Patents

Literature

340results about How to "Fully bonded" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

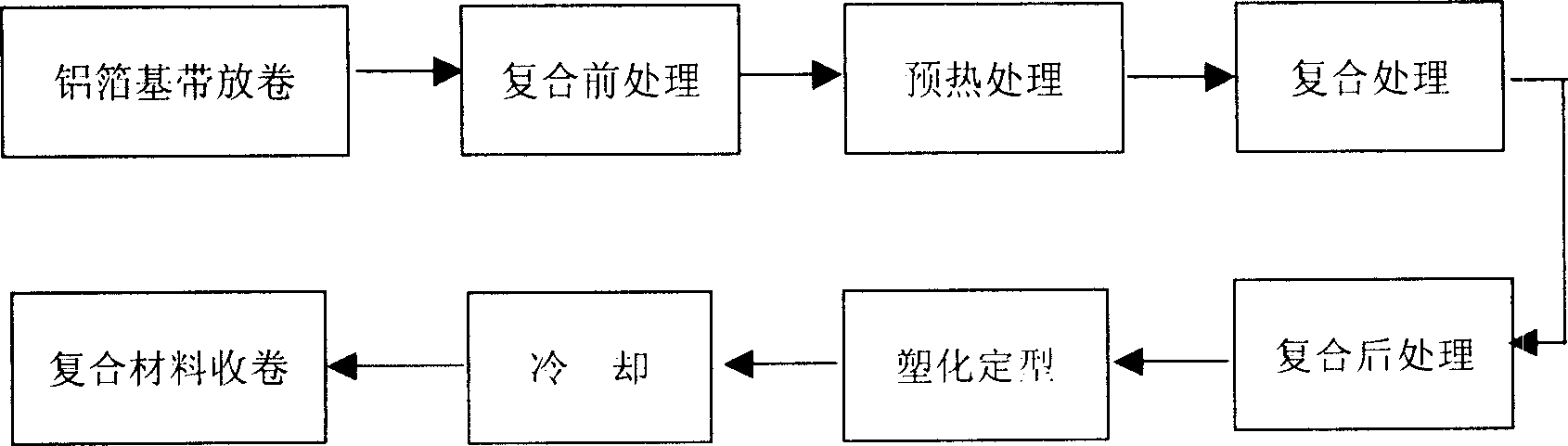

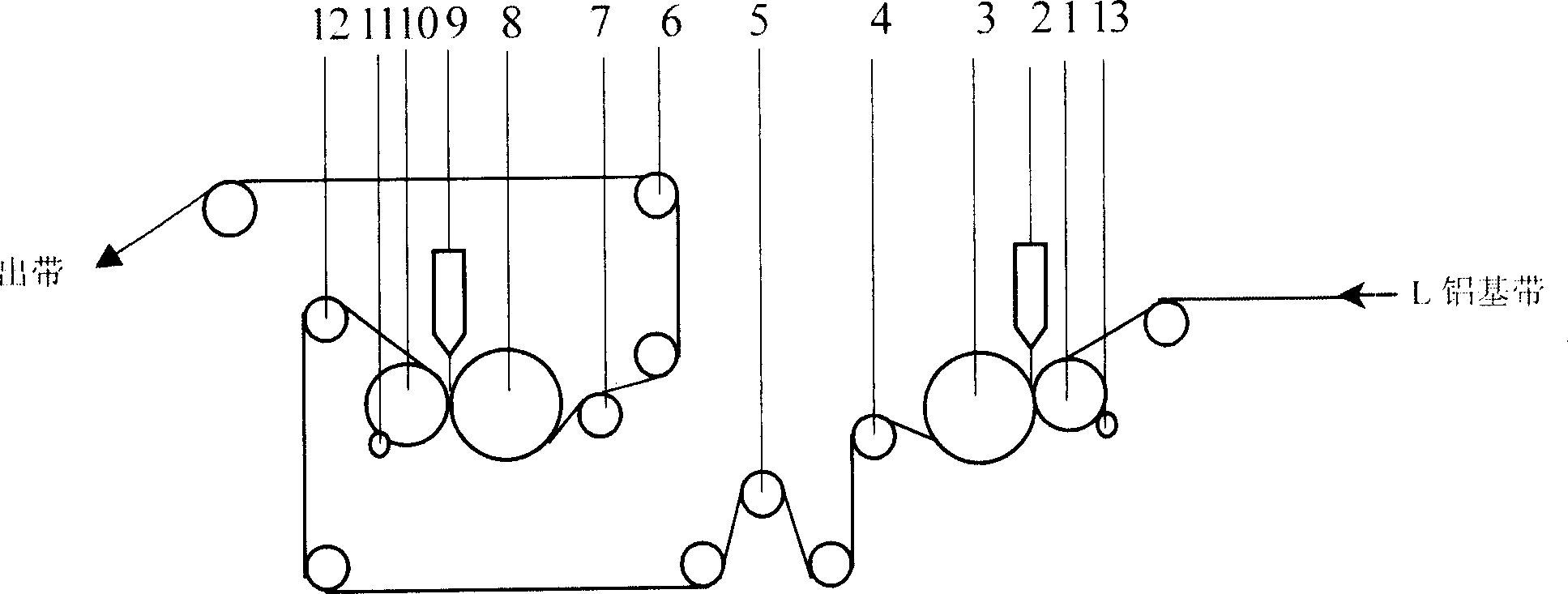

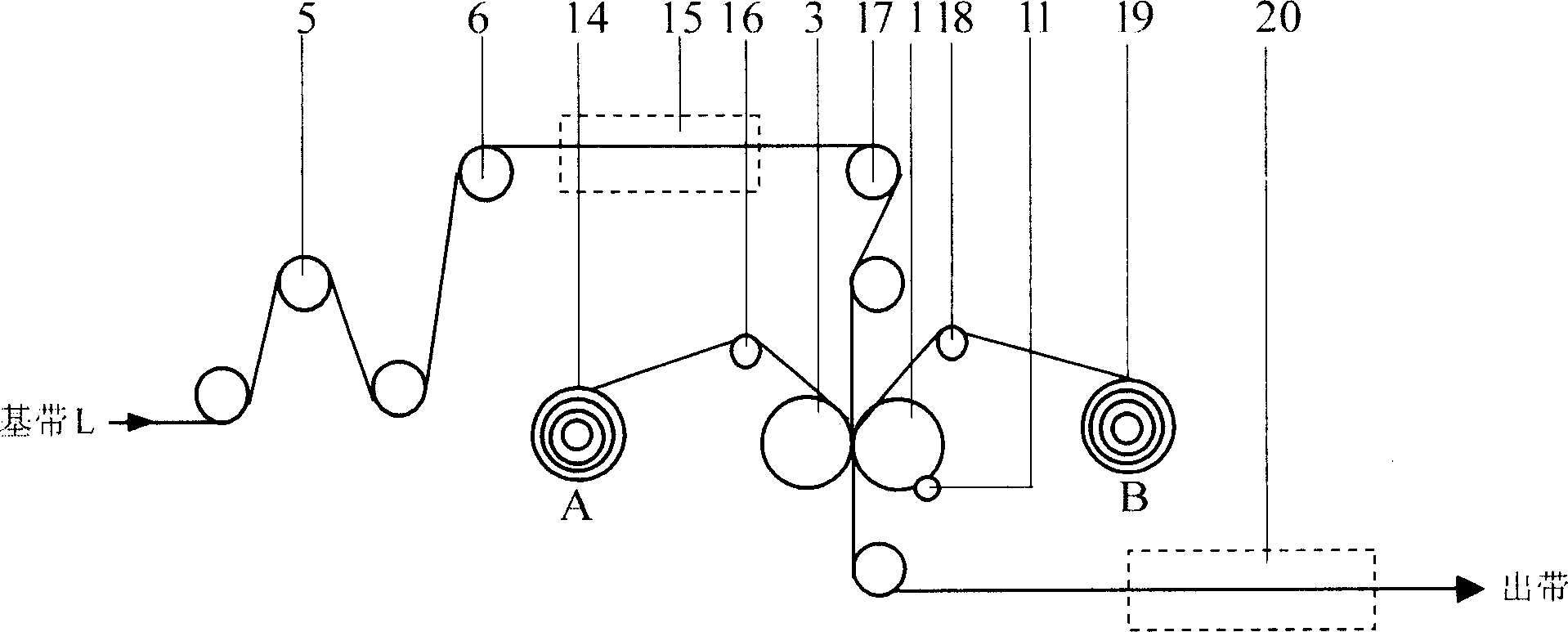

Method for mfg. sub light smooth type aluminium plastic compound band

ActiveCN1792605AReduce weightSave materialSynthetic resin layered productsBeltsPlastic filmAluminum foil

A process for preparing the dull and smooth aluminum-plastic band includes such steps as choosing an aluminum foil as basic band, pre-treating, extruding out at least one plastic film layer onto one or two surfaces of basic band, rolling while heating, and heat-treating by controlling the temp between Vicat softening point and fusion point for obtain dull and smooth surface. It can be used for optical cable or electric cable for high moisture tight effect.

Owner:上海网讯新材料科技股份有限公司

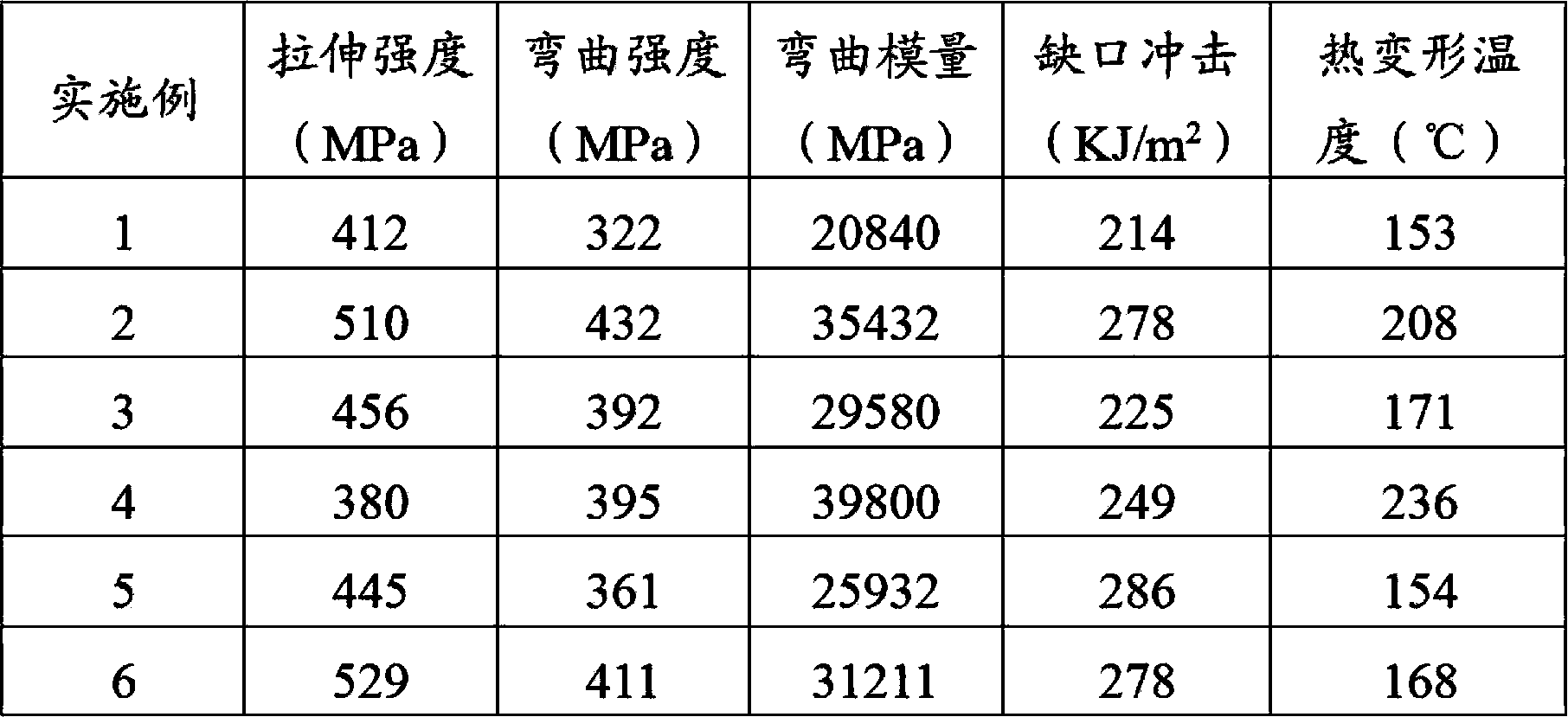

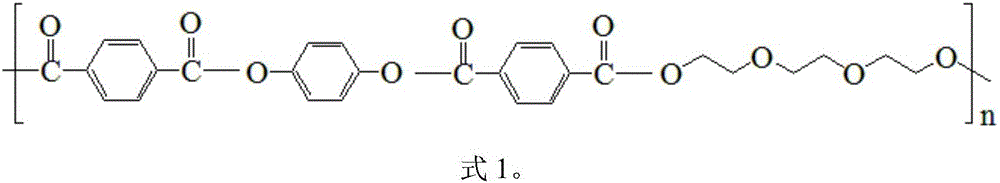

Ultra-high strength glass fiber reinforced thermoplastic resin composite plate and preparation method thereof

InactiveCN103571046AImprove mechanical propertiesImprove flame retardant performanceSynthetic resin layered productsLaminationGlass fiberAging resistance

The invention discloses an ultra-high strength glass fiber reinforced thermoplastic resin composite plate. The composite plate comprises the following components in parts by weight: 40-60 parts of thermoplastic resin, 40-60 parts of continuous ultra-high strength glass fiber and 0.2-0.5 parts of silane coupling agent. The invention further discloses a preparation method of the ultra-high strength glass fiber reinforced thermoplastic resin composite plate. The ultra-high strength glass fiber reinforced thermoplastic resin composite plate disclosed by the invention has the advantages of high mechanical properties, relatively good flame retardancy, aging resistance and high temperature resistance, excellent comprehensive performances, low price and relatively high performance-price ratio.

