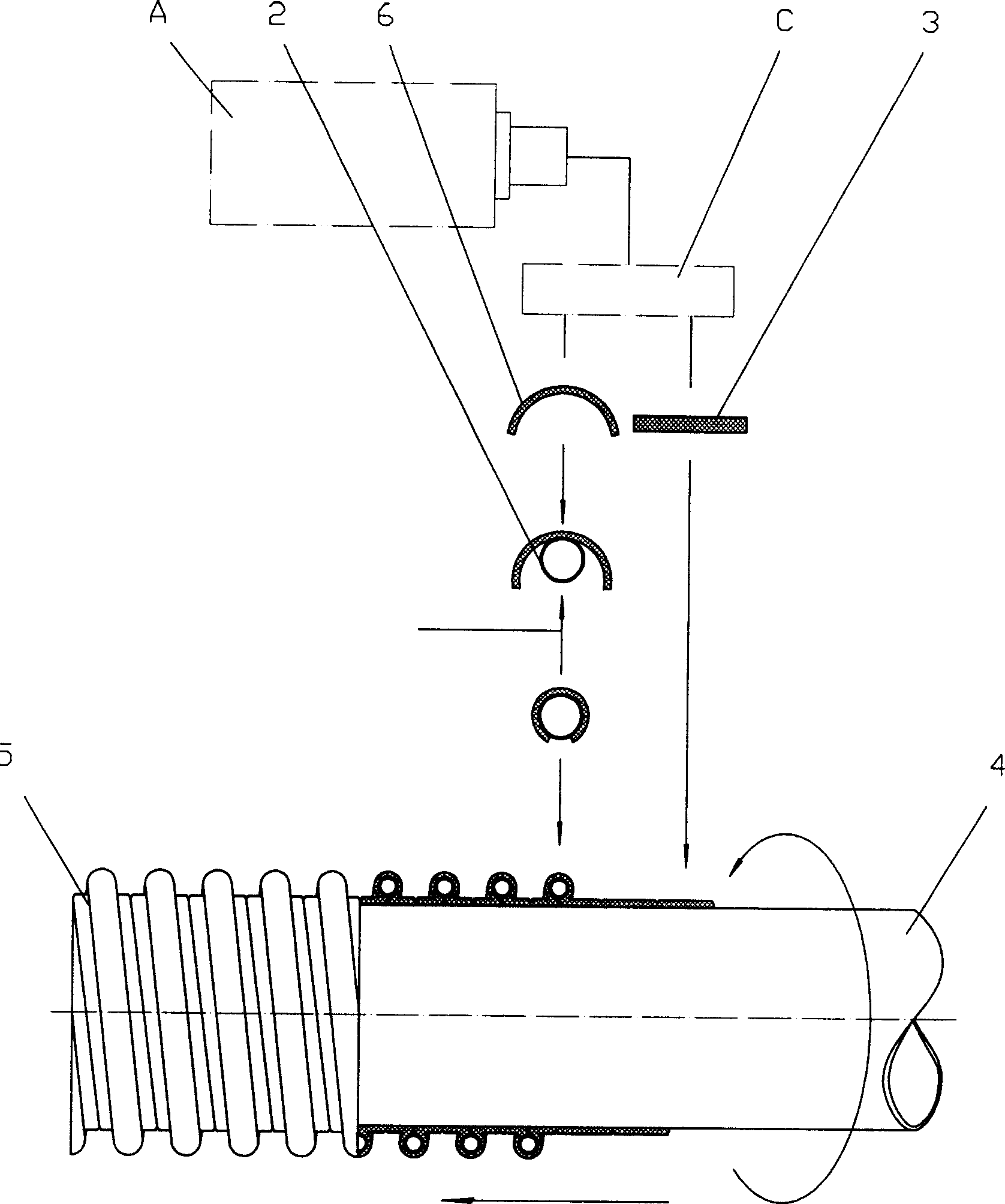

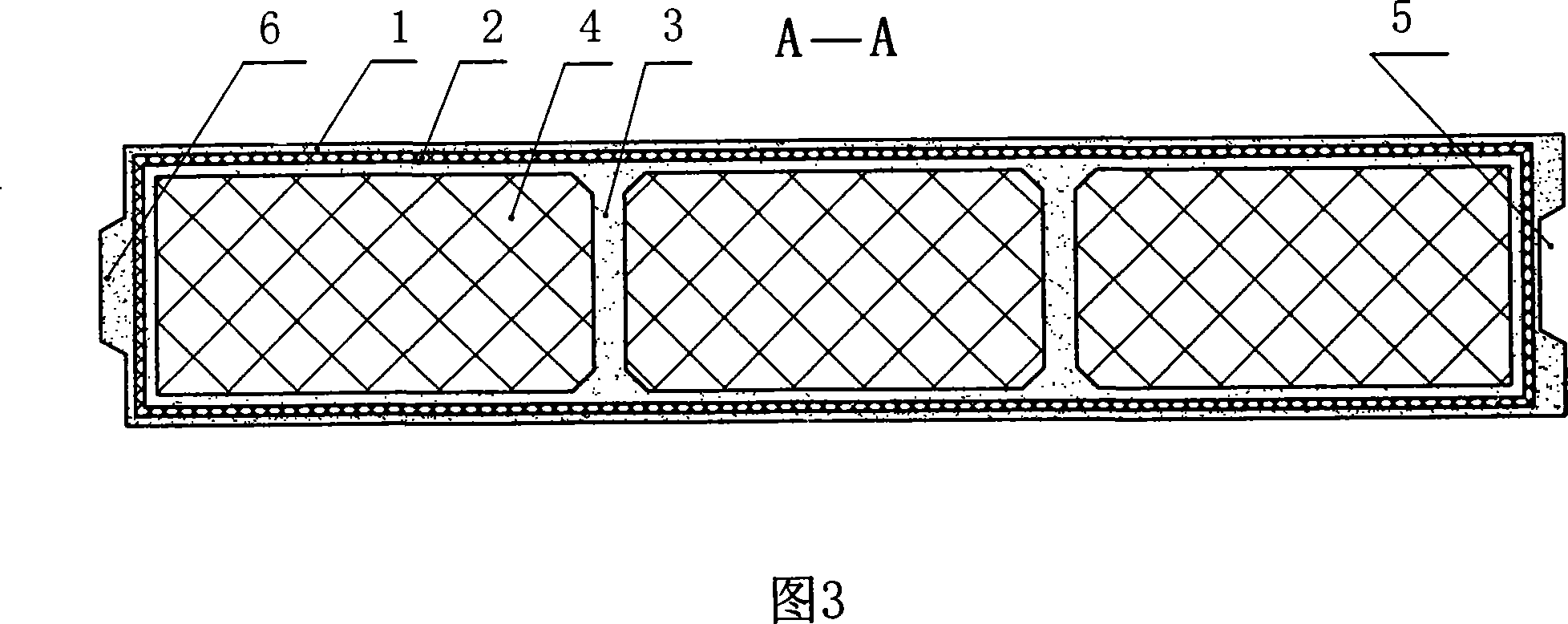

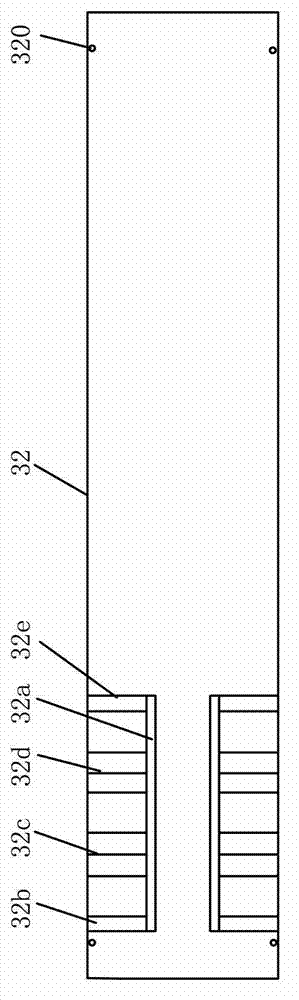

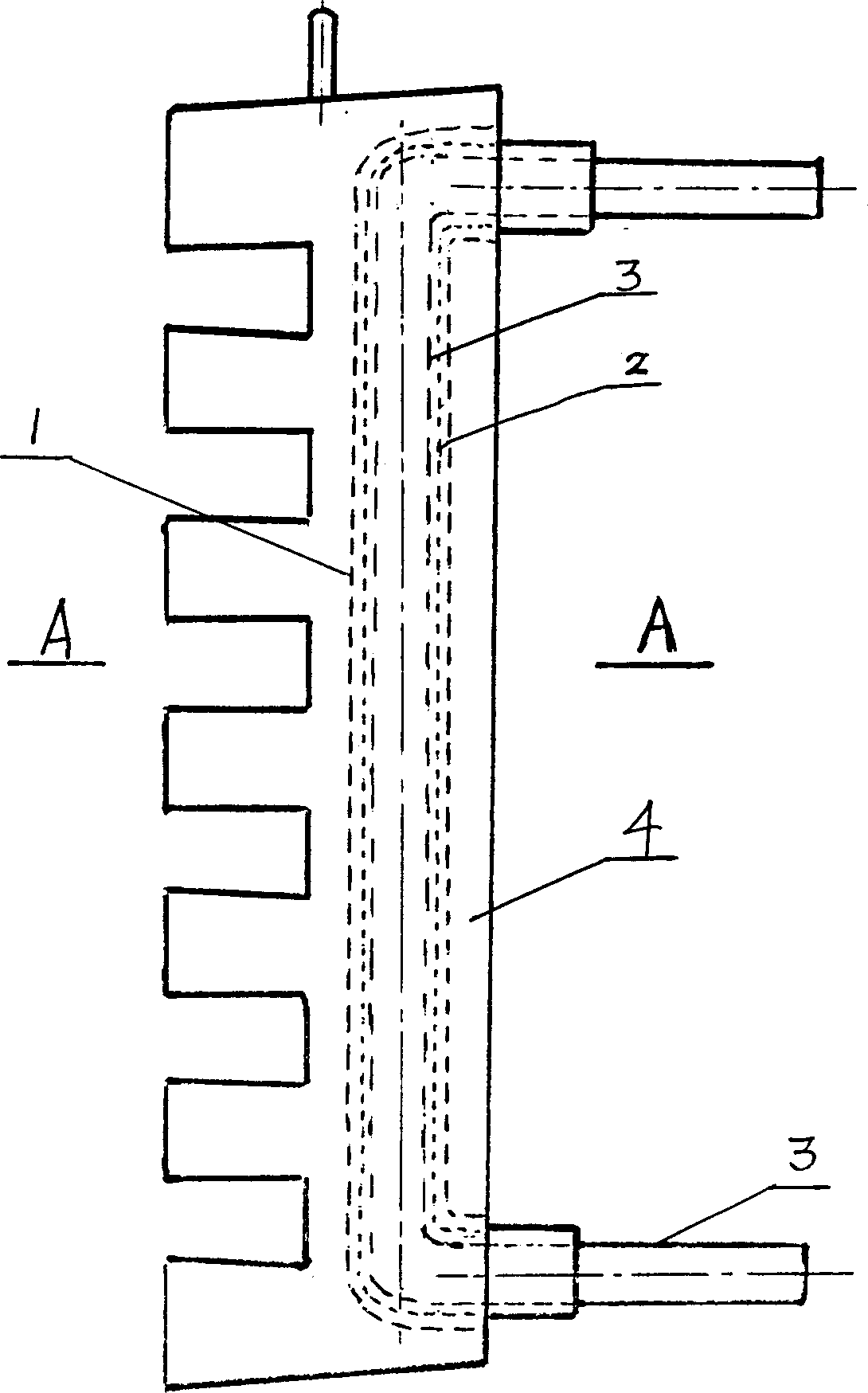

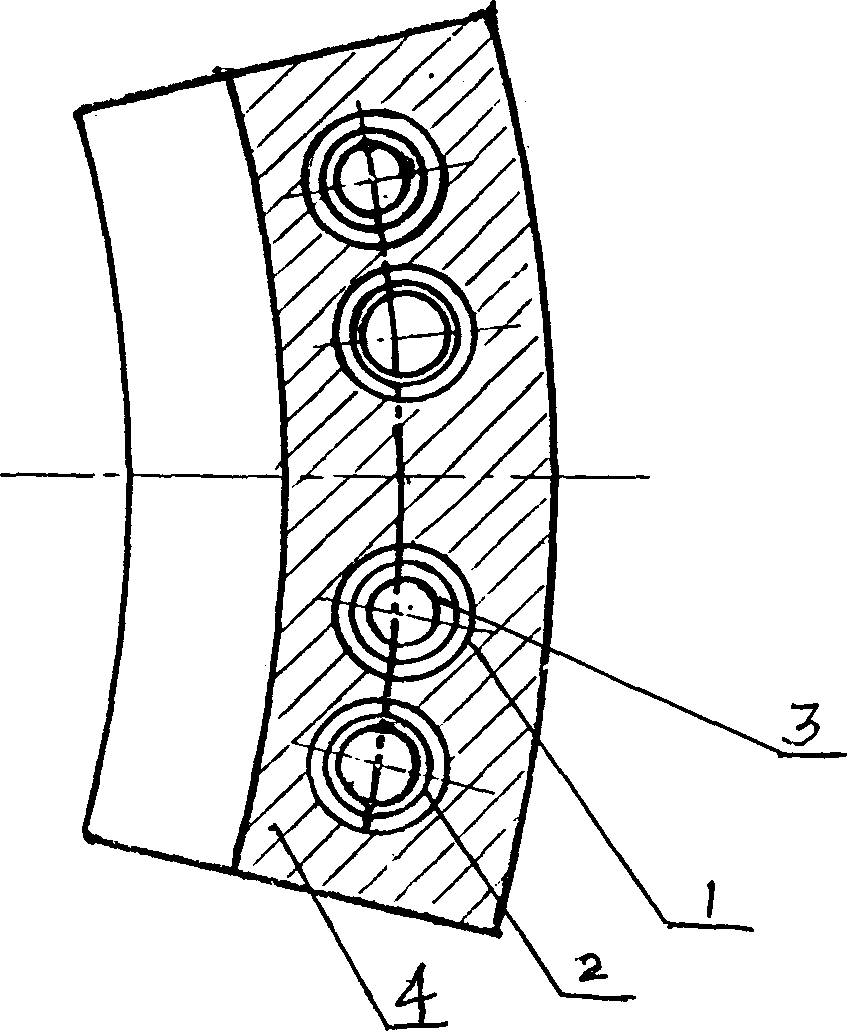

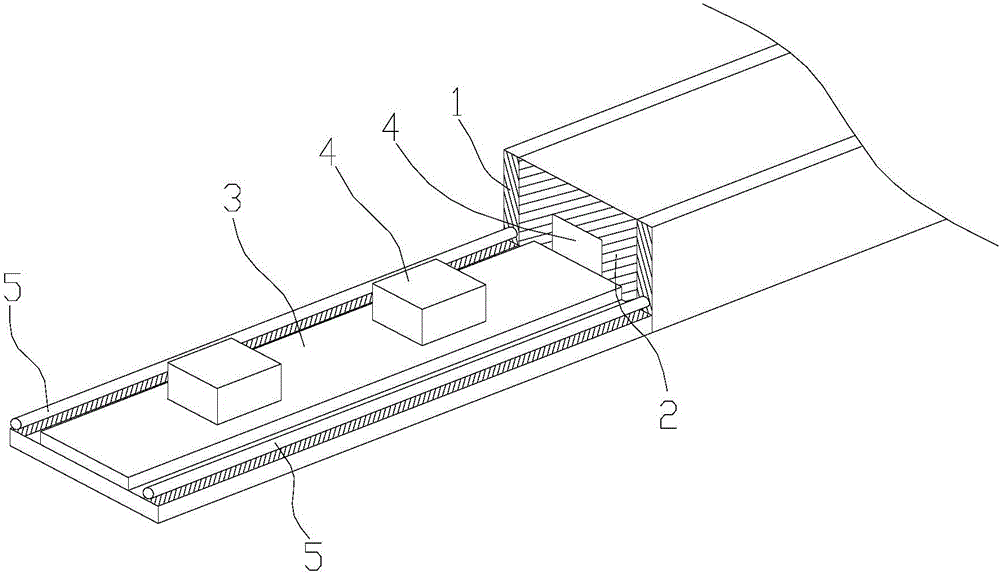

Coextruding heat winding structure wall pipe, processing method and method

ActiveCN1749626AHigh strengthIncrease stiffnessRigid pipesTubular articlesMaterial consumptionEngineering

The present invention provides a kind of hot wound and extruded pipe and its production process and forming mold, and the new product with low material consumption and high annular rigidity is produced based on equivalent wall thickness principle. The hot wound and extruded pipe is produced through hot screw winding plastic belt onto mold core and extruding to coat with the same kind of material. The present invention can produce co-extruded polyethylene pp pipe and polyethylene coated polypropylene single wall corrugated pipe with high strength and capable of being used as the reinforcing pipe for great caliber pipe. The present invention has high production efficiency.

Owner:福建纳川管业科技有限责任公司

Preparation method of wear-resistant coating for high-accuracy roller piece

The invention relates to a preparation method of a wear-resistant coating for a high-accuracy roller piece. In the invention, a nickel-based (or cobalt-based) prefabricated layer is prepared by using a supersonic flame spraying process, and the prefabricated layer is treated by adopting an induction heating method, so that the bonding intensity between the coating and a substrate is enhanced. Thewear-resistant coating is prepared by adopting a composite surface treatment technology, so that a workpiece is prevented from being deformed in the machining process, the prepared coating is dense and crackless and has uniform hardness and high binding intensity, and the surface wear resistance and impact resistance of the workpiece are enhanced; and moreover, a preparation technology has the advantages of simple process, high cladding efficiency, low machining cost and the like. After machining, the binding intensity between the coating and the substrate is more than or equal to 70 MPa, andthe hardness of the coating can be up to HRB 55-70 by adjusting the adding amount of solid-phase wolfram carbide (WC) in spraying powder. The preparation method can be widely applied to the preparation of surface reinforced layers for industrial components with severe working conditions, such as high-frequency friction pairs, papermaking rollers, pumping rods, loops and the like.

Owner:BGRIMM ADVANCED MATERIALS SCI & TECH +1

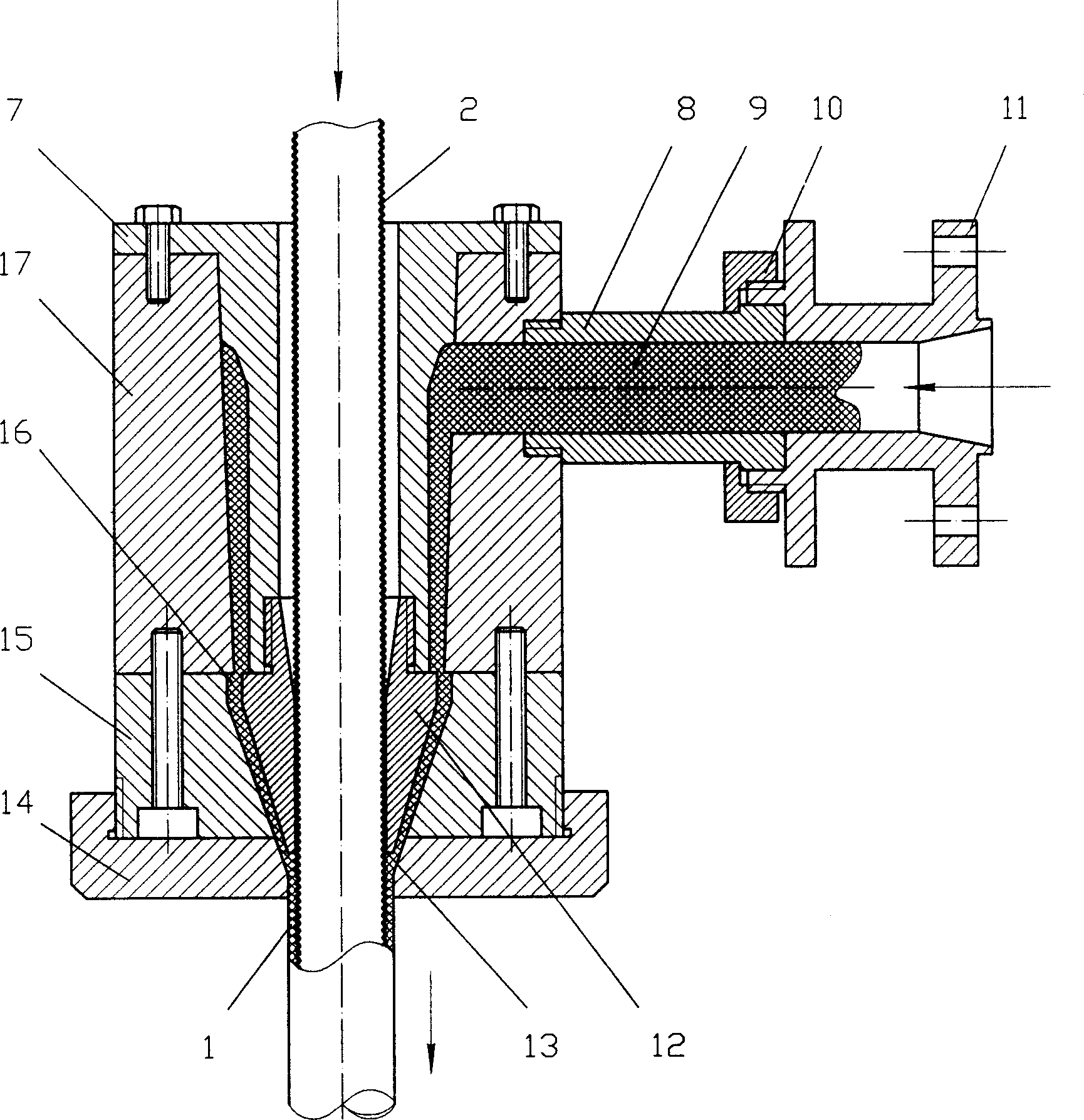

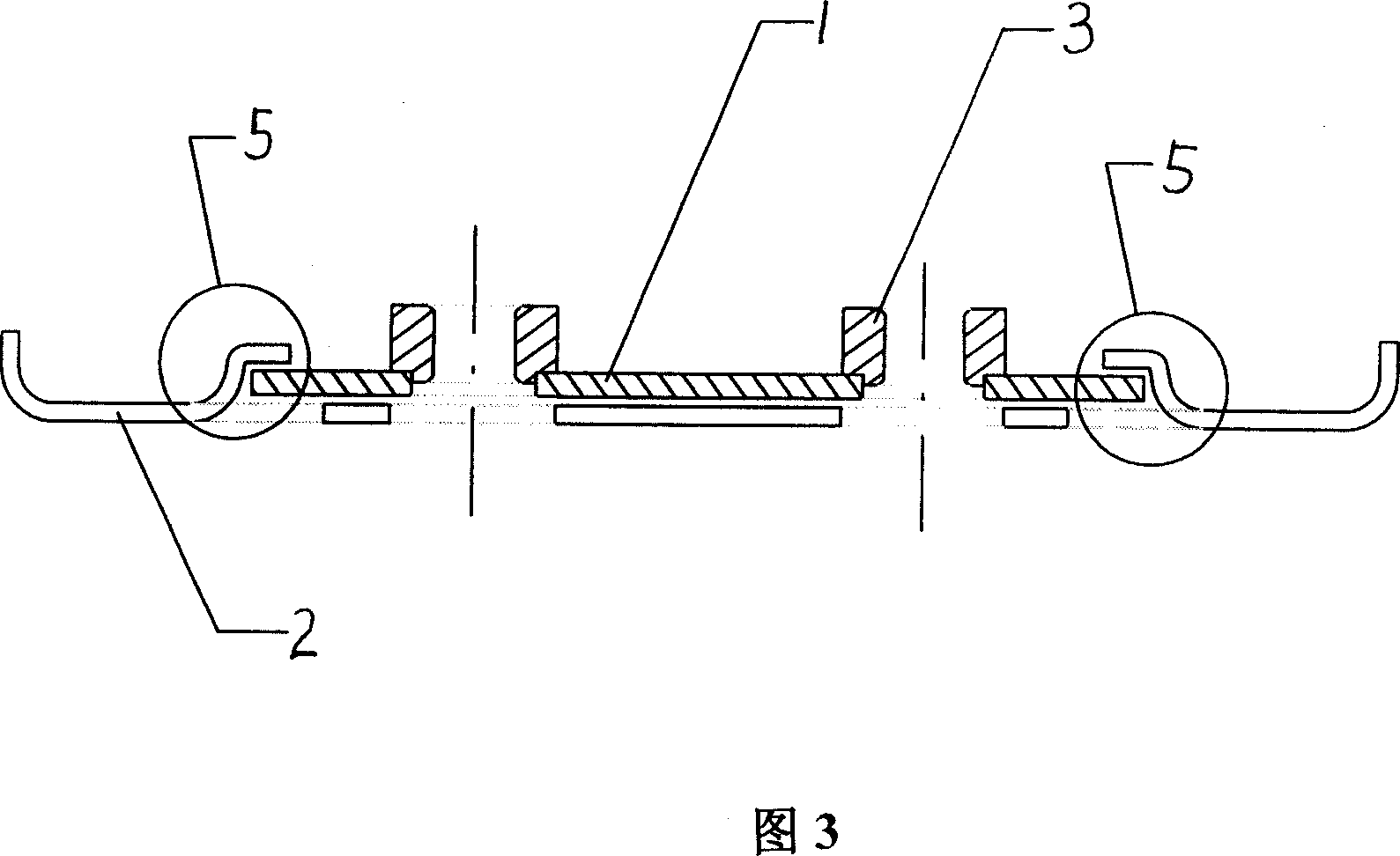

Double-faced adhesive tape pasting machine

The invention provides a double-sided glue sticking machine, comprising a feeding mechanism, a guiding mechanism, a cutting mechanism, a gluing mechanism, and a material receiving mechanism; the feeding mechanism includes a reel; the guiding mechanism includes a guiding wheel 1, Guide wheel II; the cutting mechanism includes a non-stick glue cutting blade, cylinder I, cylinder II, slide rail, slider; the gluing mechanism includes a gluing wheel; the receiving mechanism includes a receiving shaft, a receiving Motor and reducer; double-sided film material is placed on the feeding reel, and the tape head of the double-sided tape is pulled out through the guide wheel I, the glue wheel, and the guide wheel II to connect to the receiving shaft; the non-stick adhesive cutting blade is set On the telescopic shaft of the cylinder II, the cylinder II is horizontally fixed on the slide block, the cylinder I is vertically arranged, and its end is connected with the slide block, and the slide block is arranged on the vertical slide rail. The present invention adopts the mode of die-cutting to cut the glue, which can control the depth of glue application; the effect of cutting the film is that the adhesive tape breaks off the release paper continuously, and the release paper does not need to be manually removed.

