Alignment support device for rotor of permanent-magnetic wind power generator and rotor bearing replacement method

A technology for wind turbines and supporting devices, which is used in electromechanical devices, manufacturing motor generators, casings/covers/supports, etc., can solve the problems of weakened end plate strength, poor economy, easy deformation, damage, etc. Auxiliary equipment, saving construction costs, reducing the effect of operation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

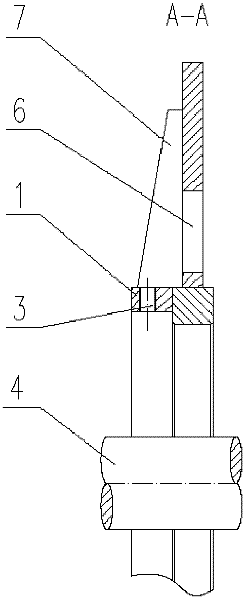

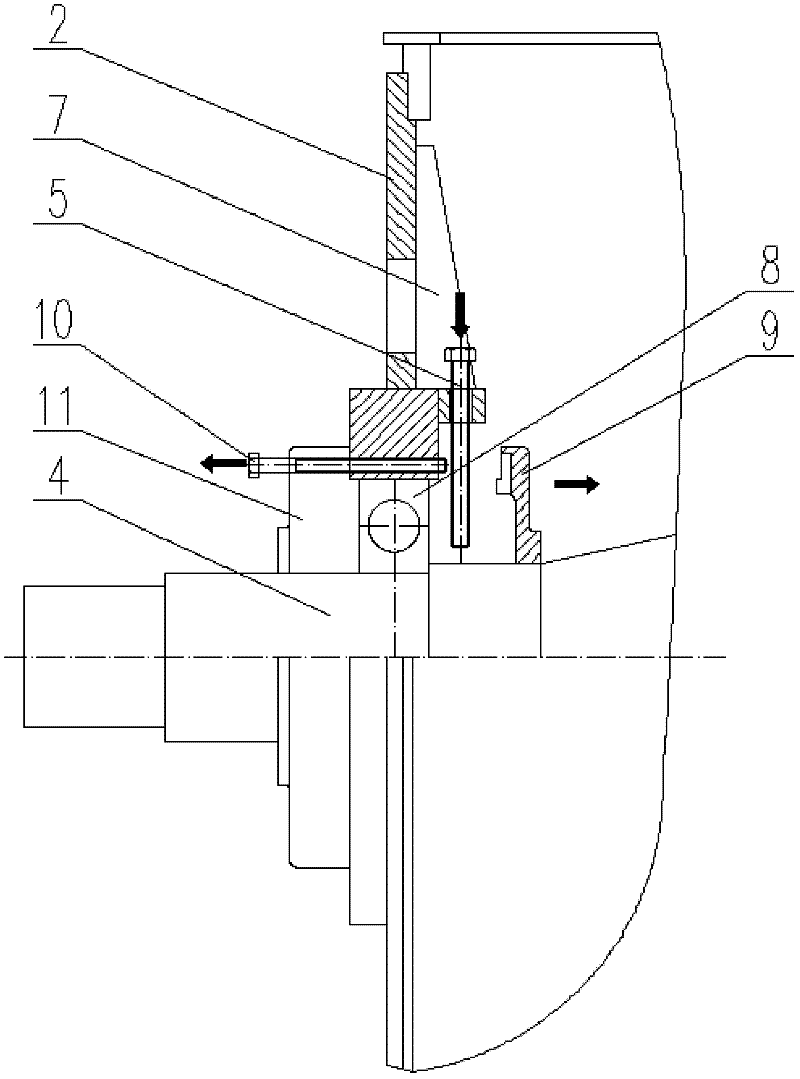

[0058] After the support bolts 5 are evenly tightened on the support plate 1, the end of the threaded section of the support bolt 5 is in contact with the outer surface of the generator shaft 4. At this time, the support bolts 5 on the three support plates 1 are used to pass through the 1 Screw-connected support bolts 5. The rotor is fixed with the generator end cover 2 as a support body, and the degree of freedom of the rotor is limited, so that the rotor is always in a state of force balance, and the rotor is prevented from being damaged due to magnetic attraction when other parts on the rotor are disassembled. The role of adsorption or impact on the stator.