Owner:LIAONING LIAOJIE SCI & TECH

High-strength aramid paper and method for preparing same through dissolving and re-pressing self-reinforcing

ActiveCN106087529AFully contactedFully bondedNon-fibrous pulp additionMechanical paper treatmentProcess equipmentAramid

The invention discloses a high-strength aramid paper and a method for preparing the same through dissolving and re-pressing self-reinforcing. The method comprises the following steps: subjecting polyphenylene sulfide fiber to pretreatment, then mixing the pretreated polyphenylene sulfide fiber, aramid fiber and aramid pulp, subjecting dried raw paper to dipping and then pressing treated sample paper; soaking the treated sample paper in a washing solution and removing an organic solvent and inorganic salt left in the paper; and pressing the treated sample paper. When the high-strength aramid paper has gram weight of 10 to 200 g / m<2>, the aramid paper has a thickness of 20 to 400 [mu]m, tensile strength of 10 to 150 KN / m and dielectric strength of 30 to 70 kV / mm. According to the invention, aramid paper and polyphenylene sulfide are used as raw materials; the method is environment friendly and low in cost; the prepared paper has high strength and good evenness; and industrial production can be realized through partial reconstruction of conventional paper machines.

Owner:SOUTH CHINA UNIV OF TECH

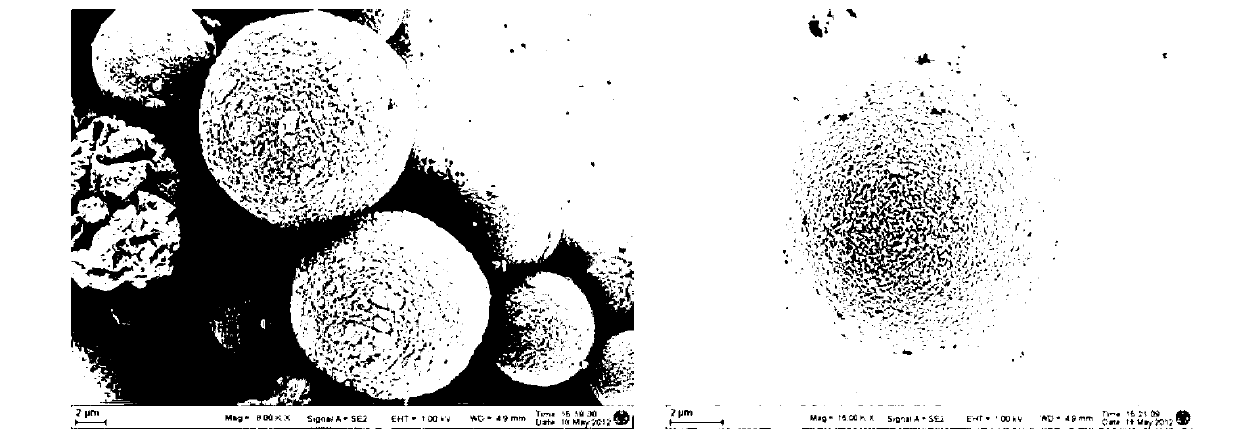

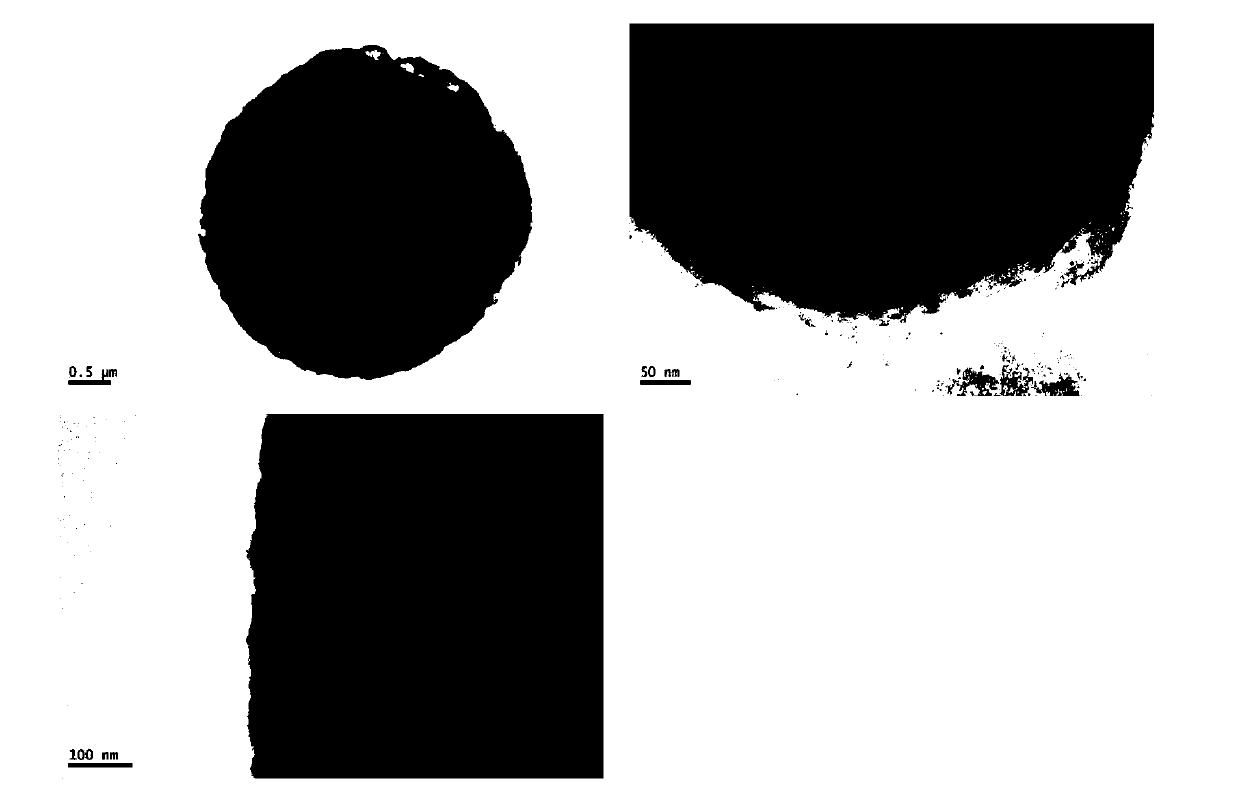

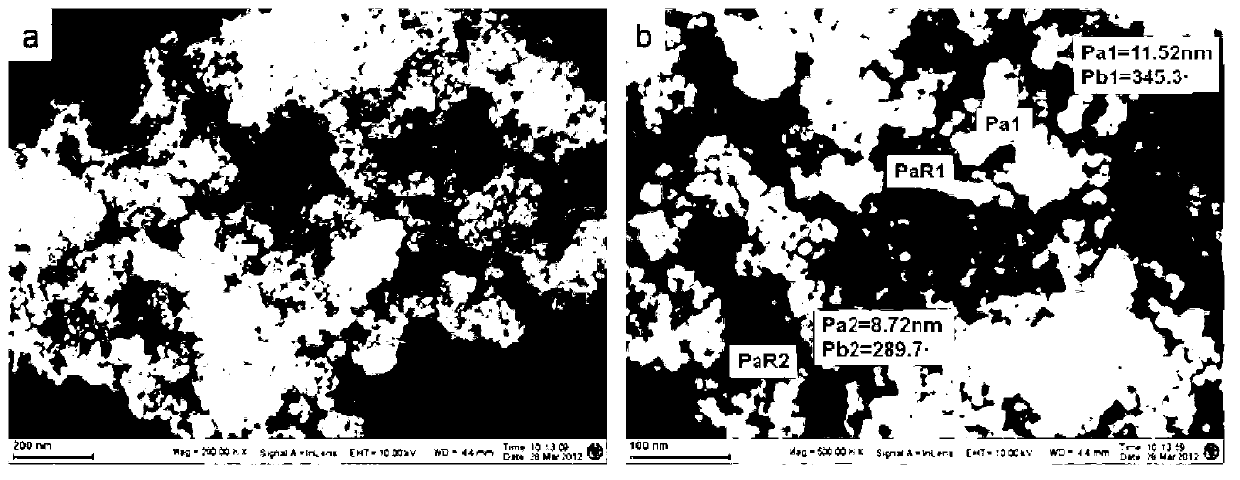

Preparation method of porous magnetic polystyrene microspheres

ActiveCN102964539AEasy to shapeEvenly distributedOrganic/organic-metallic materials magnetismCross-linkBenzoyl peroxide

The invention discloses a preparation method of porous magnetic polystyrene microspheres. The method comprises steps of: (1) adding dry Fe3O4 magnetic nanoparticles into an aqueous ethanol solution, treating with ultrasonic, adding vinyltriethoxysilane, transferring into a reactor together, stirring under a constant temperature and a nitrogen atmosphere for aging, and then washing, drying under vacuum and grinding the obtained product into powder; (2) mixing the powder obtained in the step (1) and benzoyl peroxide, and then adding into styrene containing a pore forming agent and a cross-linking agent for the ultrasonic treating; (3) dissolving polyvinylpyrrolidone and sodium dodecyl sulfate into water by using the ultrasonic; and (4) adding the liquid obtained in the step (2) into the liquid obtained in the step (3), treating with the ultrasonic, pouring the obtained mixture into a reactor, heating for condensation reflux to obtain a suspension liquid, separating with magnet, washing with ethanol, re-separating with the magnet, re-washing with pure water, drying under vacuum and grinding to obtain claybank powdery product, extracting with a soxhlet way, and drying under vacuum to obtain the finish product.

