Automatic forming machine of thin-walled short U bent pipe with welding ring

An automatic forming machine and pipe bending technology, which is applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of difficult multi-point clamping, limited clamping and positioning area, waste of pipe material, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] The present invention will be further described below, but the present invention is not limited to the following embodiments.

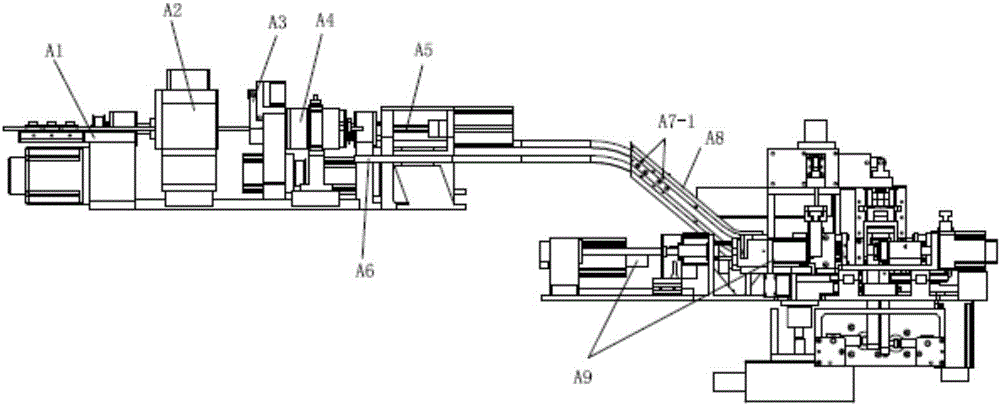

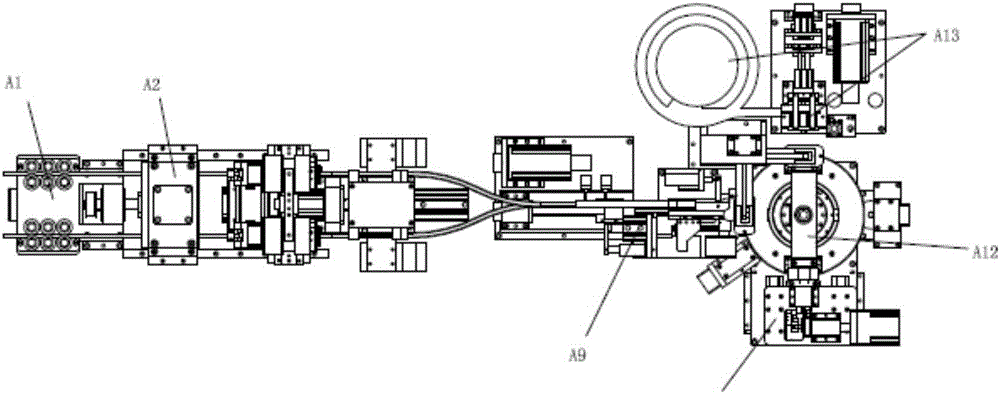

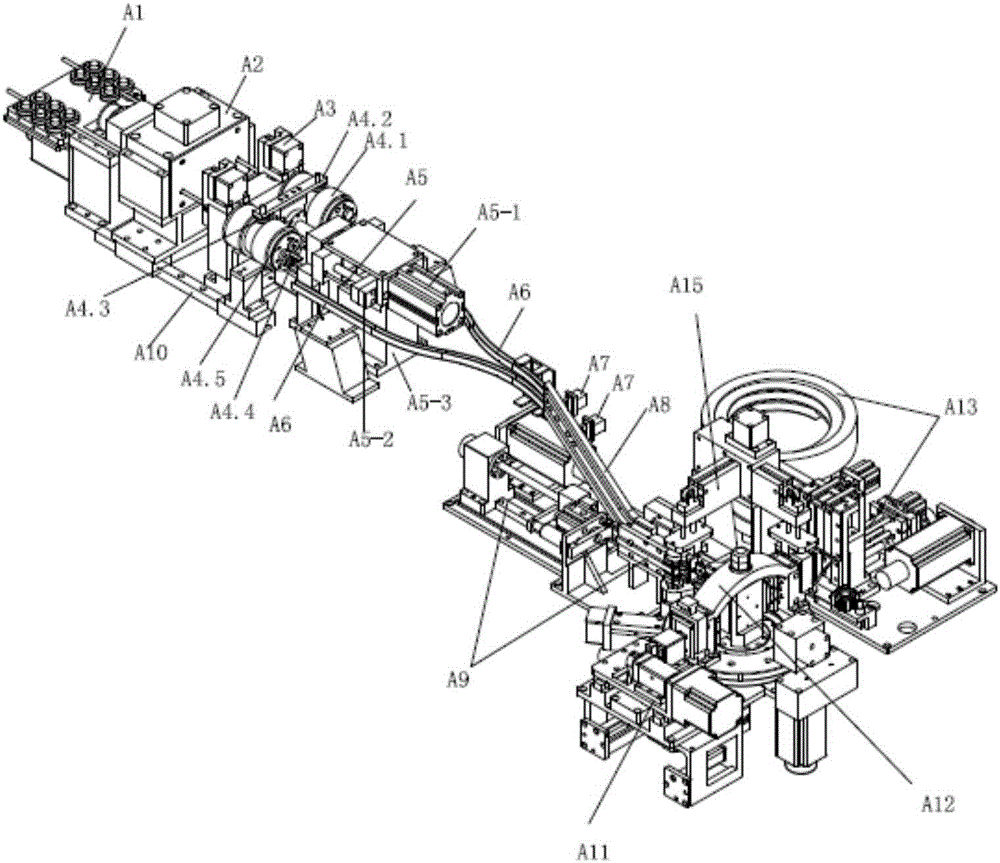

[0086] Such as Figure 1 to Figure 3 As shown, an automatic forming machine for thin-walled short U-bend pipes with welding rings includes the following parts: a feeding assembly A1, with at least one clamping mechanism A2 and a No. 1 driving mechanism (motor and screw nut pair), The pipe A14 is clamped by the clamping mechanism, and the material is fed forward under the drive of the No. 1 drive mechanism; the cutting assembly A4 has at least one cutter mechanism and the No. 2 drive mechanism (motor), and the tool is driven by the No. 2 drive mechanism. Cut the pipe into fixed-length pipe A14.1; an elbow assembly A9, with at least one fixed part, one semicircular die, one movable part and the third drive mechanism A9.7 (motor), one end of the fixed-length pipe is clamped At the fixed part, the other end is movably fitted to the movable part after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com