[0059] When the length of the threaded section of the supporting bolt 5 is greater than the thickness of the supporting plate 1 and the sum of the distance between the supporting plate 1 and the surface of the generator shaft 4, the supporting bolt 5 is evenly tightened on the supporting plate 1, and the end of the thre...

Embodiment 2

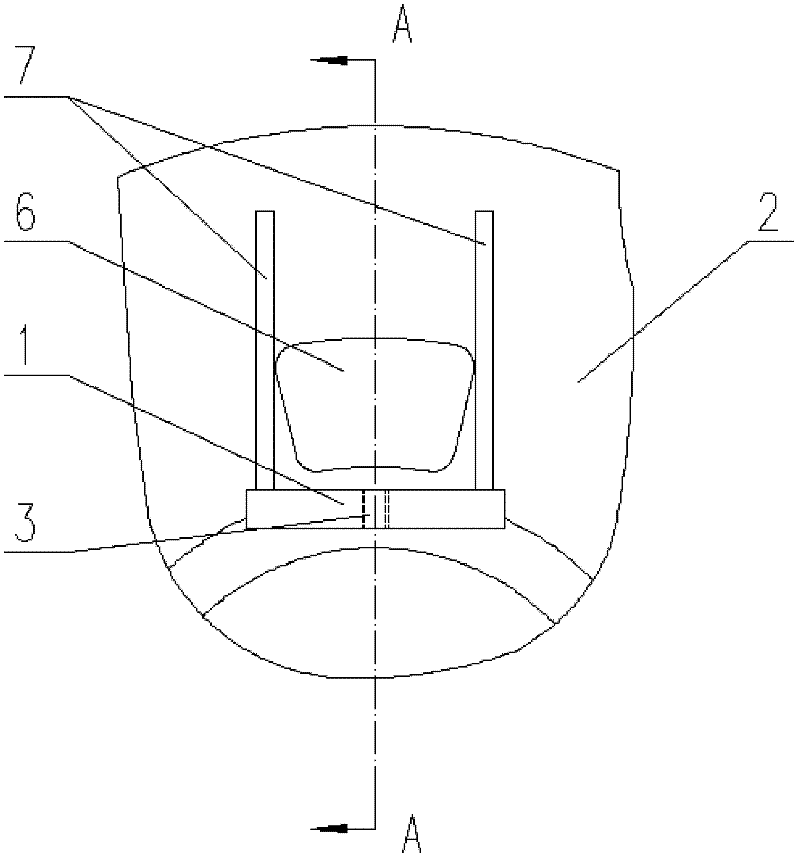

[0067] That is, taking the axis center line of the generator shaft 4 as the X axis, the center of one of the measuring air gap holes 6 is set on the XZ plane, and the other two measuring air gap holes 6 are mirror symmetrically set with respect to the XZ plane. The side of the air gap hole 6 adjacent to the generator shaft 4 is provided with a support plate 1, the number of the support plate 1 is the same as the number of the measurement air gap hole 6, the support plate 1 is arranged on the inner side of the generator end cover 2, and on the support plate 1 is provided with a threaded hole 3 and a matching supporting bolt 5, the threaded hole 3 penetrates the supporting plate 1 along the radial direction of the generator shaft 4, wherein the measuring air gap hole 6 centered on the XZ plane is close to the generator The axis of the threaded hole 3 on the support plate 1 provided on one side of the machine shaft 4 is parallel to the Z axis to balance the gravity of the rotor. ...

Embodiment 3

[0078] Example 4

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com