Owner:NANJING FORESTRY UNIV

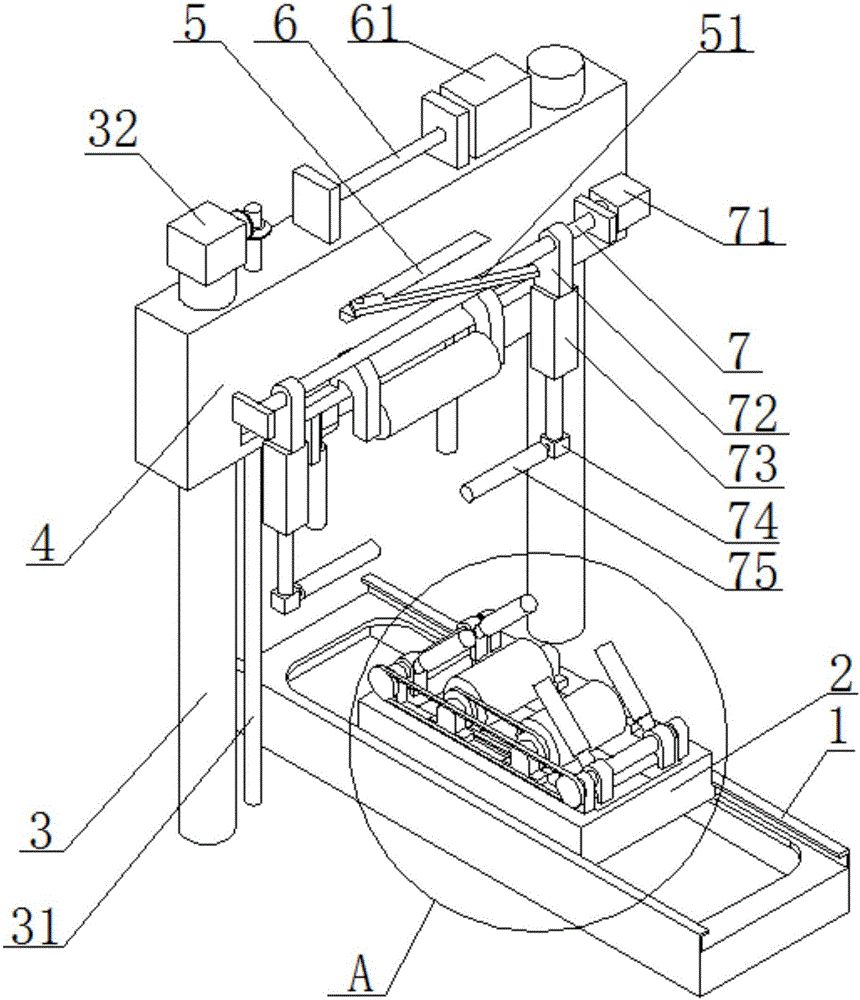

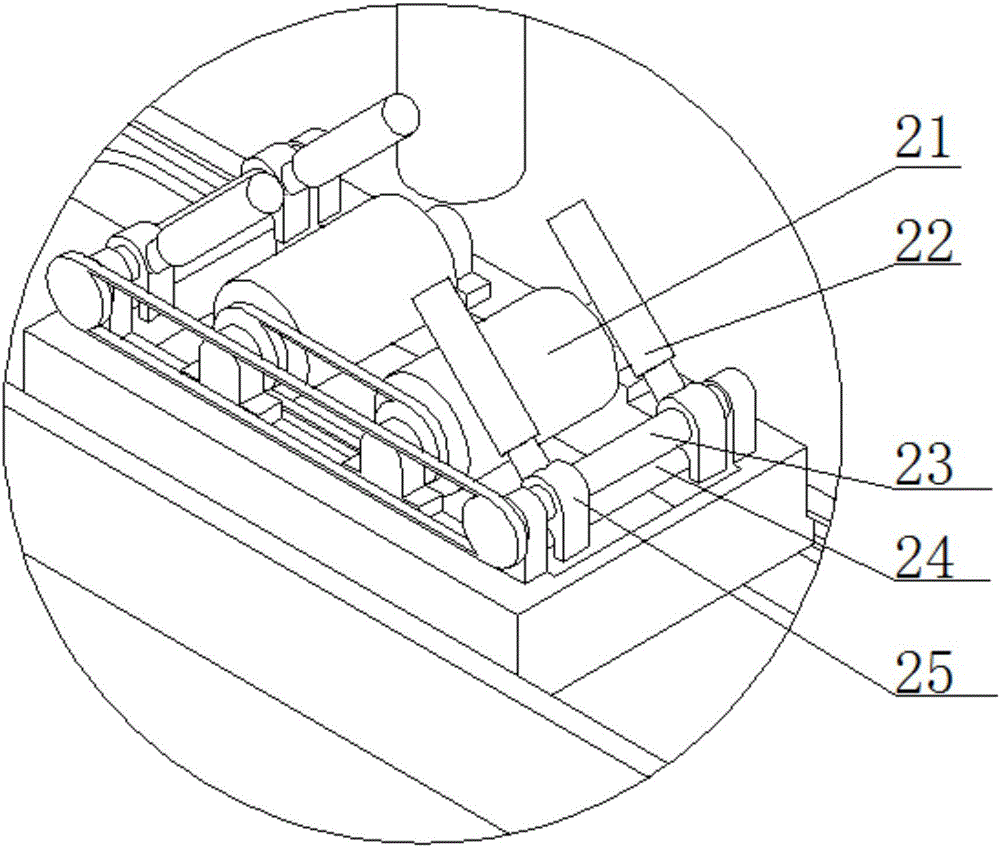

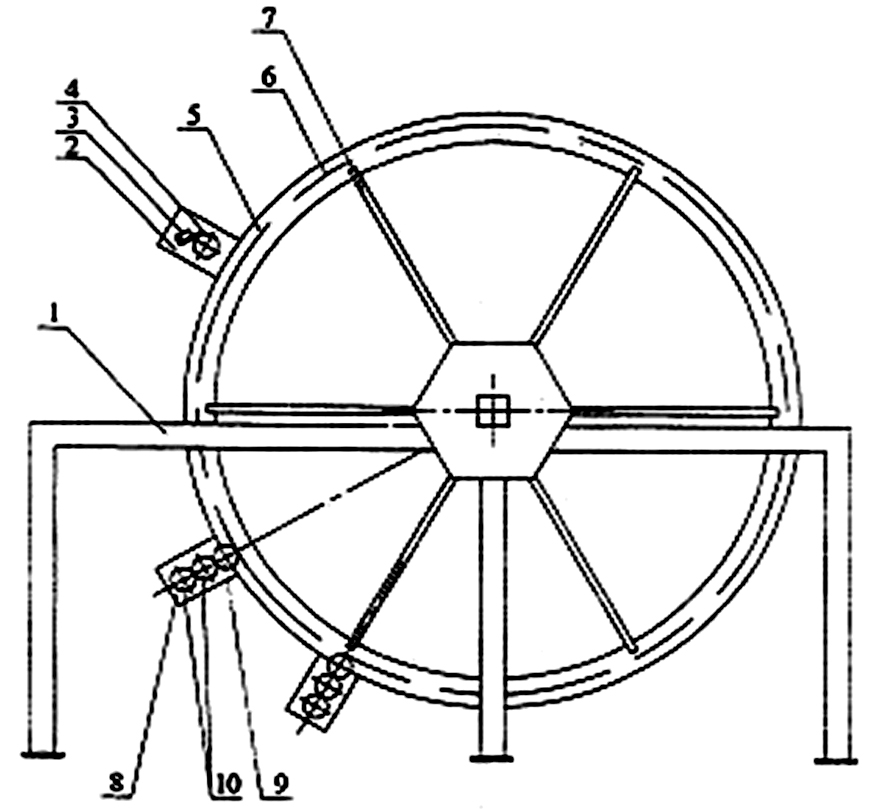

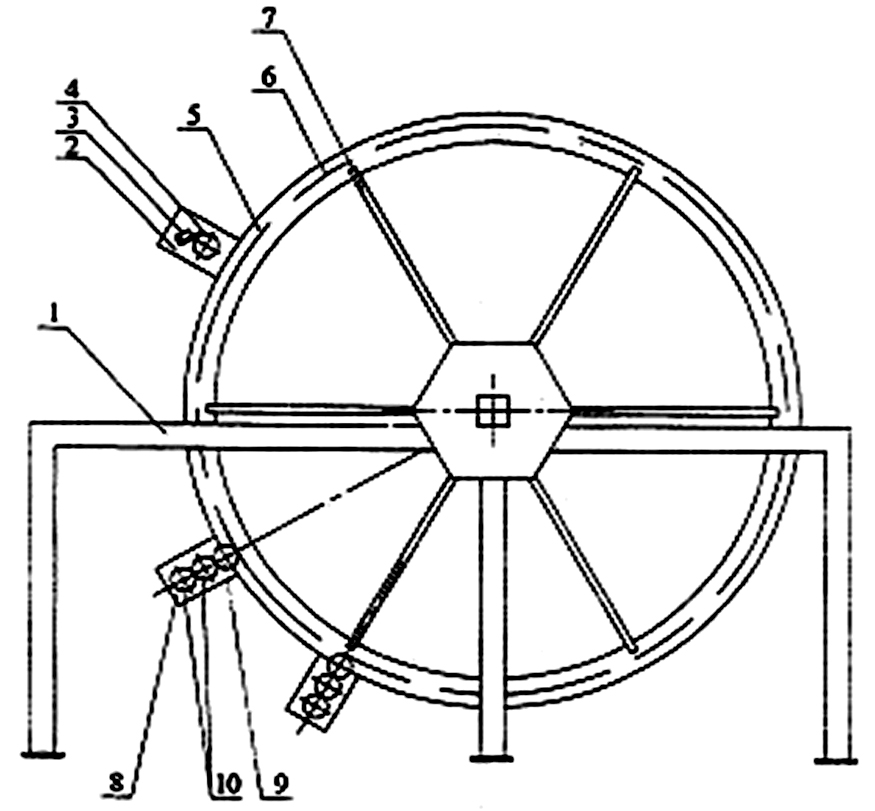

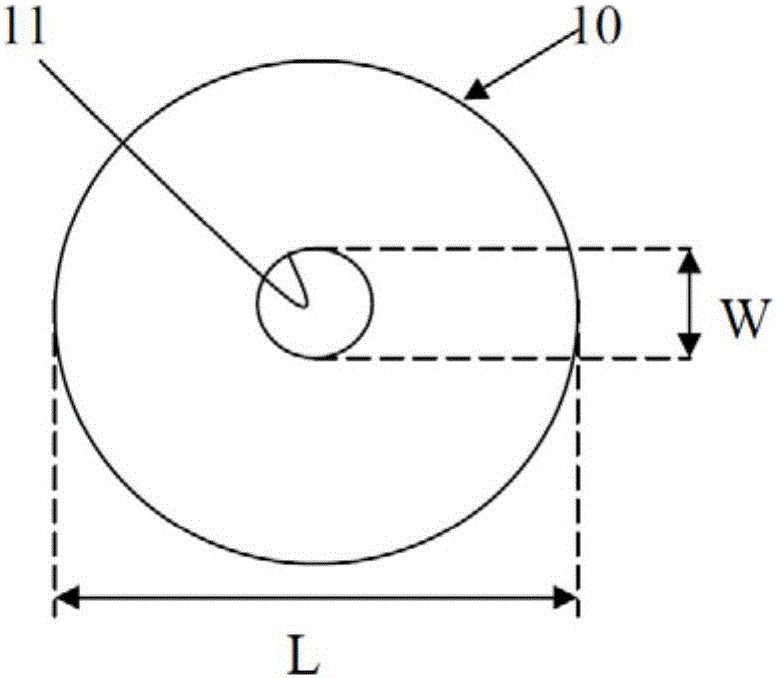

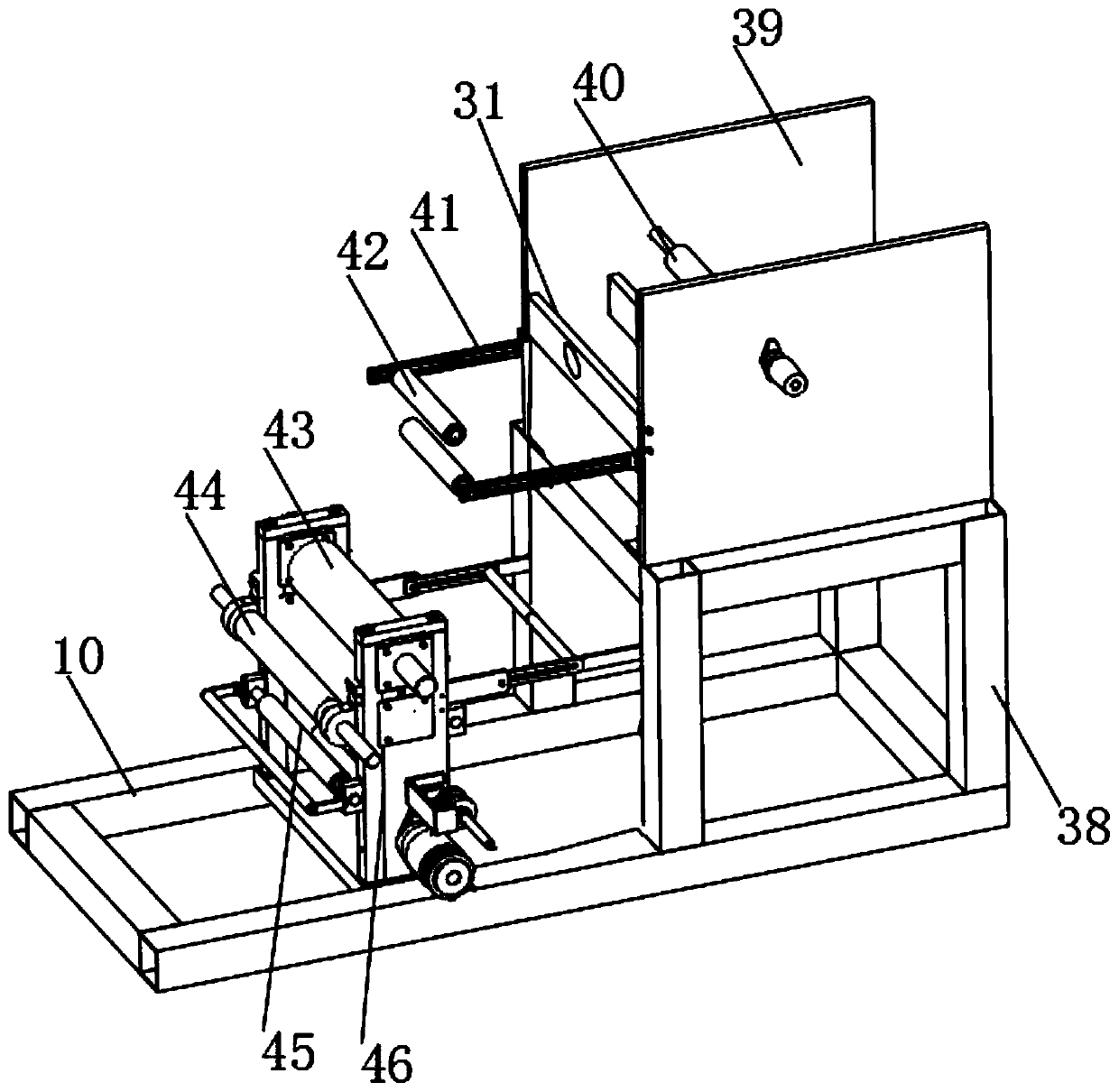

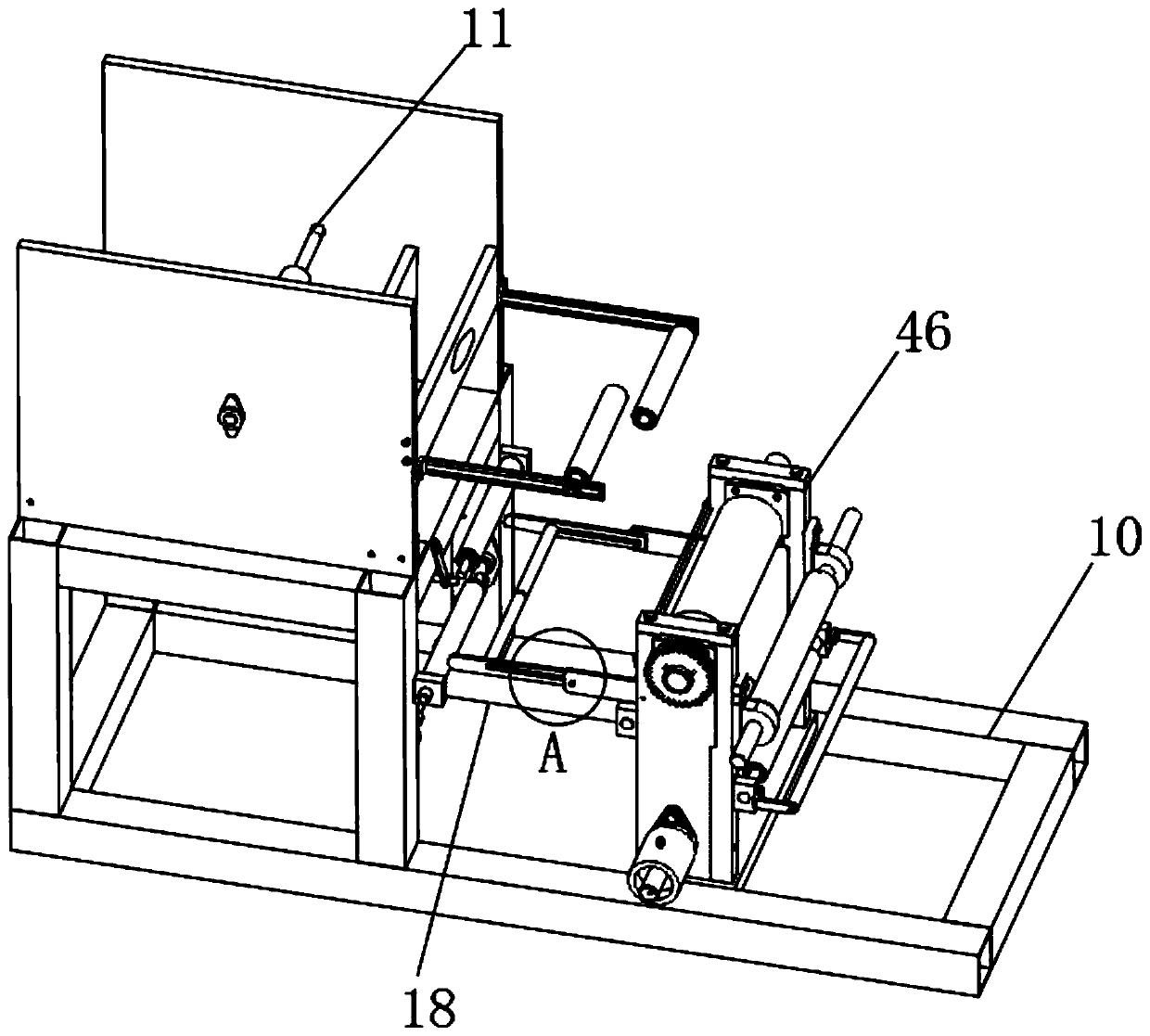

Automatic steel roll packaging device

InactiveCN106064679ASimple structureEasy to use and maintainWrapping with article rotationElectric machineryEngineering

The invention provides an automatic steel roll packaging device which comprises a material transporting trolley, a lifting mechanism, a side pressing unit and a core penetrating pressing unit. The upper end of the material transporting trolley is rotationally connected with two material rotating rollers. Rolling shafts of the two material rotating rollers are in chain transmission. The roller shaft of one material rotating roller is in chain transmission with a motor shaft of a motor. The lifting mechanism is rotationally connected with a paper pressing roller. The two ends of the paper pressing roller are rotationally connected with paper pressing frames. The longitudinal section of each paper pressing frame is in a shape like the Arabic number '7', and the end portion of each paper pressing frame is fixedly connected to the front wall of the lifting mechanism. The side pressing unit comprises side pressing rollers which are in left-right symmetry about the center line of the lifting mechanism, and the axial direction of the side pressing rollers is the vertical direction. The core penetrating pressing unit comprises two core penetrating pressing rollers which are in left-right symmetry about the center line of the lifting mechanism, and the two core penetrating rollers reciprocate at the same time in the vertical direction. According to the automatic steel roll packaging device, it is ensured that a packaging material can be attached to the outer circular side wall, the two end portions and the inner circular side wall of a roll completely; and packaging materials are saved, the packaging time is also shortened, and the working efficiency is improved.