Owner:HEFEI BYAT AUTOMATIC TECH CO LTD

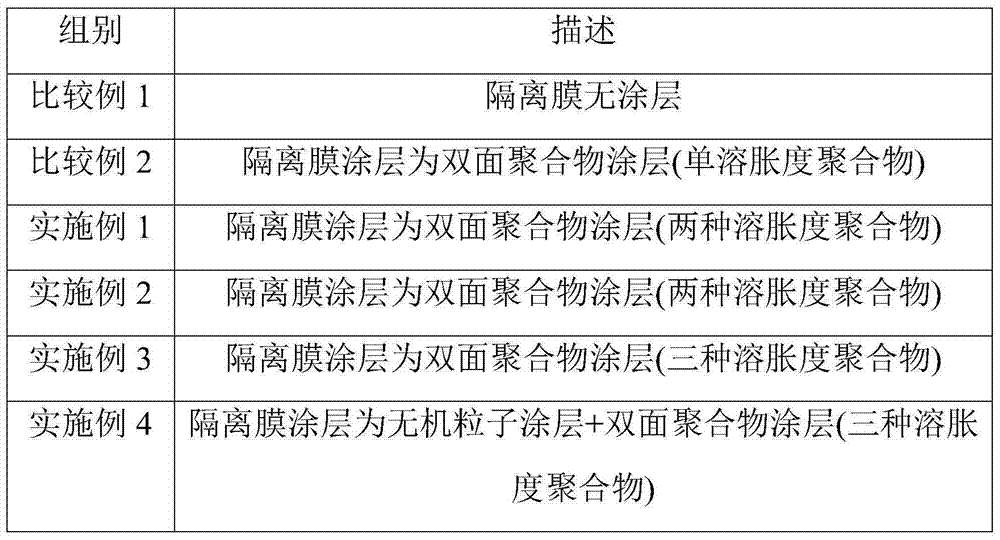

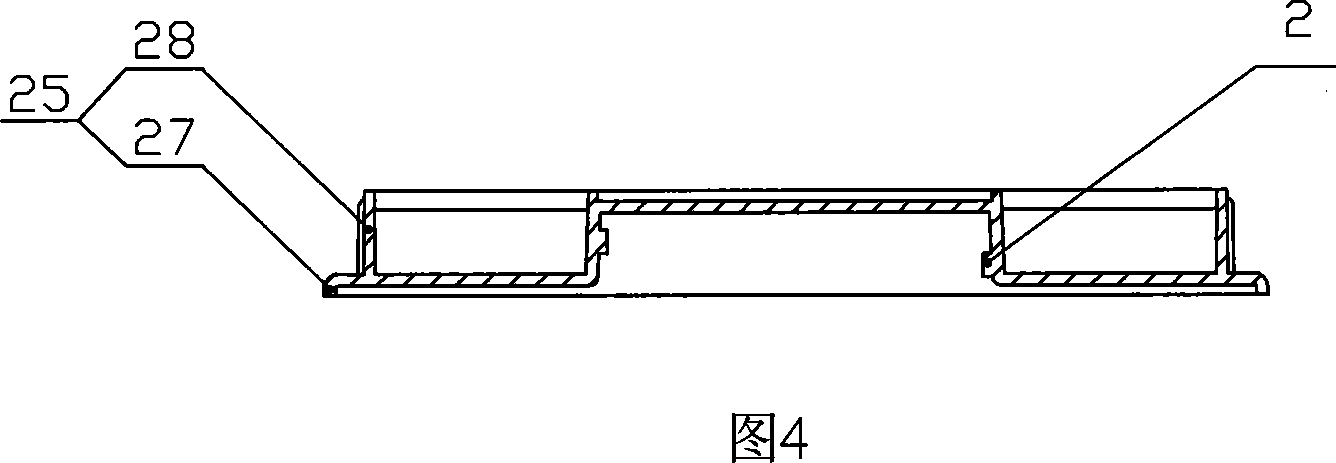

Isolating membrane for lithium ion secondary battery

InactiveCN104852008AGuaranteed not to deformPerformance is not affectedSecondary cellsCell component detailsCell fabricationPhysical chemistry

The invention belongs to the technical field of battery manufacture, and specifically relates to an isolating membrane for a lithium ion secondary battery, comprising an isolating membrane main body, wherein at least one surface of the isolating membrane main body is coated with a binder-polymer coating, and the binder-polymer coating comprises a binder polymer and a binder, and the binder-polymer coating at least comprises two polymers with different swelling degrees, wherein at least one polymer with lower swelling degree is used as cage construction for holding a certain expansion space for a pole piece of the lithium ion battery, and at least one polymer with higher swelling degree can be well bonded with the pole piece. Because the binder-polymer coating comprises the binder polymer and the binder, and the system is an environmental water system, and the coating coverage rate is 10 percent to 90 percent, the isolating membrane for the lithium ion secondary battery not only can be used for providing the expansion space of the pole piece, but also has small blockage for the hole of the isolating membrane, which cannot have influence on the battery performance. The polymer with high swelling degree can be well bonded with the pole piece so as to effectively restrain the deformation of the battery.

Owner:东莞市魔方新能源科技有限公司 +1

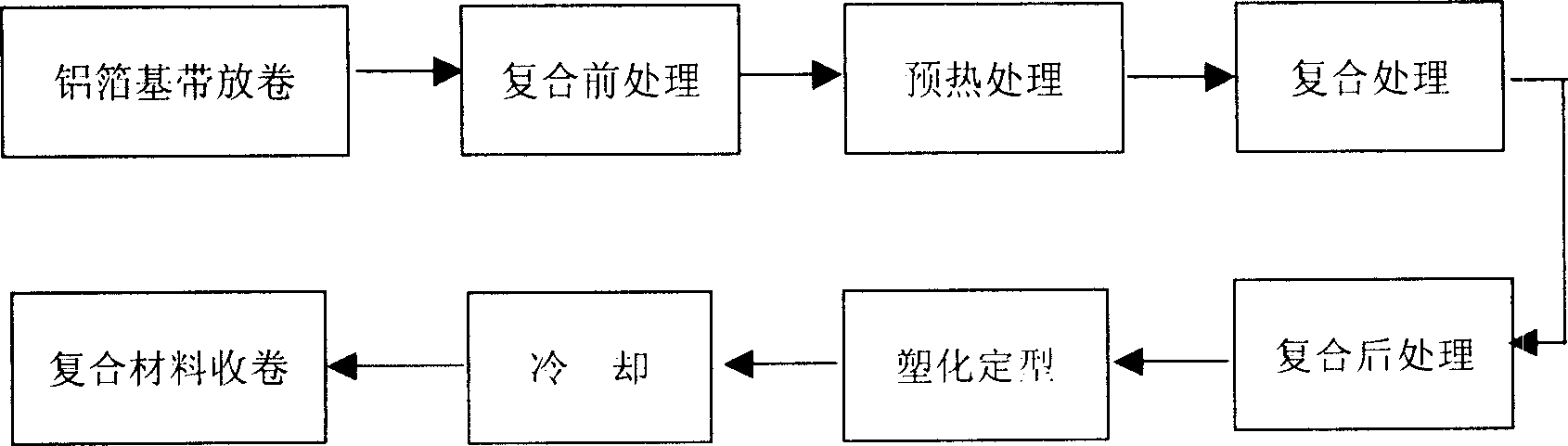

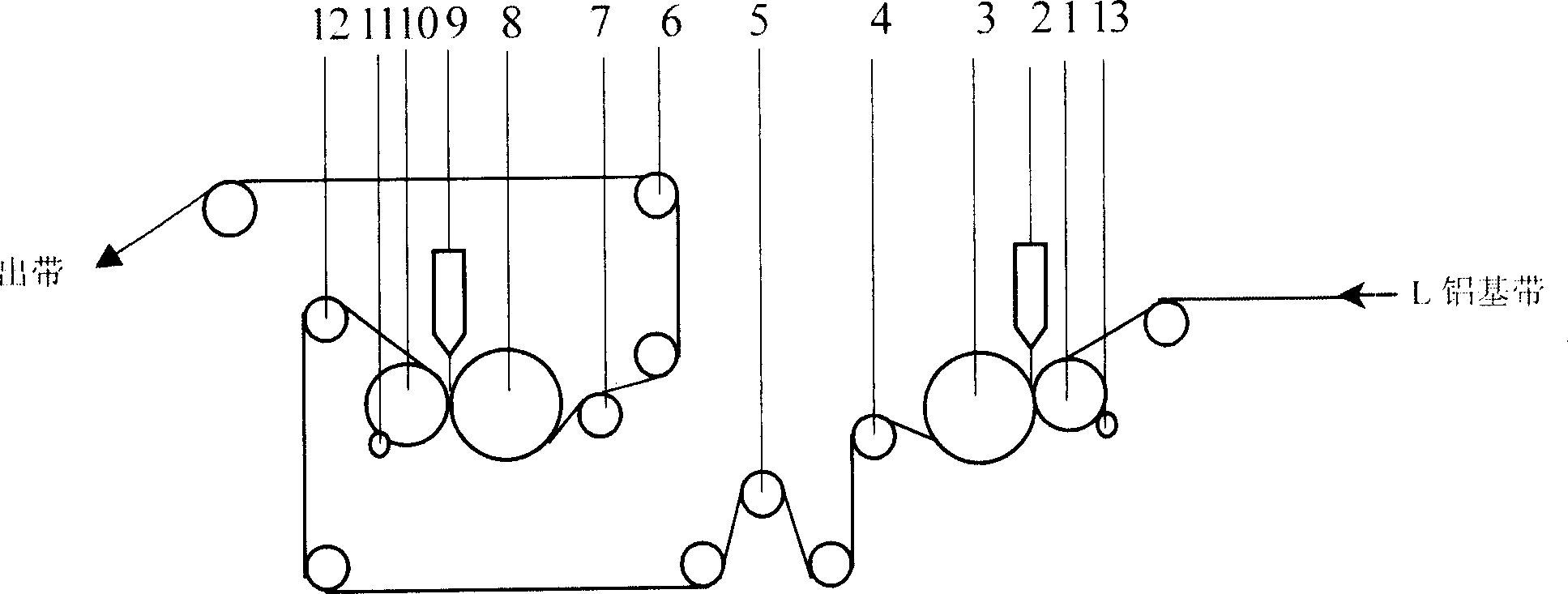

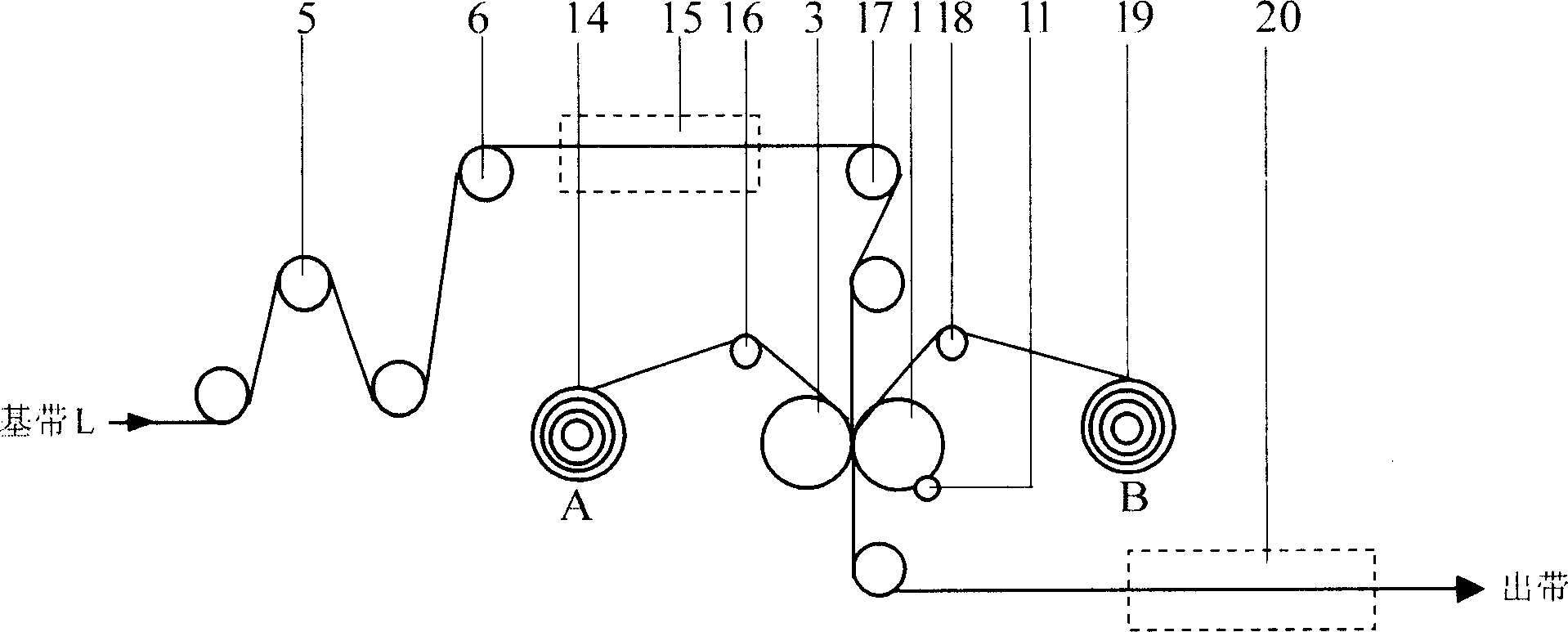

Method for mfg. sub light smooth type aluminium plastic compound band

ActiveCN1792605AReduce weightSave materialSynthetic resin layered productsBeltsPlastic filmAluminum foil

A process for preparing the dull and smooth aluminum-plastic band includes such steps as choosing an aluminum foil as basic band, pre-treating, extruding out at least one plastic film layer onto one or two surfaces of basic band, rolling while heating, and heat-treating by controlling the temp between Vicat softening point and fusion point for obtain dull and smooth surface. It can be used for optical cable or electric cable for high moisture tight effect.

