Method for mfg. sub light smooth type aluminium plastic compound band

An aluminum-plastic composite belt and a production method technology, applied in chemical instruments and methods, belts, synthetic resin layered products, etc., can solve the problems of high production cost, self-adhesion, water seepage, etc., and achieve low production cost and reduced production cost. , the effect of improving peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

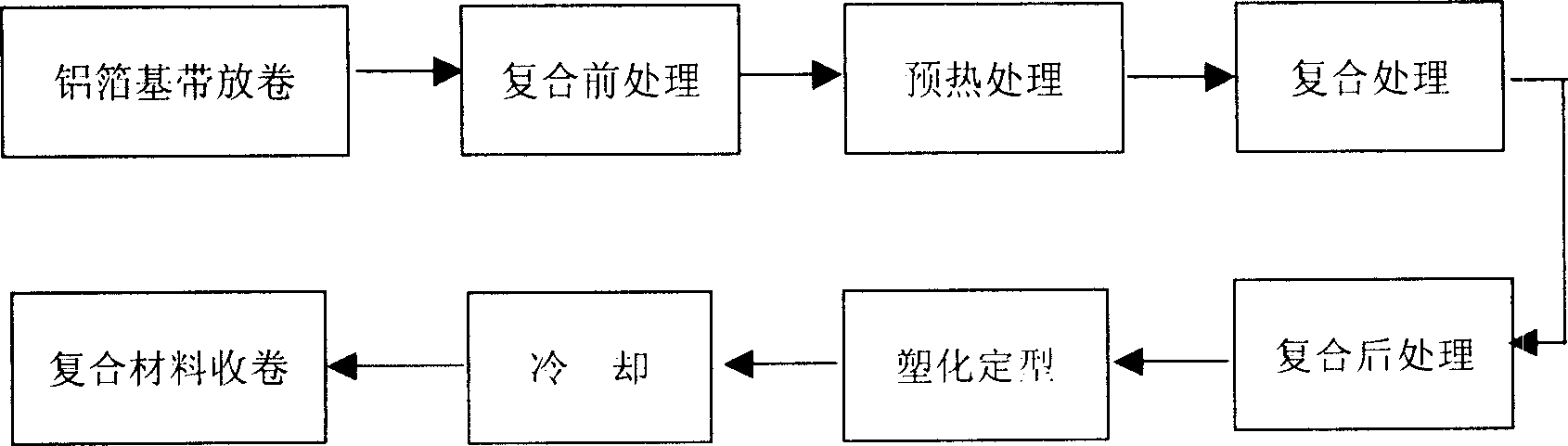

[0034] The manufacture process of the present invention is as follows:

[0035] 1. Select an aluminum foil with a thickness of 0.12mm±0.005mm as the aluminum base belt, according to figure 1 The process of tape casting coating composite pretreatment.

[0036] The process of composite pre-treatment is as follows: firstly, the aluminum base strip roll is opened, then the aluminum base strip L is flattened, and then preheated. The preheating of the base tape is carried out by an oil heating roller or an electric heating roller, and its temperature is 90-220°C;