Owner:天津松洋金属制品有限公司

Transparent double-sided adhesive sheet, laminate obtained using same for constituting image display device, process for producing said laminate, and image display device obtained using said laminate

ActiveCN104937059AGood dimensional stabilityHigh deformation sensitivityAdhesive processesAdhesive articlesMeth-High humidity

The present invention provides a new transparent double-sided adhesive sheet which, when used in such a manner that a member which is a component of an image display device and in which the surface to be laminated has a difference in level is applied through the transparent double-sided adhesive sheet, can conform to the difference in level to completely fill the gap. Furthermore, the strain that arises inside the adhesive sheet can be mitigated, and the adhesive sheet can be made to retain non-foaming properties in high-temperature or high-humidity environments, without impairing the handleability. This adhesive sheet is a B-stage transparent double-sided adhesive sheet which is characterized firstly by comprising one or more (meth)acrylic ester (co)polymers, an ultraviolet polymerization initiator (A) which has a molar extinction coefficient, measured at a wavelength of 365 nm, of 10 or greater and a molar extinction coefficient, measured at a wavelength of 405 nm, of 0.1 or less, and a visible-light polymerization initiator (B) which has a molar extinction coefficient, measured at a wavelength of 405 nm, of 10 or greater, and is characterized secondly in that the value obtained by dividing the dynamic storage modulus (E') as measured by a tensile method at 60°C by the dynamic storage modulus (G') as measured by a shear method at 60°C, E' / G', is 10 or greater.

Owner:MITSUBISHI CHEM CORP

Production technology of soft and hard layer sound insulating pad of automobile

ActiveCN102423945AImprove sound insulationFully bondedSynthetic resin layered productsLaminationSoft layerFiber

The invention relates to a production technology of a soft and hard layer sound insulating pad of an automobile, belonging to the technical field of automobile interior component manufacture. The sound insulating pad is hot-formed for one time by letting a soft layer fibrofelt, a film and a hard layer fibrofelt be subject to steam heating, wherein, the steps of the method comprise paving the raw materials, carrying out hot forming, molding through adsorption, and cutting with water. The technology reduces production procedures, greatly increases production efficiency, can well control the thicknesses of the soft layer and hard layer. According to the invention, steam has strong penetrating force and good effect of heat transfer, thus the film is completely molten, and the soft and hard layers are bonded firmly. The prepared sound insulating pad of the automobile has good sound insulation performance, and can well satisfy the using requirements of clients.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

Insulating system of external wall and its construction technology

InactiveCN1334389AHigh masonry strengthShorten drying timeWallsClimate change adaptationAdhesiveEngineering

An insulating system for external wall and its construction technology are disclosed. The system features that unique cement mate, insulating adhesive, alkali-resistant glass reinforced grid, special cutting tools, grinding tools and toothed plastering tool are used. Its advantages are high quality, short construction period, low cost and saving energy by more than 50%.

Owner:LIMEISHUN PAINT RESIN DALIAN

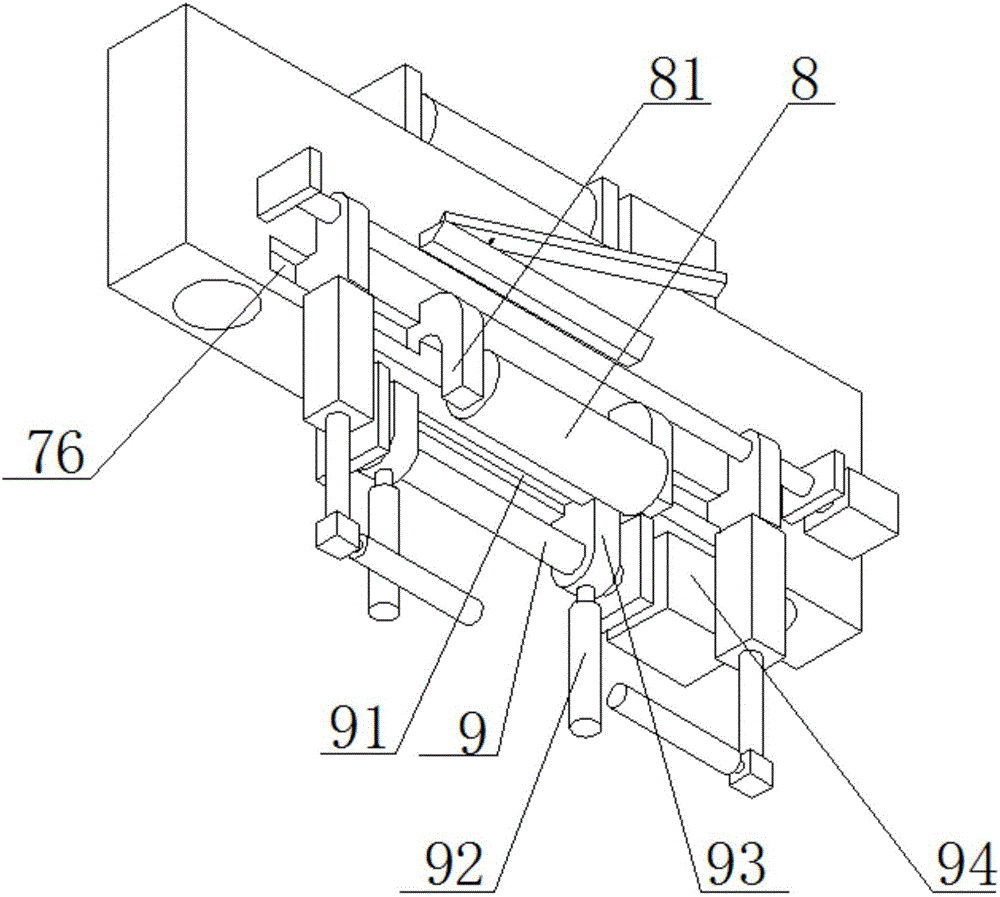

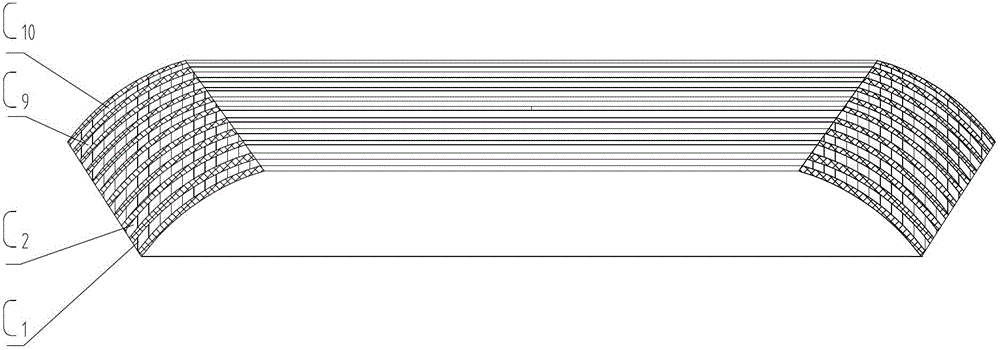

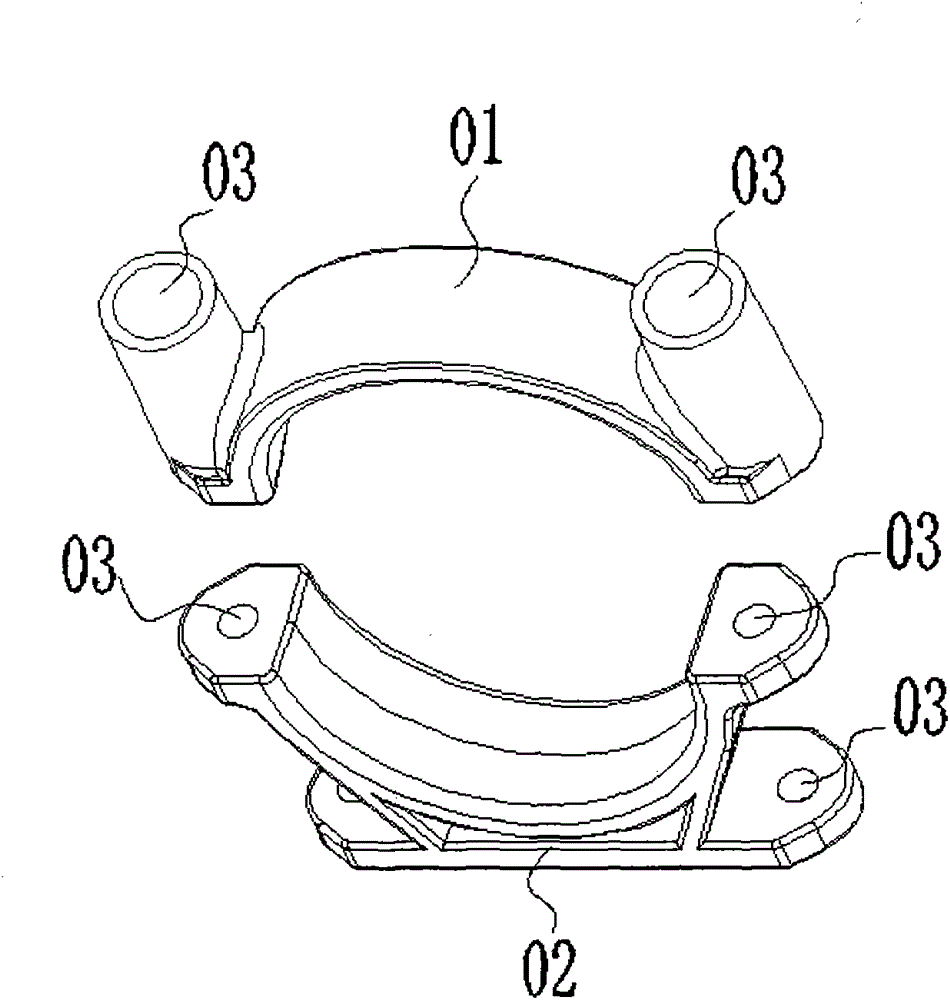

Flexible connector assembly for flexible spraying pipe of solid rocket engine and manufacture method thereof

The invention discloses a flexible connector assembly for a flexible spraying pipe of a solid rocket engine and a manufacture method thereof. The flexible connector assembly comprises a front flange body and a back flange body which are connected through an elastic piece group and a reinforcing piece group. The elastic piece group is formed by n+1 layers of homocentric sphere annular elastic slices which are matched. The reinforcing piece group is formed by n layers of homocentric sphere annular rigid slices, and n is a natural number. The n+1 layers of homocentric sphere annular elastic slices and the n layers of homocentric sphere annular rigid slices are of an interactive interval bonding structure and are subjected to heat vulcanization bonding with the back flange body to form a heat bonding composite body. The heat bonding composite body and the front flange body are bonded through a cold adhesive to form a sphere homocentric connection body. The flexible connector assembly is high in bonding force, good in sealing performance, simple in manufacture method and operation, good in usability and low in cost.

