Hook face layering fusion deposition forming 5-axis 3D printing device and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

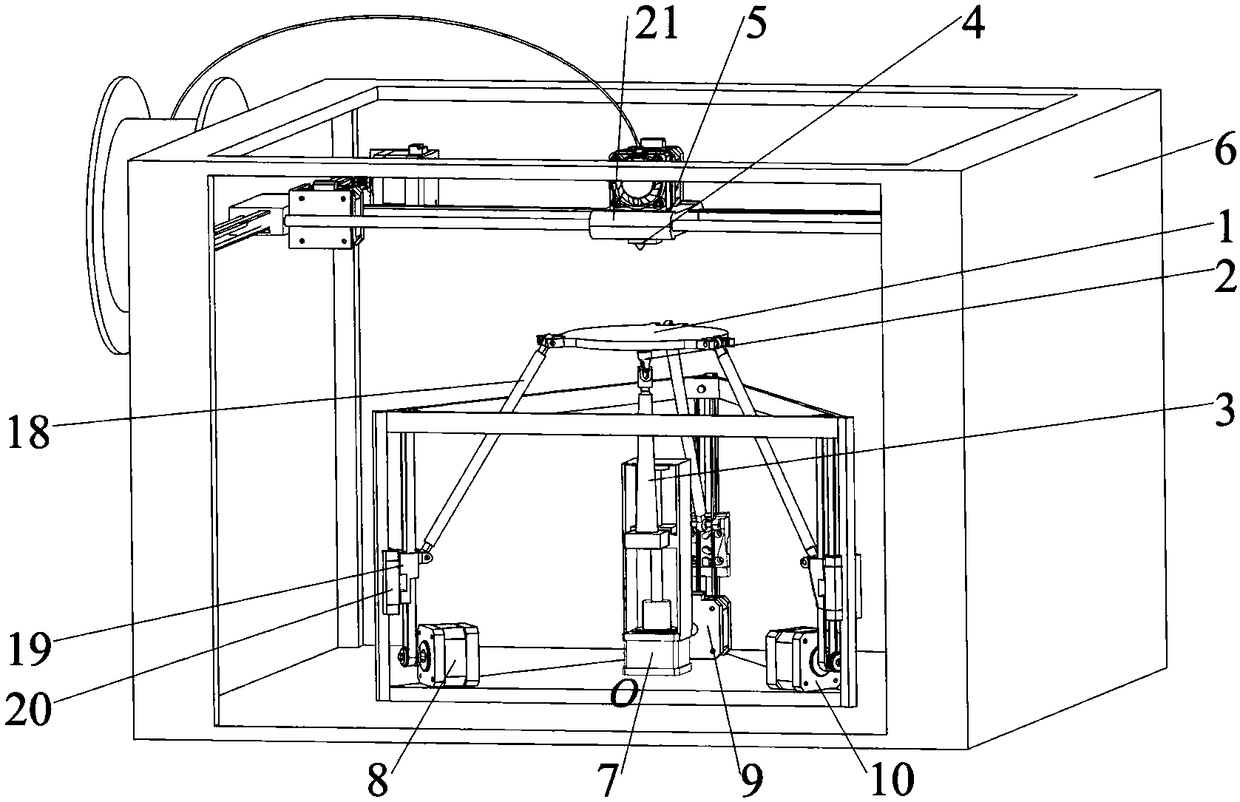

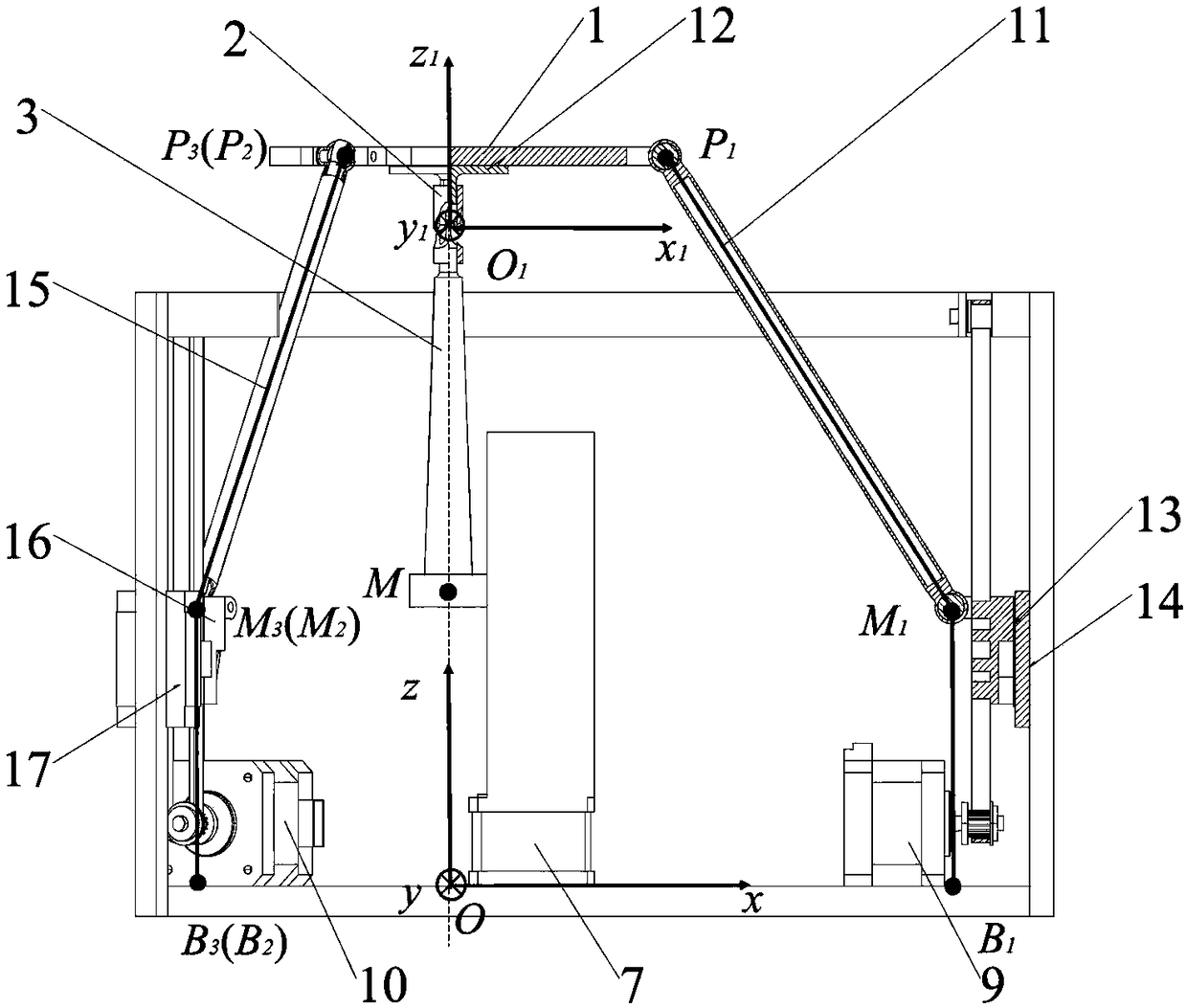

[0033] refer to figure 1 and figure 2 , a 5-axis 3D printing device for curved surface layered fusion deposition molding, including a 3D printing head 4, plastic filaments are fed into the 3D printing head 4 through a wire extruder 5, and the 3D printing head 4 is installed on a two-dimensional motion platform 21, The two-dimensional motion platform 21 is fixed on the fixed frame 6, and the bottom of the 3D printing head 4 is provided with a moving platform 1, and the moving platform 1 is connected to one end of the universal joint 2 through the platform extension shaft 12, and the other end of the universal joint 2 is installed on the On the support rod 3, the support rod 3 is connected with the lifting device 7, and the lifting device 7 is installed on the fixed frame 6;

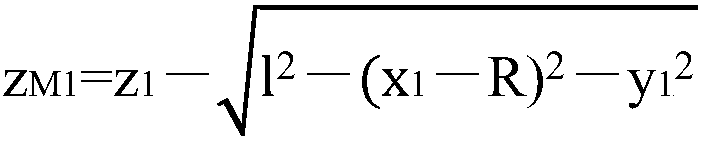

[0034] refer to figure 2 , the edge of the moving platform 1 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com