Owner:上海网讯新材料科技股份有限公司

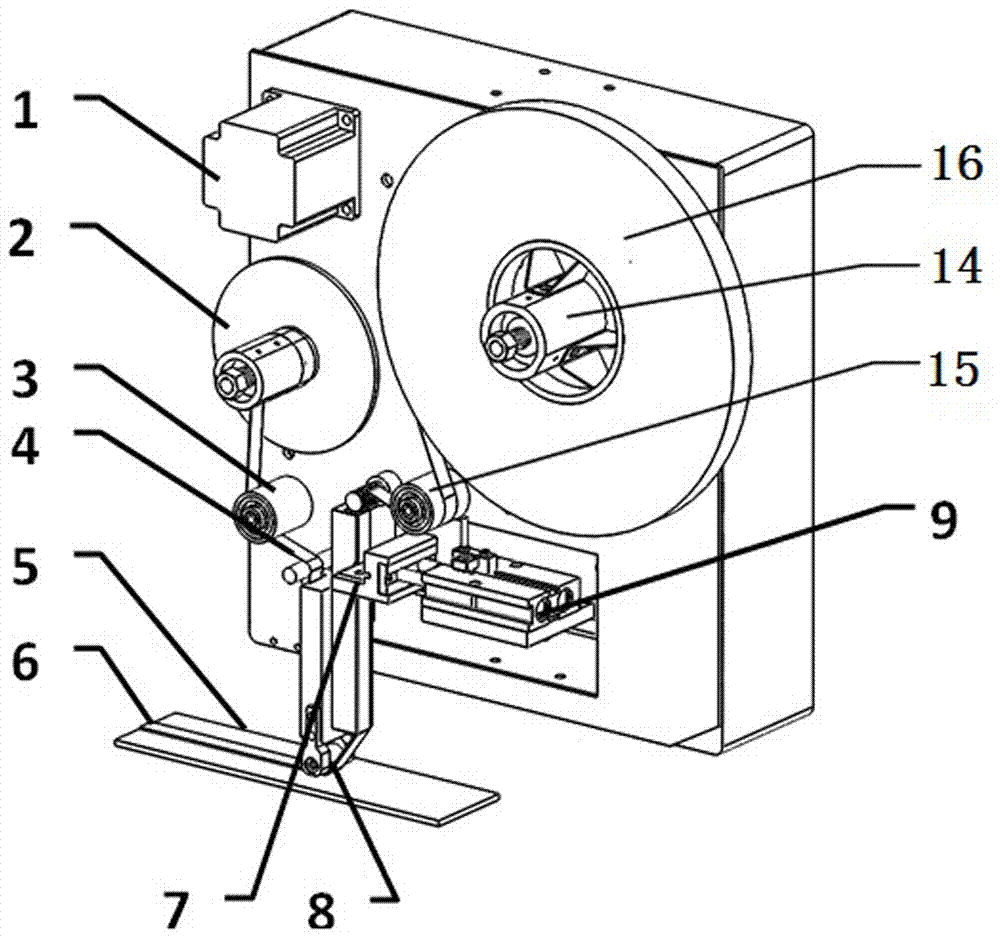

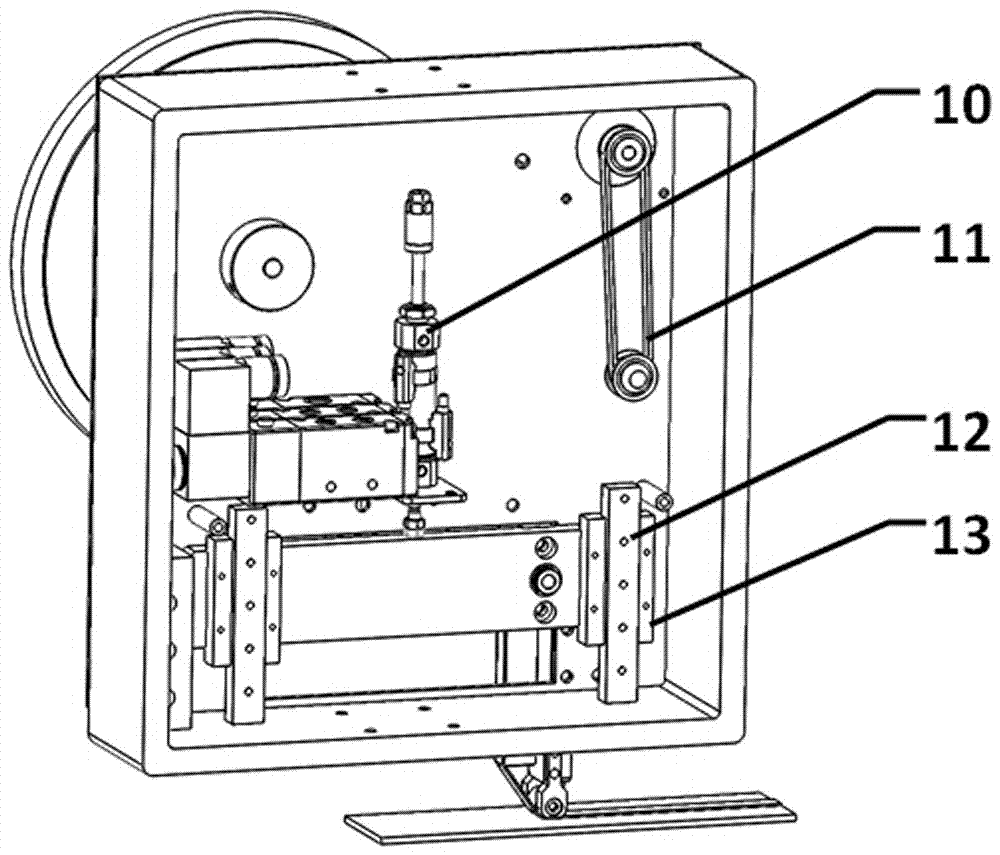

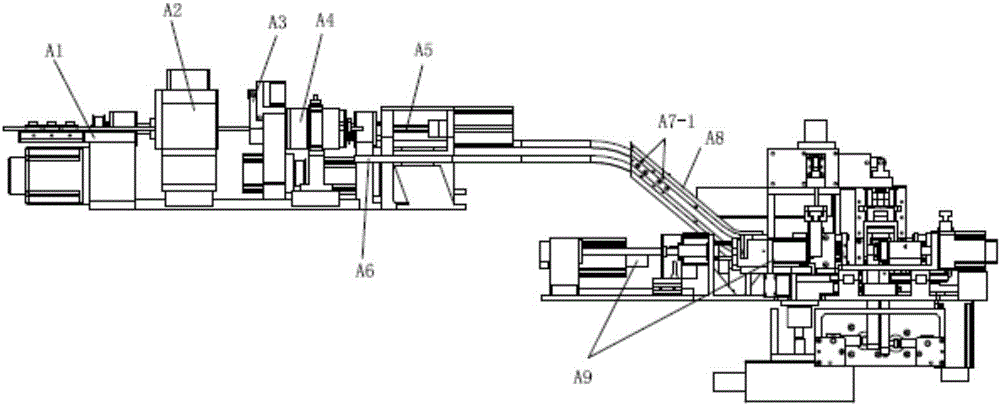

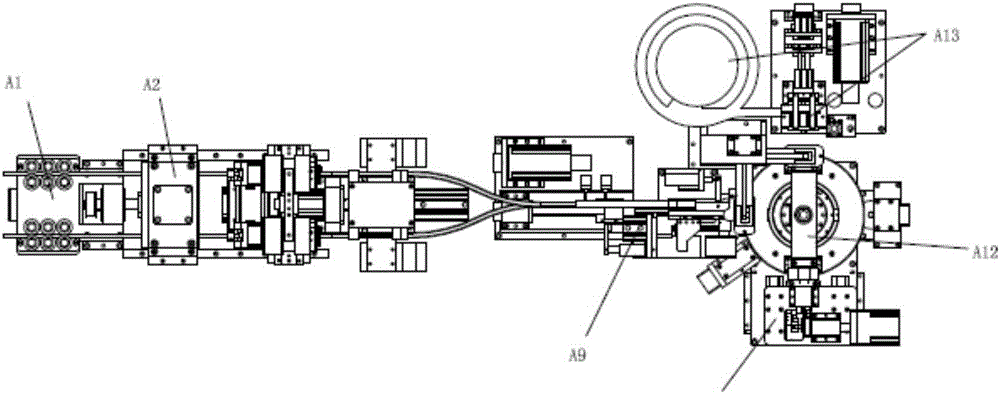

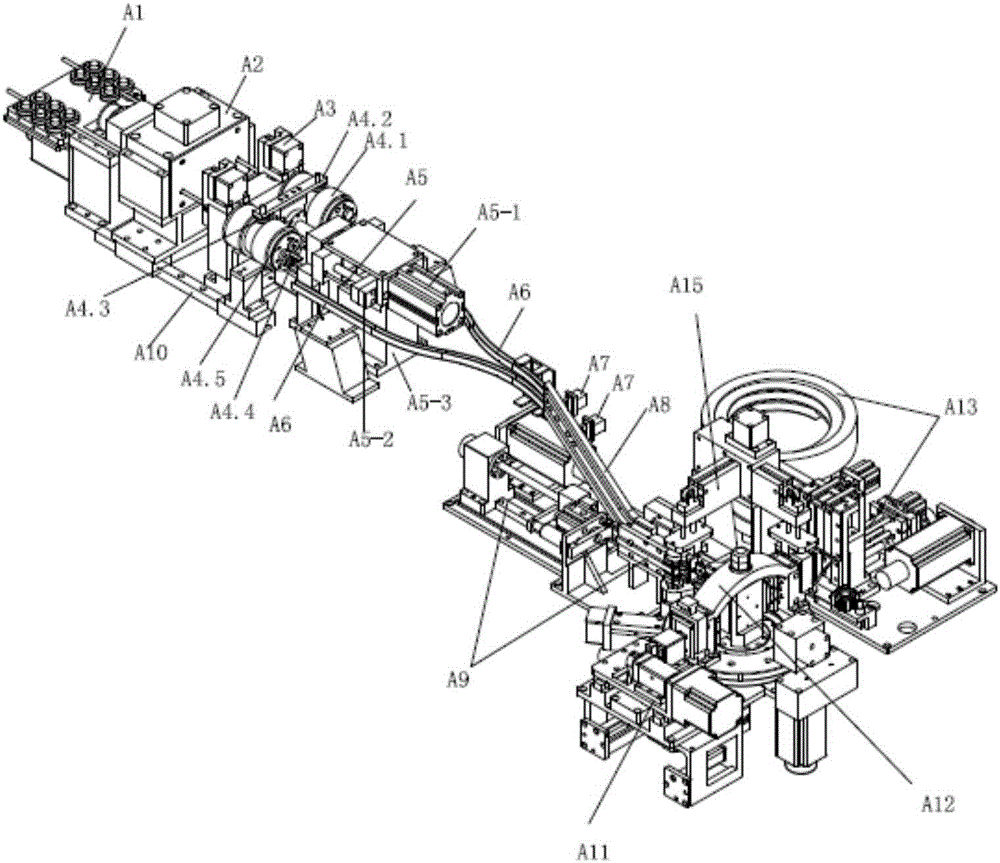

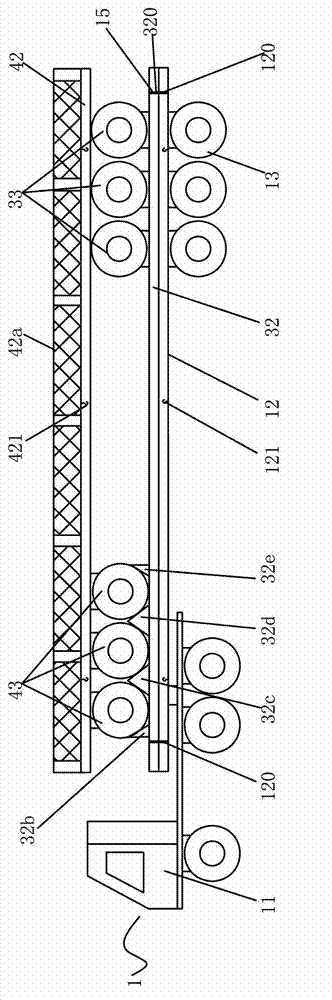

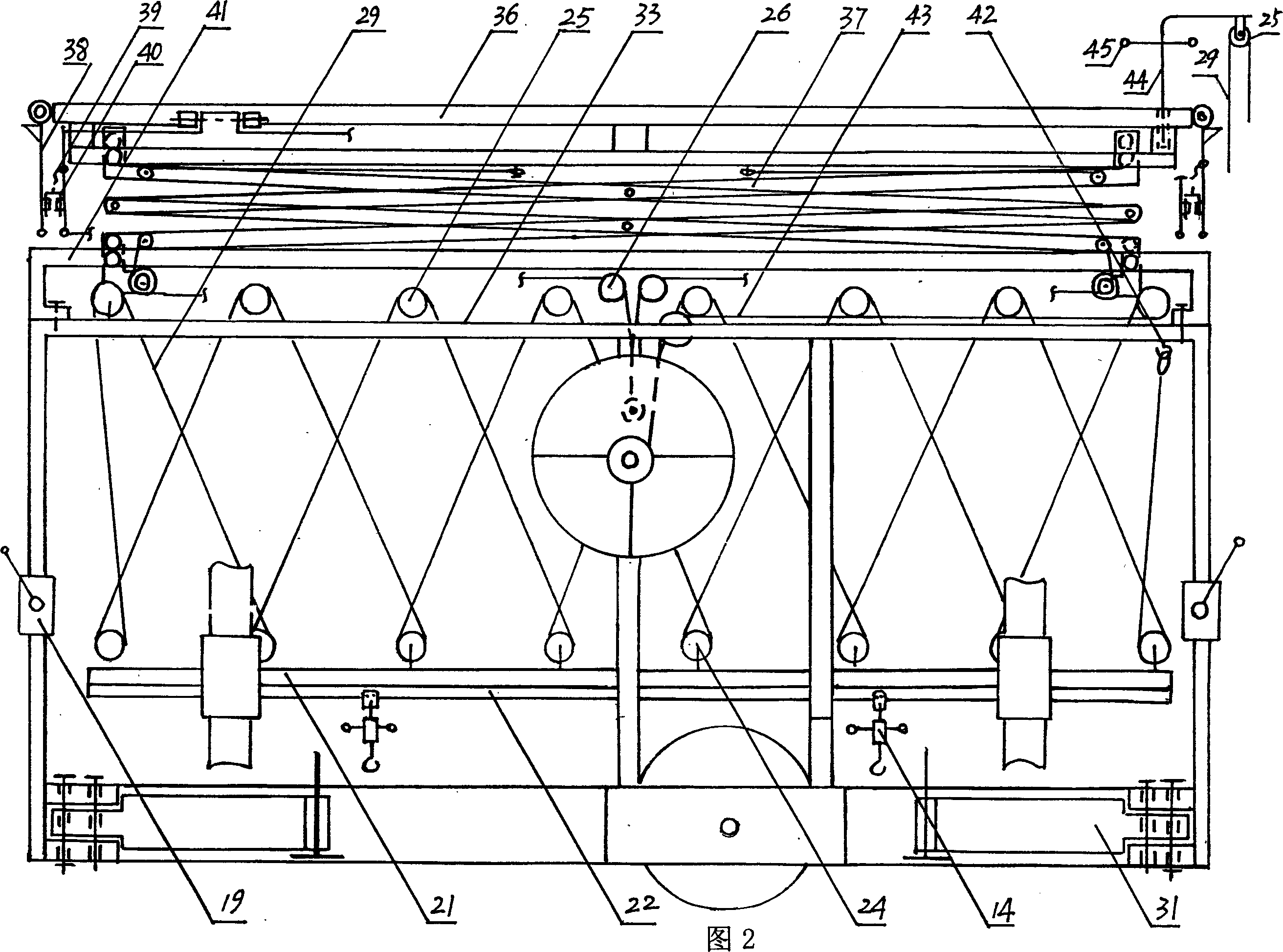

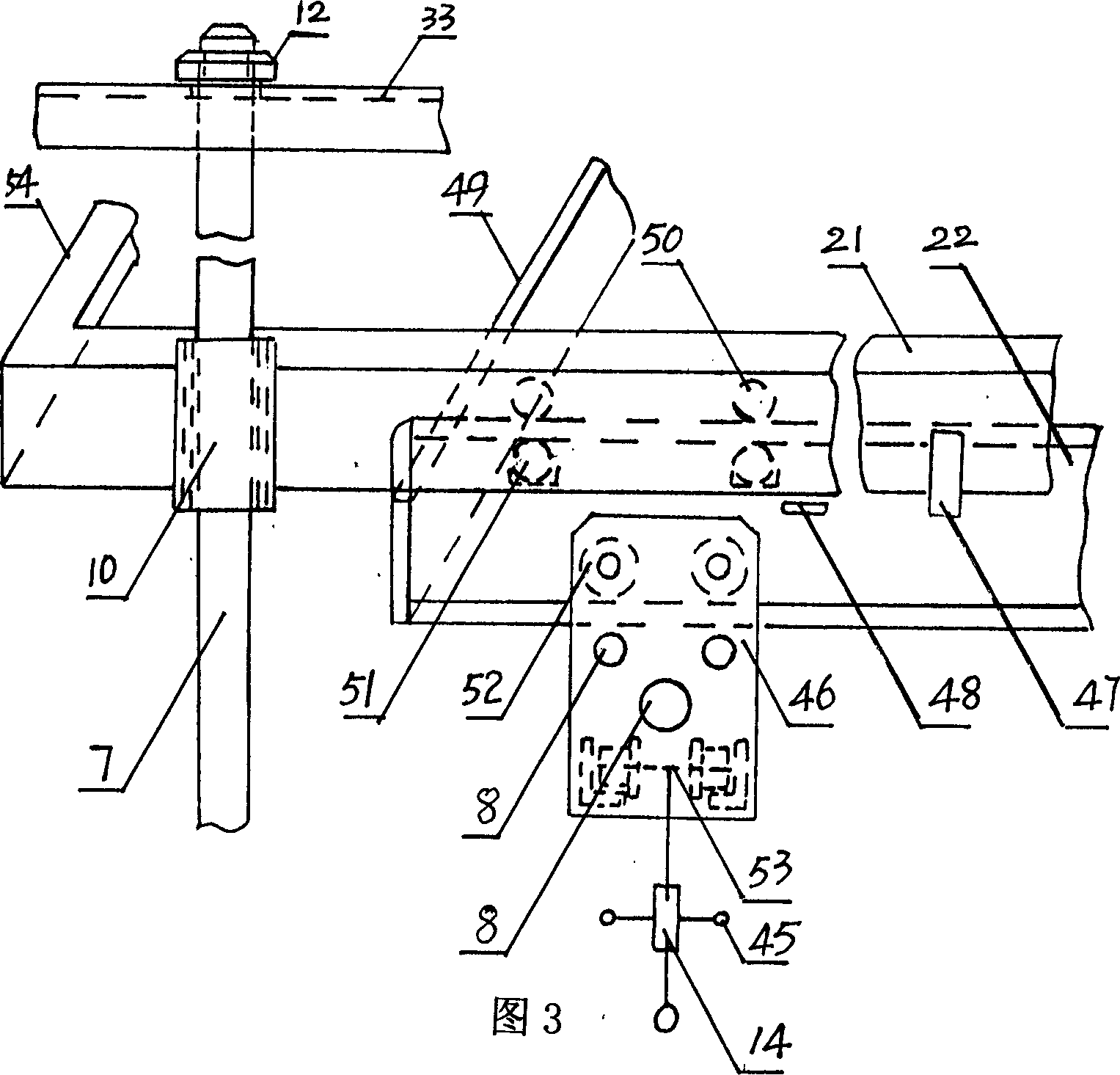

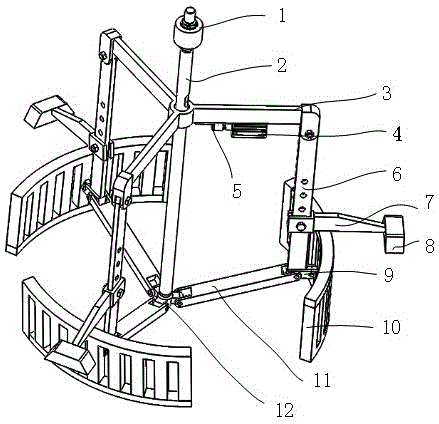

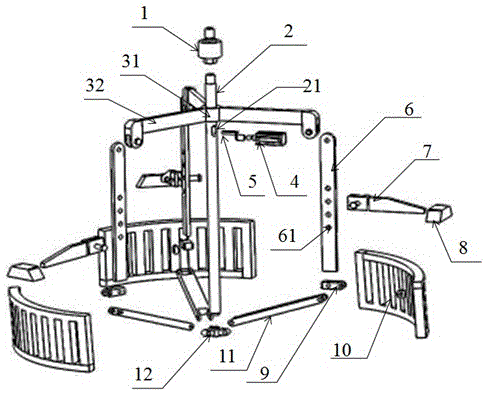

Automatic forming machine of thin-walled short U bent pipe with welding ring

ActiveCN106270239AEliminate wasteGuaranteed not to deformMetal-working feeding devicesOther manufacturing equipments/toolsEngineeringFixed length

The invention discloses an automatic forming machine of a thin-walled short U bent pipe with a welding ring, relates to the technical field of automation equipment, and can continuously accomplish the forming of the thin-walled short U bent pipe and socket welding ring operation, so as to prevent a pipe wall from folds. The automatic forming machine comprises a feeding assembly, a pipe cutting assembly, a pipe bending assembly, a circumference position rotating assembly and a socket welding ring assembly, wherein the feeding assembly at least comprises a clamping mechanism and a No.1 driving mechanism; the No.1 driving mechanism drives the clamping mechanism to perform forward feeding; the pipe cutting assembly at least comprises a cutting tool mechanism and a No.2 driving mechanism; the No.2 driving mechanism drives a cutting tool to act; the pipe bending assembly at least comprises a fixed part, a semicircle die, a movable part and a No.3 driving mechanism; one end of a fixed length pipe is clamped at the fixed part; the other end of the fixed length pipe gets over the semicircle die and then is movably matched with the movable part; the circumference position rotating assembly at least comprises a rotating frame, a pipe clamping mechanism, a No.4 driving mechanism and a discharging cylinder; the socket welding ring assembly at least comprises a welding ring feeding unit, a welding ring guide unit and a socket welding ring unit; the socket welding ring unit pushes the welding ring to a straight pipe section of the thin-walled short U bent pipe.

Owner:TONGLU QIANDING TECH

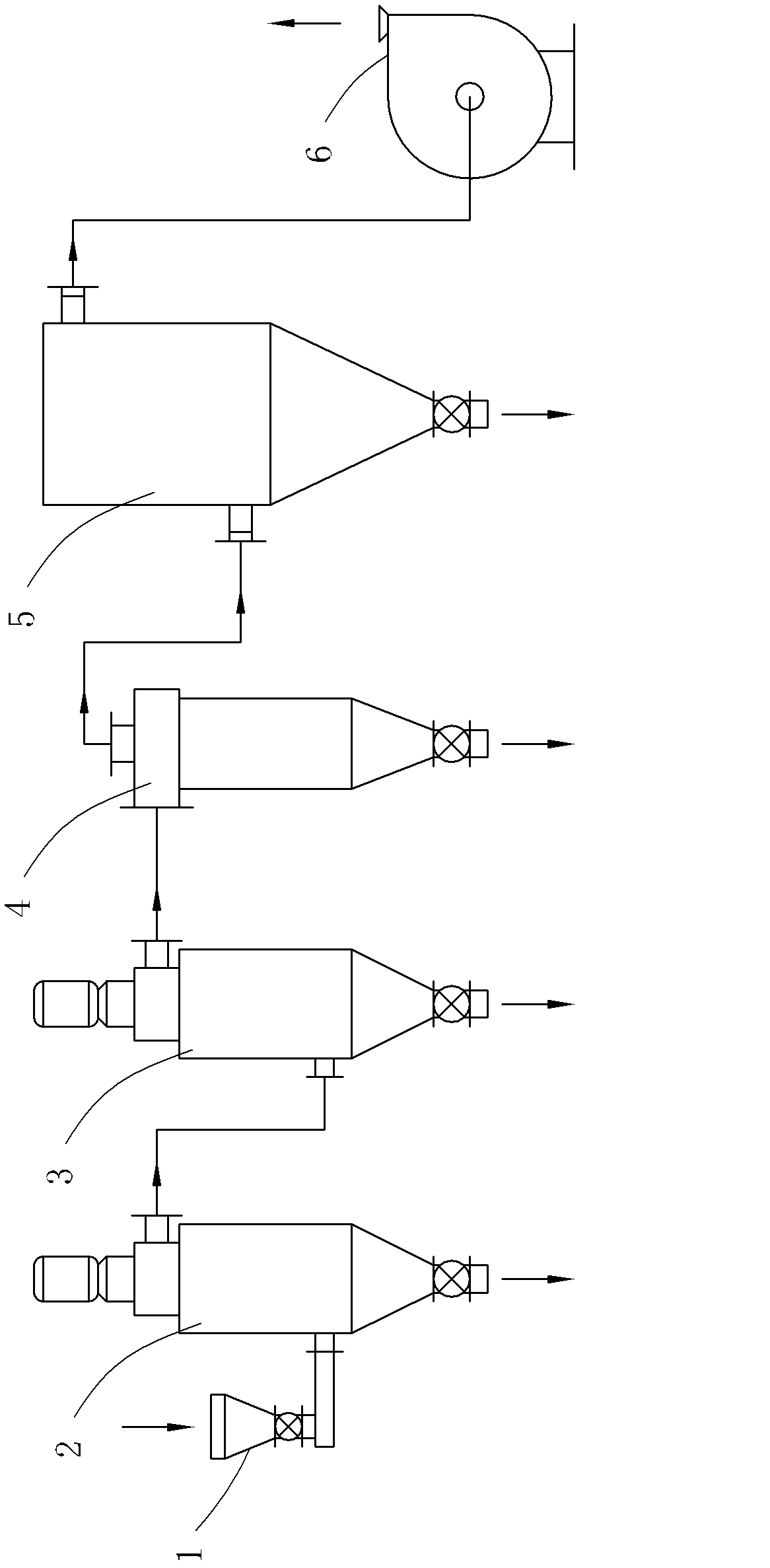

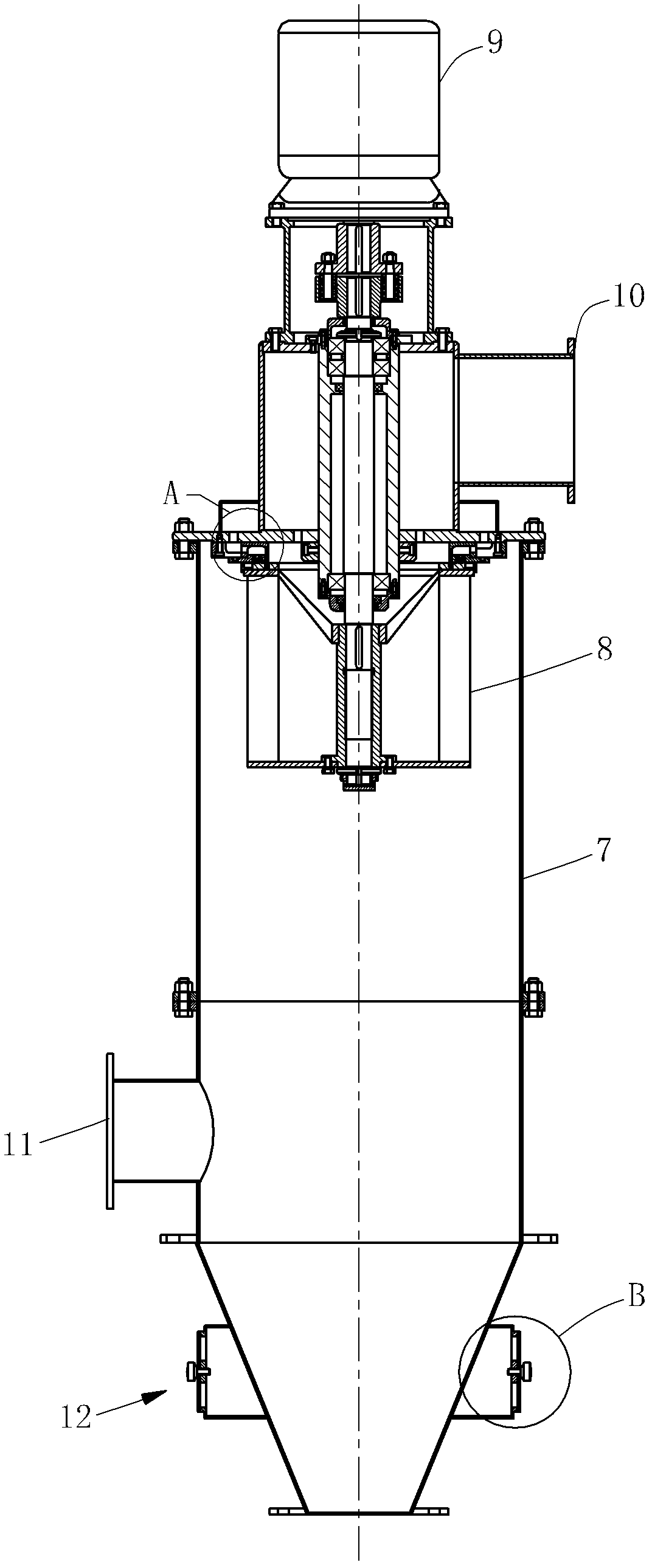

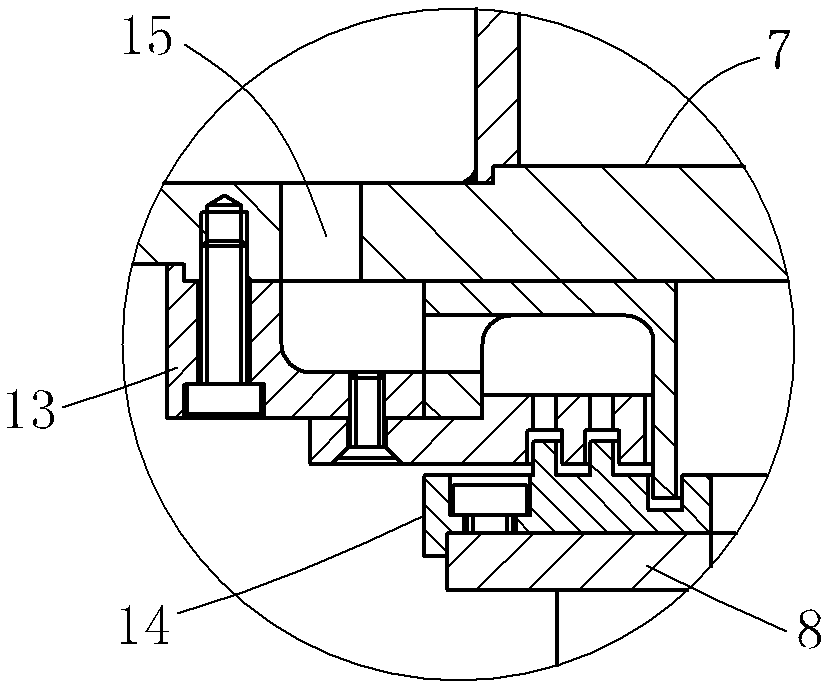

Method for classifying silicon carbide micro powder and classifying equipment of method

InactiveCN102580928ABalanced self-sharpeningNarrow particle size distributionEngine sealsGas current separationCycloneGranularity

The invention discloses a method for classifying silicon carbide micro powder and classifying equipment of the method, which belong to the technical field of classification of micro powder. The method mainly includes steps that the silicon carbide micro powder sequentially enters at least two classifying machines which are serially connected, each classifying machine is provided with a self-suction sealing device, the classifying precision of each downstream classifying machine is higher than that of the adjacent upstream classifying machine, a cyclone collector is connected with the tail-end classifying machine and collects sorted silicon carbide micro powder; a bag dust collector collects waste discharged from the cyclone collector, and a system is powered by an induced draft fan disposed on a downstream of the bag dust collector. By the aid of the method and the classifying equipment, technical problems that in the prior art, the classifying precision of silicon carbide micro powder is low, extraction rate of fine powder is low, distribution of granularities of finished products is wide are solved. In addition, the method and the classifying equipment are widely applied to finely classifying silicon carbide grains.

