Preparation method of semiconductor wafer cutting blade material

A wafer and cutting edge technology, which is applied in the field of semiconductor wafer cutting edge material preparation, can solve the problems of long pickling time, high water consumption, low jet mill output, etc., and achieve good wafer cutting effect, Uniform particle size distribution and good high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 A method for preparing a cutting blade material for a semiconductor wafer includes the following steps:

[0033] (1) For raw material crushing, select green silicon carbide blocks with a purity of ≥99% and black silicon carbide blocks with a mass ratio of 18:1, and perform jaw crushing and sieving to collect silicon carbide sand with a particle size of ≤3mm;

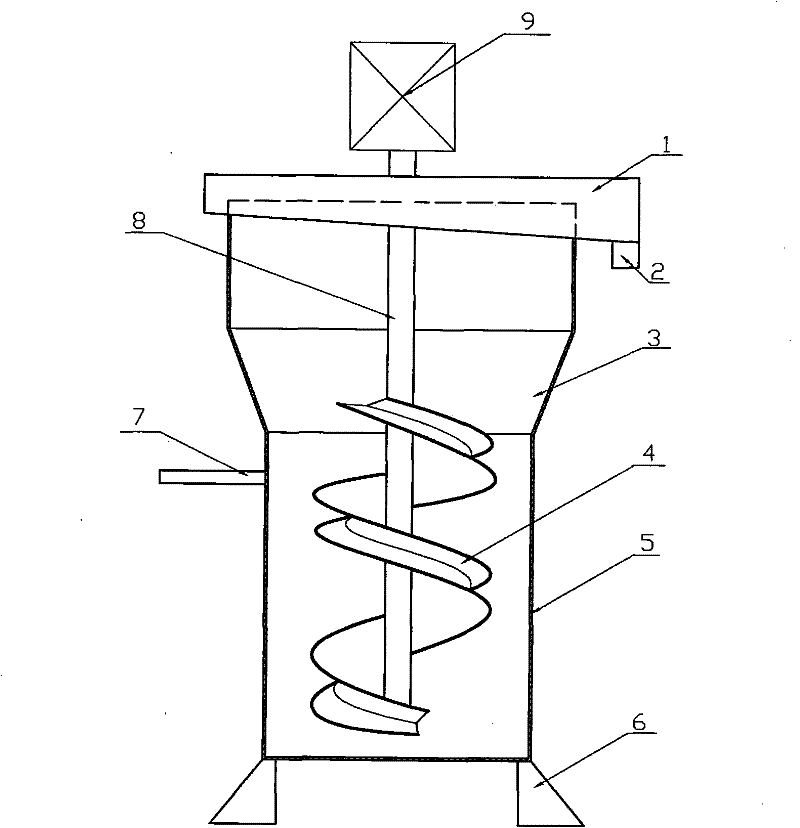

[0034] (2) Wet ball milling and overflow classification are in the wet frequency conversion ball mill classification device (see figure 1 When grinding and grading in ), add media ball and silicon carbide particle sand at the weight ratio of media ball: silicon carbide particle size 4:1. The frequency conversion wet ball mill rotates at 80rpm for 0.5h in the early stage and 100rpm at 2h in the middle. In the later period, the rotation speed is 120 rpm and the water inlet is 600 L / h; the wet variable frequency ball mill classification device includes a vertical cylinder 5 and a double agitating spiral body...

Embodiment 2

[0043] Embodiment 2 A method for preparing a cutting blade material for a semiconductor wafer includes the following steps:

[0044] (1) For raw material crushing, select green silicon carbide blocks with a purity of ≥99% and black silicon carbide blocks with a mass ratio of 19:1, and perform jaw crushing and sieving to collect silicon carbide sand with a particle size of ≤3mm;

[0045] (2) Wet ball milling and overflow classification The same wet frequency conversion ball mill and classification device as in Example 1 is used for wet grinding and classification. When grinding and classifying, the medium ball: silicon carbide particle size sand is 5:1 Add media balls and silicon carbide granular sand to the weight ratio of the medium. The frequency conversion wet ball mill has a rotation speed of 90 rpm in the first 0.6h, 100 rpm in the middle 1.9h, and 150 rpm in the later 1.6h, with a water intake of 500L / h;

[0046] (3) Pickling vacuum dehydration Introduce the above-mentioned sil...

Embodiment 3

[0054] Embodiment 3 is a method for preparing a semiconductor wafer cutting blade material, which is basically the same as embodiment 1, except that: in the step (2), wet grinding is performed by ordinary wet frequency conversion ball mill, and then Commonly used hydraulic classification device performs classification to obtain silicon carbide powder slurry with the required particle size range.

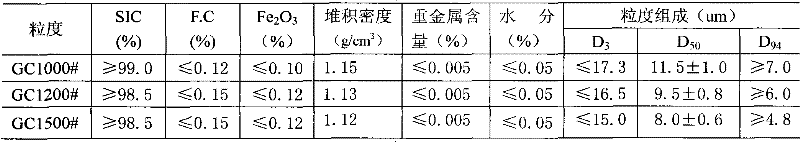

[0055] The performance indexes of the obtained semiconductor wafer cutting blade materials are shown in Table 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com