Mold for press forming small hole

A technology of molds and punches, which is applied in the field of molds for stamping small holes, and can solve the problems of high cost, difficulty in ensuring drilling quality, and time-consuming and labor-intensive problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

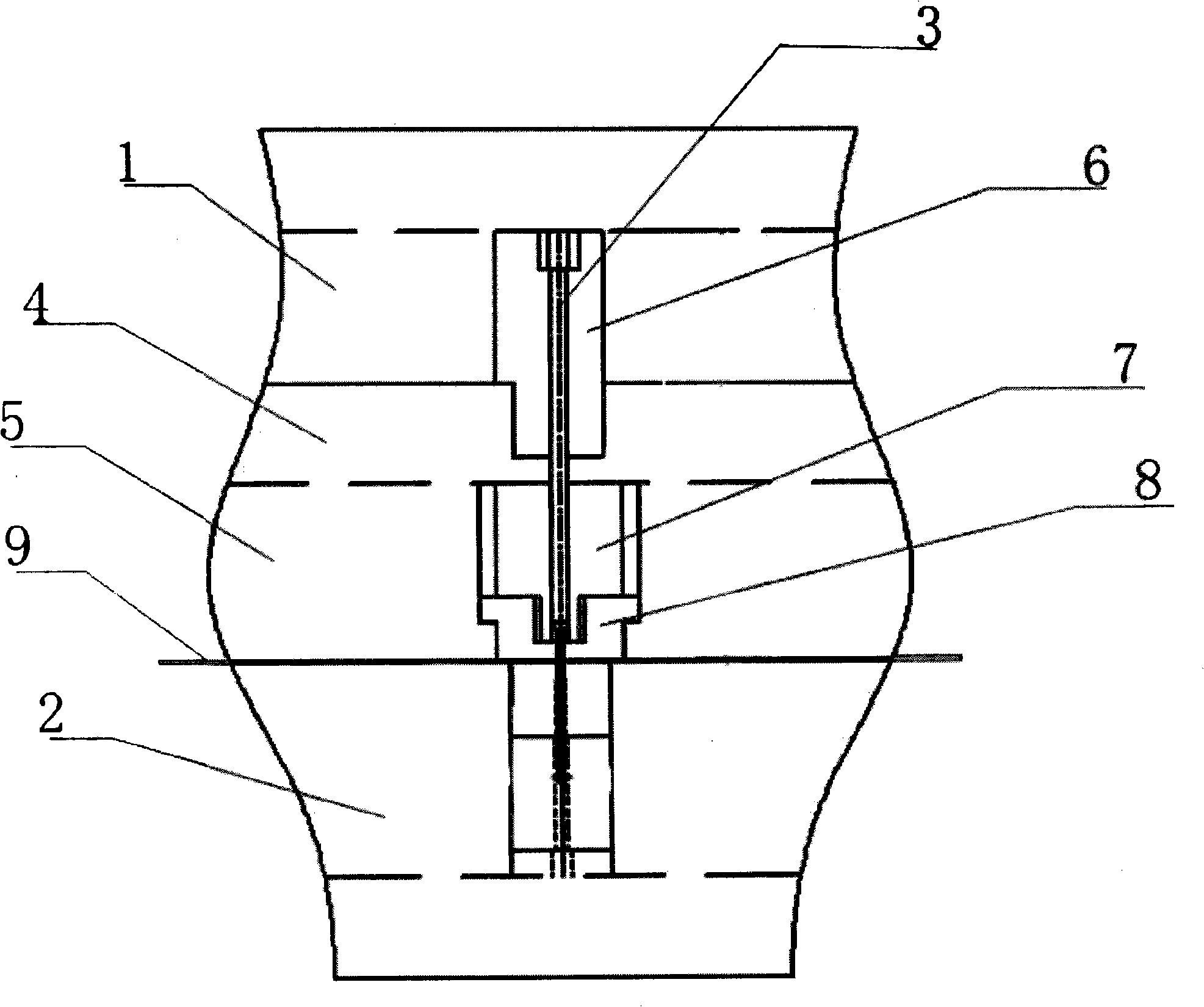

[0007] The present invention implements according to above-mentioned technical scheme, and the diameter of punch rod is about 0.8 millimeter, and the diameter of small hole is 0.3 millimeter or less, and small hole is round hole also can be oval hole or other shape, and band material is the thick non-embroidered of 0.2 millimeter. Steel strips can also be other materials. There are dozens to hundreds of small holes on each stamped product, which can be completed at one time, which greatly improves work efficiency, improves product quality, and reduces The production cost is unmatched by other processing methods.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com