Owner:WEIFANG HUICHENG NEW MATERIAL TECH

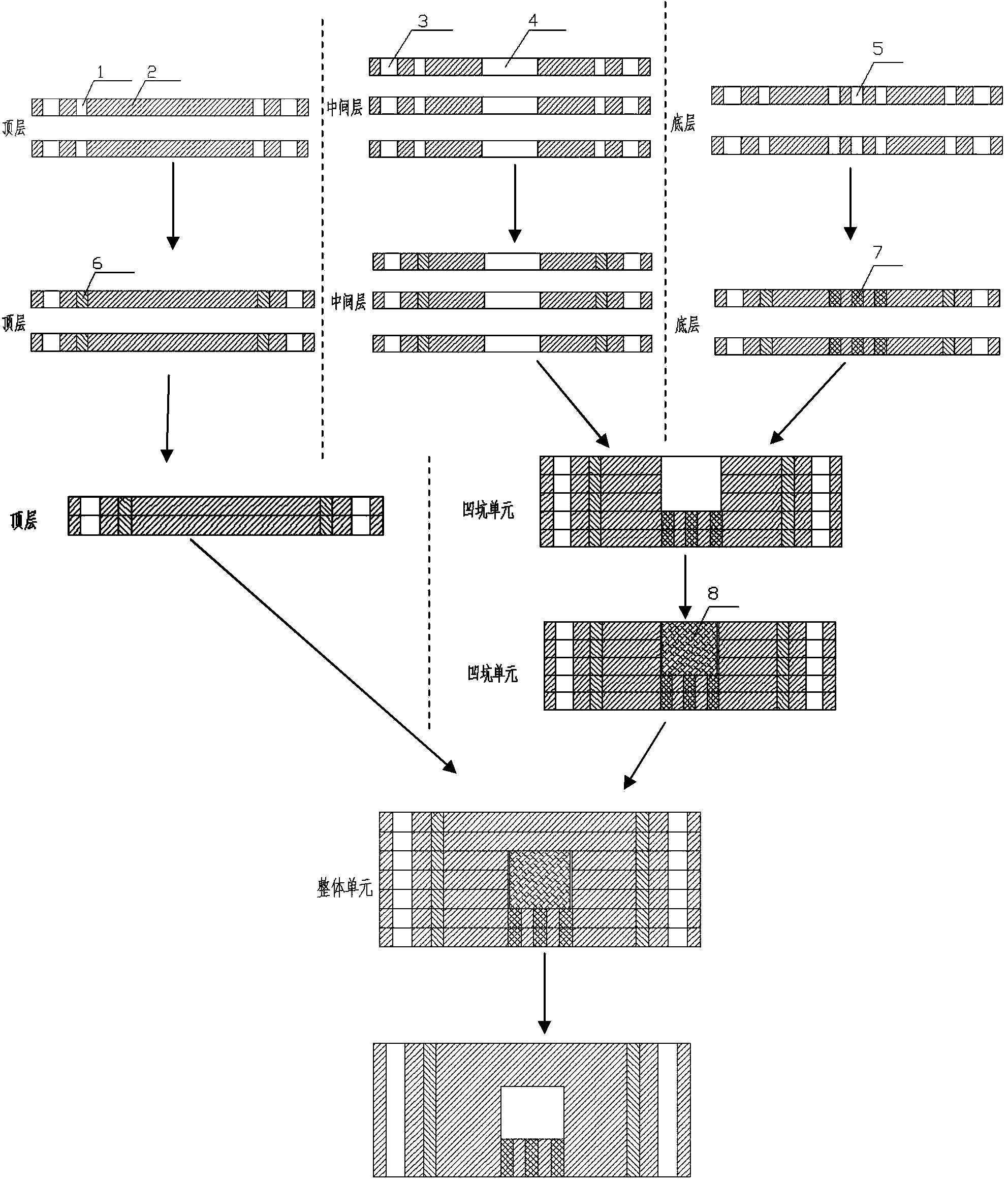

Method for preparing multilayer low-temperature cofired ceramics integrated liquid cooling circulation channel

ActiveCN103456646AGuaranteed not to deformGuaranteed deformationAntenna supports/mountingsSemiconductor/solid-state device manufacturingFilling materialsCeramic

The invention provides a method for preparing a multilayer low-temperature cofired ceramics integrated liquid cooling circulation channel. By the adoption of the method, the fact that the liquid cooling circulation channel does not collapse can be guaranteed, and the problems of layering and swelling in the sintering process can be solved. According to the technical scheme, the method is achieved through the following steps that firstly, a plurality of low-temperature cofired raw ceramic chips are divided into three layers, locating holes, via holes, heat radiating holes and the liquid cooling circulation channel are prepared respectively, then, integral lamination is conducted on the top raw ceramic chip layer with an antenna unit to form a top unit, and integral lamination is conducted on the middle raw ceramic chip layer with the liquid cooling circulation channel and the bottom raw ceramic chip layer with a TR component unit to form a pit unit; volatilizable filling materials are printed into pits of the pit unit, organic adhesive coats the surface of the pit unit, the top unit is stacked on the pit unit, and an integral module is formed in a low-temperature and low-pressure mode; the integral module which is laminated is placed in a sintering furnace for sintering, and a liquid cooling external joint is welded to a corresponding liquid cooling inlet and outlet on the surface of the top layer of the module.

Owner:10TH RES INST OF CETC

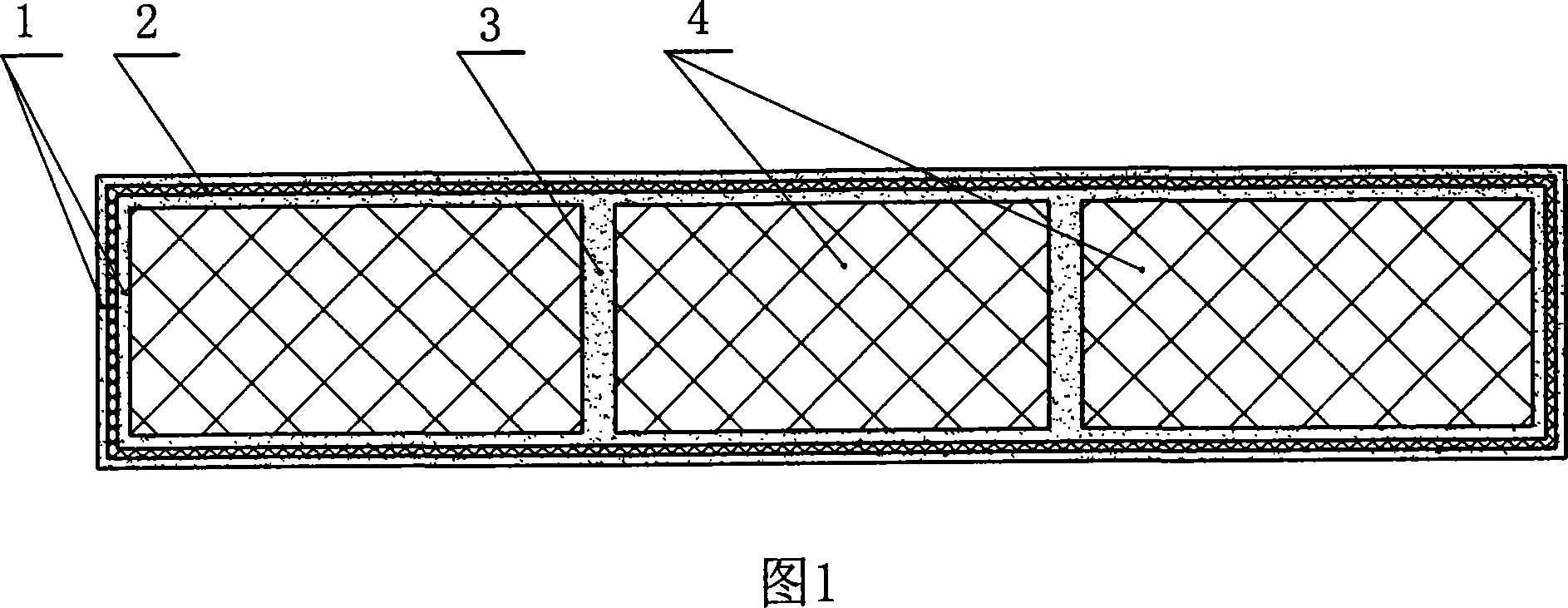

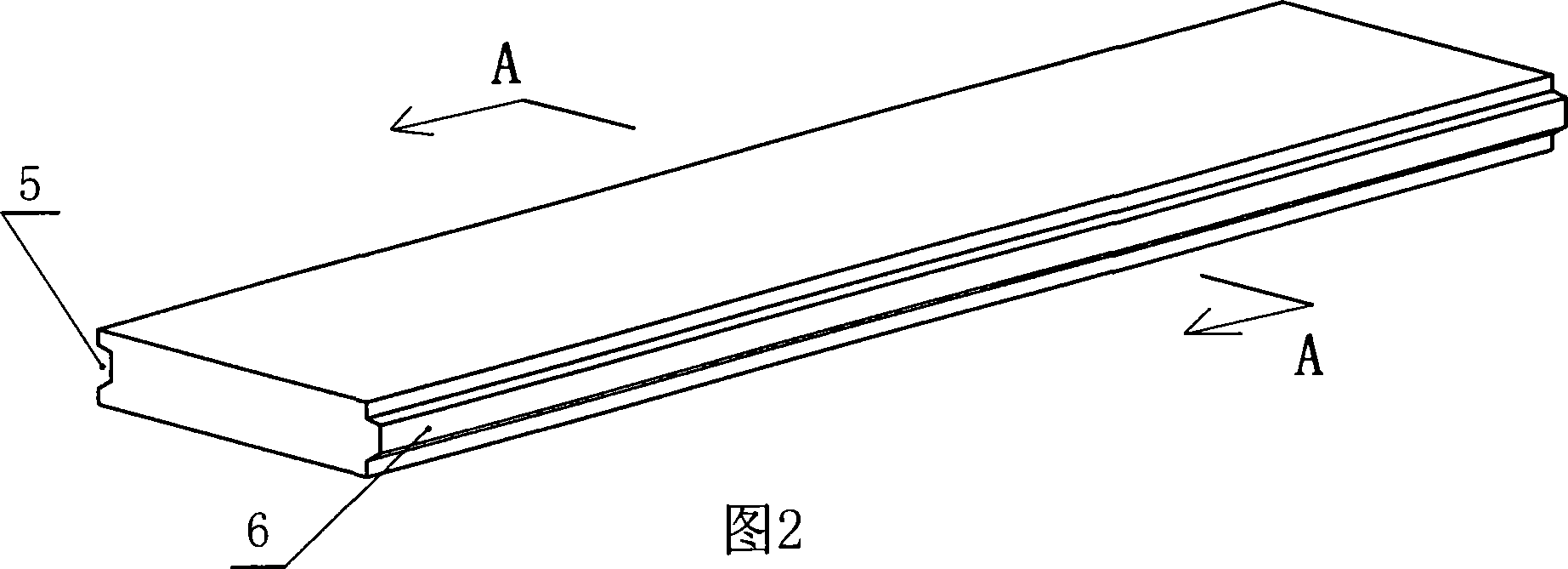

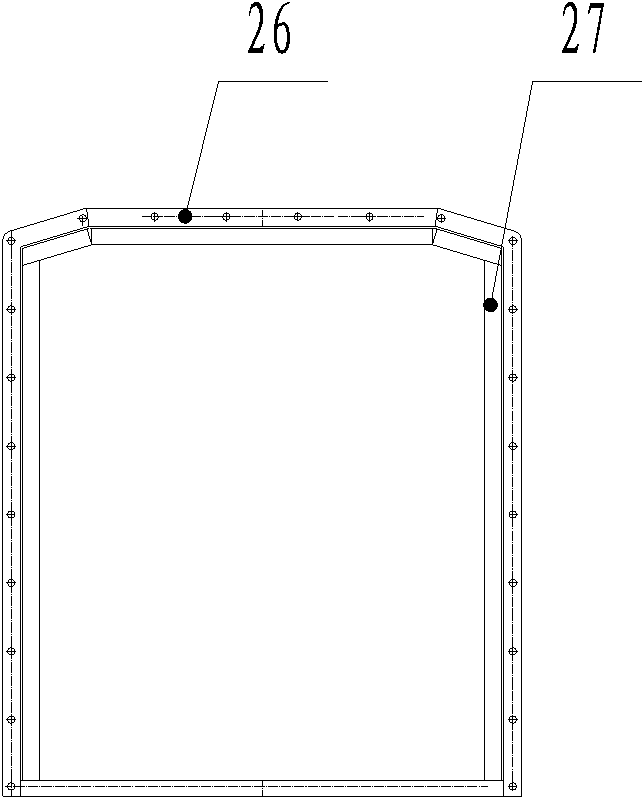

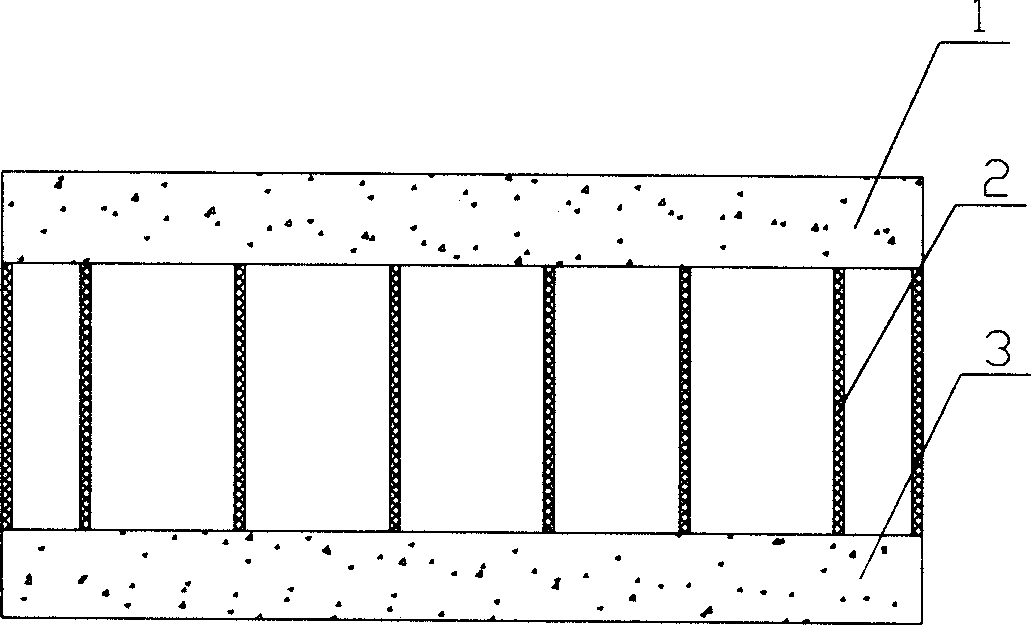

Compact composite light internal and external wall plate

InactiveCN101050658AImprove surface strengthGuaranteed not to deformSolid waste managementBuilding componentsPolystyreneSlurry

The present invention relates to a compact composite light-weight internal and external wall panel. It includes slurry material layer of external layer. Said slurry material layer is made up by using (by weight portion) 100 portions of quick-hardening early-strength sulphoaluminate cement, 0-35 portions of fly-ash, 0-10 portions of building glue and 0.2 portions as raw material through the processes of mixing, adding water and making slurry. It the slurry material layer interior a plastic-coated glass fiber mesh fabric is filled, and the slurry material layer interior is covered with a foamed plastic layer, said foamed plastic layer is a high-foamed polystyrene foam plastic plate. In the foamed plastic layer several through holes are set, in every through hole a column slurry material body is injected, and two sides of said panel body are equipped with tongue and slot mortise.

Owner:周胜利

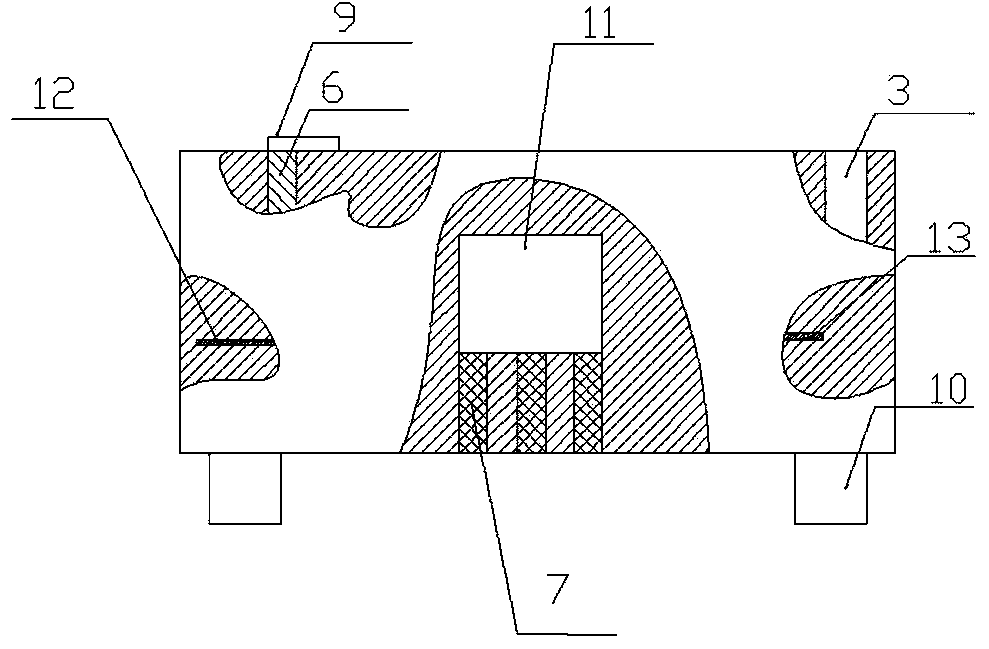

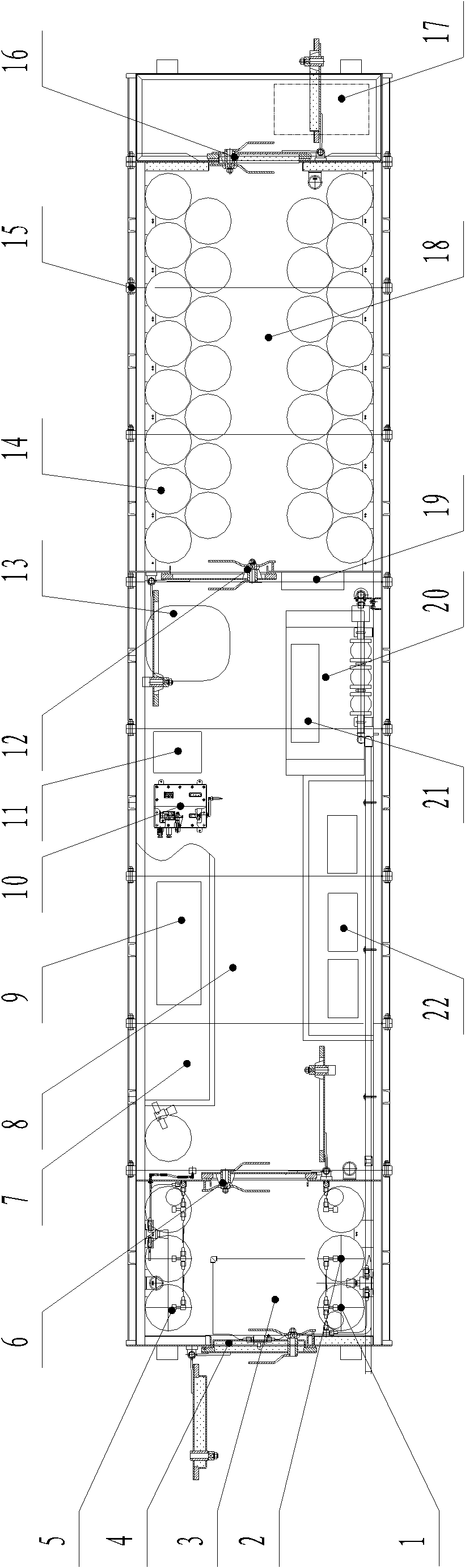

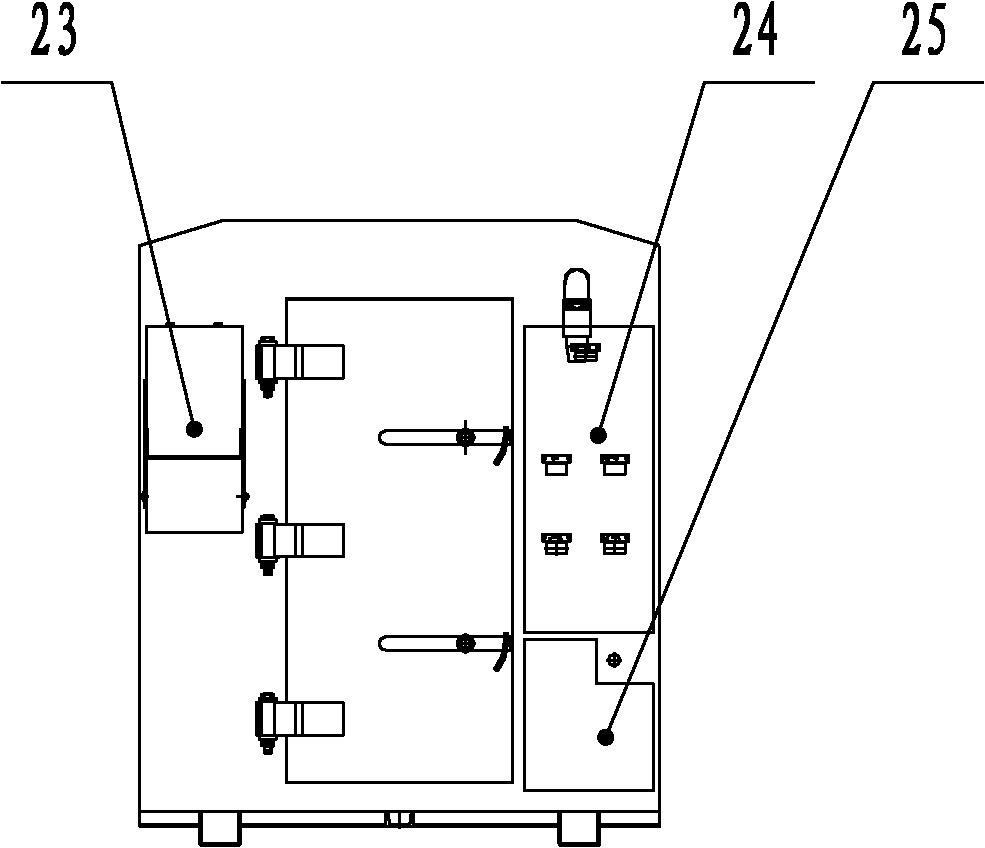

Movable split-type refuge chamber

InactiveCN102003206AAnti-collapseWith heating, drying and humidity adjustmentSafety equipmentsFood storageEngineering

The invention relates to a movable split-type refuge chamber, belonging to the technical field of life saving apparatus. The movable split-type refuge chamber is characterized by comprising a transfer chamber, a main chamber and an auxiliary chamber; the movable transfer chamber and the main chamber which are combined by sealing joints and the movable auxiliary chamber and the main chamber which are combined by sealing joints form the refuge chamber; a transfer chamber body is provided with a front chamber door, the main chamber body is provided with a side chamber door, and the auxiliary chamber is provided with a life saving chamber door; and the refuge chamber is provided with an environment monitoring device, a power supply, a communication telephone, an oxygen gas steel cylinder and / or a food storage device. The movable split-type refuge chamber has the advantages of collapse resistance, gas explosion resistance, sealing of the influx of underground noxious gas, adjustment of temperature and humidity, automatic oxygen supply, free arrangement and combination, favorable air tightness and heat insulation effect, simpleness of installation, convenience and flexibility, investment saving, and ability to provide a set of complete life assurance system for escaping persons on site, and the like.

Owner:天津市天矿电器设备有限公司

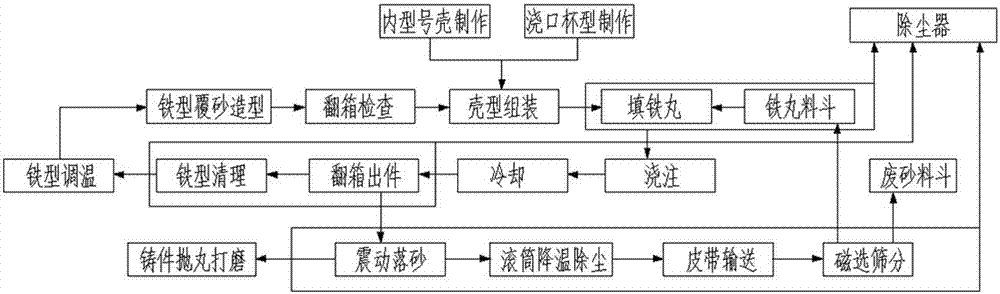

Novel casting technique of semitrailer brake drum

InactiveCN103286279AGuaranteed not to deformBack-off guaranteeCasting plantsFoundry mouldsBrakeDust control

The invention relates to a novel casting technique of a semitrailer brake drum. The novel casting technique of the semitrailer brake drum comprises the following steps of: manufacturing an inner mold shell and a pouring cup; regulating the temperature of an iron mold, covering with sands, and modeling; checking by turning over a mold; assembling a shell mold; filling iron shots; pouring and cooling; turning over the mold, discharging elements, assembling the elements, and recovering; carrying out magnetic separation, and screening; dedusting and cleaning. No deformation of the brake drum is ensured fully; the steel shots are filled in an internal mold sand shell; poured steel liquids generate pressure inward; firstly, because of the 'arch bridge principle', the internal mold sand shell has great support force; and then the steel shots also can block the pressure by steel liquids, and the internal mold sand shell cannot be cracked or deformed absolutely. Before cast elements are condensed and contracted, the internal mold sand shell is scattered, the filled steel shots are at the scattered state, the deformability of the cast elements in contraction is ensured fully, so that free contraction instead of hindered contraction is formed; a bottom-pouring-type pouring mode is adopted, air is discharged smoothly; the cracking possibility at the crossed part is reduced; air holes of the cast elements caused by dampness of a sand mold are prevented; the novel casting technique of the semitrailer brake drum is an environment-friendly casting technique.