Owner:湖北三江航天江北机械工程有限公司

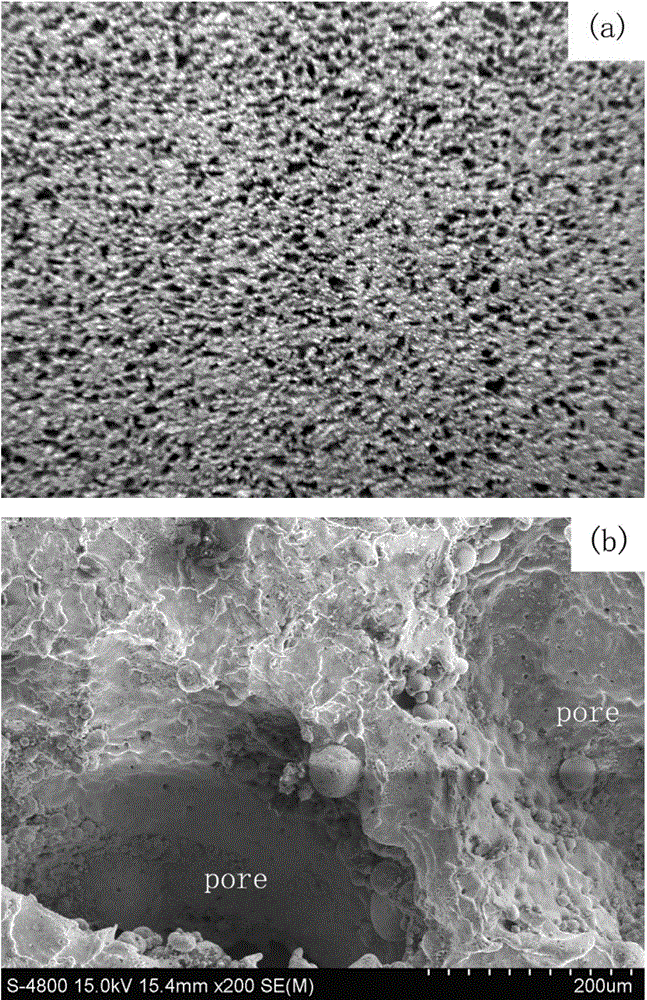

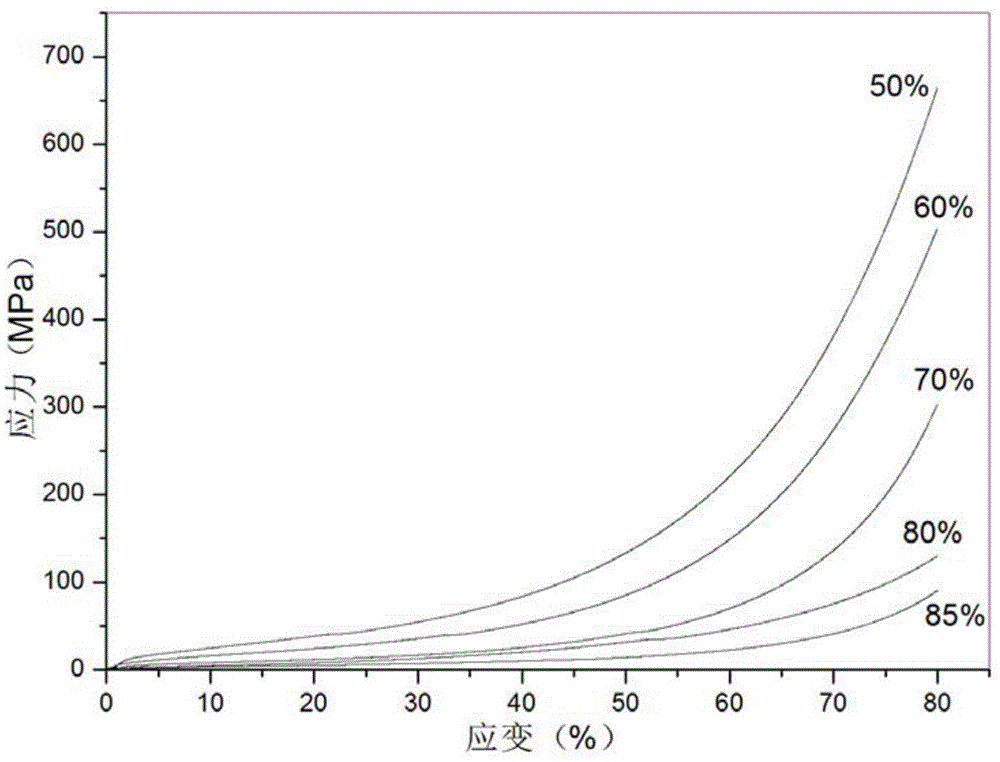

Preparation method of pore-opening foamy copper having controllable porosity and pore diameter

The invention discloses a preparation method of pore-opening foamy copper having controllable porosity and pore diameter. The method comprises the steps: adopting a powder metallurgy method, mixing uniformly rock candy particles with an electrolytic copper powder and an additive anhydrous ethanol, then pressing to obtain a green blank, placing the green blank in boiling water, rinsing to thoroughly dissolve and remove the rock candy particles, after washing and drying, placing the obtained article in an inert gas atmosphere for sintering, cooling together with a furnace to the room temperature, and thus obtaining the pore-opening foamy copper product constructed by a three-dimensional interconnected space network and having the porosity of 50-85% and the average pore diameter of 0.2-2 mm. The obtained pore-opening foamy copper has higher sintering quality, and has quite good mechanical properties and compressive energy absorption characteristic.

Owner:HEBEI UNIV OF TECH

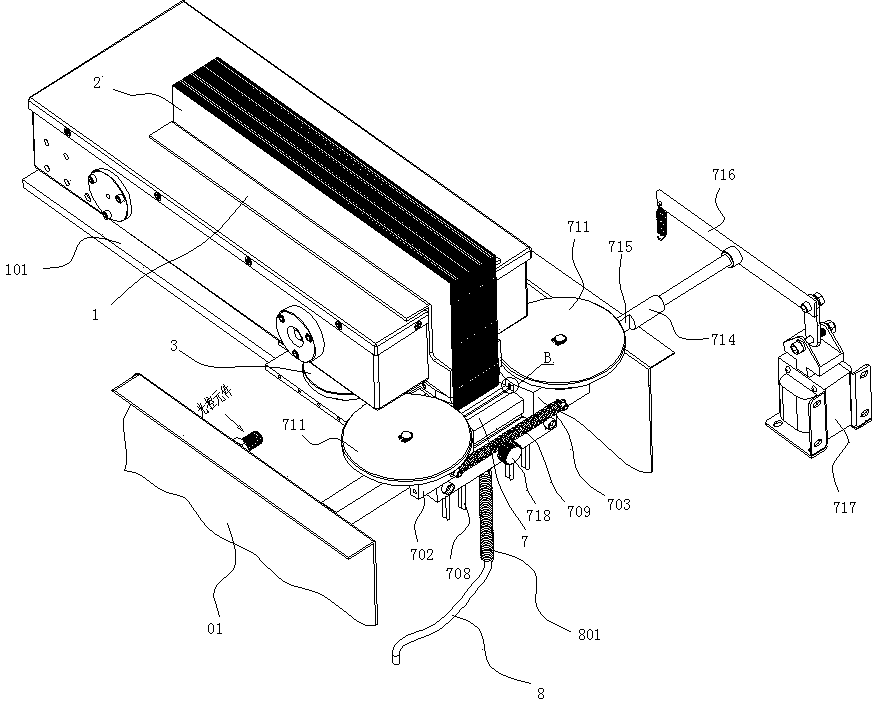

Glue-spray type wireless glue binding machine

ActiveCN102815110BAdhesion does not decreaseGood adhesionBook making processesBookbinding adhesiveFiberMilling cutter

The invention discloses a glue-spray type wireless glue binding machine, comprising a rack, a page fold clamping mechanism, a milling cutter mechanism, a gluing mechanism, a cover installing mechanism, and a control device, wherein the gluing mechanism comprises a spray nozzle, a glue tank, and a heating component, a linear spray slit is arranged on the top of the spray nozzle, the linear spray slit is communicated with a glue outlet at the bottom of the glue tank through a glue solution control valve and a glue transmission tube sequentially, the linear spray slit is provided with a left spray nozzle slide block and a right spray nozzle slide block which are close to each other by virtue of the pulling of a reset spring, in the form of being capable of sliding to the left and the right, and guide wheels are arranged on the tops of both of the left spray nozzle slide block and the right spray nozzle slide block. According to the glue-spray type wireless glue binding machine disclosed by the invention, the melted glue water is sprayed to page fold sides, and the glue solution is adequately bonded with paper fibres, so that the binding performance is good and the glue binding quality is high; moreover, the defects of repeated heating and using of the glue solution are overcome, pollution is avoided, glue binding for complete books or texts is ensured, and the phenomena of page missing, book back cracking and the like are prevented; and the two adjacent pages can be flatly spread with 180 degrees, thus facilitating reading, copying or scanning, which is another revolution for wireless glue binding for books or texts.

Owner:浙江大祥办公设备有限公司

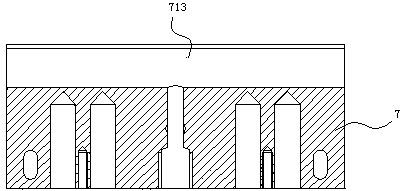

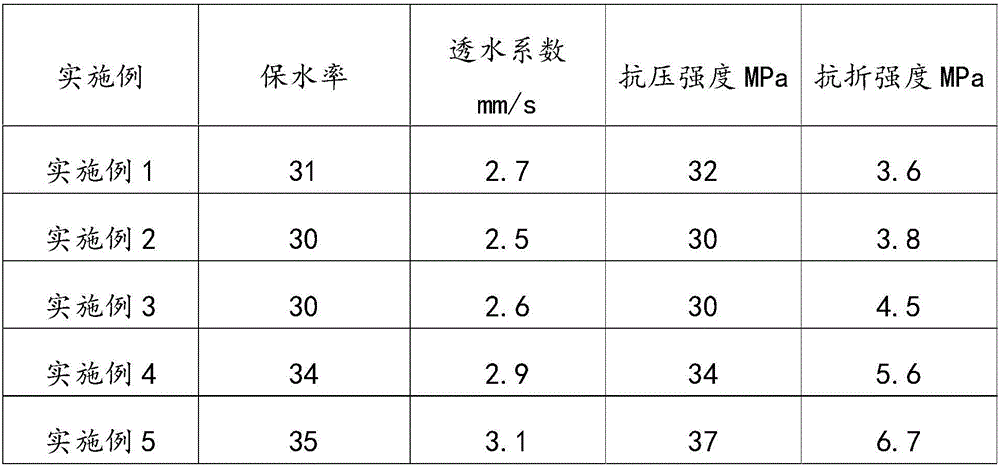

Water-retention and water-permeable brick and preparation method thereof

ActiveCN105924057ALow costHigh compressive strengthSolid waste managementBreaking strengthEcological environment

The invention provides a water-retention and water-permeable brick and a preparation method thereof. The water-retention and water-permeable brick is prepared by adopting a specific amount of cement, a stone stock, a gelling agent, a coloring dispersant and water. The water-retention and water-permeable brick has the advantages of low cost, high compression strength, high breaking strength, water-retention and water-permeable functions and the like, wherein the stone stock can be selected from waste exploited stones, so that not only can comprehensive utilization of the waste stones be realized but also the ecological environment is cleaned, and particularly the problem of dust raising caused by deposition of a large amount of stone chips is solved. The preparation method of the water-retention and water-permeable brick is simple in process, does not need kilning, has a significant energy conservation and emission reduction effect, has a low manufacturing cost and significant social and economic benefits, is reasonable in process design, is simple and convenient in manufacturing, generates no secondary pollution, and is suitable for large-scale production.

Owner:深圳无为彩石环保新材料有限公司

Glaze-coated sand method of electrified railway contact net rod-shaped porcelain insulator

ActiveCN102254655AImprove mechanical propertiesFully bondedQuartz/glass/vitreous enamelsGranularityControl line

The invention discloses a glaze-coated sand method of an electrified railway contact net rod-shaped porcelain insulator. The method comprises the following steps of: firstly, manufacturing porcelain sand with required granularity, then coating glaze, naturally shade drying the glaze-coated porcelain sand and sieving the sand with a sieve set, wherein the sand in the sieve set is the qualified glaze-coated sand; and uniformly coating a layer of bonding agent in a sanding control line on a glaze-coated blank, and uniformly spreading the glaze-coated sand, wherein sand lacking or sand stacking is required to be avoided. The method has the advantages that: by the method, the mechanical property of porcelain surface and cemented parts is greatly improved; bending resistance and tensile strength of the product are enhanced; the sand, the glaze and the porcelain blank are fully bonded, and the sand grains are difficult to be stripped from the porcelain blank; and the sands of the sintered product are fixedly bonded on the porcelain blank by the molten glaze layer, and a dead corner problem is avoided.

Owner:JIANGSU SOUTH PORCELAIN INSULATOR CO LTD

Toughened epoxy-resin-based glass fiber composite material and preparation method thereof

ActiveCN106476365AGood dispersionEvenly dispersedLamination ancillary operationsSynthetic resin layered productsGlass fiberEpoxy

The invention provides a toughened epoxy-resin-based glass fiber composite material and a preparation method thereof, wherein the composite material comprises at least one composite material unit, each composite material unit comprises an epoxy resin substrate layer and a glass fiber cloth laying layer, the glass fiber cloth laying layer is laid on the epoxy resin substrate layer, the epoxy resin substrate layer comprises the following components by mass: 40 to 90 parts of epoxy resin, 20 to 80 parts of a curing agent and 1 to 25 parts of a toughening agent; and the toughening agent is one or more substance of a liquid crystal material, nano silica and TPU. According to the number of the composite material units containing in the composite material to be prepared by the method, the epoxy resin substrate layer and glass fiber are alternately coated or laid to prepare the toughened epoxy-resin-based glass fiber composite material. Compared with the prior pure epoxy resin based glass fiber composite material, the impact strength of the toughened epoxy-resin-based glass fiber composite material is increased by 17% to 35%, and the tensile strength is not reduced.

Owner:广东丙辛新材料有限公司

Production technology for manufacturing soft layer sound insulation pad and hard layer sound insulation pad by utilizing high-temperature steam

InactiveCN103317811AStrong penetrating powerImprove sound insulationLaminationLamination apparatusTemperature controlWater vapor

The invention relates to a production technology for manufacturing a soft layer sound insulation pad and hard layer sound insulation pad by utilizing high-temperature steam. The production technology comprises the following steps of: a raw material paving step, a compression forming step, a cooling customization step and a water cutter cutting step, wherein the temperature of an upper module is controlled at 140 DEG C-160 DEG C in compression forming, the temperature of a lower module is controlled at 160 DEG C-180 DEG C, and mould closing is carried out for compression forming; after the mould closing is carried out for 10-20 seconds, the upper module is vacuumized, the vacuumizing time is controlled within 10-20 seconds, and after the vacuumizing of the upper module is finished, water vapor the temperature is introduced into the upper module so as to carry out heating forming on a material, wherein the temperature of the water vapor is 140-180 DEG C and the pressure of the water vapor is 9-11MPa, the water vapor is discharged through the lower module, and the introducing time of the water vapor is controlled within 15-20 seconds, according to the production technology provided by the invention, high-temperature and high-pressure water vapor is adopted, the water vapor penetrating power is high, the heat transfer effect is good, a film is fully melted, soft and hard layers are firmly cohered, the soft layer sound insulation pad and the hard layer sound insulation pad manufactured by the technology provided by the invention have good sound insulation property.

