Copper tube inner ring gripper

A copper tube and inner ring technology, which is applied in the directions of manipulators, chucks, manufacturing tools, etc., can solve the problems of insufficient clamping of copper tubes, different replacements, poor adaptability, etc., and achieve the effect of adjustable structure and uniform distribution of force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

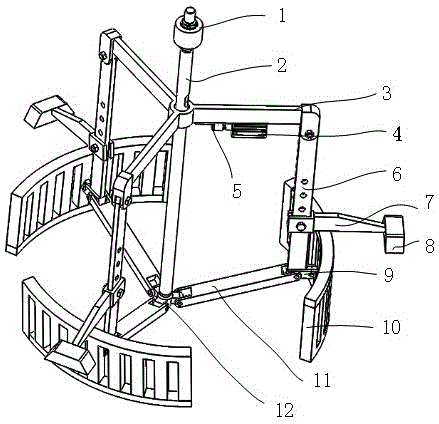

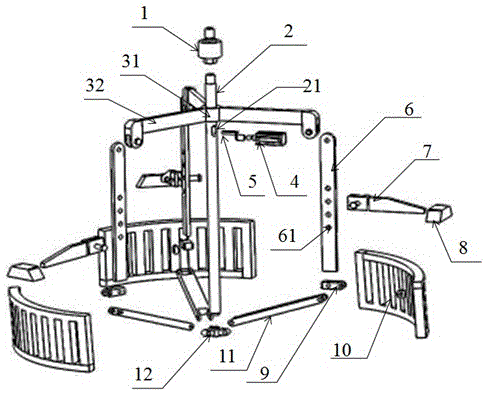

[0016] Embodiment: A kind of gripper of inner ring of copper pipe.

[0017] refer to figure 1 As shown, a copper pipe inner ring gripper includes a hanger 3, the hanger 3 includes a collar 31 located in the middle, and at least two fixed beams 32 connected to the outside of the collar; The pull rod 2 in the ring, the top of the pull rod 2 is provided with a floating joint 1 connected with the external drive mechanism; a locking mechanism for locking the collar 31 and the pull rod 2 together; a vertical beam 6 corresponding to the fixed beam 32 one-to-one , the top end of the vertical beam 6 is hinged to the outer end of the fixed beam 32, the vertical beam 6 is fixed with a support rod 7 extending outward, the outer end of the support rod 7 is fixed with a rubber handle 8, and the lower end of the vertical beam 6 A support plate 10 for pressing the inner wall of the copper pipe when grabbing the copper pipe is connected through the fixed rod 9; a connecting rod 11 correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com