Owner:FUDI PRECISION CASTING

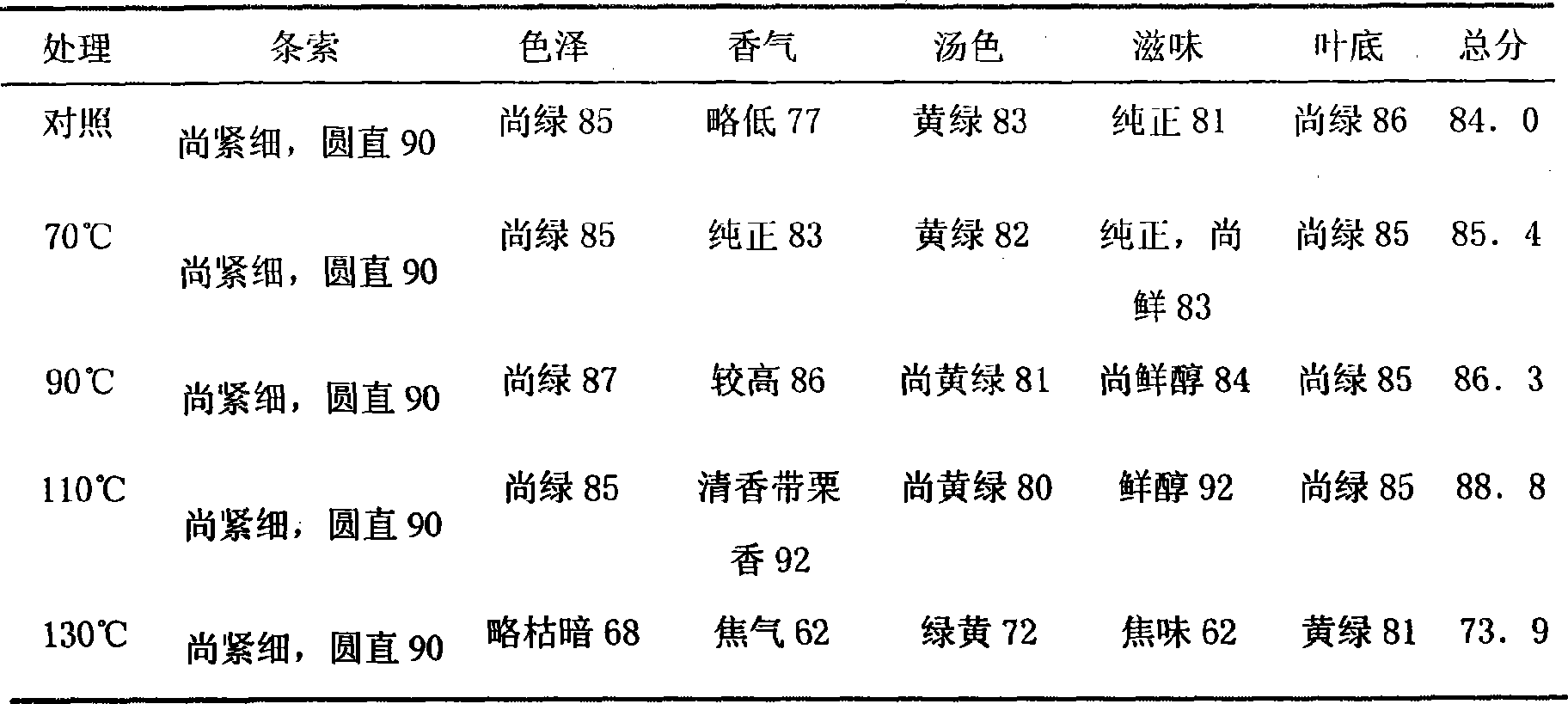

Mechanized method for processing styliform green tea

InactiveCN101366419AThe shape is tight, thin, round and straightBright green colorPre-extraction tea treatmentGreen teaEnzyme

The invention belongs to the technical field of tea manufacture, in particular to a method for mechanically processing acicular green tea. The method is characterized in that fresh green tea leaves are prepared into tea with acicular shape through spreading, enzyme deactivating, tightening, sorting, solidifying, drying, flavoring and other steps. The acicular well-known tea has the characteristics of tight, thin, round and straight strips, shape similar to pine straw, bright and green color and luster, silver tip exposedness, pure fragrance, fresh and rich taste, tender green and bright liquor color, tender and uniform leaves and the like. The tea quality can completely reach the level of manually processing, and the method is applicable to mechanical processing production.

Owner:HUAZHONG AGRI UNIV

Vacuum pneumatic ink containers

InactiveCN101054012ASo as not to damageGuarantee the quality of closed storageDispensing apparatusPackaging under vacuum/special atmospherePrinting inkEngineering

The invention relates to a vacuum pneumatic printing ink container which can realize mechanical filling, vacuum packing storage during printing ink production and pneumatic ink taking during printing. The container includes cylinder body and hollow piston, ink outlet, protruding column; air guide inlet holes of the hollow piston are respectively located on inner side face of annulus air guide slot of root portion of the protruding column of the hollow piston and circumference side face of the hollow piston, and two air guide discharge columns are arranged at back end of the hollow piston and are connected to the back cavity in order to completely discharge air; screw thread on ink outlet is tightly screwed with the screw thread of end cover, then the printing ink can be vacuum sealed in front cavity for the convenience of transportation and vacuum storage; outer diameter of the end cover is close to the same of the cylinder, so that force on the printing ink container entirety can be balanced thereby preventing the printing ink container deformation and being damaged; screw thread on peripheral of back end of the cylinder can couple with the screw thread of the aeration seal cover, and gas incoming switch valve on the aeration seal cover is convenient for plugging air tube of air source, and safe pressure limiting valve can relieve the pressure in the back cavity in time, and it is easy to pick and supply the printing ink, and can smoothly output the printing ink, and reduces work intensity.

Owner:谭慈源

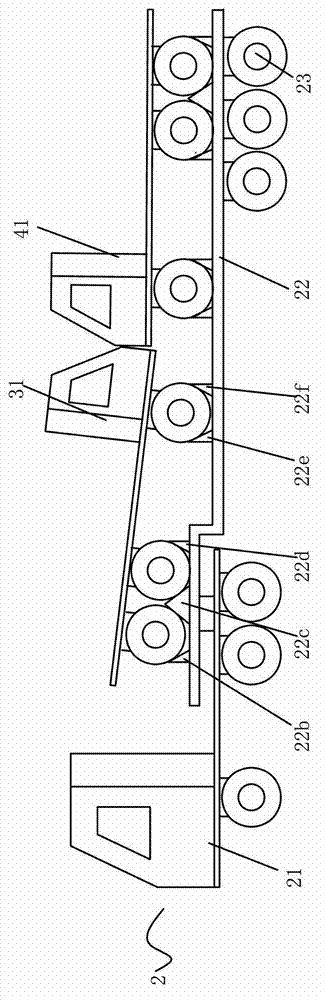

Large-scale transport vehicle parallel operation transporting system and method

ActiveCN102756763AReduce overall heightMeet shipping requirementsTractor-trailer combinationsVehicle carriersRolloverMode of transport

The invention discloses a large-scale transport vehicle parallel operation transporting system and a method. The parallel operation method includes that four large-scale semi-trailers are combined to form a transporting unit; when the transporting unit performs cargo-loading transportation, the four large-scale semi-trailers of the transporting unit perform cargo-loading transportation respectively; and when the transporting unit performs empty load transportation, by means of a rollover system, two large-scale semi-trailers of the transporting unit are loaded on the rest two large-scale semi-trailers so that a parallel operation transporting method that the two large-scale semi-trailers transport the rest two large-scale semi-trailers is formed. Under the condition that the transporting unit integrated by the four semi-trailers is not ultra-high, ultra-long and ultra-wide, the transporting unit is capable of performing reliable transportation according to requirements of road transportations and substantially reducing transportation costs.

Owner:河北省冀交物流有限公司

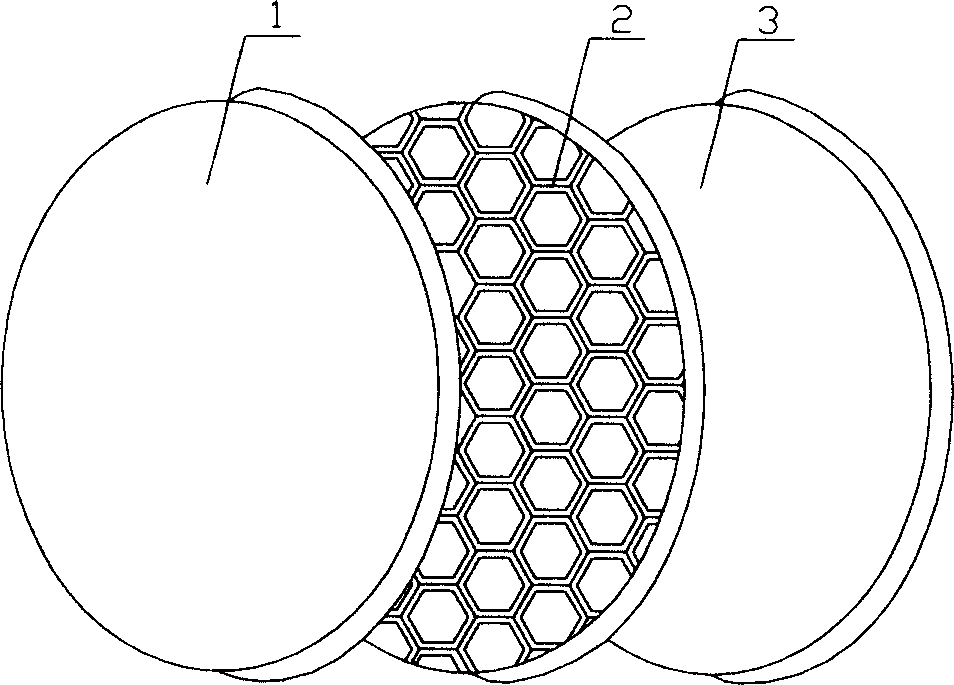

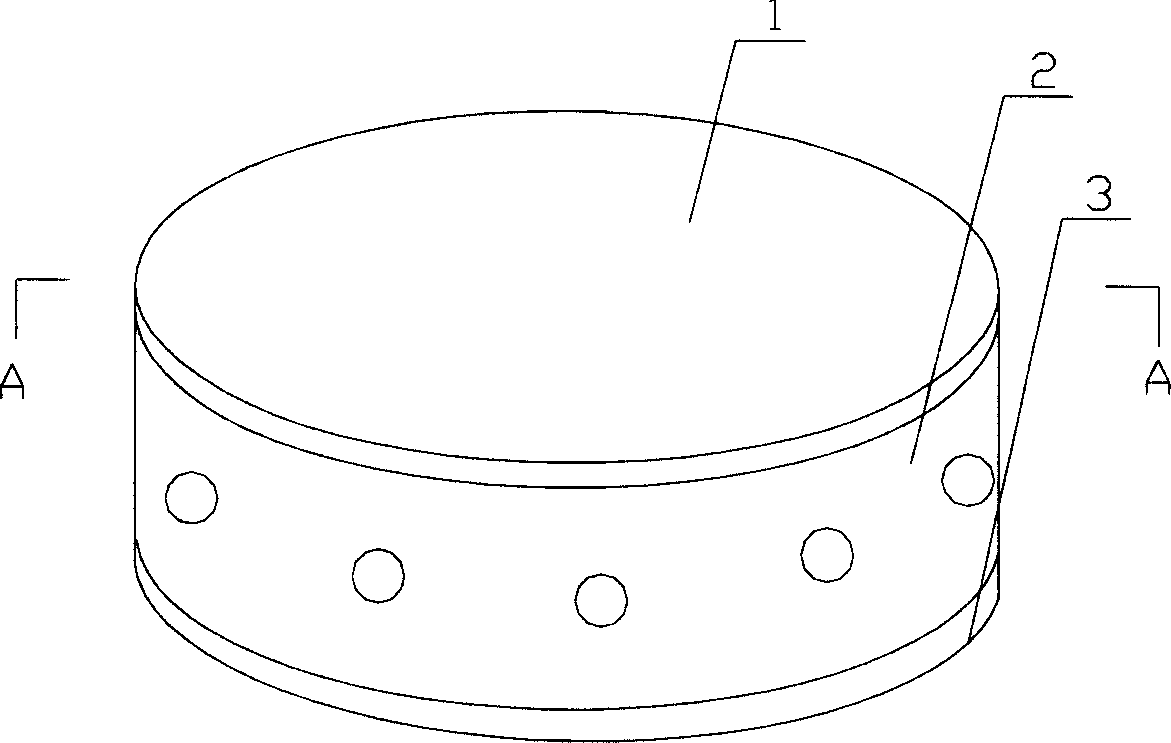

Reflection mirror with honeycomb sandwiched structure silicon carbide base composite material and its preparation method

The present invention relates to a silicon carbide base composite material reflector with honeycomb sandwich structure. It is characterized by that after the upper cover plate, sandwich layer with honeycomb structure and lower cover plate are bonded, then they are undergone the processes of siliconing and sintering treatment so as to obtain the invented reflector whole body with the characteristics of light weight, high rigidity and good workability, etc. Besides, said invention also provides its preparation method and concrete steps.

Owner:NAT UNIV OF DEFENSE TECH

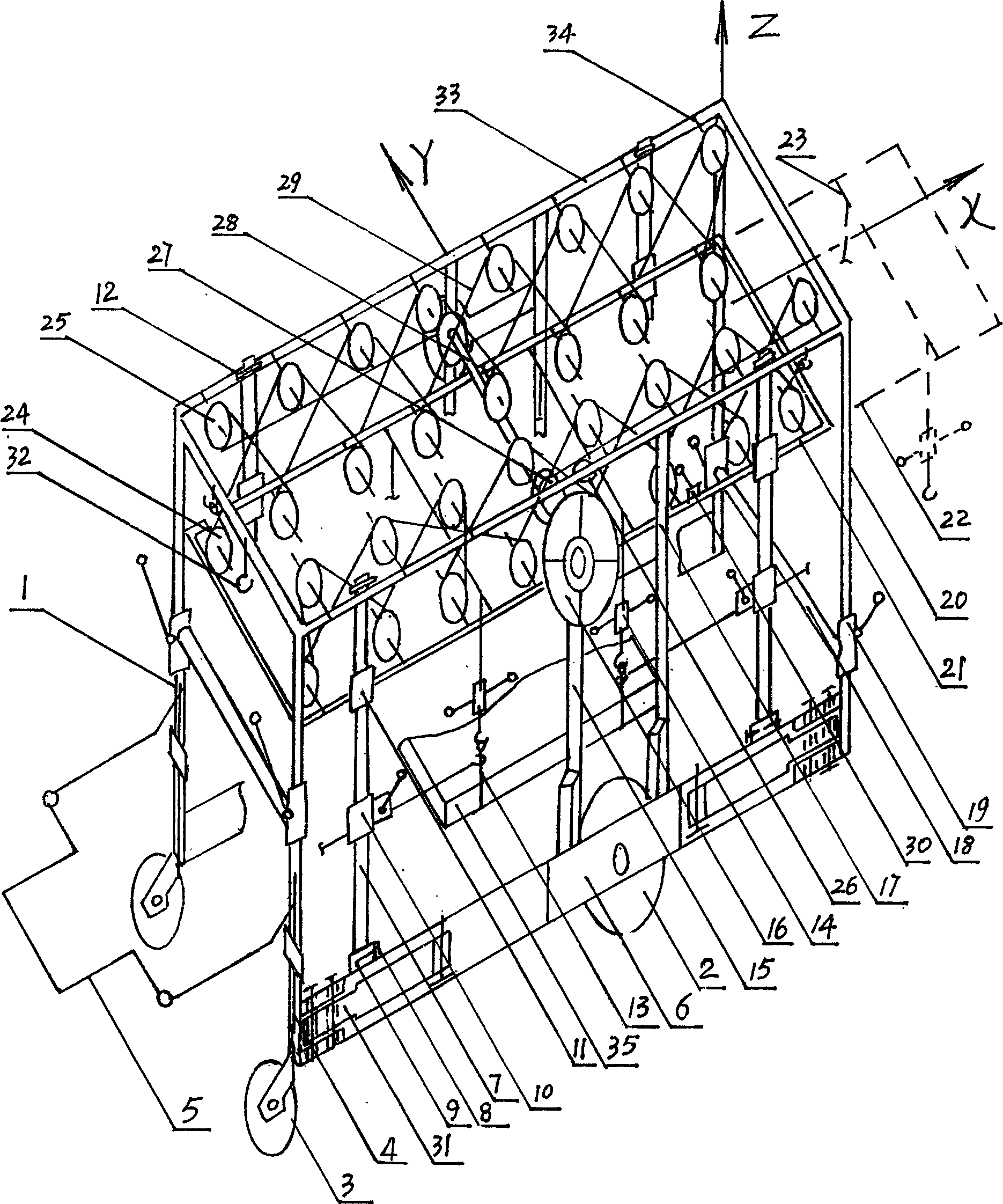

Multifunctional engineering installation vehicle

InactiveCN1544307AEasy to operateImprove installation qualityLifting devicesHydraulic cylinderPull force

The present invention discloses a multifunctional engineering installation vehicle used for engineering construction, which comprises a vehicular support frame, a walking and the like. In the vehicle as a gantry supporting frame structure, a extensible guide supporting frame for X axial movement is connected forwards with a Z axial direction tunable movable lift hook; at the C axial movement extensible guide supporting frame, there is an outside force acting at the Z axial direction, which can be a pull force of a armored rope or a cylinder rod clean and jerk force of the hydraulic cylinder and used for pushing the X axial movement extensible guide supporting frame for a vertical motion; a lifting platform is installed at the vehicle roof to execute pipe laying pipe laying, anti-corrosion, heat preservation, laying and maintenance of cable rope and crane span structure, and the like; the Z axial direction tunable movable lift hook inside the vehicle is used for lifting and loading articles of merchandise to realize installation of equipments; a labor saving and quick-releasing pipeline frame is allocated for carriage of pipelines; a ground tray is allocated, which is used for lifting, loading and transporting large and heavy workpieces. The multifunctional engineering vehicle is a powerful machinery for constructions, and the plurality of functions mentioned above greatly improves the installation quality, saves 2 times for the human energy and improves the work efficiency more than 10 times.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD

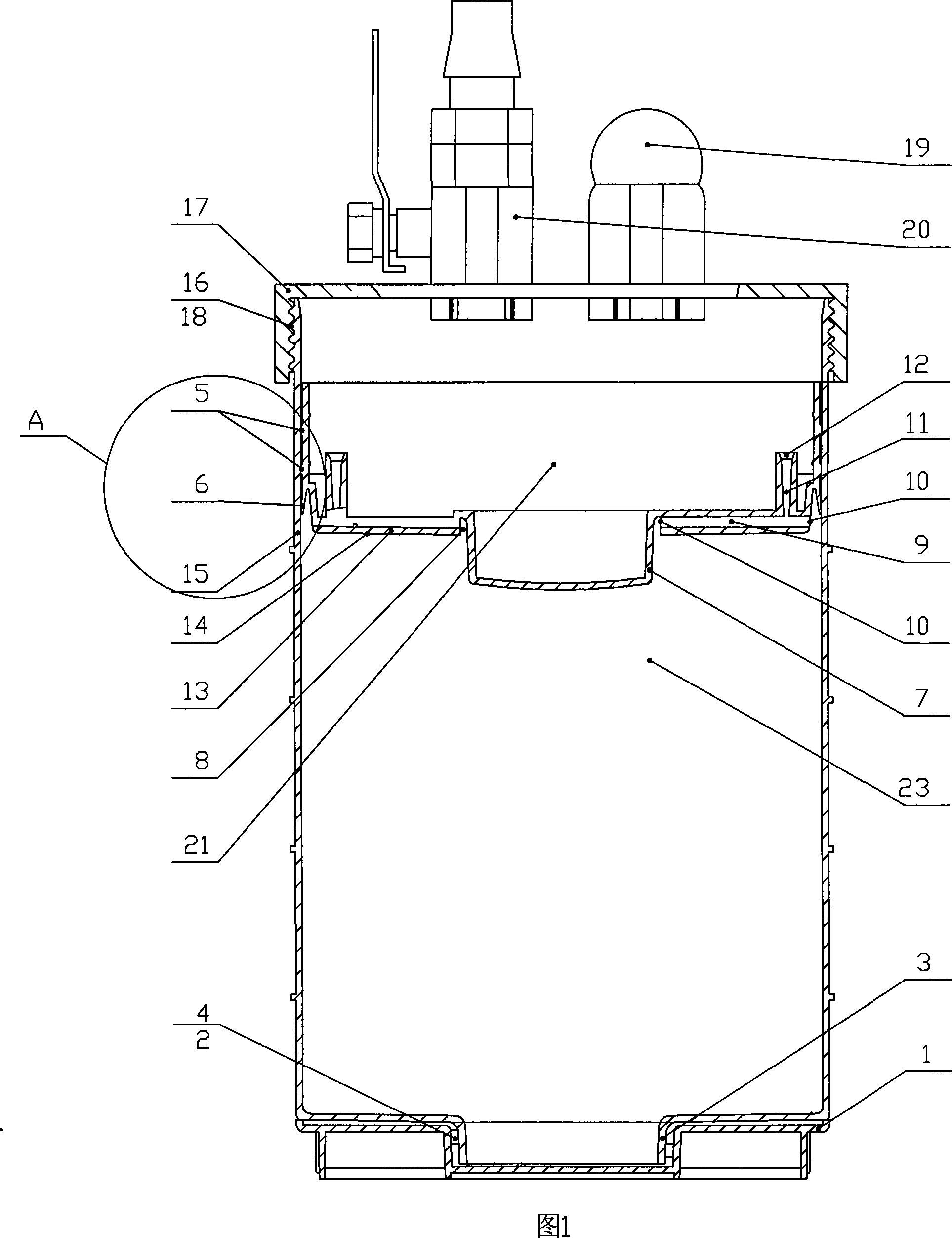

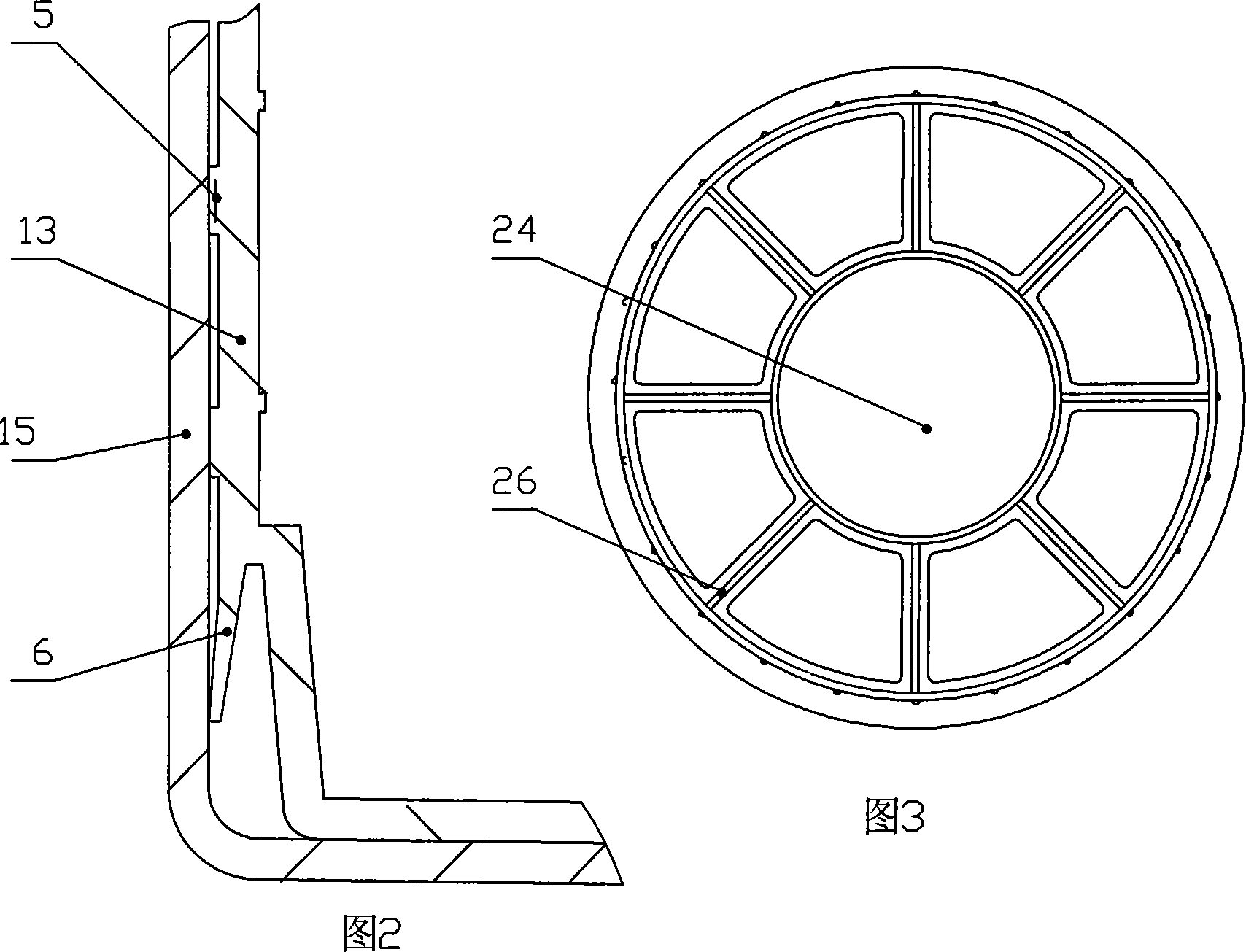

Production method of built-in water-cooling channel cast steel component

The production method of internal water cooling channel steel-casting is characterized by that two layers of spiral internal chill are winded round external periphery of steel pipe, in which first layer of spiral internal chill is winded round the steel pipe, and second layer of spiral internal chill is winded round first layer of spiral internal chill, at the same time, when it is poured, the low-temp. nitrogen gas is blown into the steel pipe, the nitrogen gas inlet temp. is -5- -10 deg.C, the nitrogen gas pressure is less than or equal to 0.2 MPa. After the pouring is completed, the low-temp. nitrogen gas is further blown into the steel pipe for 2-4 min. so that the steel pipe will not be melted through and can not be deformed when the molten metal whose melting point is identical to that of steel pipe is poured, therefore there is not gap or thermoresistance layer between steel pipe and base body.