Owner:WUXI GISSING AUTO PARTS CO LTD

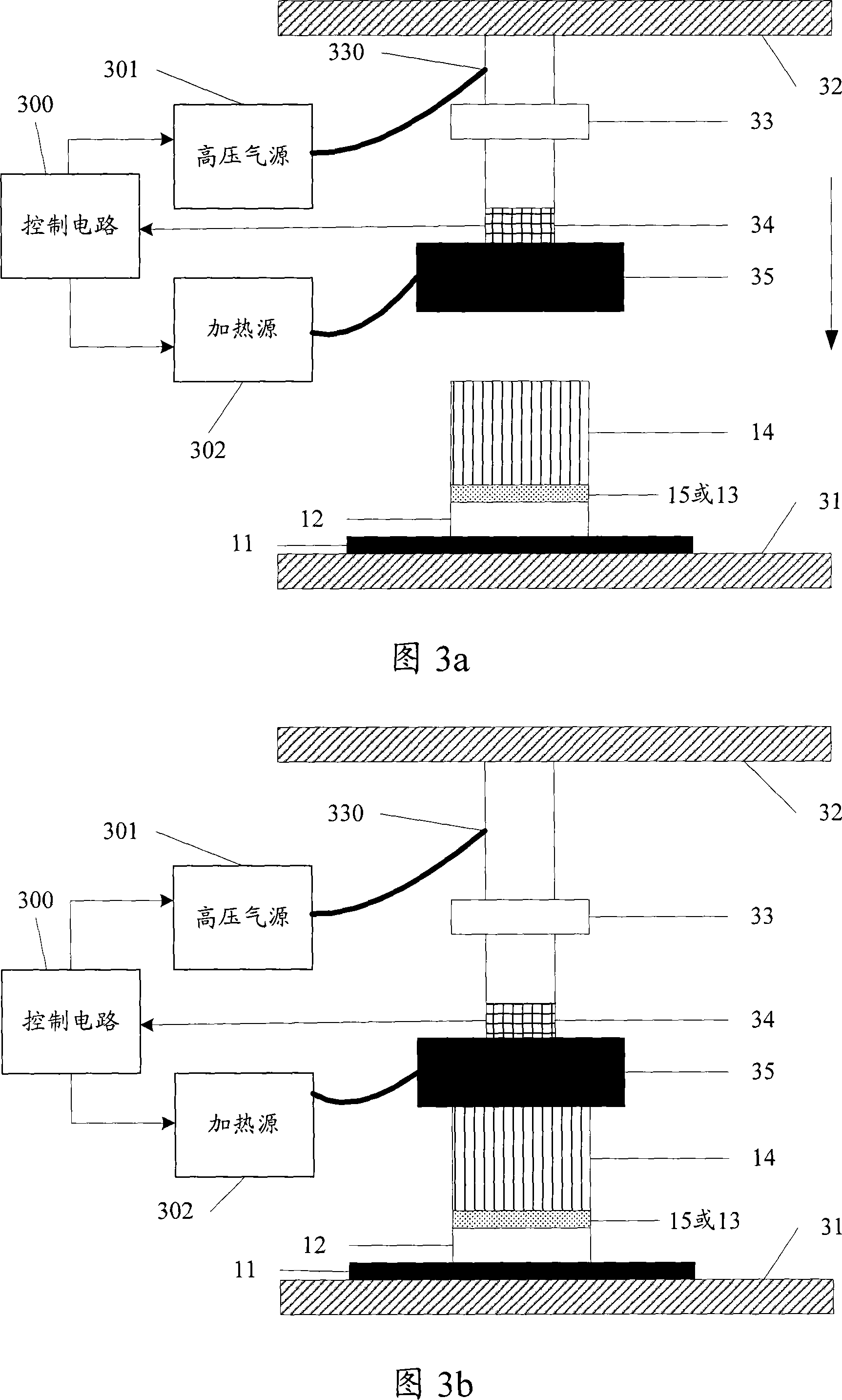

Pressure mounting device and pressure mounting method

InactiveCN101026953AImprove installation efficiencyImprove practicalityElectrical componentsAutomatic controlClosed loop

No need of manpower to take part in, the invention raises installing efficiency, and reduces possibility of physical damaging chip and heat sink. Under automatic control, movement-feeding structure (MFS) drives press set table (PST) to implement press installation. Being installed between MFS and PST, pressure sensor is capable of feeding magnitude of press in current installation procedure in real time so as to realize closed loop control for MFS as well as to raise precision of press, and guarantee reliability of press installation. Magnitude of press is dependent on displacement of PST driven by MFS and not by size of pressing block. Thus, lots of pressing block is not needed so as to save installation space and cost. Moreover, it is not possible to occur that pressing block with large weight is unable to be placed in limited space between chips so as to cause instance of installing failure. The invention increases practicability and generality of press installation.

Owner:NEW H3C TECH CO LTD

Novel cable bracket hoop and preparation method thereof

InactiveCN104419157AImprove flame retardant performanceNo eddy currentPipe supportsGlass fiberEngineering

The invention relates to the technical field of cable burying, and particularly provides a novel cable bracket hoop and a preparation method thereof. The novel cable bracket hoop is a molded part of an even SMC composite material; a reserved inserting hole is formed in the novel cable bracket hoop; the novel cable bracket hoop is connected with a cable bracket upright post through a bolt made of the SMC composite material; and the SMC composite material comprises the following components in percentage by mass: 18%-22% of unsaturated polyester resin, 8%-10% of a low-shrinkage additive, 45%-50% of a flame-retardant filler, 18%-20% of glass fiber and 3%-4% of other additives. The preparation method comprises the following steps: firstly preparing resin paste in preparation; and adding the glass fiber, stirring, heating, pressurizing and molding. The novel cable bracket hoop disclosed by the invention is energy-saving, environmentally-friendly, long in service life, good in flame retardant property, free of eddy, good in safety performance.

Owner:重庆杰友电气材料有限公司

Technique for fabricating Nano self-cleaning glass

This invention discloses a process for manufacturing self-cleaning glass. The method comprises: (1) pretreating the glass; (2) spraying TiO2 nanosol onto the glass surface; (3) heating and curing; (4) photocuring. The method can utilize the present production line of special glasses to manufacture the self-cleaning glass, and does not need large-scale equipment or factory buildings. The method can realize the manufacture of the self-cleaning glass and the toughening of the glass by introducing TiO2 nanosol spraying and photocuring process, and has such advantages as high efficiency.

Owner:蒋建新

Process for making permeable concrete by building rubbish recycled aggregate

The invention discloses a process for making permeable concrete by building rubbish recycled aggregates, and relates to the technical field of building rubbish regeneration. The process includes the steps: 1) uniformly mixing water and the recycled aggregates to obtain wetting materials of the recycled aggregates; 2) mixing the wetting materials of the recycled aggregates, cement and addition agents to obtain wrapping materials wrapped with the cement and the addition agents; 3) mixing the wrapping materials wrapped with the cement and the addition agents, the cement and water to obtain the permeable concrete made of the building rubbish recycled aggregates. By the aid of a method of aggregate wrapped with mortar, namely, raw materials are added in batches and uniformly mixed, residual raw materials or parts of raw materials are then added, the surfaces of the recycled aggregates can be uniformly wrapped with cement slurry, the aggregates can be sufficiently adhered, and the strength and the permeable rate of the permeable concrete are improved.

Owner:JIANGSU TIANYING ENVIRONMENTAL PROTECTION ENERGY COMPLETE EQUIP CO LTD

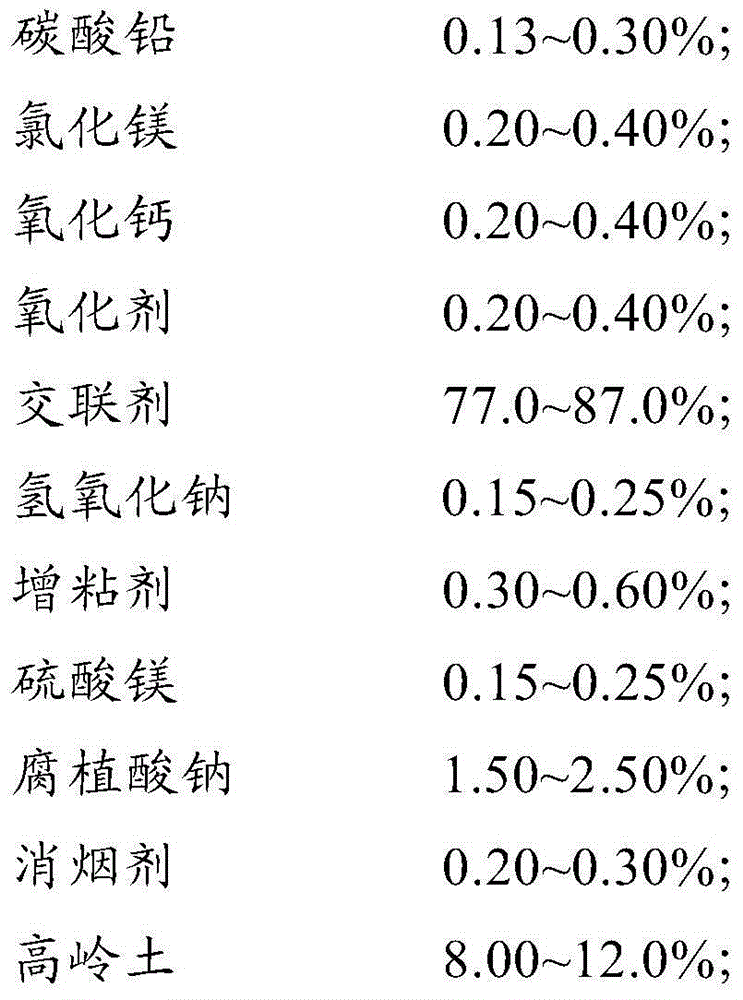

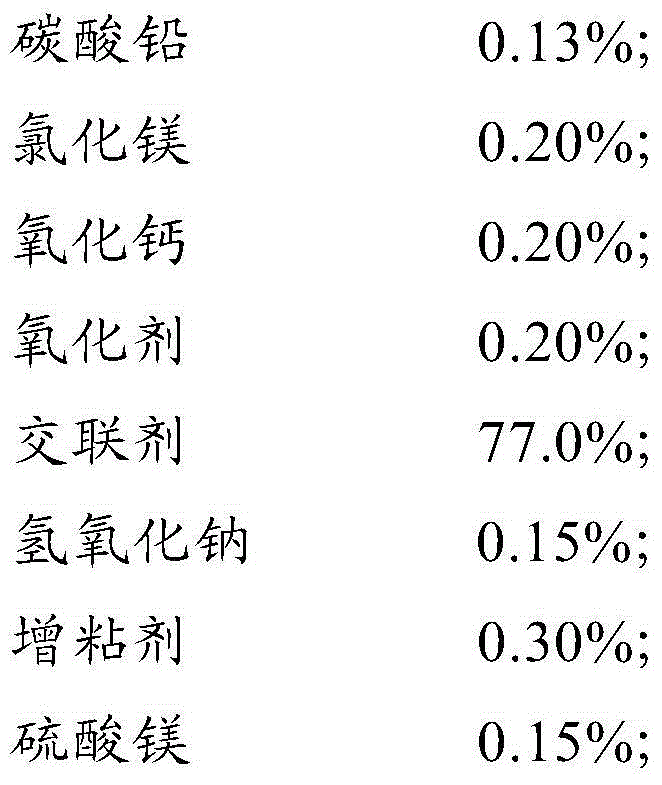

Cleaning briquette coal binder

The invention discloses a cleaning briquette coal binder. The binder comprises the following raw materials: 0.13-0.30% of lead carbonate, 0.20-0.40% of magnesium chloride, 0.20-0.40% of calcium oxide, 0.20-0.40% of an oxidizing agent, 77.0-87.0% of a crosslinking agent, 0.15%-0.25% of sodium hydroxide, 0.30-0.60% of a tackifier, 0.15%-0.25% of magnesium sulfate, 1.50-2.50% of sodium humate, 0.20-0.30% of a smoke suppressant and 8.00-12.0% of kaolin. The briquette coal binder disclosed by the invention has the effects of suppressing smoke, preventing moisture, reducing dust, fixing sulfur, inhibiting nitrogen and the like, and is developed in line with the national situation of energy conservation, emission reduction and haze treatment according to China coal energy actual application and the characteristics of the haze formation cause in recent years; the binder has prominent energy conservation and emission reduction effects and an oxidative combustion-promoting effect; and since the binder is fully burnt, the energy conservation effect is achieved.

Owner:李晓雷

Color printing method for polypropylene film composite corrugated paper box

InactiveCN102029770AHigh strengthSatisfied with packaging and refrigerated transportationLamination ancillary operationsSynthetic resin layered productsColor printingPaperboard

The invention discloses a color printing method for a polypropylene film composite corrugated paper box, which comprises the following steps that: 1, a power supply drives a driving shaft to respectively drive an annular composite roller, a glued anilox roller and flexible printing rollers of a flexible composite printing device; 2, a corrugated paper box is tightly adhered to the annular composite roller during primary compounding, and gluing contact is finished through paper tension; 3, the annular composite roller is rotated to drive the primarily compounded multi-layer corrugated paper box to make the paper box pass through a plurality of groups of flexible printing rollers; 4, ink color adjusted by an ink adjusting roller is transferred to the printing rollers; and 5, the printing rollers transfer the ink color to the surface paper of the primarily compounded multi-layer corrugated paper box so as to finish the printing process. The structure is more compact and reasonable by fully utilizing the space, the traditional parallel compounding mode is changed into an annular composite roller mode, the phenomenon that a paperboard is low in intensity and easy to slip in the prior art is avoided, the integral production of gluing, compounding and printing the multi-layer corrugated paperboard / box is realized, and the working efficiency is improved.

Owner:泸州天源包装制品有限公司

Tree trunk whitewashing agent and spraying method thereof

The invention provides a tree trunk whitewashing agent and a spraying method thereof. The whitewashing agent is prepared from alkyl sulfate, copper sulfate, quick lime and water, wherein the weight ratio of alkyl sulfate to copper sulfate to quick lime to water is (0.6-1):(1-2):(20-40):100. Thus, by adding alkyl sulfate as an emulsifying agent, the whitewashing agent can keep a suspension state without settling easily when stored, preparation in use is not needed, and an operator can take the whitewashing agent conveniently at any time for spraying work. Besides, as settling does not occur easily, when the whitewashing agent is used in cooperation with a sprayer for spraying, it can be effectively avoided that the quick lime ingredient gathers and blocks a nozzle, and the beneficial technical effects of ensuring the spraying force and strength of the sprayer, spraying the whitewashing gent to bark grooves assuredly and the like are achieved.

Owner:INST OF AGRI SCI ALONG YANGTZE RIVER IN JIANGSU

Production technology of nano-self cleaning architechtural aluminium curtain wall board

InactiveCN1824394ALess investmentReduce manufacturing costWallsPretreated surfacesProduction lineSpray coating

The present invention discloses a production process of nano self-cleaning building aluminium curtain wall plate. Said production process includes the following steps: (1). spray-coating face paint; (2). leveling; (3). spray-coating nano self-cleaning solution; (4). heating and curing; and (5) photocuring.

