Lattice structure and lattice part

A lattice structure and lattice technology, applied in the direction of building components, etc., can solve the problems of material waste, insufficient structural high specific stiffness, high specific strength, uneven force, etc., to improve reliability, specific strength and Greater specific stiffness and reduced stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

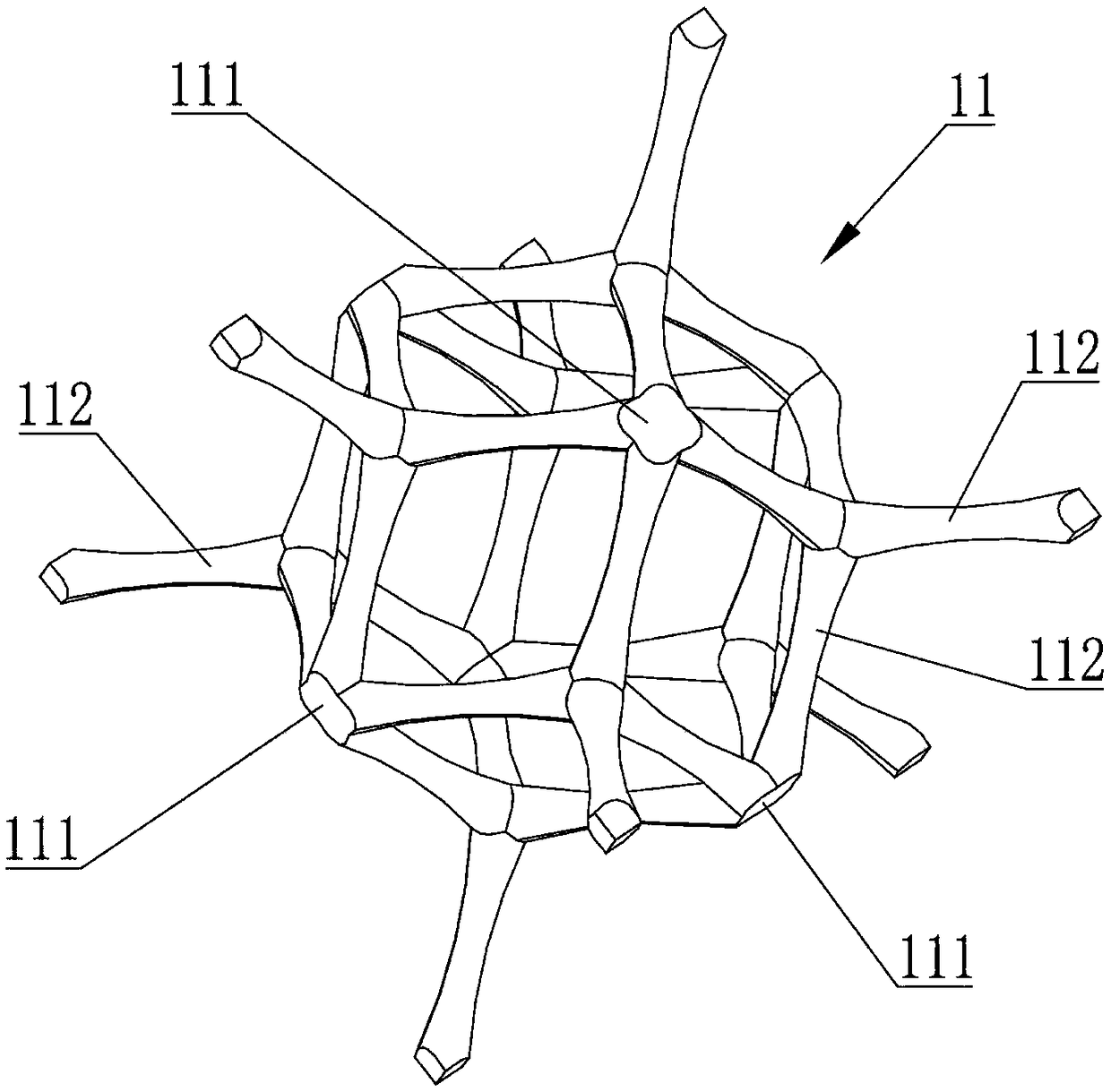

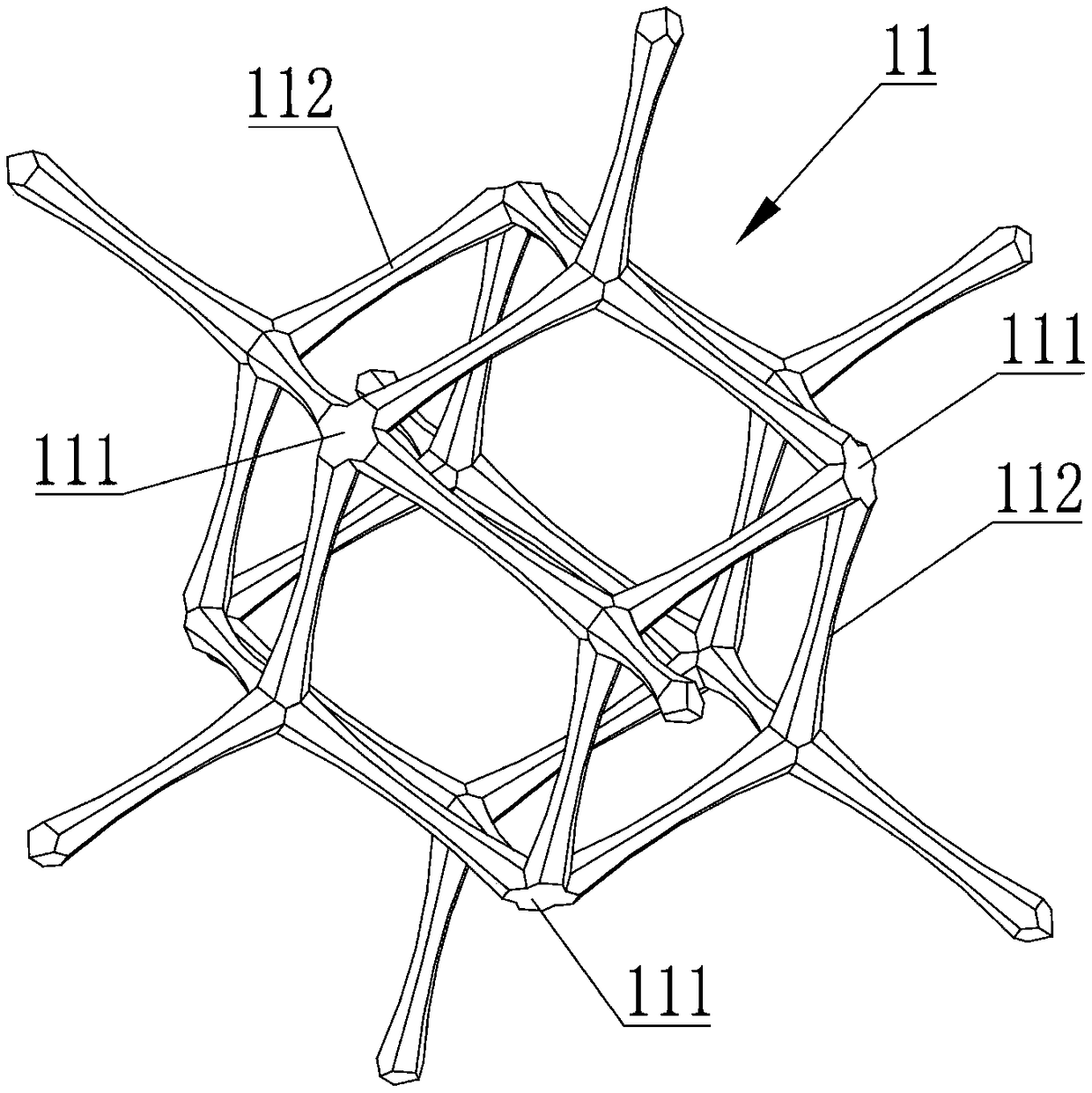

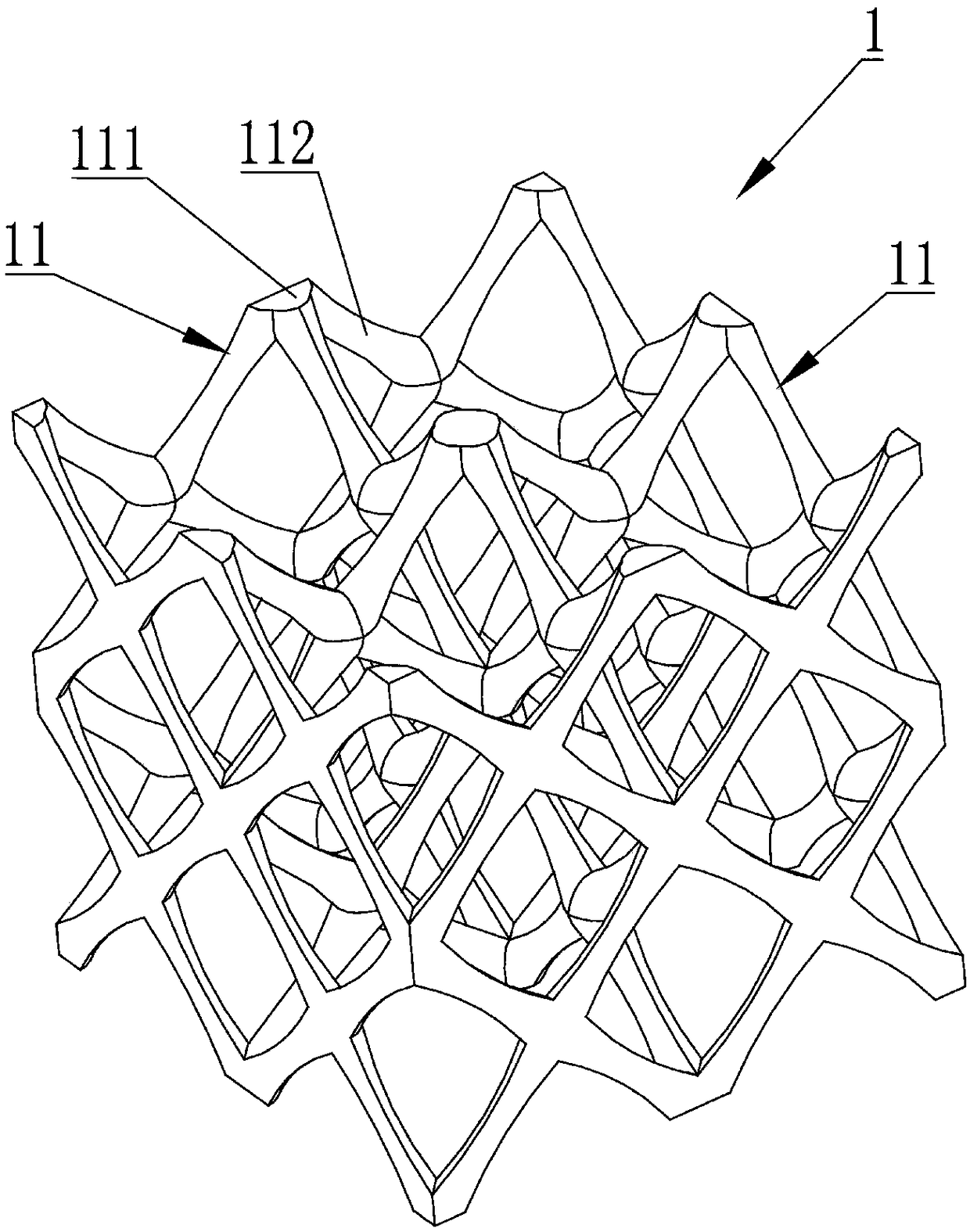

[0032] see Figure 1 to Figure 5 As shown, the lattice structure 1 provided by the embodiment of the present invention includes a plurality of lattice cells 11, and the plurality of lattice cells 11 are arranged in an array, and the array mentioned here refers to a plurality of lattice cells 11 are arranged according to