Paster type LED flexible light strip

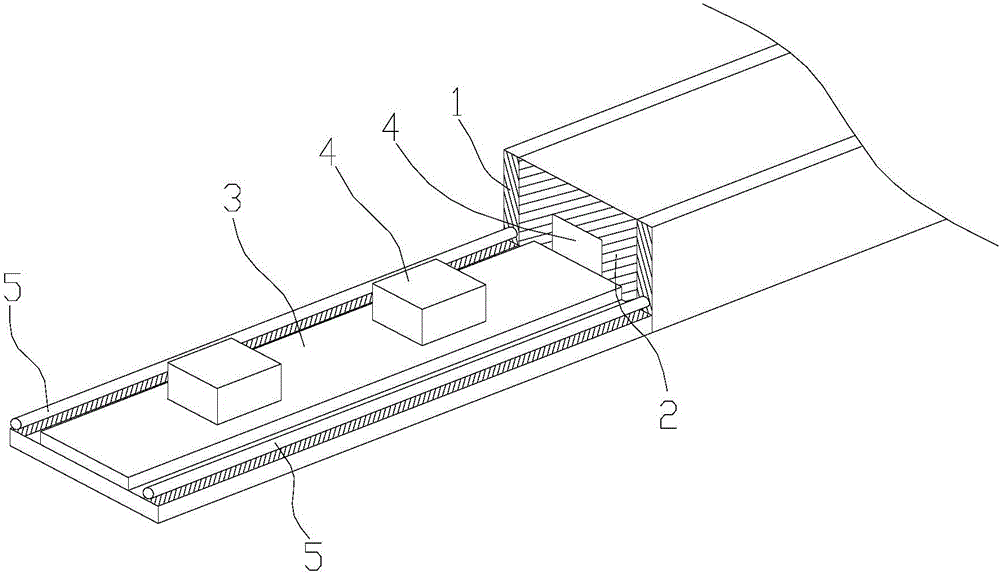

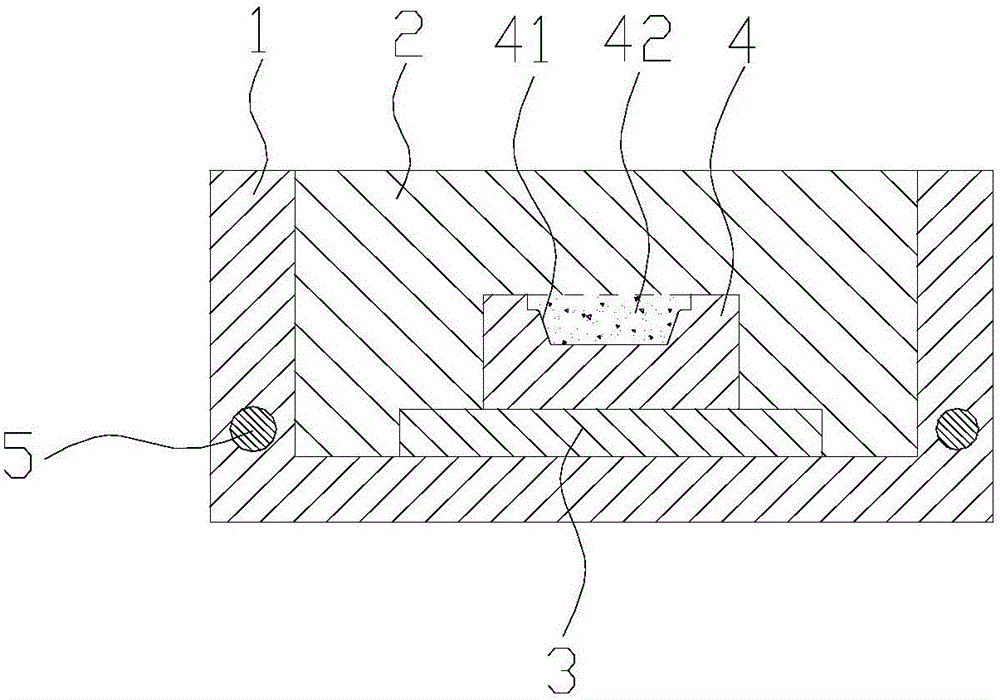

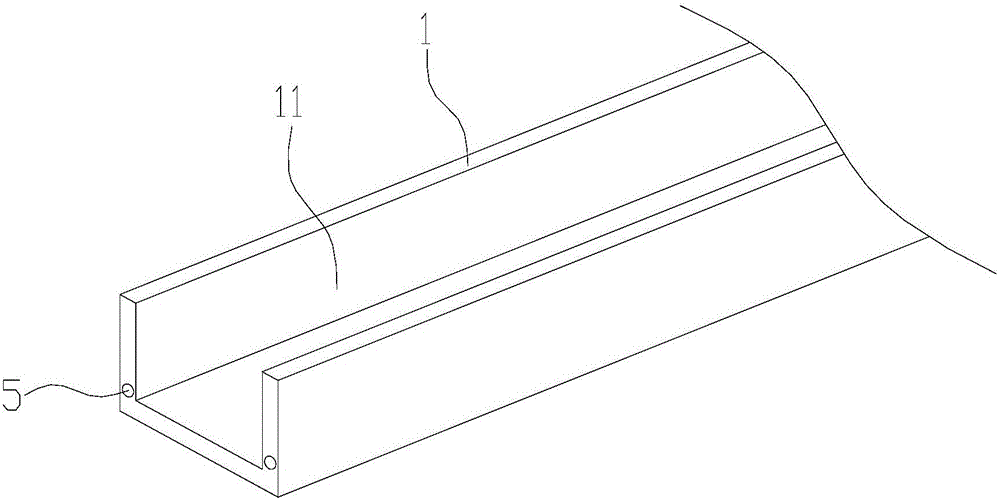

A flexible light strip and SMD technology, applied in the field of lighting, can solve the problems of the deterioration of the encapsulated silica gel, the influence of the light output, the deterioration of the light transmittance, etc., and achieve the effect of reducing reflection, increasing the light output and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0028] Example 2, such as Figure 4 , including a silica gel covering layer 6 covering the core wire. The covering layer 6 covers the core wire, so that the integrity of the light strip is good, and the overall light strip is elastically protected. The silica gel covering layer 6 is integrally formed with the light-transmitting silica gel layer. Process can be reduced

Embodiment 3

[0029] Embodiment 3, on the basis of Embodiment 2, the outer surface of the cladding layer 6 corresponding to the light-emitting surface of the LED chip 4 is arc-shaped. This is beneficial to increase the light emitting surface

[0030] On the basis of Embodiment 2 or 3, the cladding layer is provided with a light-mixing layer 7 at a position corresponding to the light-emitting surface of the LED chip, and the light-mixing layer can be air or other tangible light-mixing materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com