Owner:ANYANG IRON & STEEL GRP

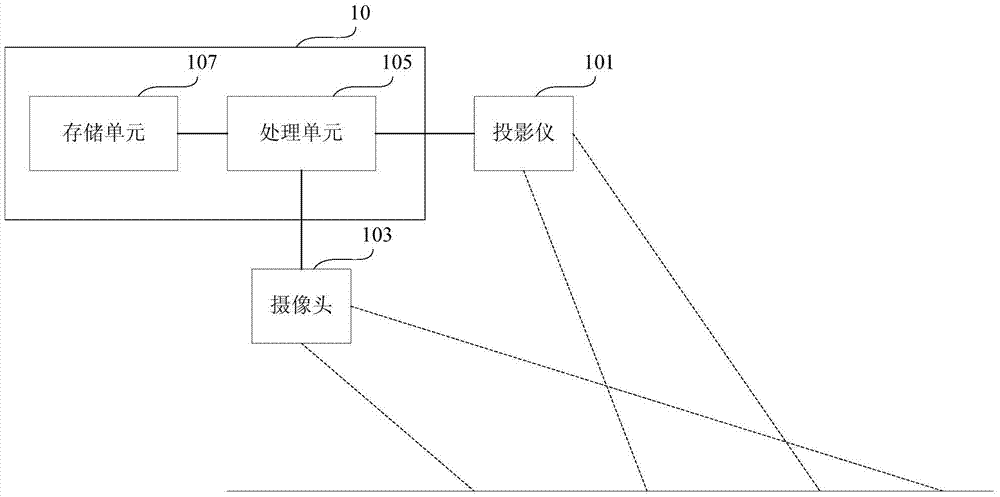

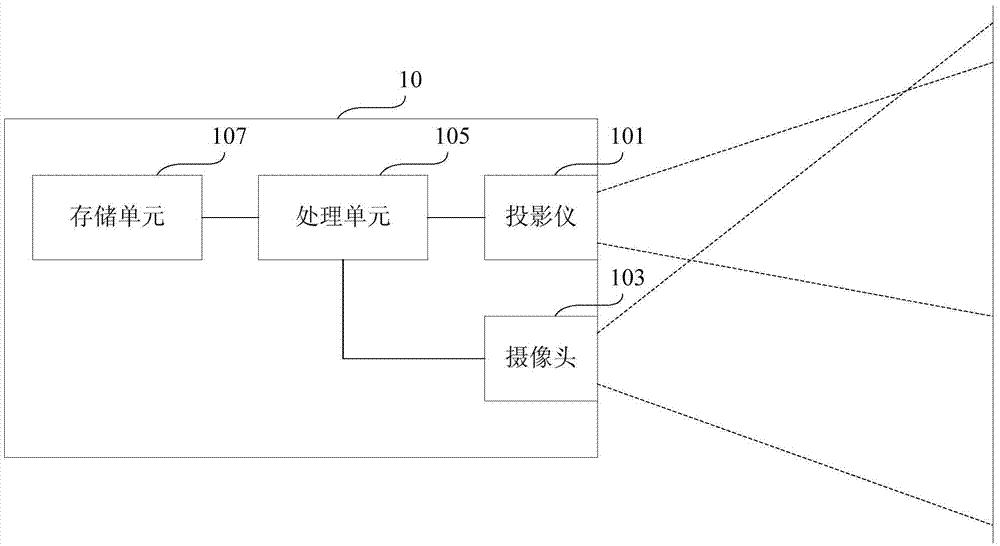

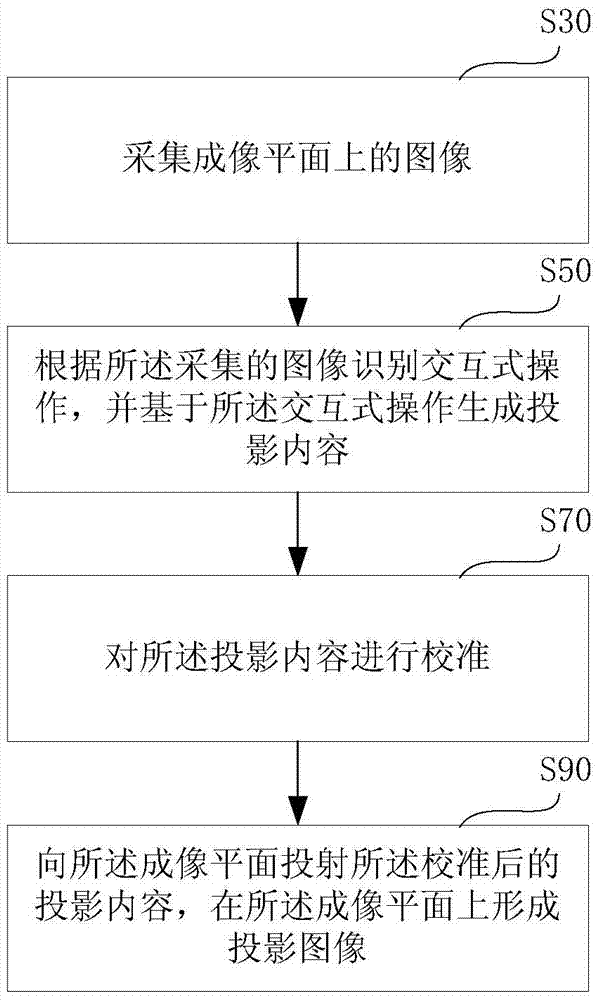

Interactive projection system and method

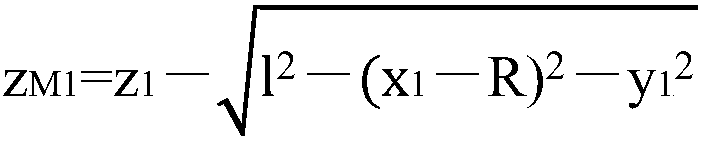

InactiveCN105451007AGuaranteed not to deformEnables real-time tracking of interactionsPicture reproducers using projection devicesInput/output processes for data processingProjection imageProjection system

The invention provides an interactive projection system and method. The system includes a projector, a camera, and a processing unit, the projector projects projection content to an imaging plane, a projection image is formed on the imaging plane, the camera acquires the image on the imaging plane, and the processing unit is connected with the projector and the camera, identifies the interactive operation based on the image acquired by the camera, generates the projection content based on the interactive operation, and calibrates the projection content. The interactive projection system and method realize the real-time tracking interaction of the user interactive operation, and are advantageous in that the projected image does not deform, an abundant interactive manner is provided, and the application condition is not limited.

Owner:上海尚镜信息科技有限公司

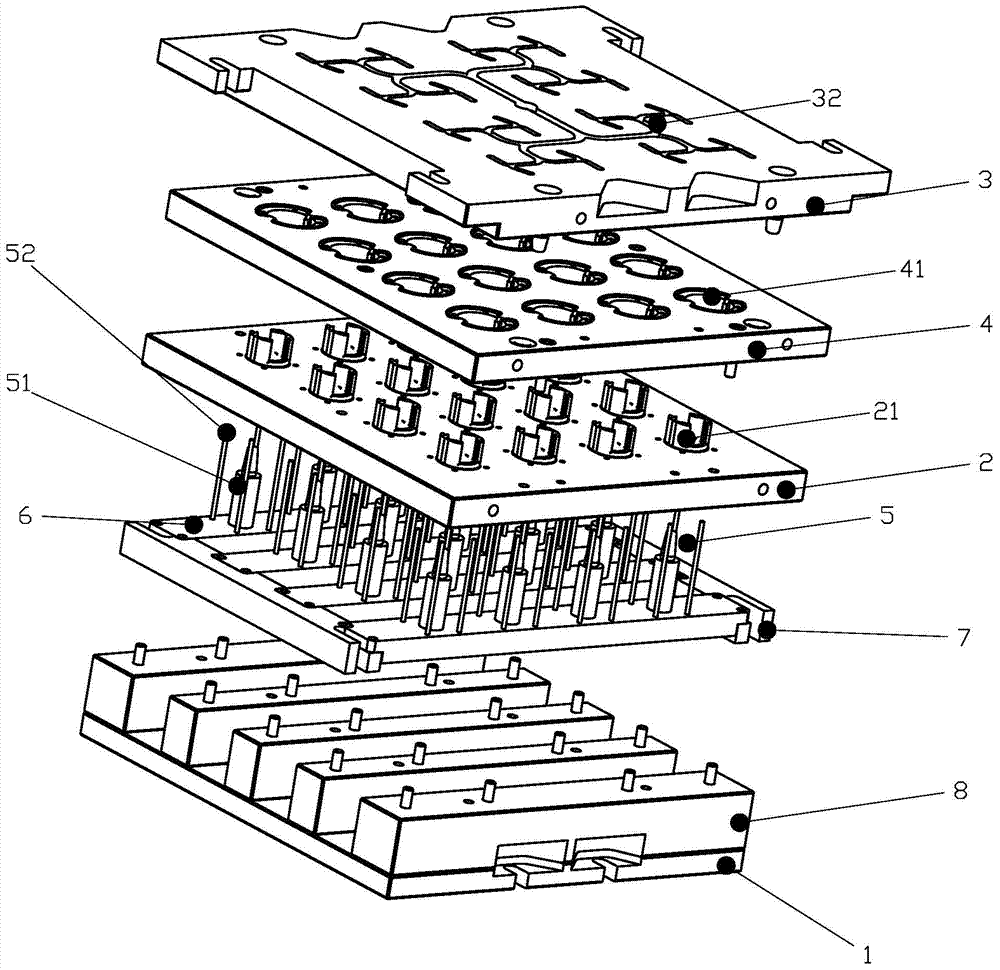

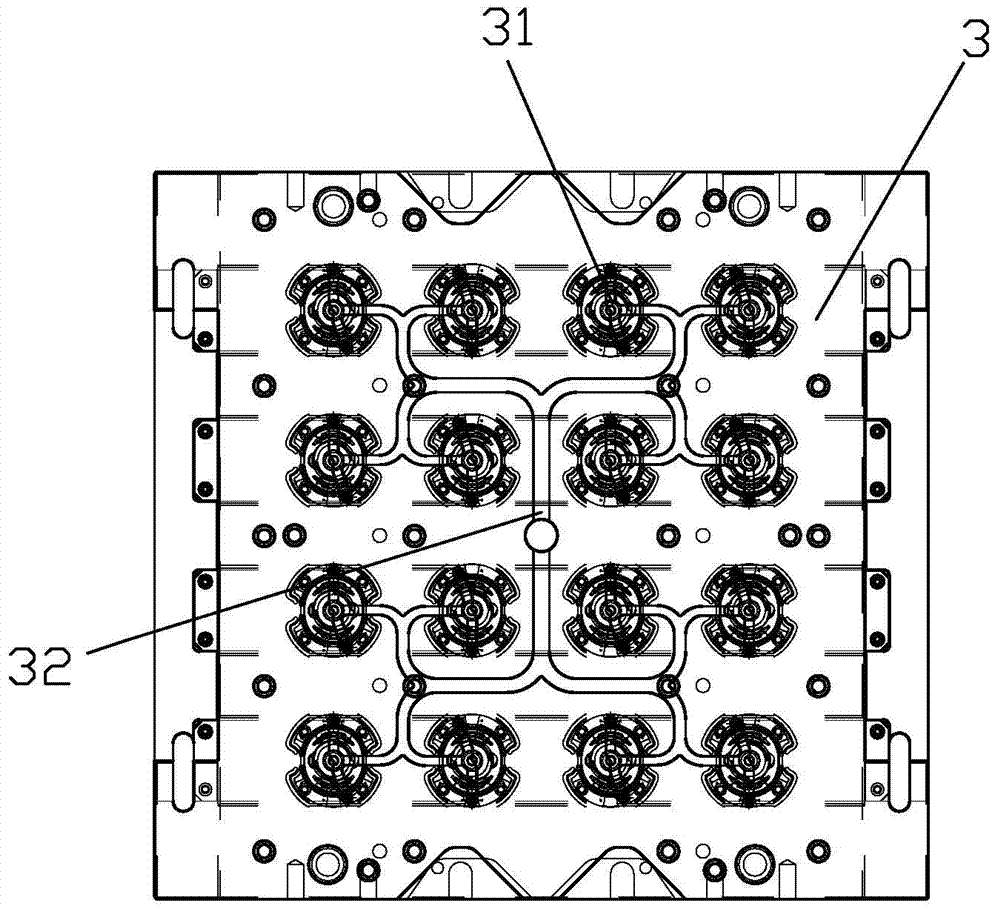

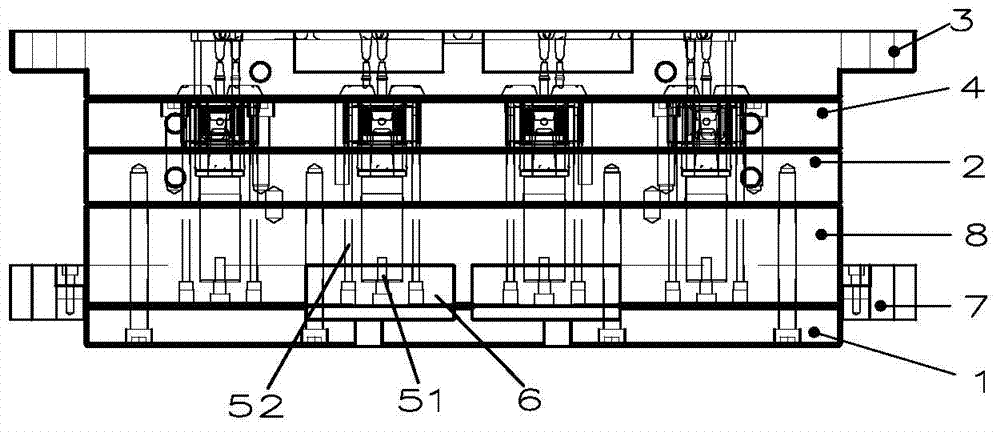

Mold for press forming small hole

The invention provides a die used for punching small holes; the punching is completed on a guiding part of a fixed plate; the upper end of a punch is fixed on the fixed plate; the punch is arranged in an insert once guiding part arranged in a position limit plate and a stripper plate, and the punch end is arranged in an insert secondary guiding part; the punch end is matched with a concave template; strip material is arranged between the stripper plate and the concave template; the secondary guiding part ensures the punch to complete the punching successfully. The concrete die of the invention is provided with a plurality of punches; a group of small holes required by one product can be completed by carrying out the punching once; the small hole is the round hole with the diameter being 0.3mm or other smaller holes or ellipses or the holes with other shapes. The die of the invention greatly improves the working efficiency and reduces the production cost.

