Automobile lock pin reinforcement assembly structure

A technology of assembly structure and reinforcement, applied in superstructure, vehicle parts, locking fasteners, etc., can solve problems such as high cost and deformation of parts, and achieve the effect of simple assembly and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

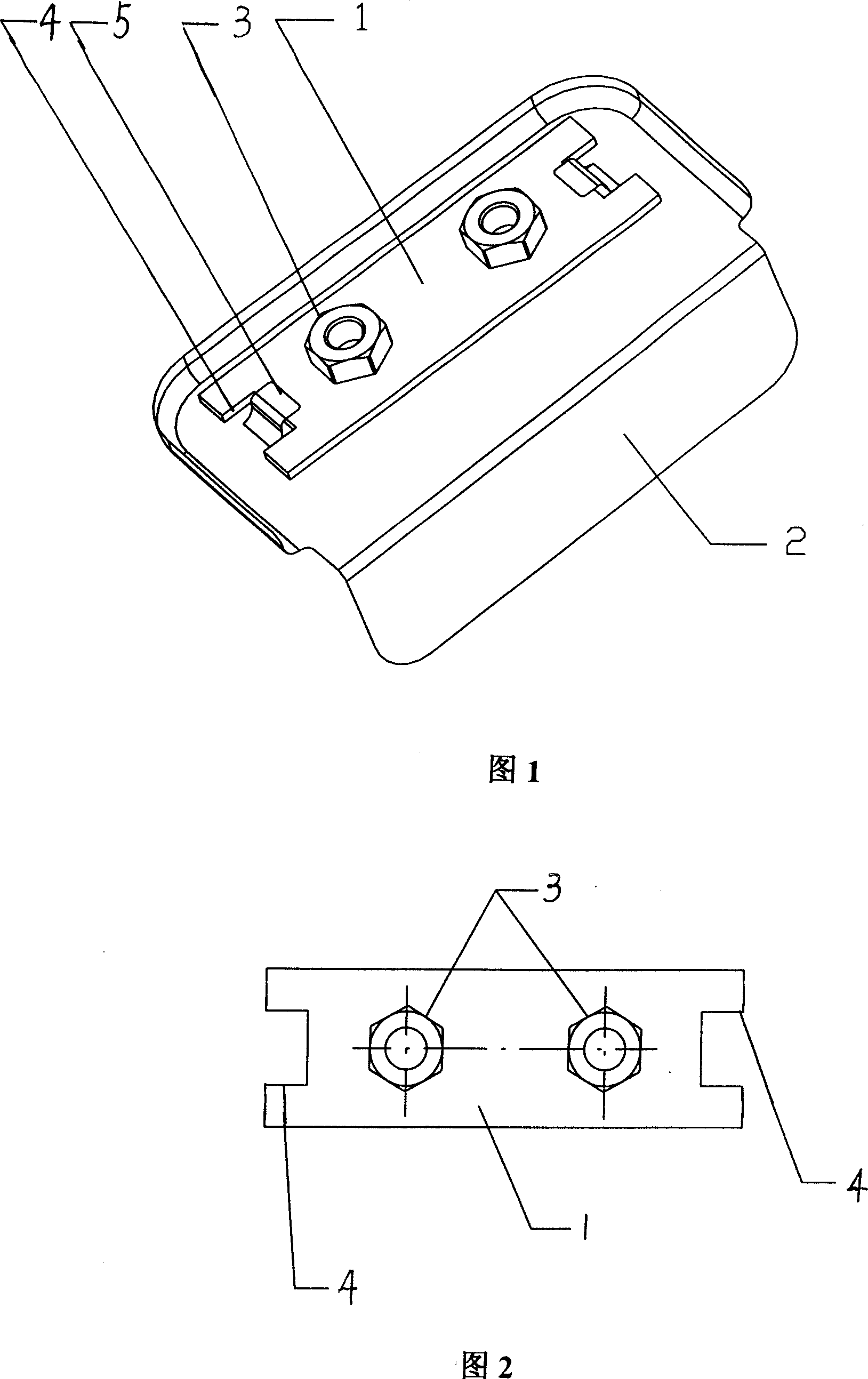

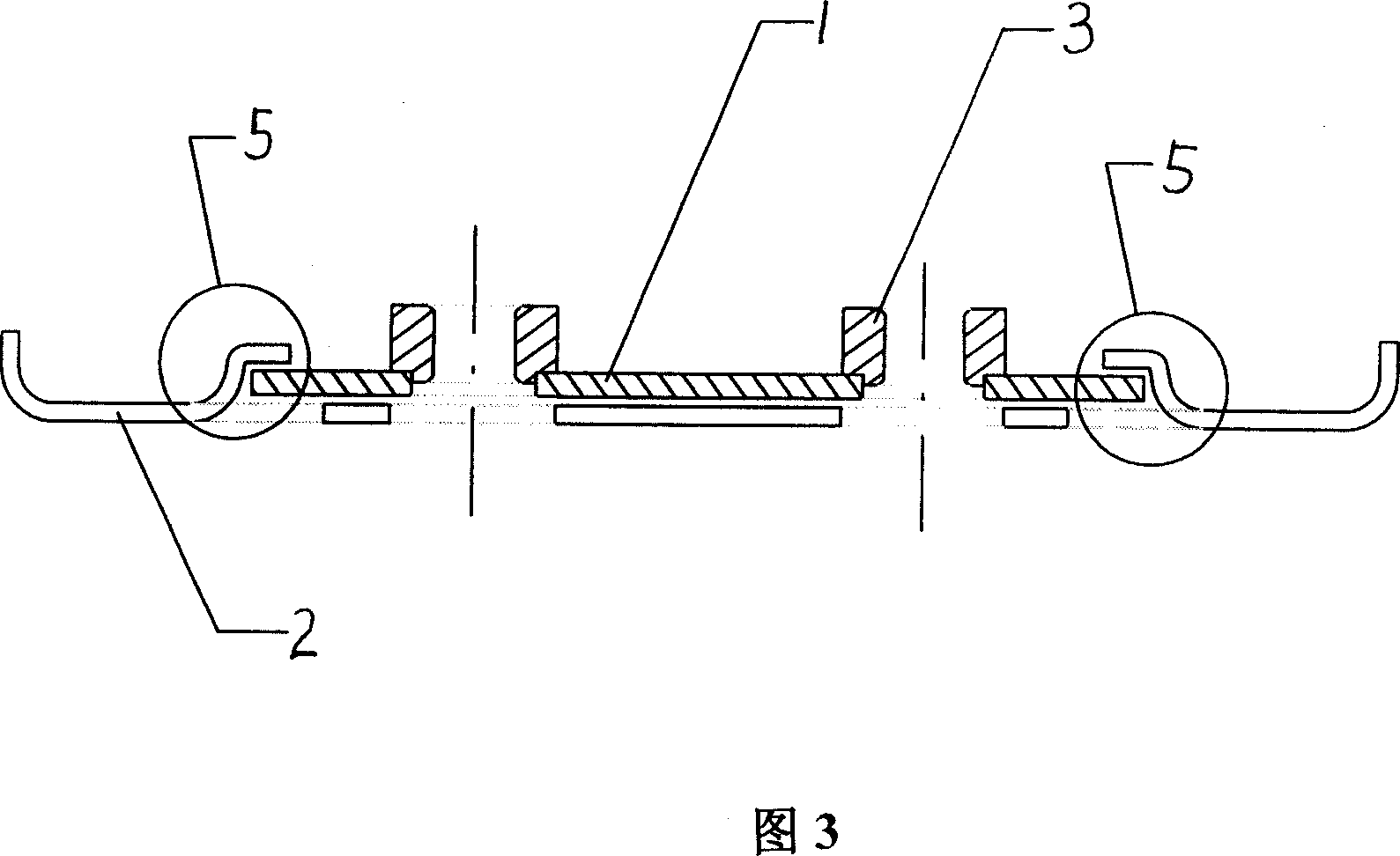

[0012] Referring to Figure 1, the lock pin reinforcement assembly consists of a nut plate 1 and a lock pin reinforcement 2. Referring to FIG. 2 , two weld nuts 3 are welded on the nut plate 1 , and square notches 4 are opened at both ends. Referring to FIG. 3 , the lock pin reinforcement 2 has two stamped "Z"-shaped hooks 5, and the square notch 4 of the nut plate 1 is engaged with the "Z"-shaped hooks 5 of the lock pin reinforcement 2. The square notch 4 makes the nut plate 1 have a certain adjustment range, and the “Z” type hook 5 makes the nut plate 6 difficult to come off.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com