certain rules, for example, by setting the number of rows, columns, and center point, the objects can be placed and arranged according to the needs. For example, in some implementations, one lattice cell 11 is used as the origin of the coordinate system, and other lattice cells 11 are arranged along the X, Y, and Z directions of the coordinate system to form a lattice structure. In some other embodiments, the lattice structure can be formed by arranging in one or two directions.

[0033] Wherein, each lattice cell 11 includes a plurality of variable-diameter connecting rods 112, and the variable-diameter side rods 112 are connected by nodes 111, that is, a cer...

Embodiment 2

[0050] The lattice structure in Embodiment 1 can be applied to many parts or material structures, for example, 3D printing fork parts, 3D printing dot matrix spherical surfaces, dot matrix interlayer materials, etc.

[0051] like Figure 9 It shows a kind of fork frame part including the lattice structure of the embodiment, the fork frame part of the fork frame part uses the lattice structure instead of the conventional structure, which reduces the weight of the fork frame, and can reduce the joints of the lattice structure nodes at the same time Stress concentration, greater specific strength and specific stiffness, improve the reliability of parts.

[0052] like Figure 10 It shows a spherical part with the lattice structure of the embodiment. The spherical part is a lattice structure as a whole instead of the conventional structure, so that the force distribution of the part can be more uniform, the stress concentration of the nodes can be reduced, and the specific strengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com