Production method of silicon wafer cutting blade material

A silicon wafer cutting and production method technology, applied in grain processing, etc., can solve the problems of uneven particle size, poor cutting efficiency, low purity, etc., achieve uniform size distribution, reduce production costs, and reduce emission pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

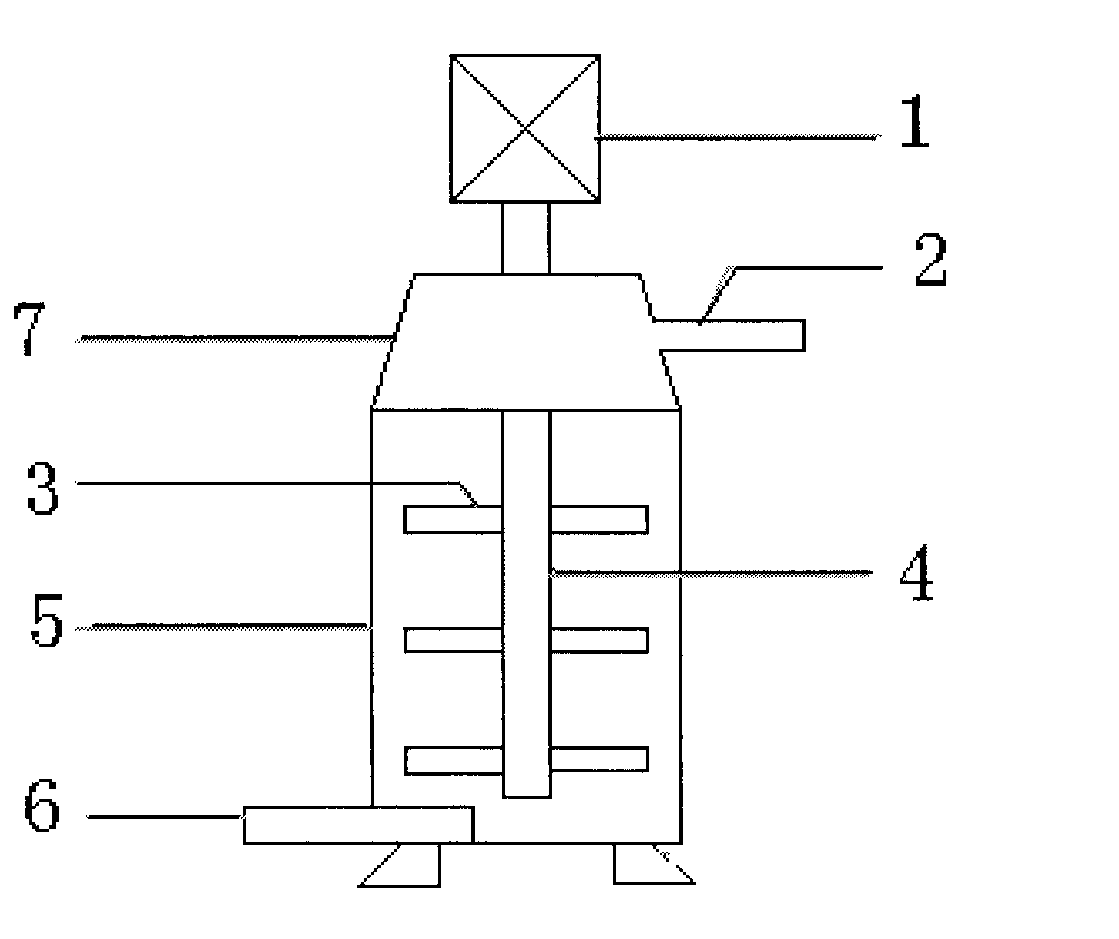

[0040] A method for preparing a silicon carbide blade for photovoltaic wire cutting, comprising the following steps:

[0041] The first step is to crush the raw materials, select the green silicon carbide block material with a purity ≥ 98% for jaw crushing and sieving, and collect the silicon carbide particle size sand with a particle size ≤ 3mm;

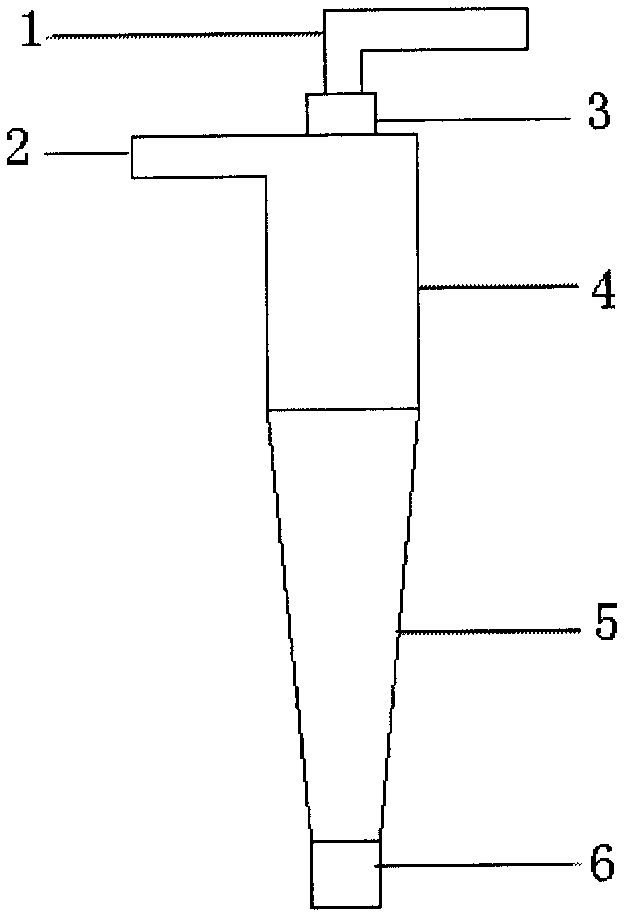

[0042] In the second step of wet ball milling and hydrocyclone classification, the silicon carbide sand particles obtained in the first step are wet ball milled and hydrocyclone classified to obtain a silicon carbide powder slurry in the required particle size range;

[0043] The 3rd step overflows automatic carbon removal, introduces the SiC powder slurry obtained in the second step in the overflow automatic carbon removal equipment, adjusts its mass concentration to 30~50wt%, then adds 30~50ml of flotation oil and 50-70ml of water glass, fully stirred for 0.5-1 hour, then overflowed to remove free carbon;

[0044] The fourth step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com