Owner:蒋建新

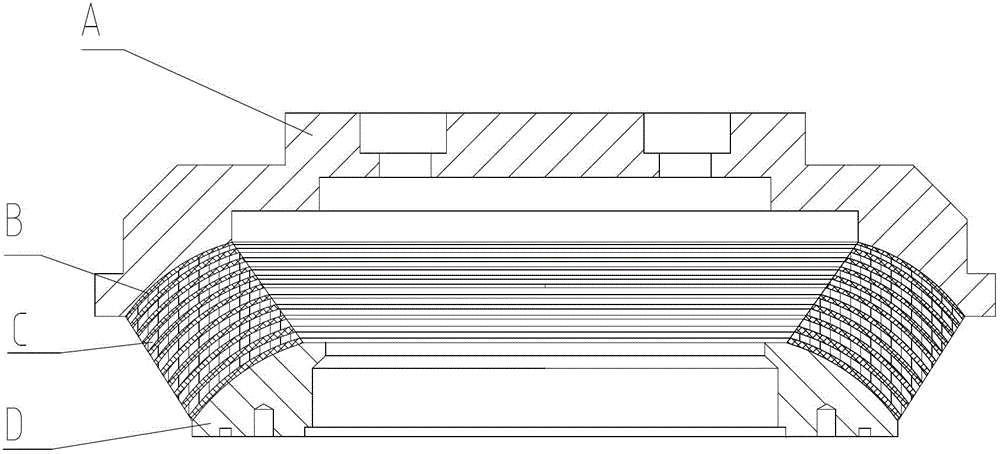

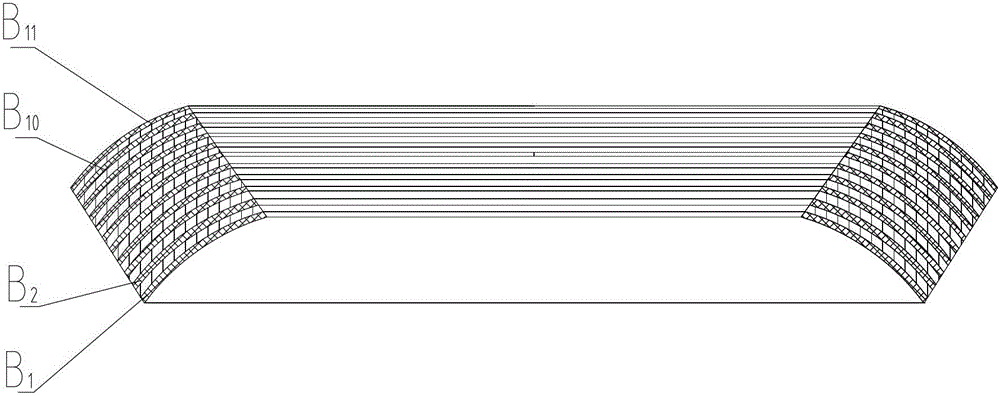

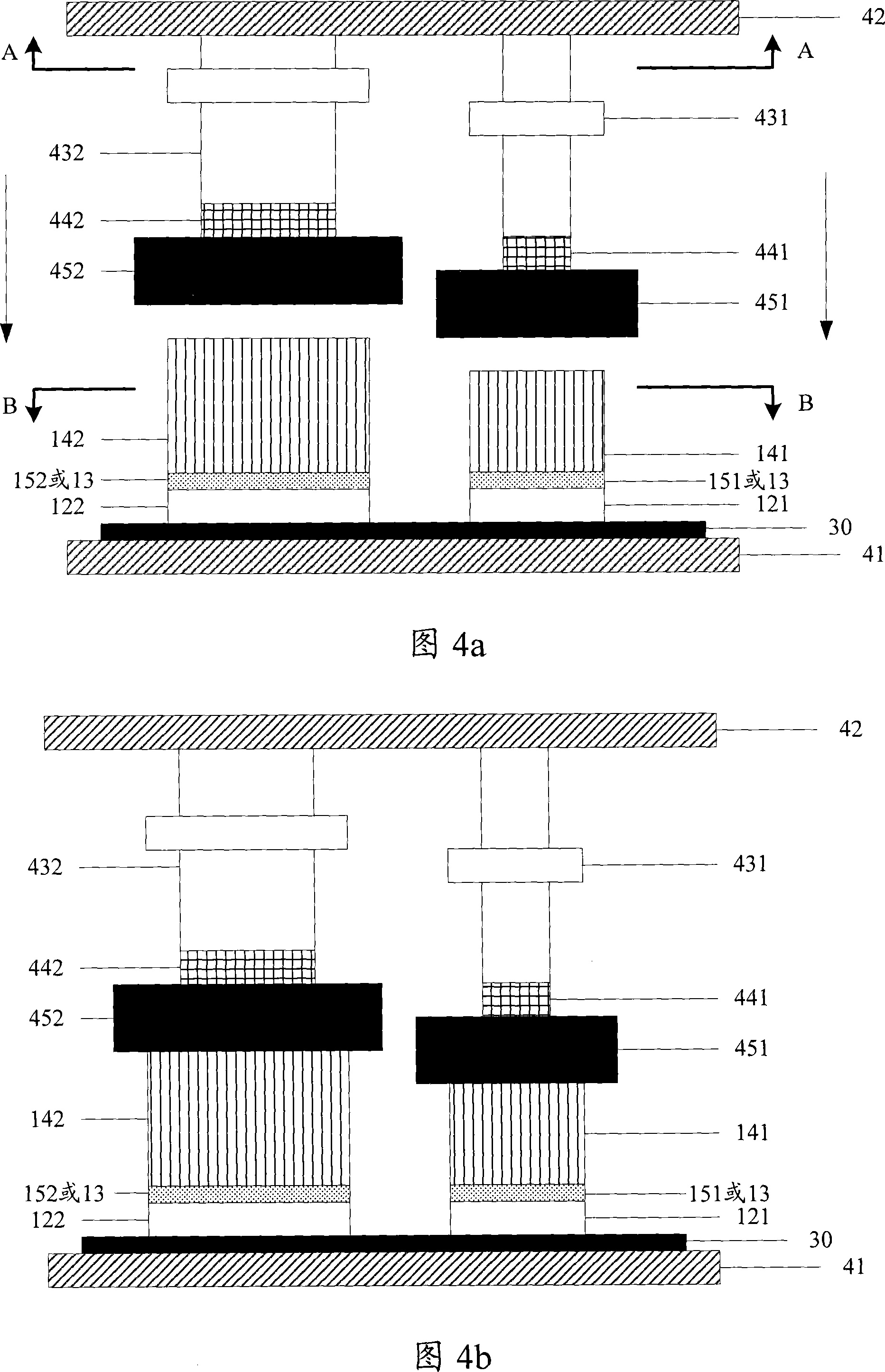

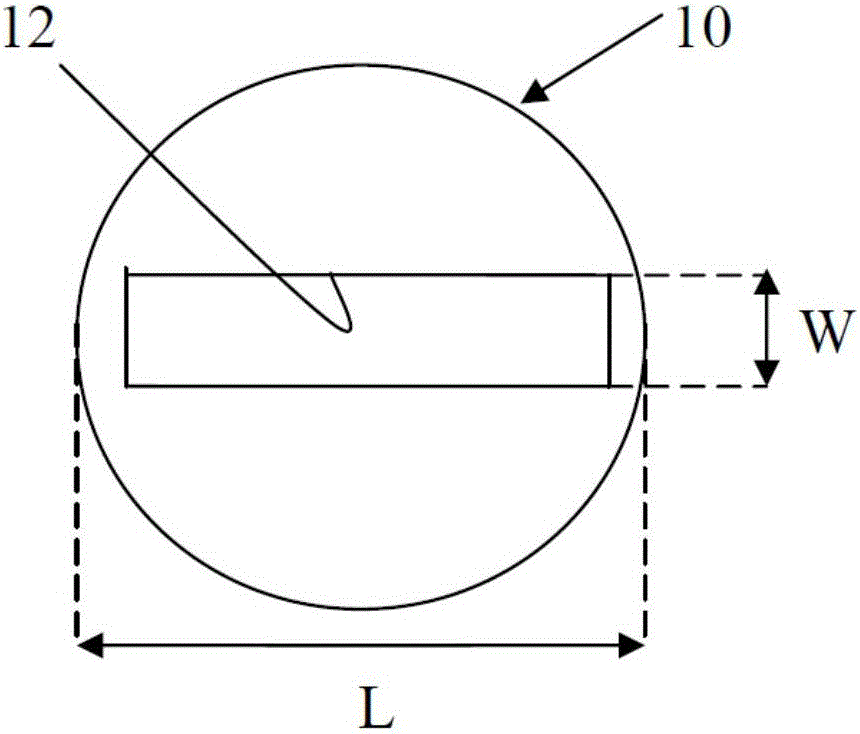

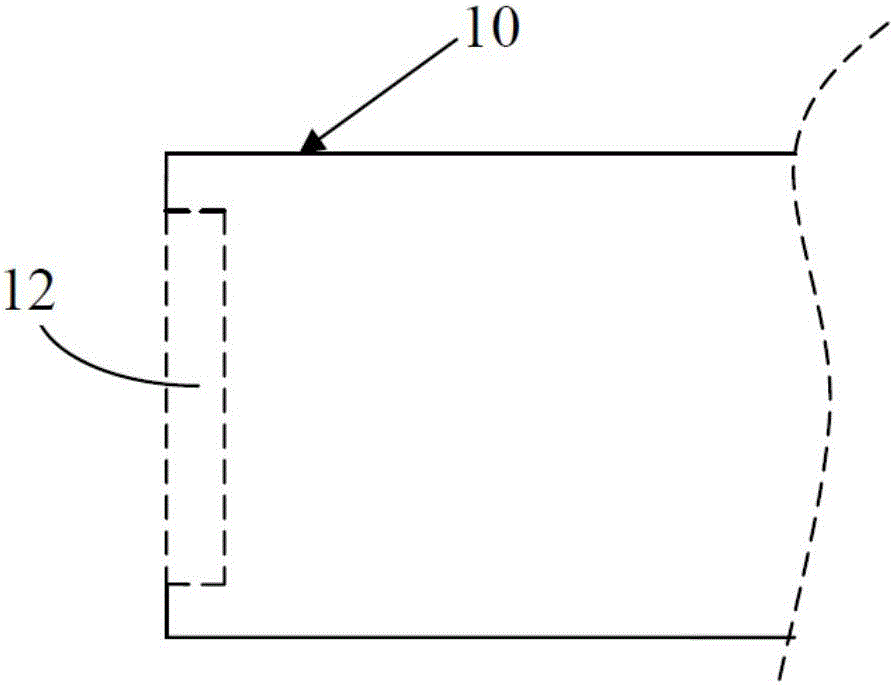

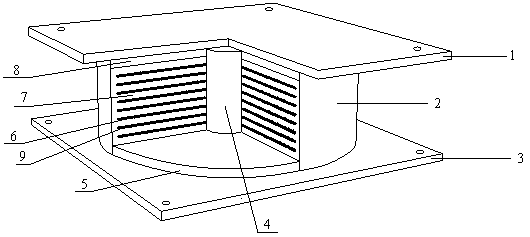

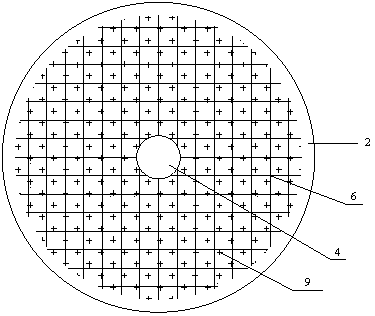

Lead core rubber support composited by high-strength steel fibers and fine steel wire meshes

InactiveCN104032672AReduce thicknessReduce weightBridge structural detailsShock proofingFiberSheet steel

The invention relates to a lead core rubber support composited by high-strength steel fibers and fine steel wire meshes. The lead core rubber support consists of an upper connecting steel plate, an upper seal plate, internal rubber layers, high-strength fine steel wire mesh layers, steel fibers, a lead core, a rubber protecting layer, a lower seal plate and a lower connecting steel plate, wherein lead core press-in holes are reserved in the high-strength fine steel wire mesh layers according to lead core design positions, hook treatment is performed on high-strength steel bars at hole opening positions, the steel fibers which are distributed in disorder are mixed in the upper sides and the lower sides of high-strength fine steel wire meshes, then the steel fibers are fully glued and vulcanized with rubber, the lead core is pressed in, and the rubber protecting layer is vulcanized outside the lead core so as to form a lead core rubber cushion; the upper seal plate and the lower seal plate are respectively adhered with the upper surface and the lower surface of the lead core rubber cushion, and are connected with the upper and lower connecting steel plates through wedges so as to form the whole support. According to the lead core rubber support disclosed by the invention, the high-strength fine steel wire meshes are used for replacing reinforced steel plates, so that the shearing capacity and the deforming capacity of the lead core rubber support are stronger, and the weight of the whole support is lighter. Through the net-shaped structures of the high-strength fine steel wire meshes and the mixing of the steel fibers, the rubber between the steel wire mesh layers can be vulcanized to form a whole.

