Method of processing steam turbine control valve long thin-wall sleeve by utilizing support device

A technology of supporting device and thin-walled sleeve, which is used in metal processing mechanical parts, positioning devices, clamping devices, etc., can solve the problems of cylindricity not meeting the requirements of drawings, poor control of dimensional tolerances, and increasing cutting processes. The effect of easy control of dimensional tolerance, simple structure and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

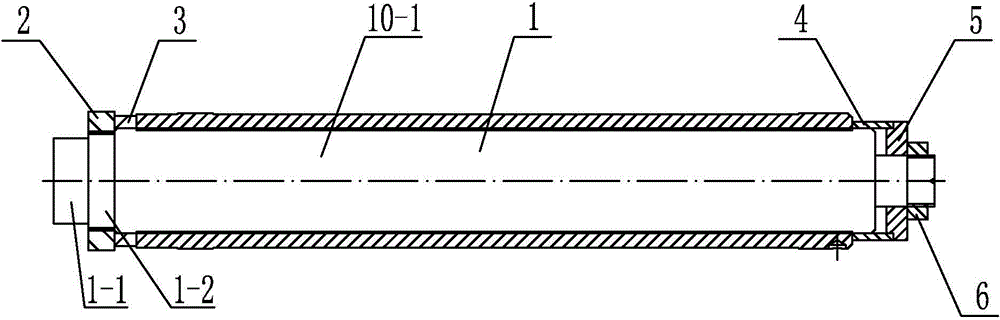

[0023] Specific implementation mode one: combine Figure 1 to Figure 5 Describe this implementation mode, this implementation mode is realized through the following steps:

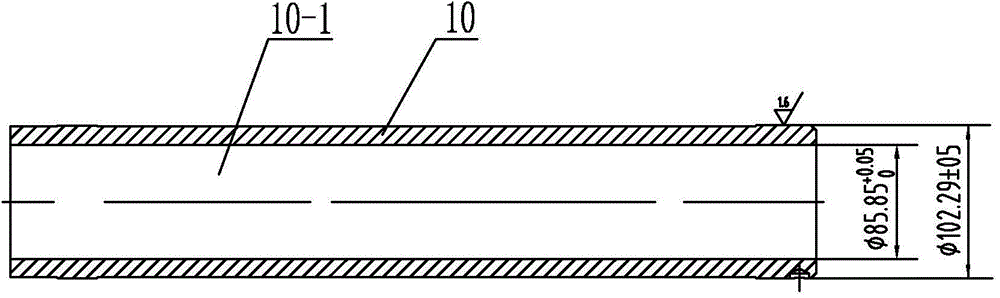

[0024] Step 1. Machining the central hole 10-1 of the long thin-walled sleeve 10: use a drilling machine to process the central hole 10-1 of the blank of the long thin-walled sleeve 10, and then process the central hole 10-1 by turning or boring to reach the drawing size request, see figure 1 ;

[0025] Step 2. Install the supporting device for turning the long and thin-walled sleeve: place the stepped shaft 1 in the central hole 10-1, and the middle section 1-3 of the stepped shaft 1 and the central hole 10-1 have 0-0.05mm interference Cooperate, the left washer 3 and the left nut 2 limit the axial degree of freedom of the left end of the long thin-walled sleeve 10, the stop ring 4, the right washer 5 and the first right nut 6 limit the axial degree of freedom of the right end of the long thin-walled sl...

specific Embodiment approach 2

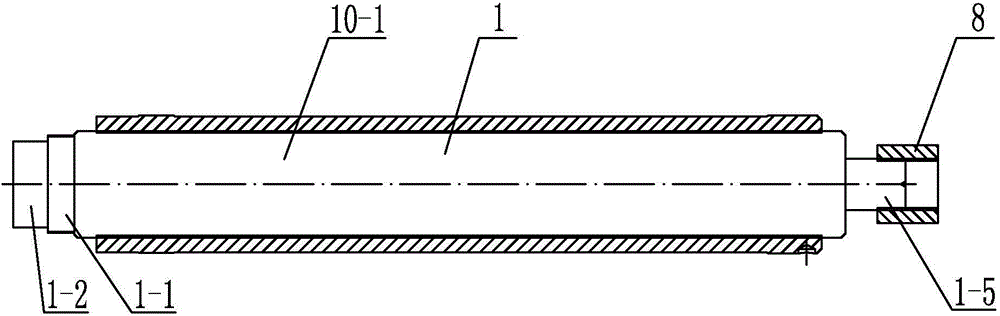

[0029] Specific implementation mode two: combination figure 2 Describe this embodiment. In this embodiment, the interference fit between the middle section 1-3 of the stepped shaft 1 and the center hole 10-1 in step 2 is 0.01 mm. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0030] Specific implementation mode three: combination figure 2 Describe this embodiment. In this embodiment, the interference fit between the middle section 1-3 of the stepped shaft 1 and the central hole 10-1 in step 2 is 0.02mm. Other steps are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com