Double-faced adhesive tape pasting machine

A double-sided tape and double-sided technology, applied in the direction of winding strips, sending objects, thin material processing, etc., can solve problems such as deformation of double-sided tape, poor adhesion effect, and easy sticking of rolling mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

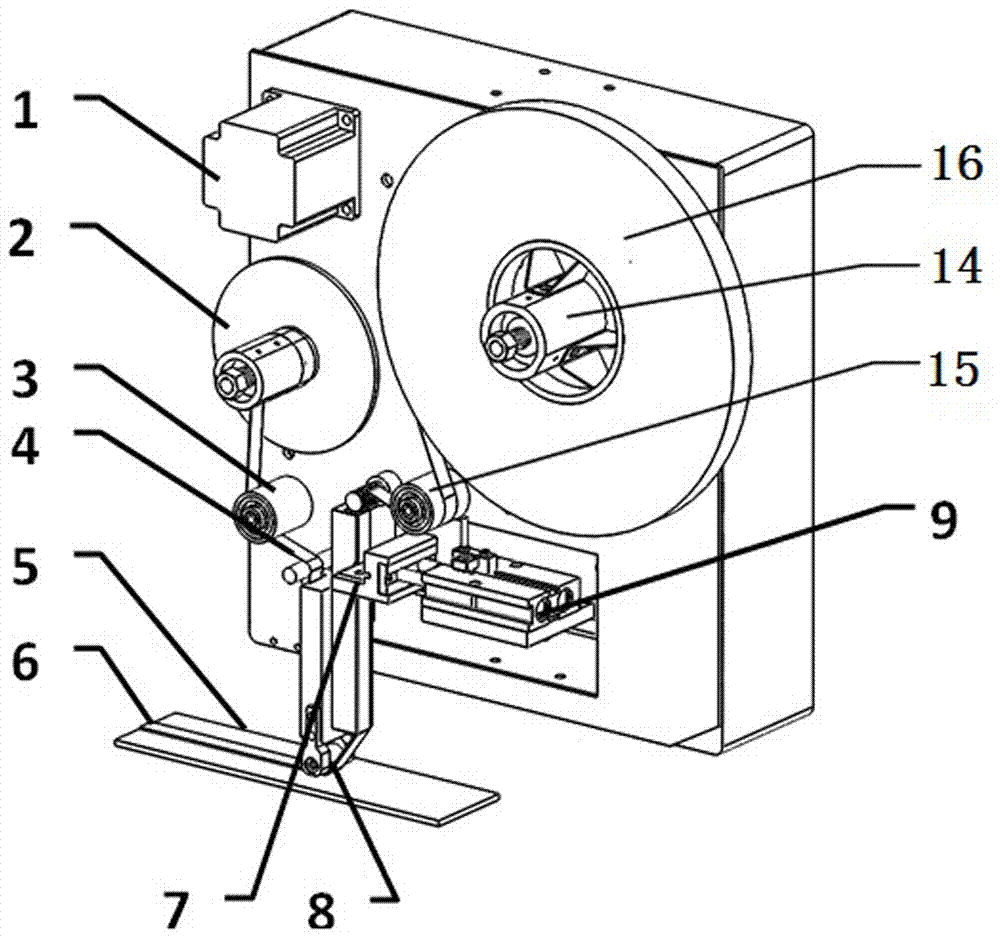

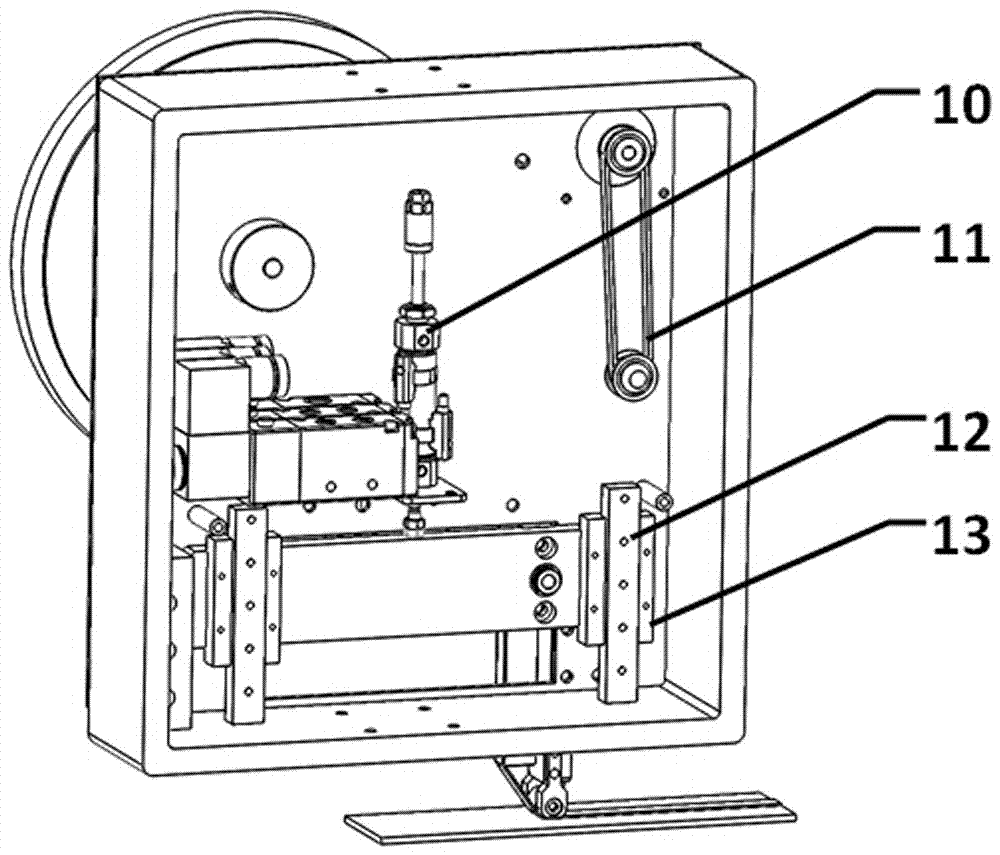

[0022] Double-sided tape sticking machine, including feeding mechanism, guiding mechanism, cutting mechanism, gluing mechanism and receiving mechanism;

[0023] It is characterized in that the feeding mechanism includes a reel feeding shaft (14); the guiding mechanism includes a guiding wheel I (15) and a guiding wheel II (3); the cutting mechanism includes a non-stick glue cutting blade (7) , Cylinder I (10), Cylinder II (9), slide rail (12), slider (13); the gluing mechanism includes a gluing wheel (8); the receiving mechanism includes a receiving shaft (2) , Receiving motor (1) and reducer (marked in the figure);

[0024] Place the double-sided film material (16) on the feeding reel, and the double-sided tape (6) tape head is pulled out through the guide wheel I (15), the rubber sticking wheel (8), and the guide wheel II (3) to connect and receive the material shaft (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com