Isolating membrane for lithium ion secondary battery

A secondary battery and separator technology, applied in secondary batteries, battery components, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

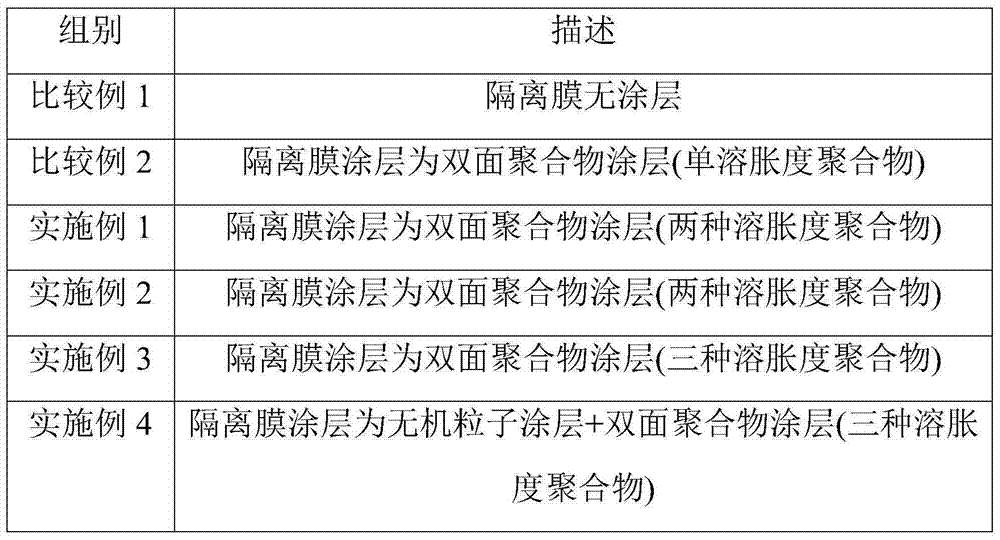

Examples

Embodiment 1

[0039] The preparation of the positive electrode sheet, the negative electrode sheet and the battery of this embodiment are the same as those of Comparative Example 1, and will not be repeated. The separator is different from Comparative Example 1. The separator and its preparation are described in detail below:

[0040] A polyethylene microporous film with a thickness of 9 μm was used as the main body of the isolation membrane.

[0041] Preparation of Adhesive Polymer Coating:

[0042] Stir polyvinylidene fluoride-hexafluoropropylene with 80% swelling degree and polyvinylidene fluoride-hexafluoropropylene with 30% swelling degree and polyacrylate solution in water for 4 hours to form a uniform slurry, and 80% swelling degree The weight ratio of polyvinylidene fluoride-hexafluoropropylene and 30% swelling degree of polyvinylidene fluoride-hexafluoropropylene and polyacrylate is 30:50:20, the solid content of the slurry is 30%, and it is printed by screen printing The polymer ...

Embodiment 2

[0044] The preparation of the positive electrode sheet, the negative electrode sheet and the battery of this embodiment are the same as those of Comparative Example 1, and will not be repeated. The separator is different from Comparative Example 1. The separator and its preparation are described in detail below:

[0045] Isolation film:

[0046] A polyimide with a thickness of 9 μm is used as the isolation membrane body.

[0047] Preparation of polymer coating:

[0048] Stir polyvinylidene fluoride-hexafluoropropylene with 90% swelling degree, polyacrylonitrile and styrene-butadiene polymer with 30% swelling degree in water for 4 hours to form a uniform slurry, and 90% swelling degree The weight ratio of polyvinylidene fluoride-hexafluoropropylene to polyacrylonitrile and styrene-butadiene polymer with a swelling degree of 30% is 20:65:15, and the solid content of the slurry is 35%. The polymer solution was coated on both sides of the isolation film with a thickness of 4um, ...

Embodiment 3

[0050] The preparation of the positive electrode sheet, the negative electrode sheet and the battery of this embodiment are the same as those of Comparative Example 1, and will not be repeated. The separator is different from Comparative Example 1. The separator and its preparation are described in detail below:

[0051] Isolation film:

[0052] A polypropylene microporous film with a thickness of 9 μm was used as the isolation membrane body.

[0053] Preparation of polymer coating:

[0054] Stir together polyoxyethylene with 90% swelling degree, 80% vinylidene fluoride-hexafluoropropylene, 40% swelling degree vinylidene fluoride-hexafluoropropylene and sodium carboxymethyl cellulose in water for 4 hours to form a uniform slurry Material, polyoxyethylene with 90% swelling degree, 80% vinylidene fluoride-hexafluoropropylene and 40% swelling degree vinylidene fluoride-hexafluoropropylene and the weight ratio of carboxymethyl cellulose sodium are 10:10: 70:10, the solid content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com