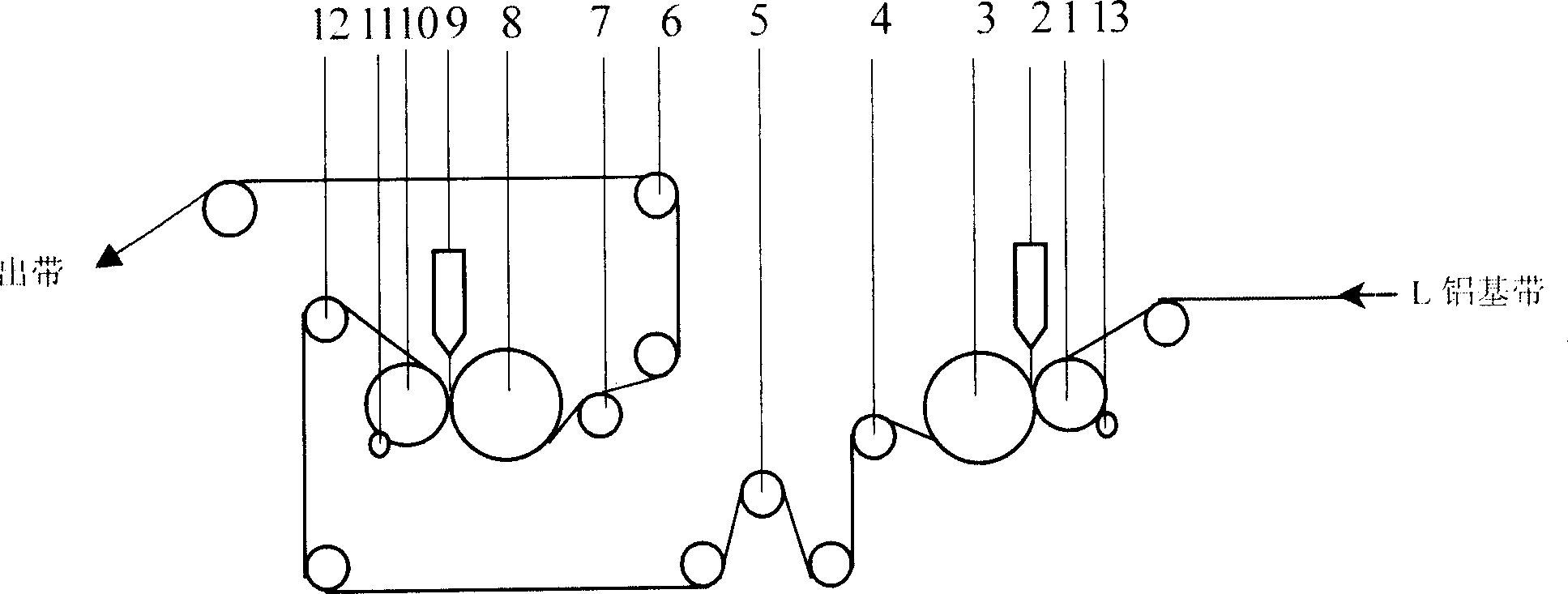

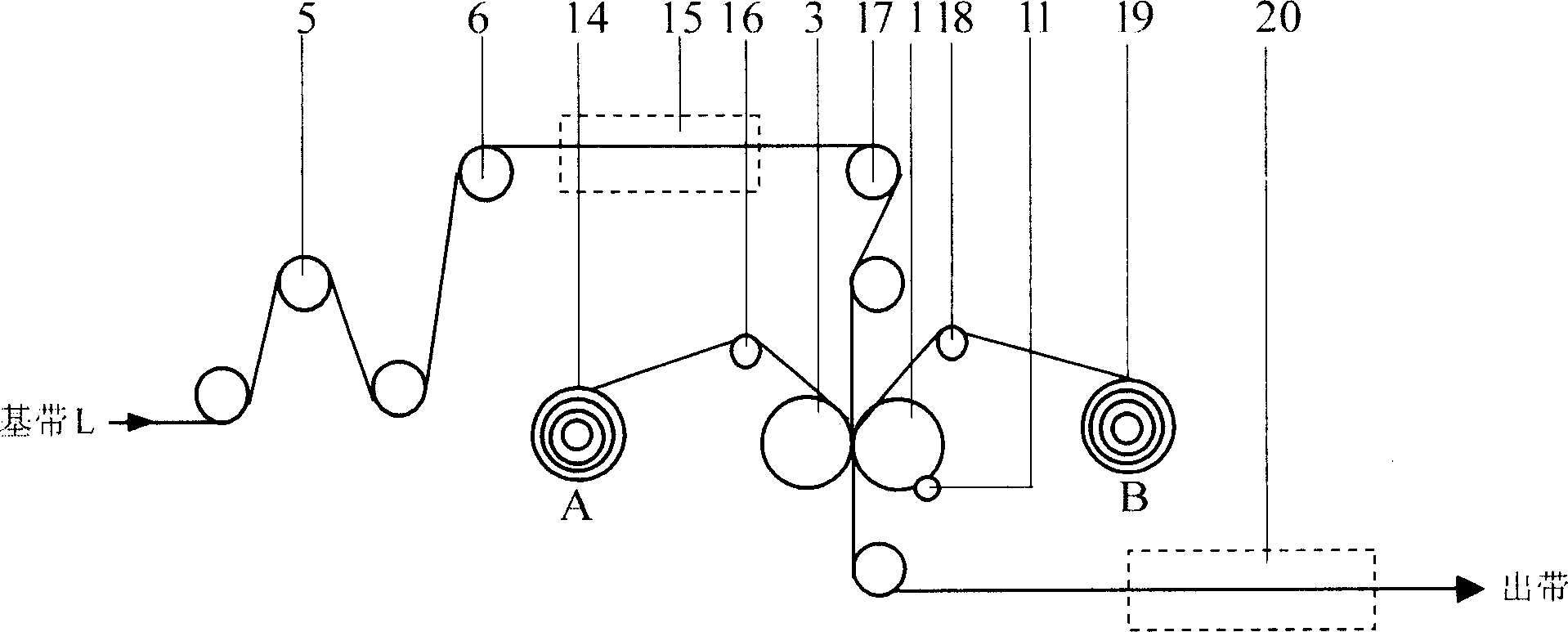

[0037] 2. Extrude and compound the aluminum base tape and the plastic with matte smoothness, refer to figure 2 , and its composite process is:

[0038] (1) The aluminum base strip L enters between the first composite pressure roller 1 and the first composite roller 3 .

[0039] The surface of the first composite rubber roller 1 is made of non-metallic material, made of fluoroplastics with a Shore hardness of 40-95, a...

Embodiment 2

[0050] Select aluminum foil with a thickness of 0.10±0.005mm as the aluminum base strip, and make the aluminum-plastic composite strip according to the process of Example 1, wherein:

[0051] The first compound pressing roller 1 adopts non-fluorine plastic roller, so Teflon tape must be pasted on both ends of the non-fluorine rubber roller to prevent the subsequent plastic melt from sticking to both ends of the rubber roller, so as to ensure the normal progress of subsequent rolling and heat sealing .

[0052] When rolling heat sealing, set the working surface temperature of the heat sealing area between the first compound pressure roller 1 and the first compound roller 3 to be 155-290°C, the pressure between the two rollers to be 0.12-1.3Mpa, and the plastic mold adopts 2 layers The co-extrusion mold adopts plastic grade: 0910 resin, whose melting temperature is 180-305°C, and can form 2 layers of plastic film on the A side of the aluminum base tape.

[0053] During the post...

Embodiment 3

[0055] Select the aluminum foil with a thickness of 0.08 ± 0.005mm as the aluminum base strip, and proceed according to the process of Example 1, wherein:

[0056] The first composite pressing roller 1 adopts a fluoroplastic roller.

[0057] When rolling heat sealing, set the working surface temperature of the heat sealing zone between the first composite pressure roller 1 and the first composite roller 3 to be 140-285°C, and the pressure between the two rollers to be 0.11-0.12Mpa.

[0058] The plastic mold adopts a 3-layer co-extrusion mold, the plastic is 30707 grade, and the melt temperature is 185-310°C, which can form a 3-layer plastic film on one side of the aluminum base tape.

[0059] During the post-heating treatment, the temperature of the tape surface is controlled between the Vicat softening point of the plastic and the melting point of the plastic, that is, 84-102°C, and finally a matte smooth aluminum-plastic composite tape with a base tape thickness of 0.08mm is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com