Owner:CHENGDU HOMIN TECH

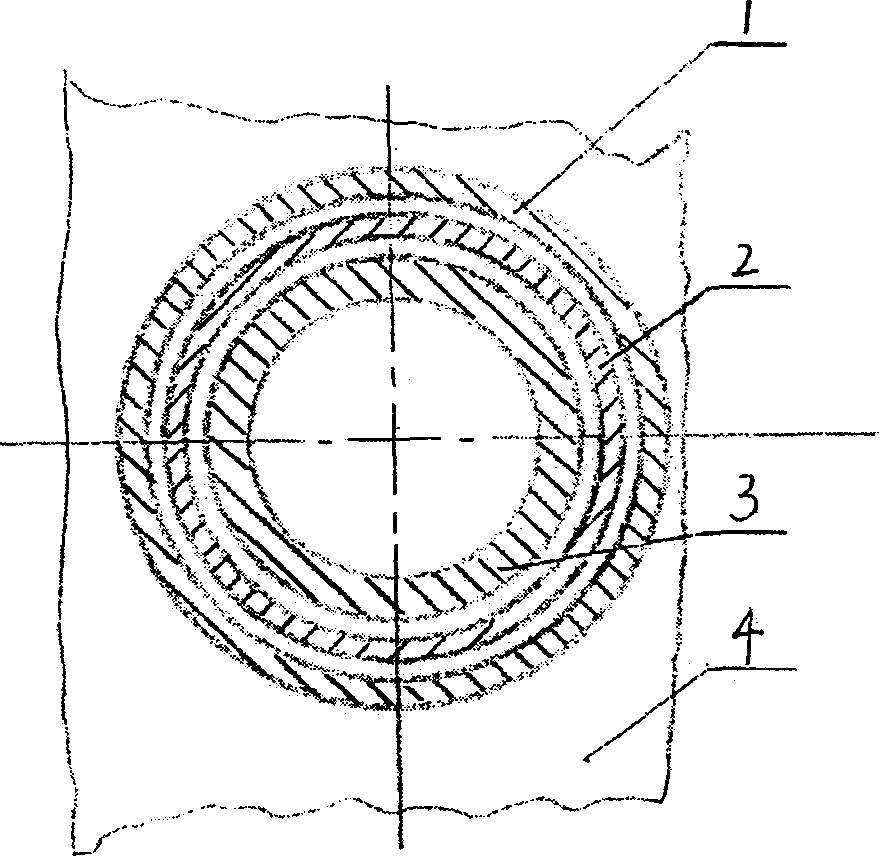

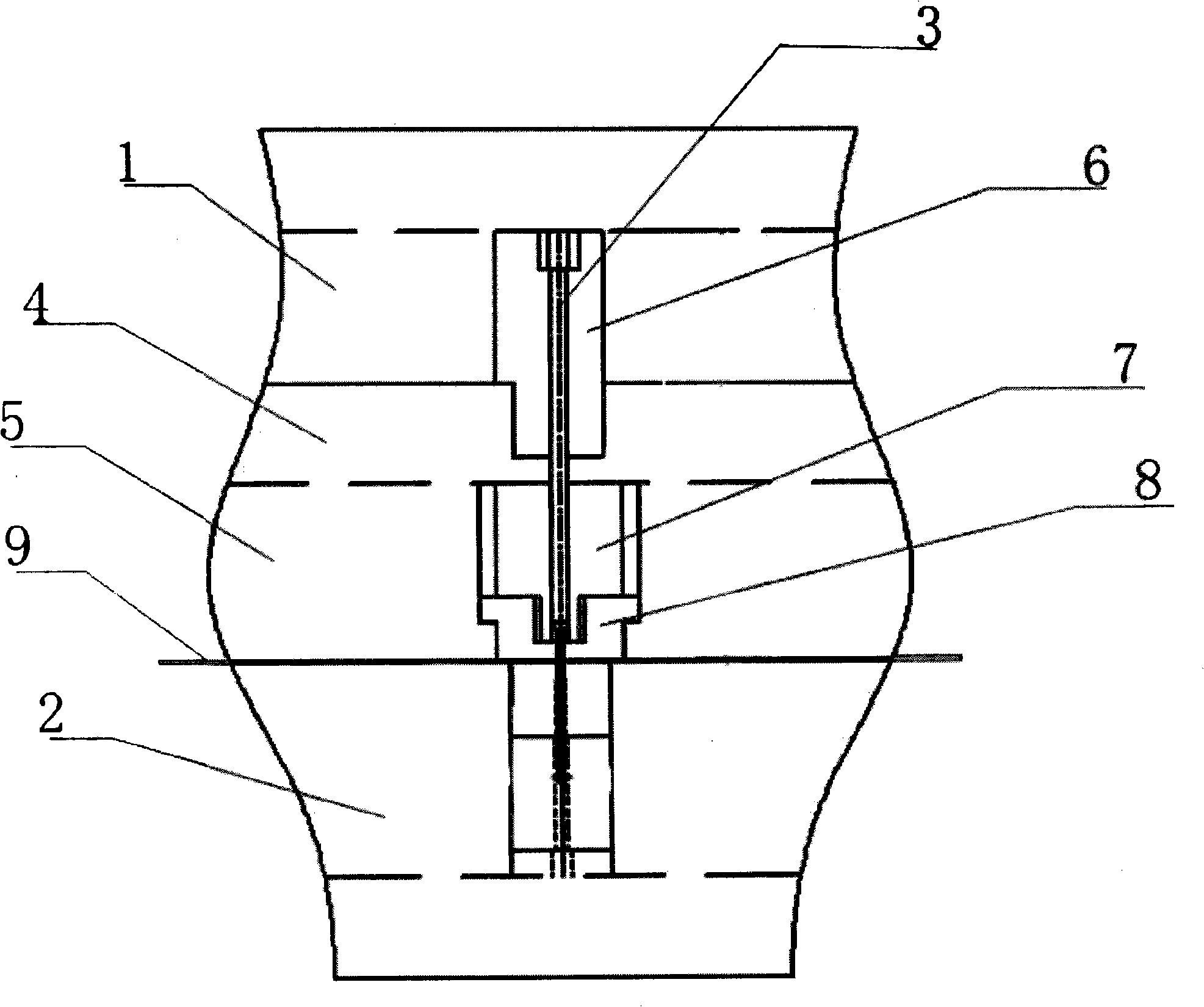

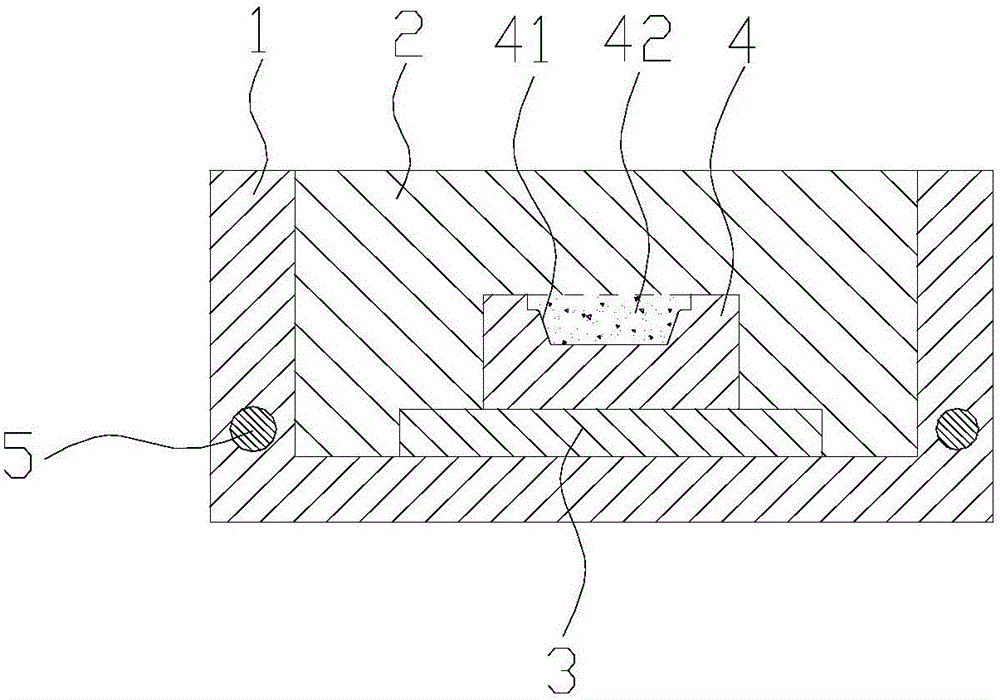

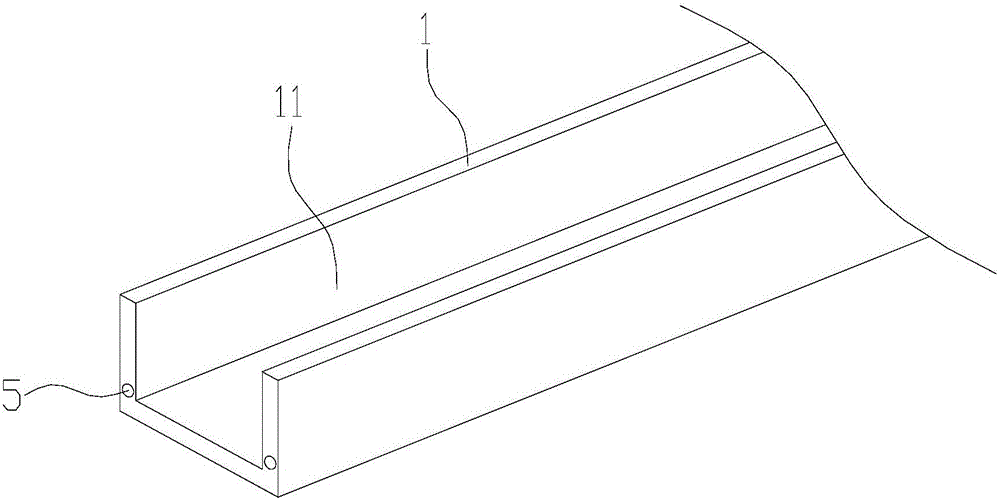

Vulcanizing mold of rubber bushing

The invention discloses a vulcanizing mold of a rubber bushing. The vulcanizing mold comprises a bottom plate, an ejecting mechanism, a lower mold plate, an upper mold plate and a product positioning plate, wherein the ejecting mechanism is arranged on the bottom plate and can move up and down; the lower mold plate is arranged on the ejecting mechanism and is fixed on the bottom plate; the upper mold plate is arranged above the lower mold plate; the product positioning plate is arranged between the lower mold plate and the upper mold plate; the upper mold plate is provided with a plurality of upper cavities and flowing channels communicated with the upper cavities; the lower mold plate is provided with a plurality of lower cavities; the product positioning plate is provided with a plurality of positioning cavities; the ejecting mechanism comprises a plurality of ejecting rod groups; each ejecting rod group comprises a first ejecting rod and a plurality of second ejecting rods which are arranged around the first ejecting rod in a circle; the lower mold plate is provided with a plurality of ejecting hole groups; each ejecting hole group is distributed around one lower cavity along one circle. The vulcanizing mold disclosed by the invention has the advantages that when in demolding, the ejecting mechanism supports an inner-layer lining pipe and an outer-layer lining pipe simultaneously, the stressing of all the parts of the rubber bushing is uniform, and the deformation is unlikely to occur, so that the locking of a product can be prevented, smooth demolding of the product can be guaranteed, the size of the product can be guaranteed, and the rejection rate is reduced.

Owner:NINGBO TUOPU GROUP CO LTD

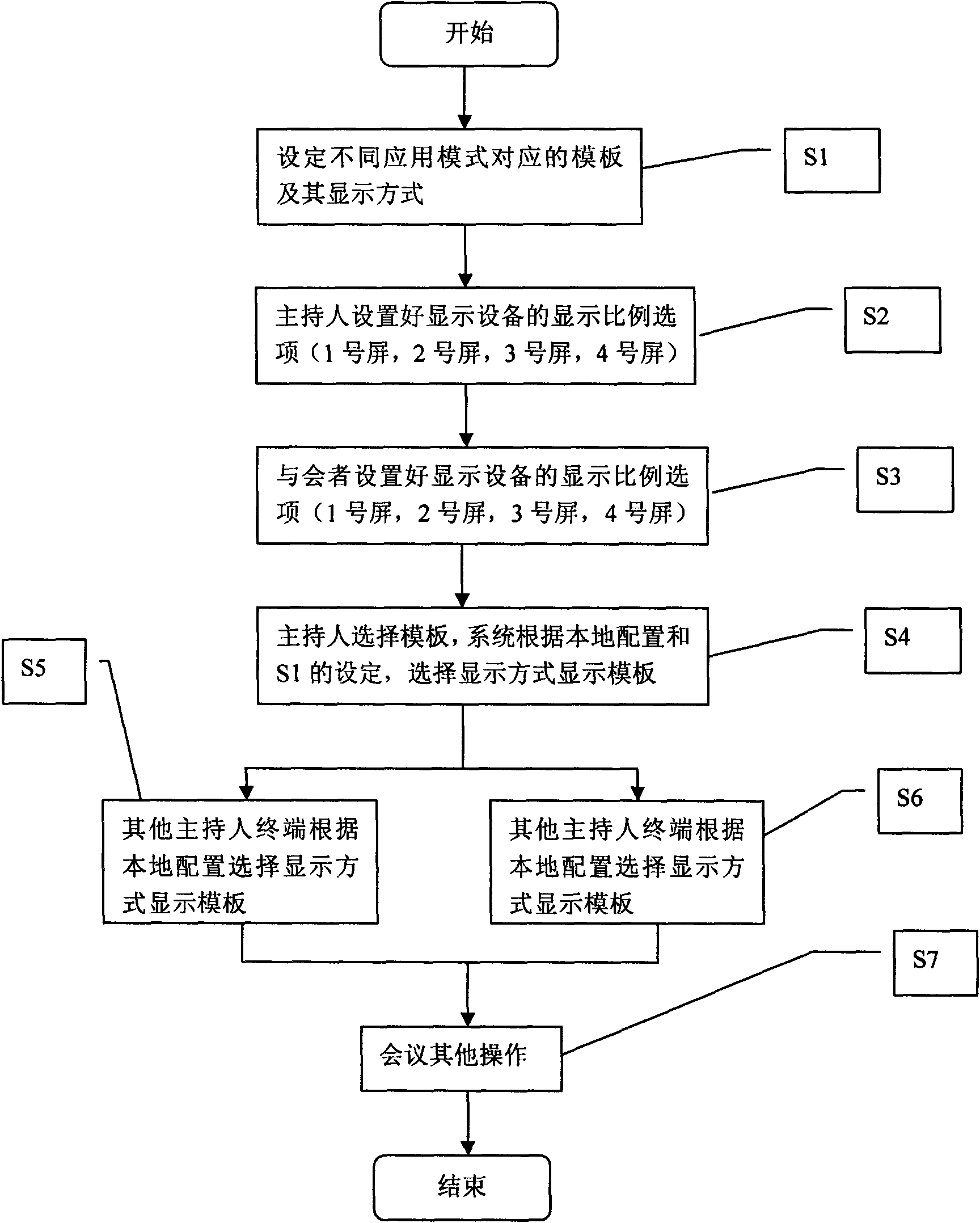

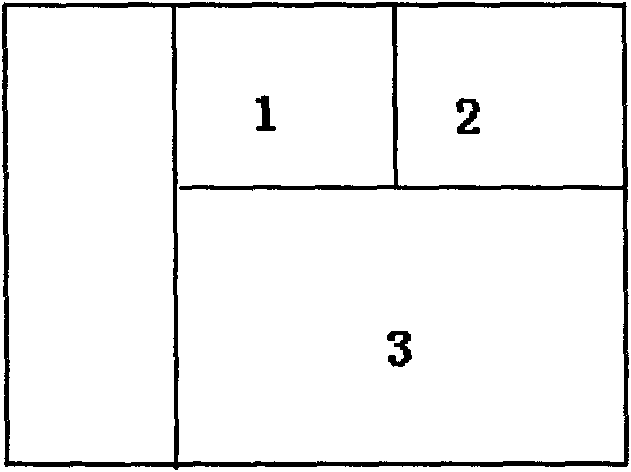

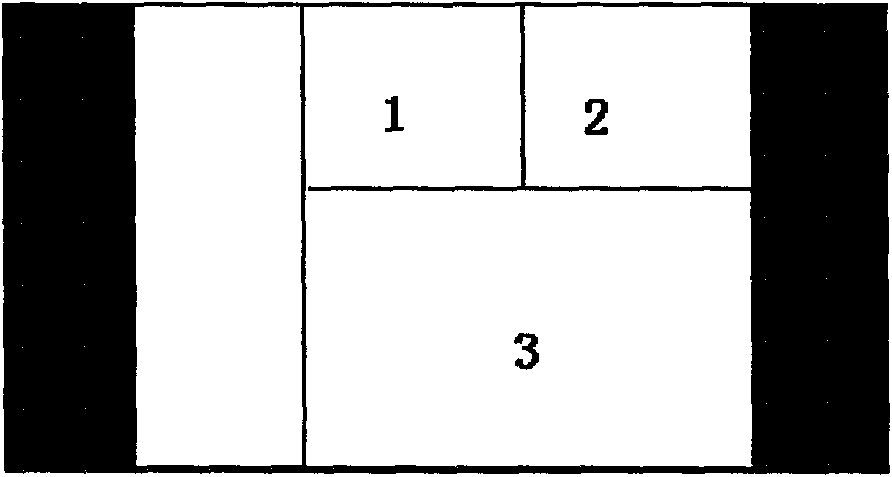

Template display method in video conference system

InactiveCN101662611AGuaranteed not to deformEnsure consistencyTelevision system detailsTelevision conference systemsComputer graphics (images)Display device

The invention relates to a template display method in a video conference system. The method comprises the following steps: presetting templates corresponding to different application modes, and setting display modes of the templates on a screen with different display scales; setting the display scales of terminal display equipment; selecting the templates by an emcee terminal, and selecting the corresponding display mode according to the set display scale of local display equipment to display the templates and sending a template synchronous command to the terminals of other emcees and other conventioneers in the conference; and receiving the template synchronous command on the terminals of other emcees and other conventioneers in the conference so that the templates of other emcees and other conventioneers are consistent with the emcee terminals, and selecting the corresponding display mode according to the set display scale of the local display equipment so as to display the templates. The method can help effectively assure non-deformation of the video displayed by a displayer in the scale of 4:3 and 16:9 in the video conference system.

Owner:SHANGHAI AVCON INFORMATION TECH

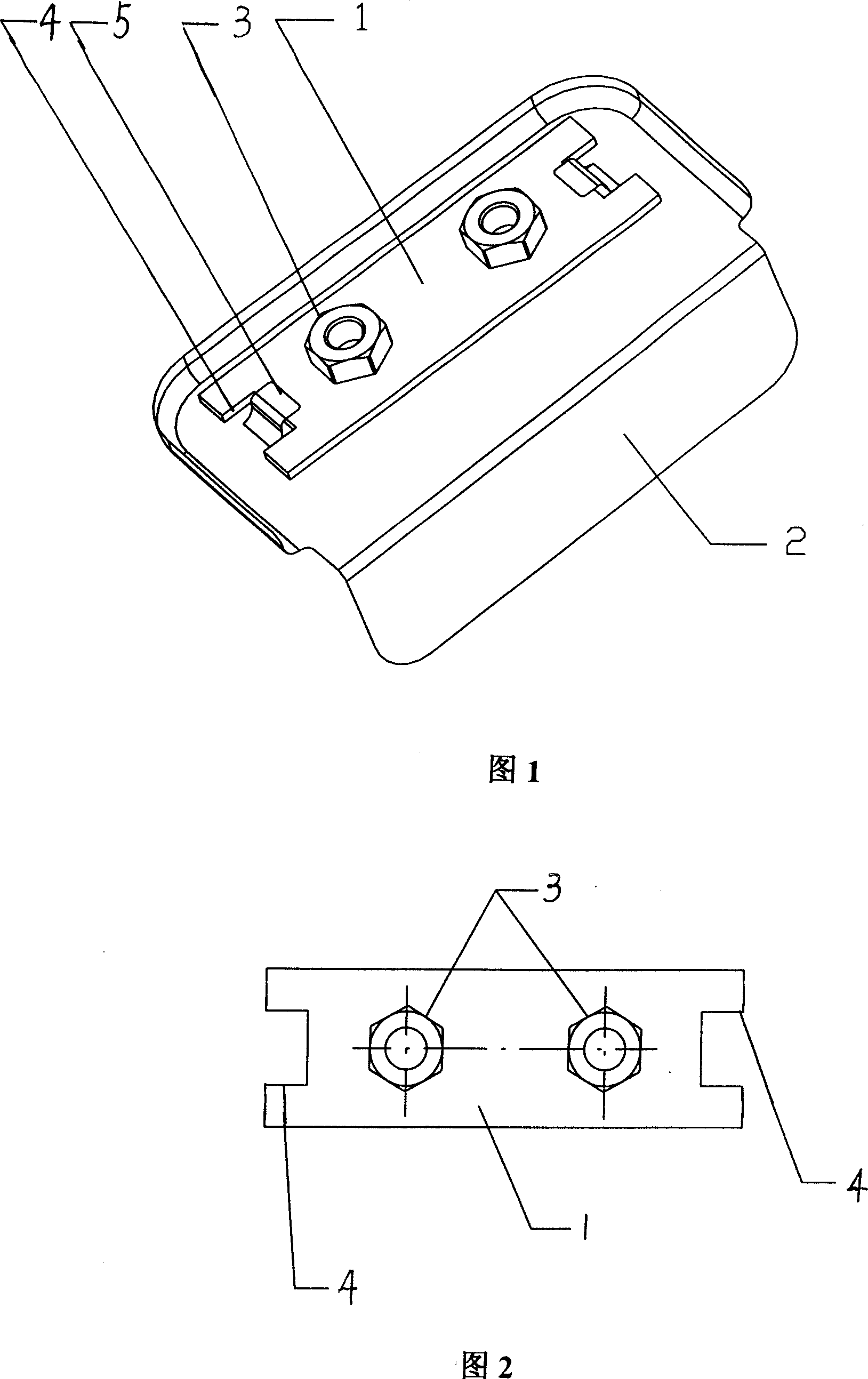

Automobile lock pin reinforcement assembly structure

InactiveCN1935580ANot easy to fall offEasy to assembleNutsBoltsAgricultural engineeringAssembly structure

The invention discloses a lockpin reinforcer assembly structure, comprising nut plate and lockpin reinforcer, where the two ends of the nut plate are make with square gaps, the middle of the lockin reinforcer is punched with two 'Z'-shaped hooks, and the nut plate is fastened between the two hooks. As compared with the existing techniques, it is simple and reliable to assemble, assuring the nut plate can be regulated but is uneasy to fall off; and it omits the nut plate box and welding procedure, effectively reducing cost and eliminating welding deformation.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Copper tube inner ring gripper

ActiveCN105150236AUniform force distributionAdjustable structureGripping headsGrippersArchitectural engineering

The invention provides a copper tube inner ring gripper which comprises a floating connector, a pull rod, a hanging frame, a cylinder, an insertion pin, a vertical beam, a supporting rod, a rubber supporting handle, a fixed rod, a supporting plate and a connecting rod. The pull rod is installed at the lower end of the floating connector. The pull rod is sleeved with the hanging frame. The cylinder is installed below the hanging frame. One end of the cylinder is connected with the insertion pin. One end of the hanging frame is connected with the vertical beam which is provided with the supporting rod. One end of the supporting rod is provided with the rubber supporting handle. The lower end of the vertical beam is connected with the fixed rod and the connecting rod. One end of the fixed rod is connected with the supporting plate. One end of the connecting rod is connected to the lower end of the pull rod through a connecting piece. The copper tube inner ring gripper is simple in structure, high in adaptability, uniform in clamping strength distribution and not prone to causing copper tube deformation.

Owner:FOSHAN NANHAI GUANGDONG TECH UNIV CNC EQUIP COOP INNOVATION INST +1

Timber water-tight and anti shrinkage-and-swell processing method

InactiveCN1788952ALittle deformation of woodImproved dimensional stabilityPressure impregnationWood impregnation detailsSolid woodAcrylate

The present invention provides waterproof and swelling and shrinking preventing timber treating method, and the method is treating timber with waterproof and swelling and shrinking preventing timber treating solution. The timber treating solution consists of fatty dihydric alcohol or its polymer 10-70 wt%, alkyl acrylate 5-10 wt%, alcohol 5-10 wt%, and distilled water 10-80 wt%. The treating process includes soaking timber or timber product in the timber treating solution inside a sealed treating tank under the pressure one -0.1 to 0.5 MPa, pressurizing and heating for soaking treatment, and final drying treatment. Thus treated timber sample has shrinkage resisting coefficient up to 70 % and moisture absorption resisting coefficient up to 60 %, so that the present invention can prevent deformation and cracking of timber product and raise the size stability of timber product effectively.

Owner:北京市龙顺成中式家具有限公司

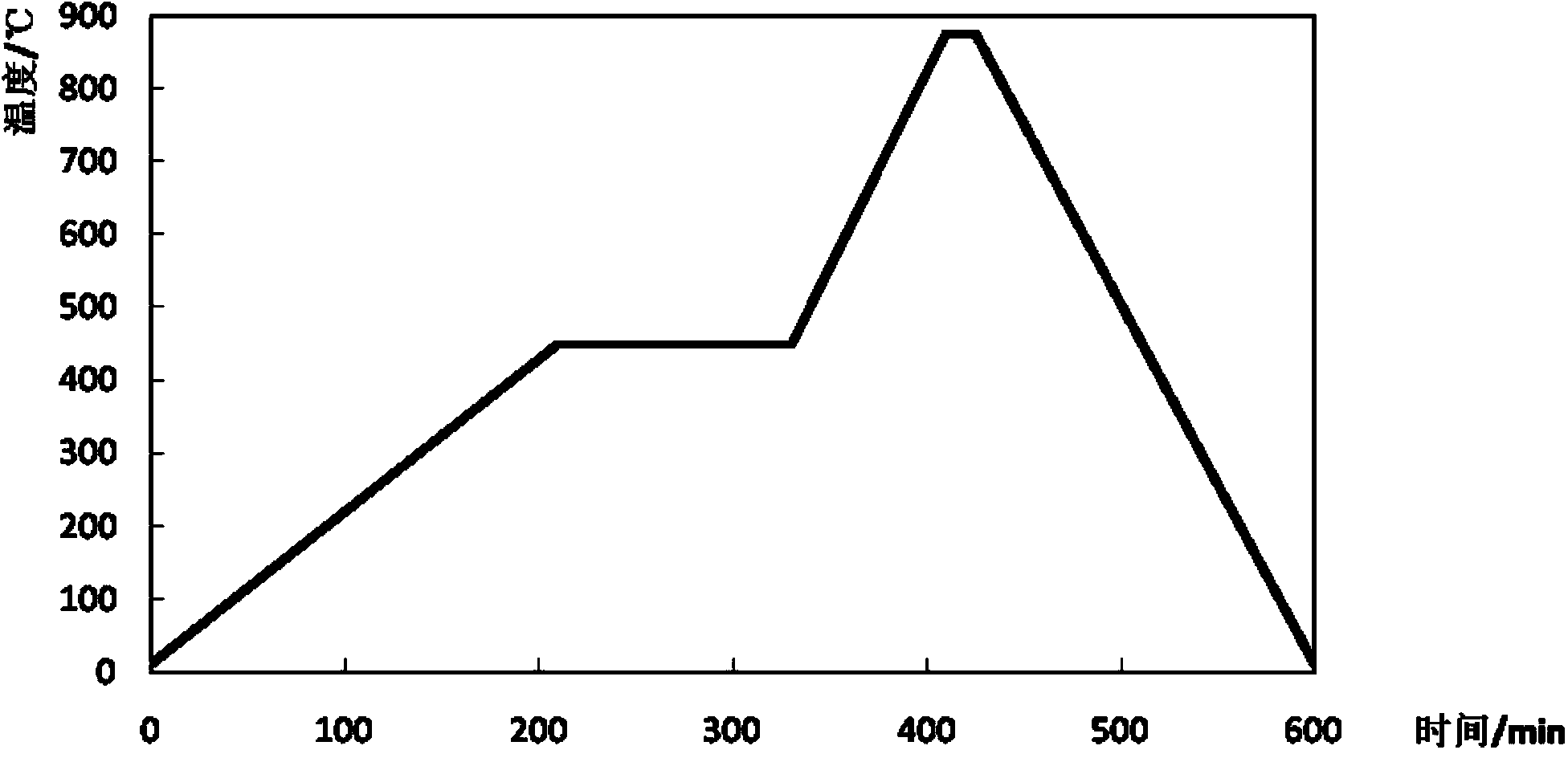

Wood drying method for solid wood furniture

InactiveCN103206837ALow internal stressExtended service lifeDrying solid materials with heatHearth type furnacesSolid woodPulp and paper industry

The invention relates to a wood drying method for solid wood furniture. The method comprises the steps of stacking drying piles of wet wood plates in a drying kiln, performing warming and humidifying drying processing for five times, performing maintenance for 48 h after kiln stopping, and obtaining finished products. The moisture content of dried wood plates obtained through the drying method is merely 8%-10%, inherent strain of wood is extremely small, and the dried wood plates are long in service lives and moisture-resistant, cannot deform easily and can be over five times as strong as ordinary plate type furniture in deformation resistance. According to the drying method, the wood undergoes about 240-hour steam drying and undergoes humidifying processing for four times, and temperature of the wood is improved step by step, so that elimination of the inherent strain and nature of the wood is accelerated, and high standard for manufacturing the furniture is met.

Owner:天津福通木业有限公司

Paster type LED flexible light strip

InactiveCN105927883AIncrease productivityQuality assuranceElongate light sourcesElectric lightingEngineeringFlexible circuits

The invention discloses a paster type LED flexible light strip, and belongs to the field of illumination. The light strip comprises a core wire, a plurality of flexible circuit boards and a plurality of paster type LED chips respectively arranged on the flexible circuit boards, wherein an accommodating groove is formed in the core wire in the length direction of the core wire; the flexible circuit boards are sequentially arranged in the accommodating groove. The paster type LED flexible light strip disclosed by the invention is characterized in that the accommodating groove is filled with a translucent silicone layer; the translucent silicone layer covers on the flexible circuit boards and the LED chips. According to the paster type LED flexible light strip disclosed by the invention, the structures are arranged, so that the paster type LED flexible light strip is thin, materials and the cost are effectively saved, the flexibility is good, the illuminating effect is good, the rate of finished products is high, and requirements of a producer and requirements of a user can be well met.

