Method for classifying silicon carbide micro powder and classifying equipment of method

A technology for silicon carbide micropowder and equipment, which is applied in chemical instruments and methods, mechanical equipment, solid separation and other directions, can solve the problems of low classification accuracy of silicon carbide micropowder, wide particle size distribution of finished products, and low extraction rate of fine powder, etc., and achieves good stability. Physical form, narrow particle size distribution, and the effect of improving the extraction rate of fine powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

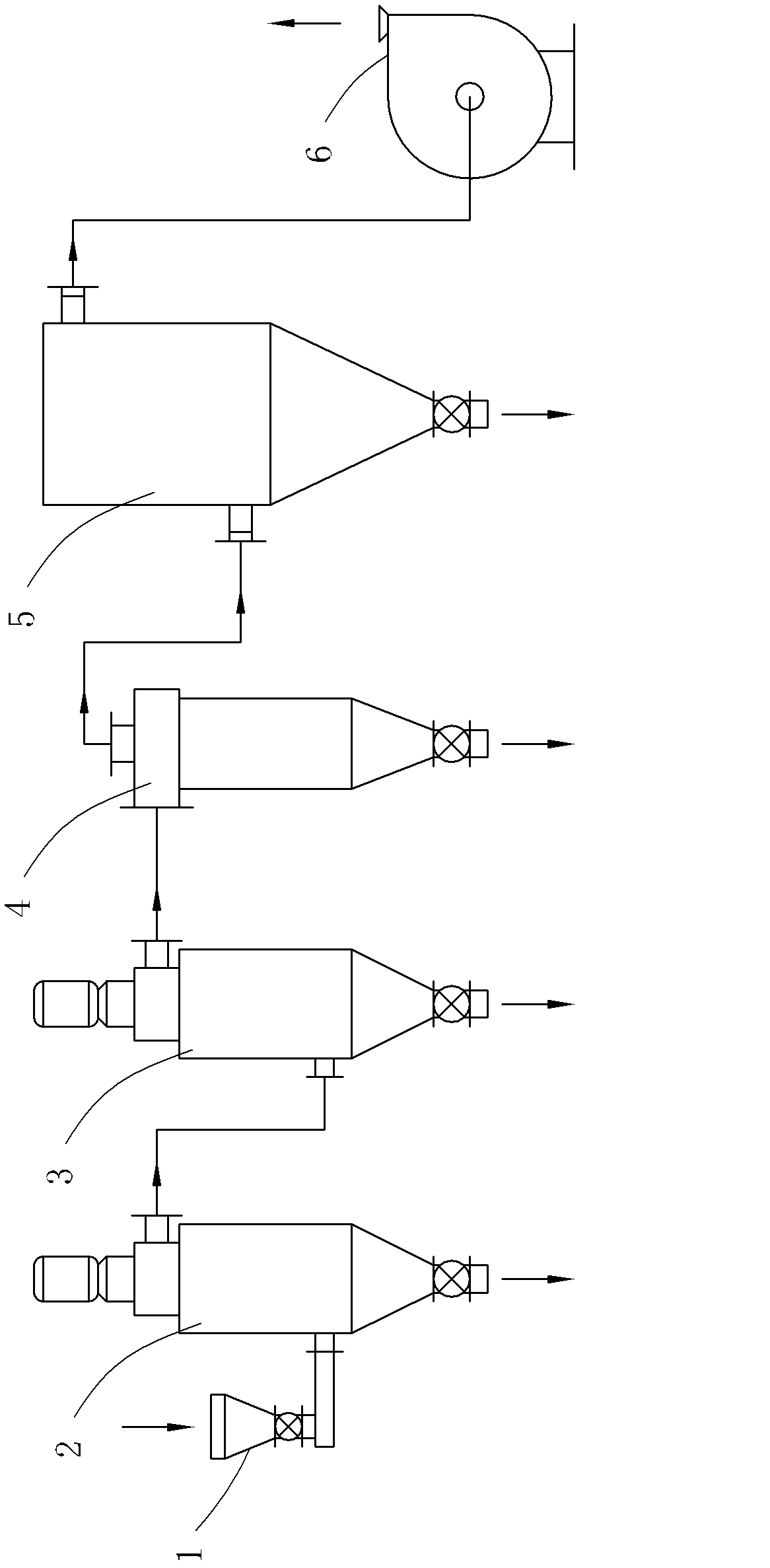

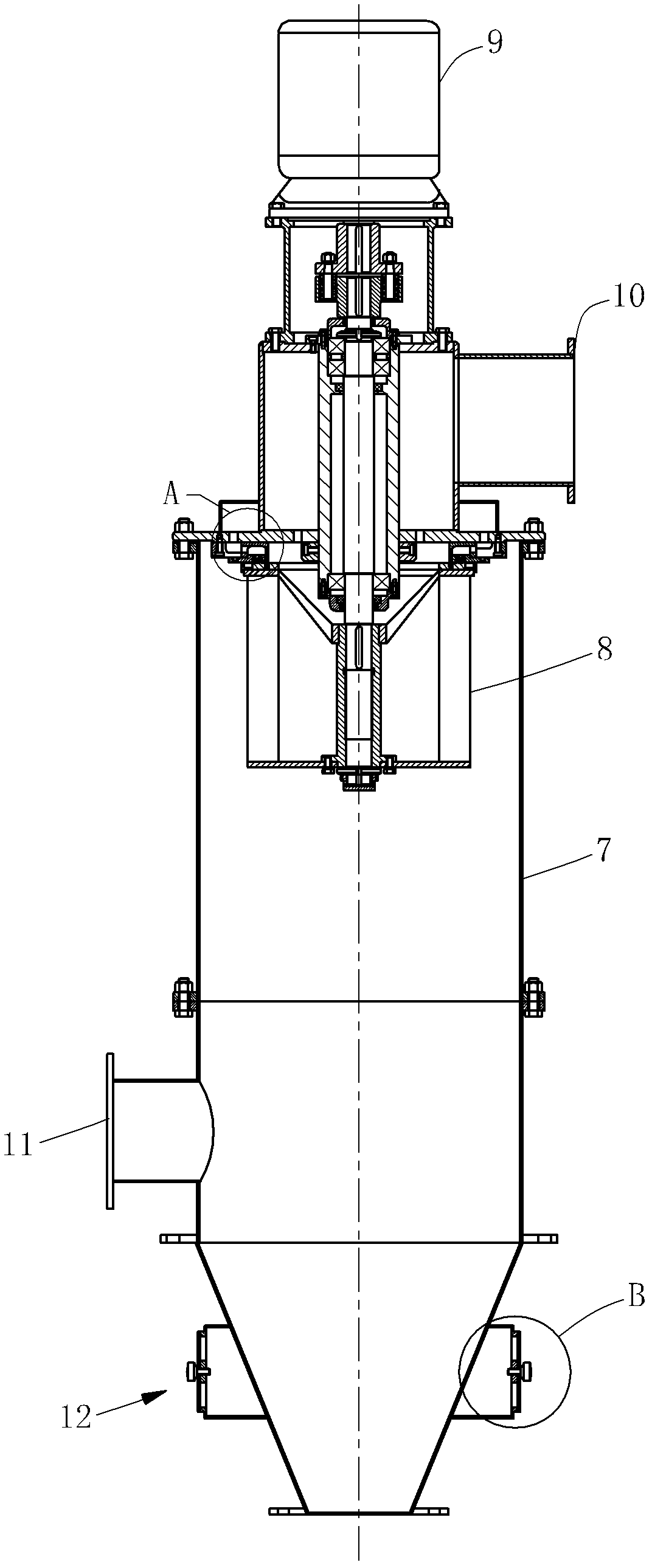

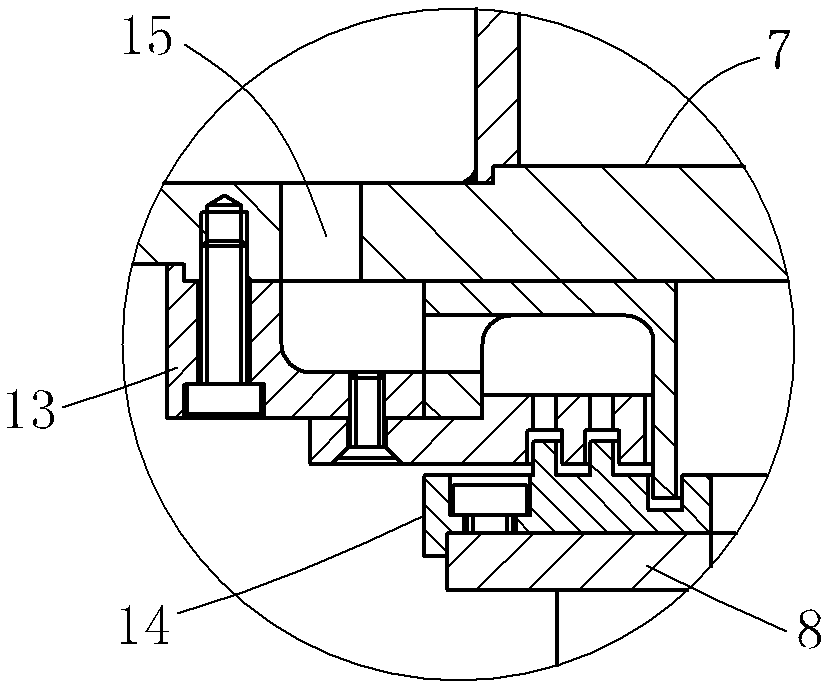

[0022] Such as figure 1 As shown, a method for grading silicon carbide micropowder comprises the following steps: silicon carbide micropowder enters at least two classifiers connected in series in turn, and the classifier has a self-suction sealing device, and the classification accuracy of the downstream classifier is higher than that of The classification accuracy of the upstream classifier, that is, the classification accuracy of the second classifier 3 is higher than that of the first classifier 2, and then the cyclone collector 4 is connected to the classifier at the end to collect the sorted silicon carbide micropowder, and the bag filter 5 The waste discharged by the cyclone collector 4 is collected, the power of the system is provided by the induced draft fan 6 arranged downstream of the bag filter 5, and the classification accuracy of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com