Owner:ZHONGSHAN MLIGHT PHOTOELECTRIC

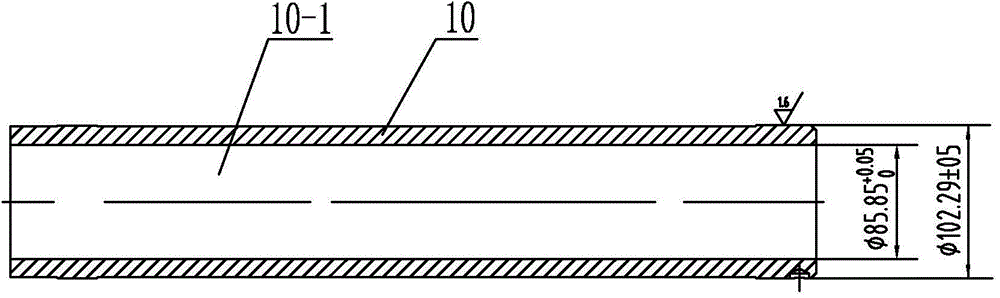

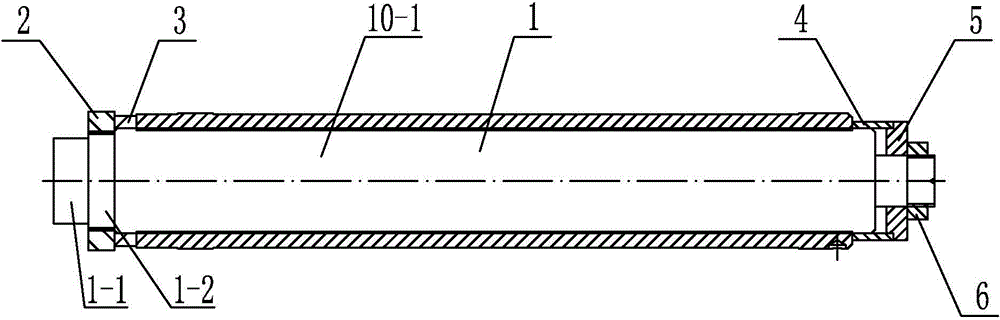

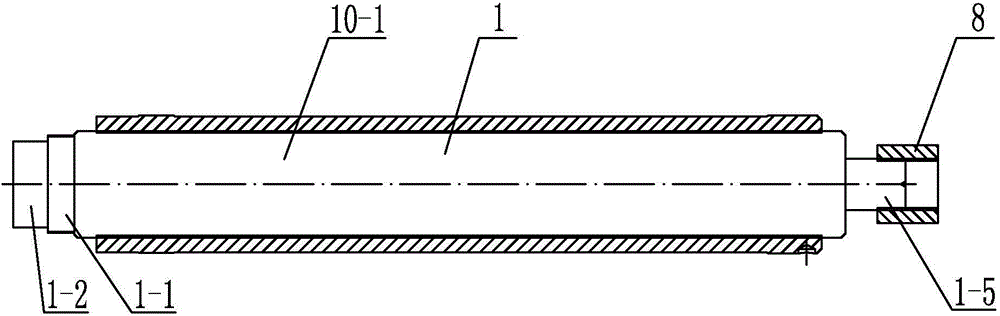

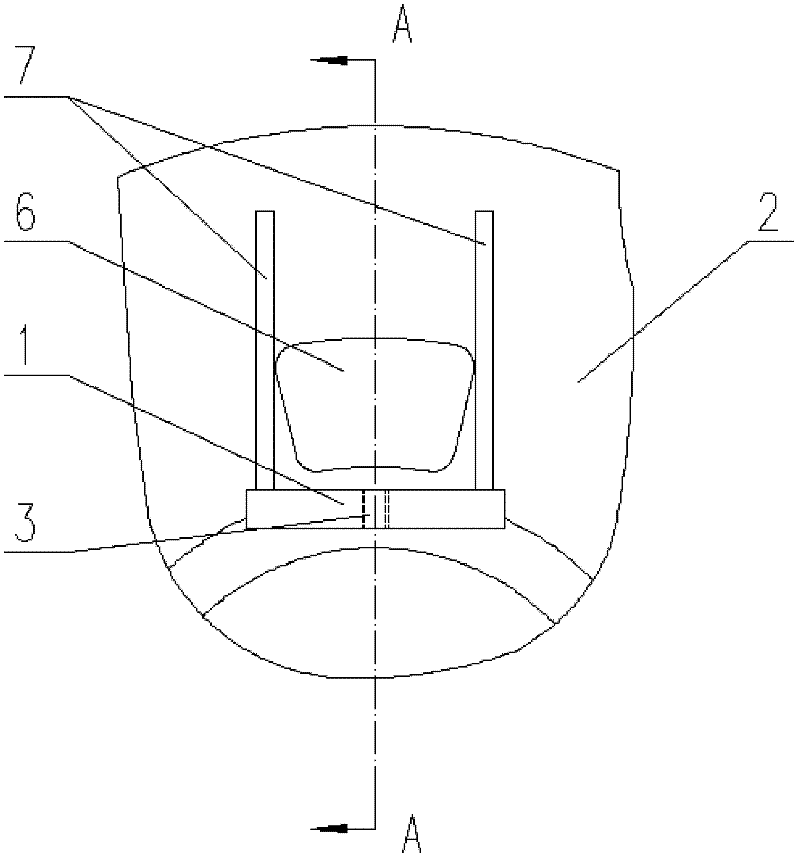

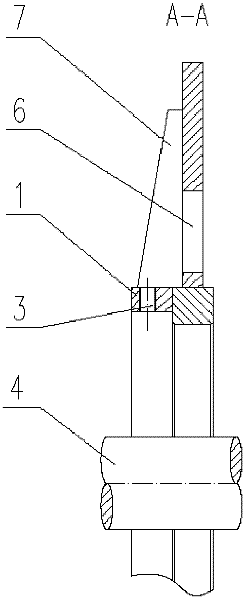

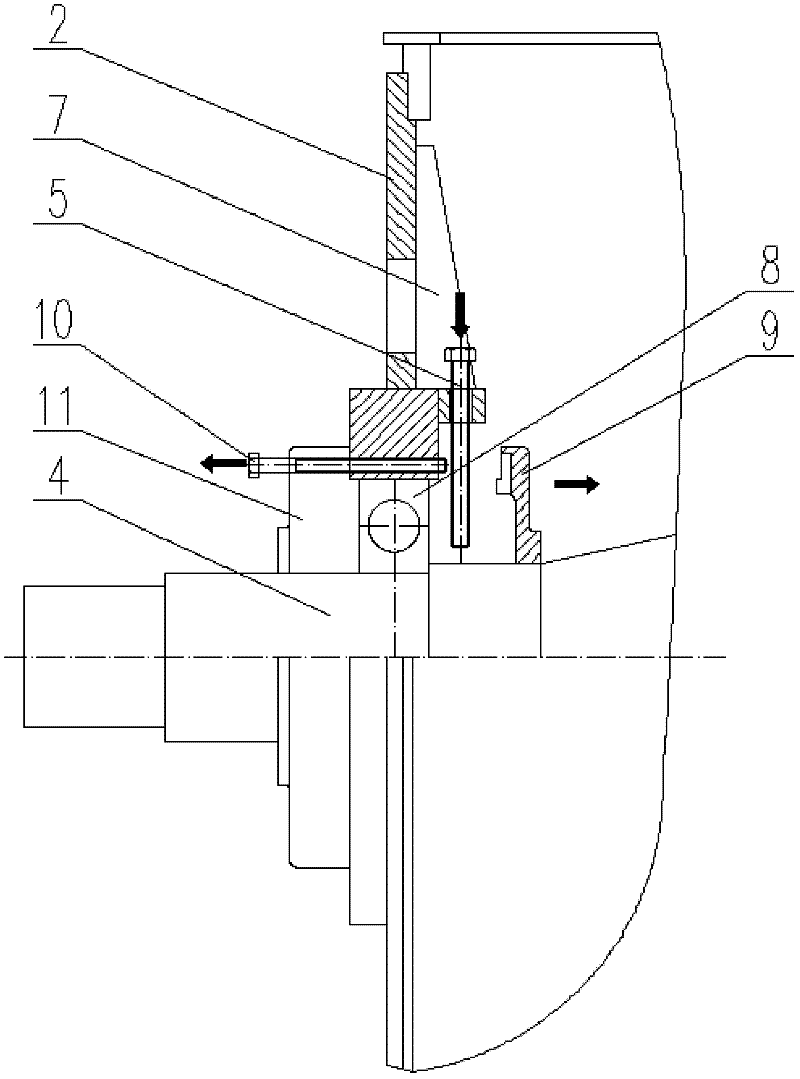

Method of processing steam turbine control valve long thin-wall sleeve by utilizing support device

ActiveCN103949847AGuaranteed not to deformGuarantee processing qualityWork clamping meansAuxillary equipmentThin walledHigh pressure

The invention discloses a method of processing a steam turbine control valve long thin-wall sleeve by utilizing a support device and relates to a thin-wall sleeve processing method used for solving the problems that the existing steam turbine high pressure control valve long thin-wall sleeve is directly processed on a horizontal lathe, the sleeve is easy to deform, the dimensional tolerance is not easy to control, and the cylindricity cannot reach a drawing requirement. The method comprises the steps that 1, a central hole of the long thin-wall sleeve is processed; 2, the support device is mounted: a stepped shaft is arranged in the central hole; 0-0.05 mm interference fit is formed between the middle section of the stepped shaft and the central hole, a left washer and a left nut limit the axial freedom degree of the left end of the long thin-wall sleeve, a baffle ring, a right washer and a first right nut limit the axial freedom degree of the right end of the long thin-wall sleeve, and the left nut and the right washer are screwed down; 3, the external diameter of the long thin-wall sleeve is processed by utilizing the horizontal lathe; 4, the support device which is used for turning and processing the long thin-wall sleeve is detached; 5, the long thin-wall sleeve is detached by an auxiliary detachment device. The method is used for processing the steam turbine control valve long thin-wall sleeve.

Owner:HARBIN TURBINE +1

Alignment support device for rotor of permanent-magnetic wind power generator and rotor bearing replacement method

ActiveCN102570680ASimple structureEasy to operateManufacturing dynamo-electric machinesSupports/enclosures/casingsSuction forceStructural engineering

The invention discloses an alignment support device for a permanent-magnetic wind power generator. The alignment support device comprises at least three alignment support parts. Each alignment support part comprises a support plate and a support bolt, wherein the support plate is fixedly arranged on an end cover of the generator; a threaded hole is formed in the support plate, and penetrates through the support plate along the radial direction of a rotating shaft of the generator; the bolt is arranged on the threaded hole; and the bottom end of the bolt can contact the outer surface of the rotating shaft of the generator. A certain number of bolts fix the rotor by taking the end cover of the generator as a support to make the rotor always in an acting force balanced state, so that the rotor is prevented from being attracted onto or colliding with a stator under the action of gravity and magnetic attraction force in operation such as the replacement of a rotor bearing and the like; compared with the prior art in which the stator and the rotor are supported by stainless steel wedged cushion blocks, the rotor support device adopting the bolts has a simple structure, and is convenientto assemble and disassemble; and the bolts have small volumes, so that a large operating space can be provided for subsequent procedures.

Owner:DONGFANG ELECTRIC MACHINERY

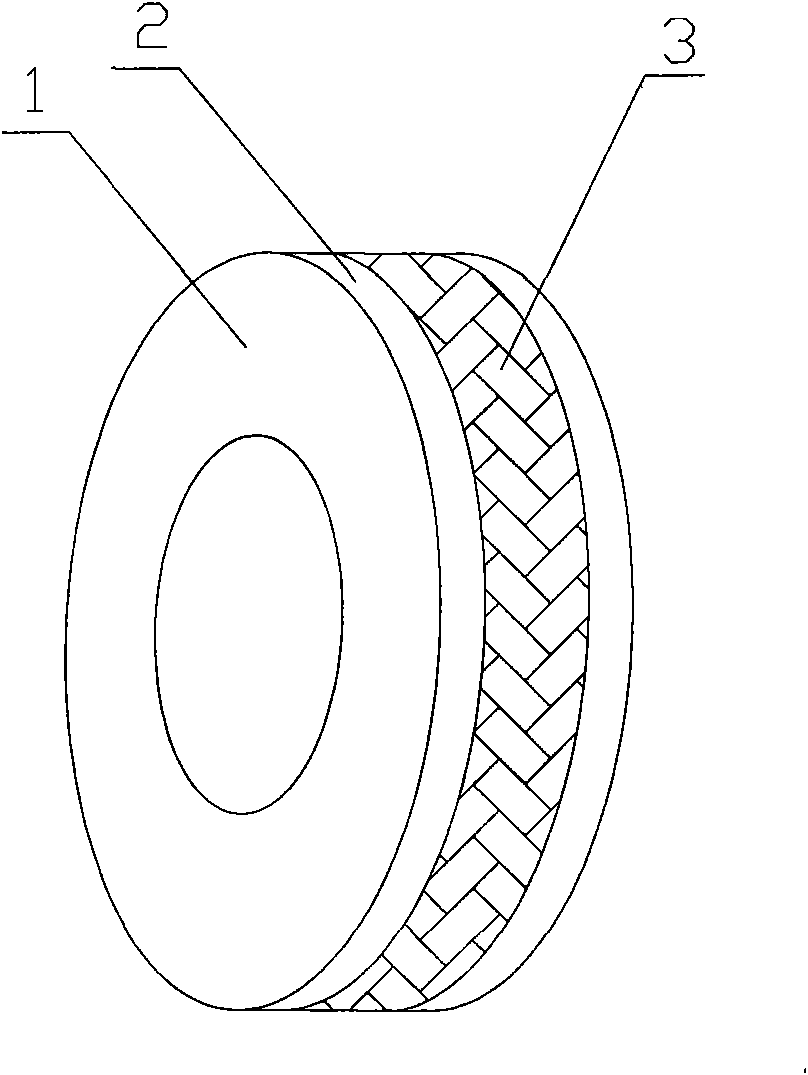

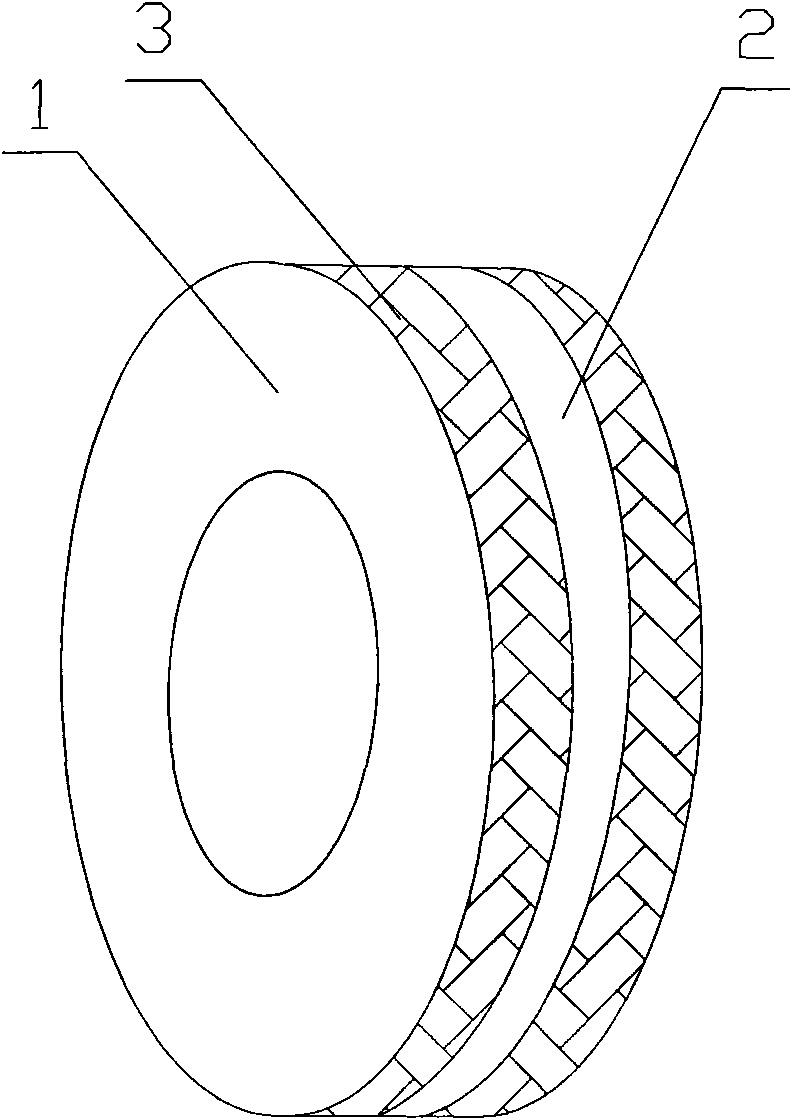

Method of retreading tyre

InactiveCN101549565AWithout breaking the balanceImprove handling comfortTyresMechanical engineeringTread

The invention relates to a method of retreading the old and useless full steel wire tyre by the meridian, comprising the steps as follow: milling the tyre surface, removing the vitiated tyre face and roughening the surface of the steel wire tyre by milling; gluing by coating the plasmagel on surface of the tyre; winding the new glued steel wire curtain cloth on the tread of tyre and adhering with the middle pad glue; adhering the matched type face glue on the tread of tyre, which wound by the glued steel wire curtain cloth, after the tyre face is adhered with glue; then sulphrizing in the tank that is sulphrizing the reinforced tread bracing layer into the sulphrizing tank. The invention will not damage the equilibrium of tyre, improve the controlling amenity, increase the anti-piercing and anti-explosion capability of the tread of tyre, prevent the skeleton of tyre from deforming and improve the retreading rate of tyre. The thickness of glue steel wire curtain cloth installed with the middle pad glue increase the cementation effect between tyre body and the tyre face, improve the anti-tearing capacity of tread block, decrease chunking and improve the bearing and buffer capacity of the tyre.

Owner:张乐平

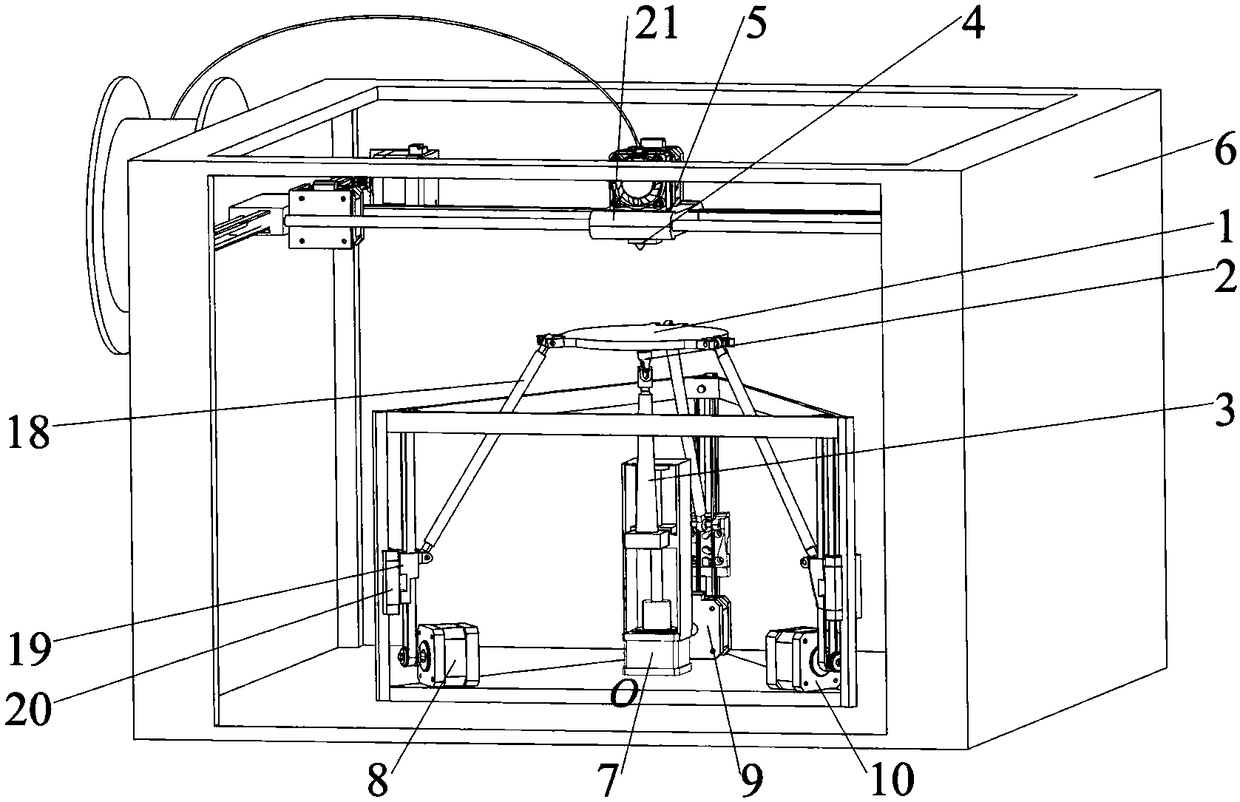

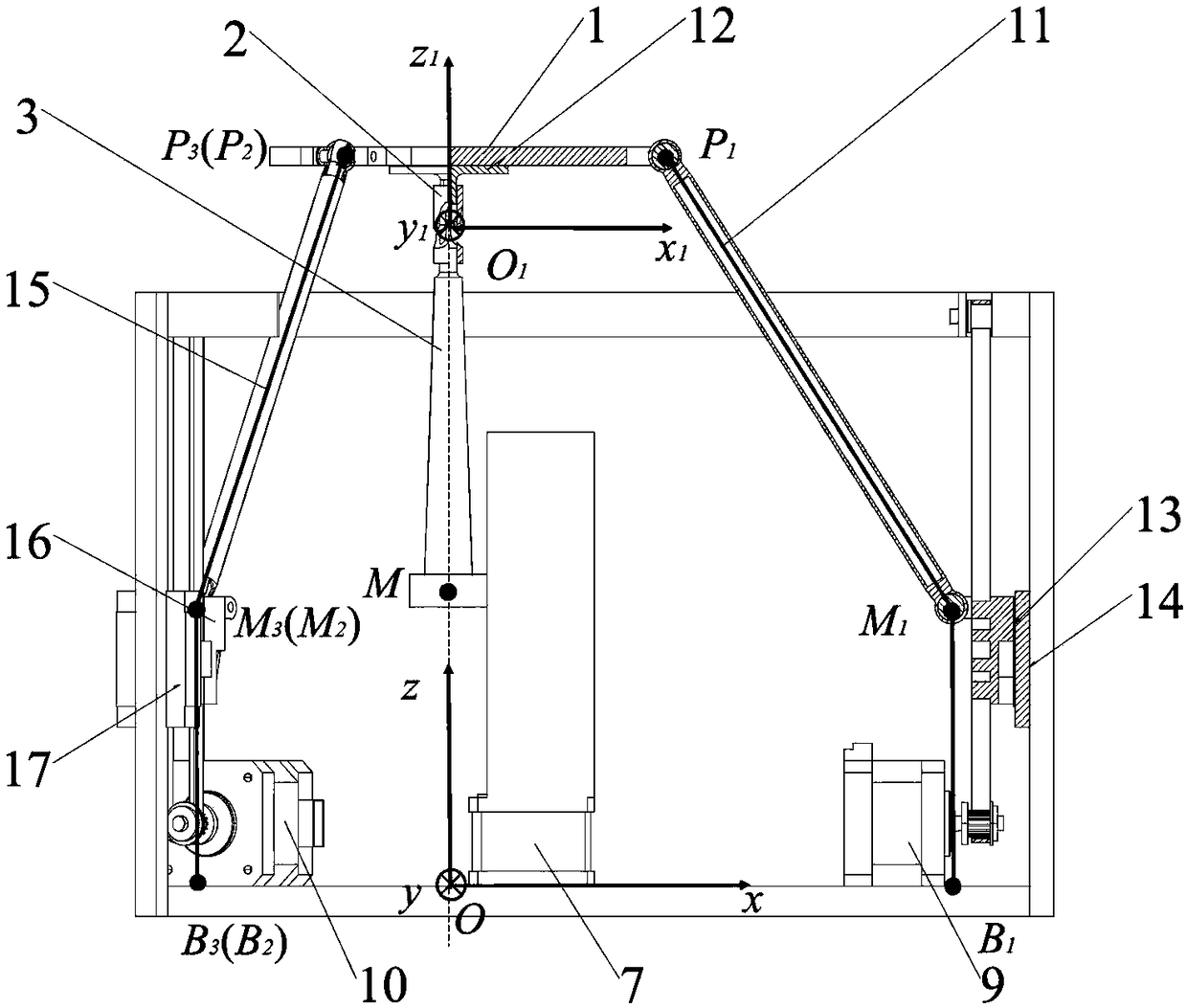

Hook face layering fusion deposition forming 5-axis 3D printing device and method

ActiveCN108527848AHigh surface finishImprove surface accuracyManufacturing platforms/substrates3D object support structuresKinematicsBall bearing

The invention discloses a hook face layering fusion deposition forming 5-axis 3D printing device and method. The device comprises a movable platform, a 3D printing head and a wire extruder. A plasticwire is conveyed into the 3D printing head through the wire extruder, the movable platform is arranged below the 3D printing head and connected with a supporting rod through a platform stretching-outshaft and a universal joint, and the supporting rod and a lifting device are connected. The edge of the movable platform is connected with the upper ends of three push rods through ball bearings. Thelower ends of the push rods are connected with sliding blocks through belt clamping pieces and spherical surface pair sphere centers. The sliding blocks are matched with vertical guide rails fixed toa fixed rack, the sliding blocks linearly move up and down along the guide rails, and the sliding blocks are controlled by motors via belts. According to the characters of a component three-dimensional model, three-dimensional model hook face layer cutting is conducted, and path planning data of each layer cutting hook face are obtained; kinematics parameters of the movable platform, the 3D printing head and the motors are obtained through mathematical derivation, and control is conducted through computer programs for component machining; and the hook face layering fusion deposition forming 5-axis 3D printing device and method have the beneficial effects of being high in precision and wide in printing range.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com