Owner:TONGJI UNIV +1

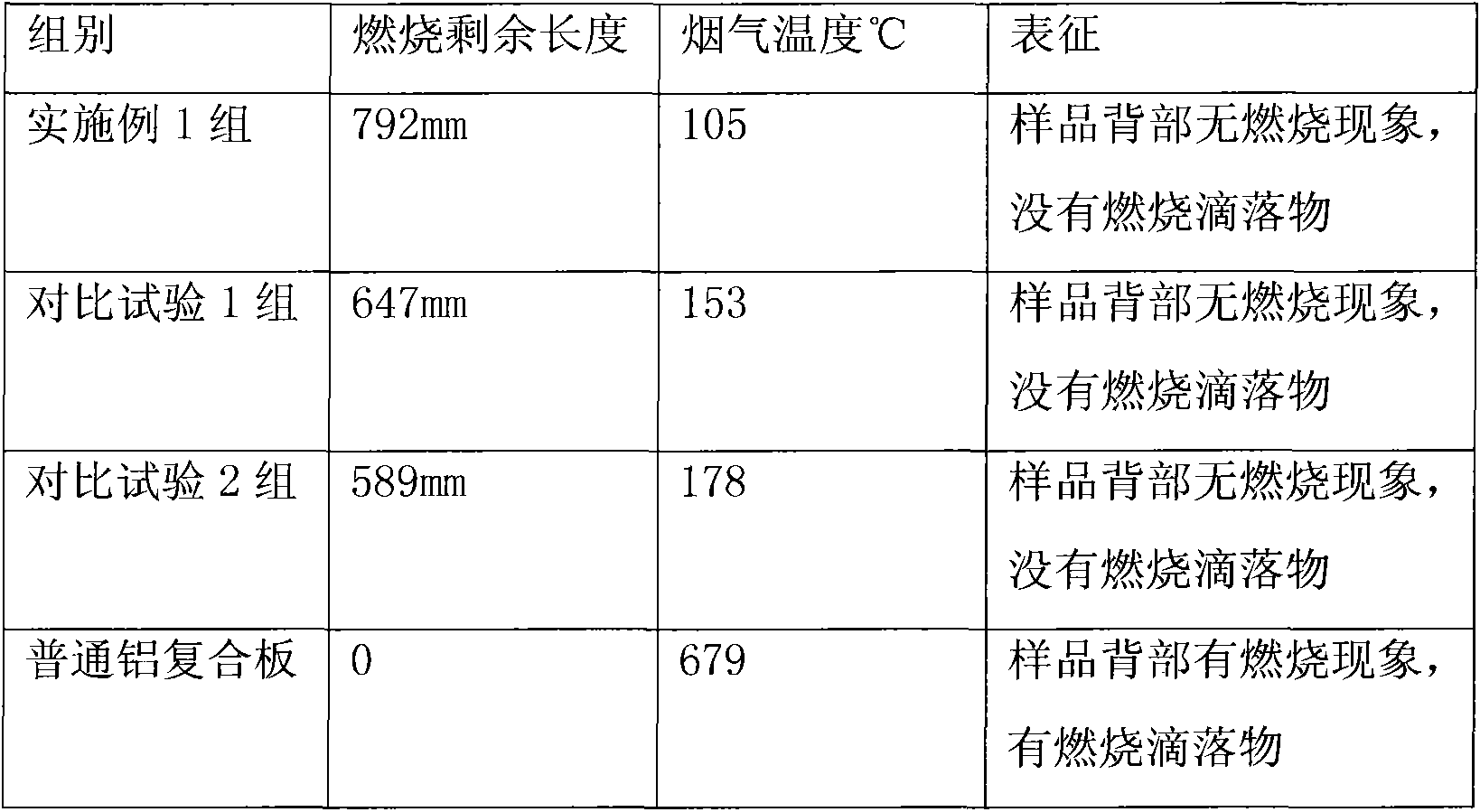

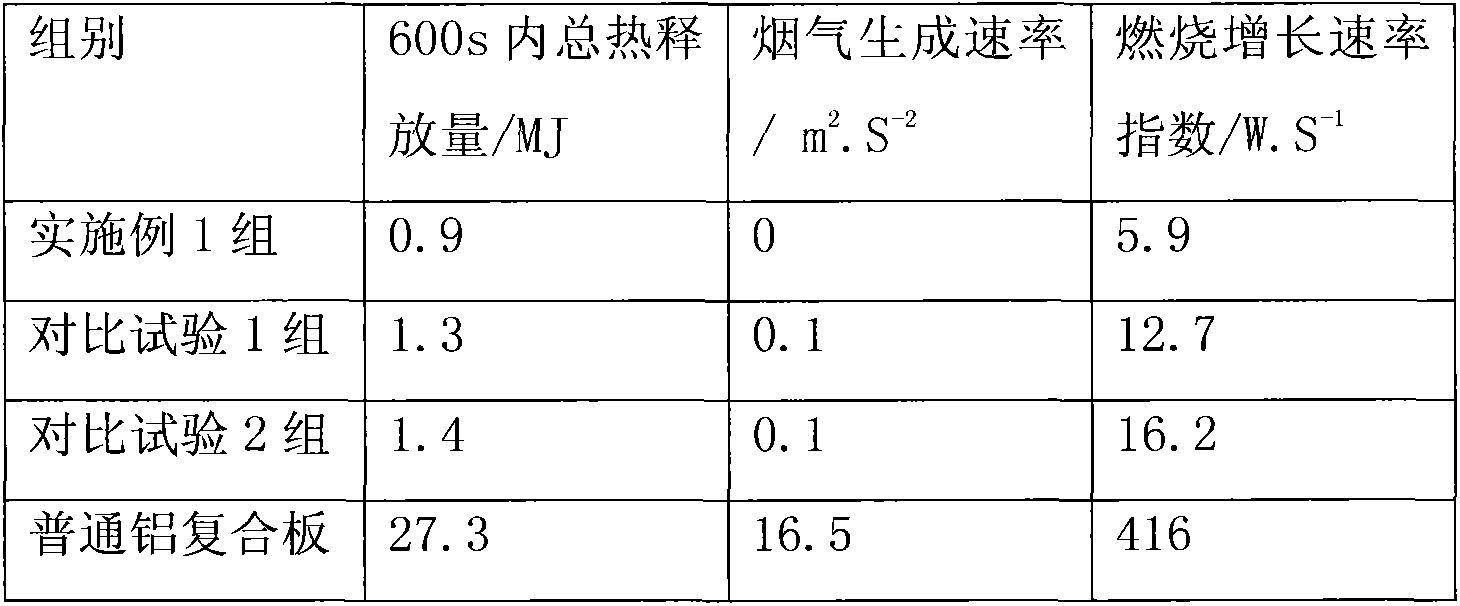

Inorganic non-combustible safe aluminum composite panel

The invention belongs to the field of advanced materials, and discloses an inorganic non-combustible safe aluminum composite panel. The composite panel comprises an aluminum substrate, an inorganic core plate and an aluminum substrate from top to bottom and is prepared in a hot-pressing continuous composite forming mode, and the aluminum substrates and the inorganic fireproof core layer are adhered through macromolecule adhesives. The composite panel is high in flame resistance and safety and has good application prospects.

Owner:山东吉祥装饰建材有限公司

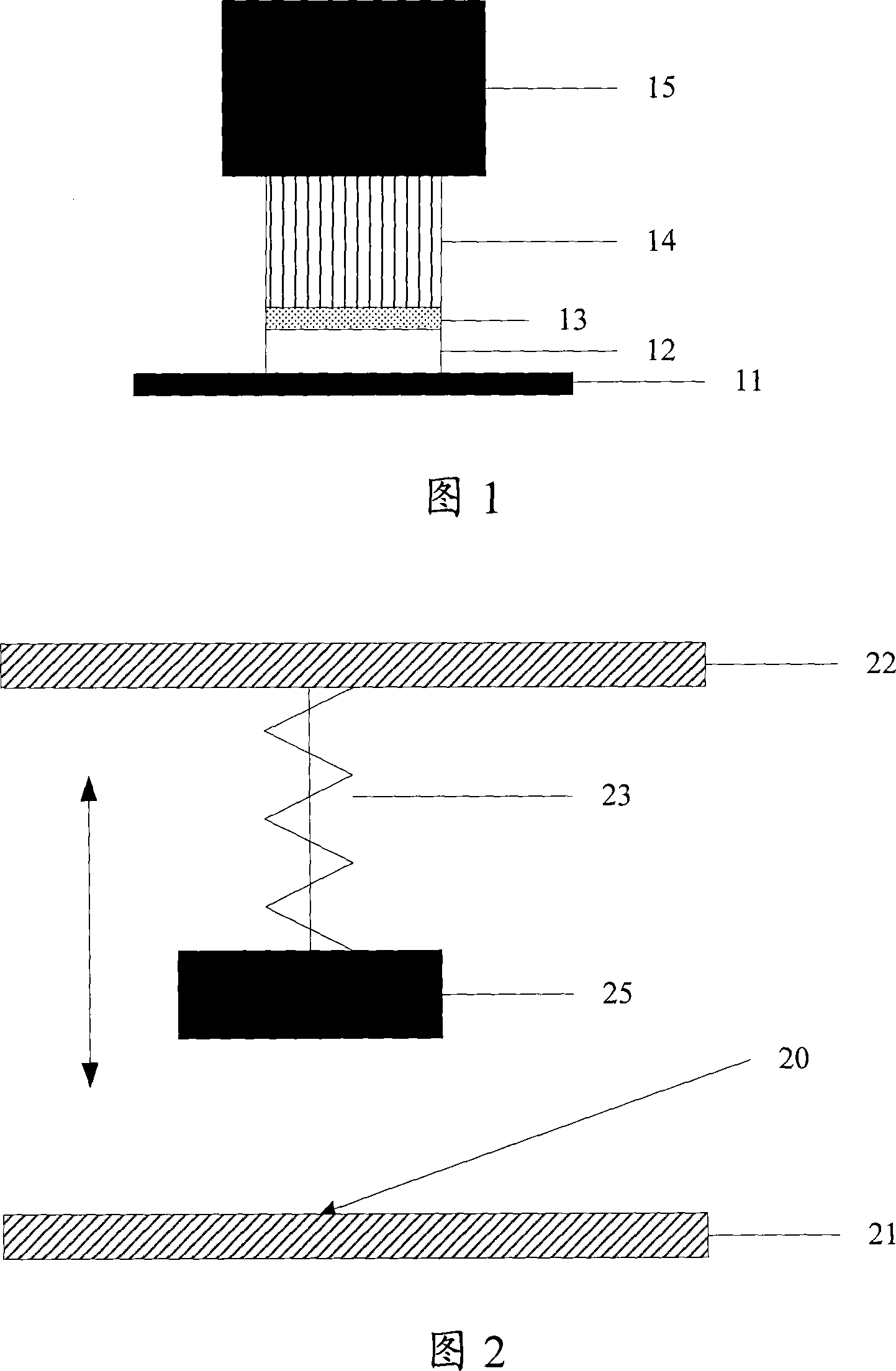

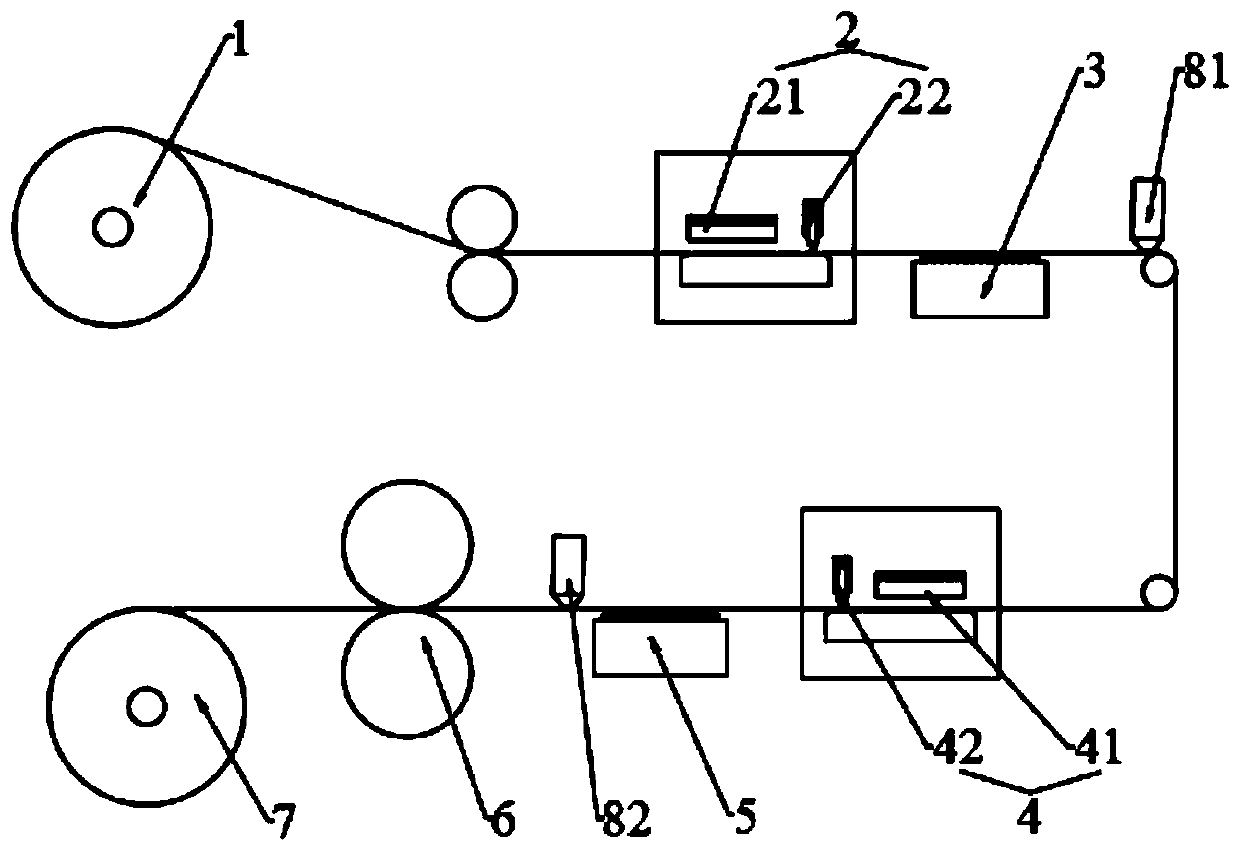

Dry preparation process of pole piece and continuous production device of pole piece

ActiveCN110828772AEvenly distributedFully bondedElectrode rolling/calenderingSecondary cellsElastomerPolymer science

The invention discloses a dry preparation process of a pole piece. The preparation process comprises the steps of S1 mixing an active substance, a conductive agent, a thermoplastic elastomer and a solvent; dissolving the thermoplastic elastomer in the solvent; and drying the mixed solution to obtain thermoplastic elastomer coated dry powder; S2 uniformly distributing the dry powder obtained in thestep S1 on the surface of a current collector; scraping the surface of the dry powder and adjusting the thickness of a dry powder layer; S 3 heating the pole piece with the dry powder layer; and S4 rolling the pole piece with the single-sided dry powder layer by a hot roller to obtain a single-sided pole piece finished product, or repeating the step S2 and the step S3 on the other side of the current collector in the pole piece obtained in the step S3, and rolling the pole piece with the double-sided dry powder layer by the hot roller to obtain a double-sided pole piece finished product. Thedry preparation process of the pole piece is reasonable in steps. The active substances, the conductive agent and the thermoplastic elastomer in the obtained pole piece are uniformly distributed. Thepole piece has good flexibility. The invention further discloses a continuous production device of the pole piece.

Owner:LINKDATA NEW ENERGY CO LTD

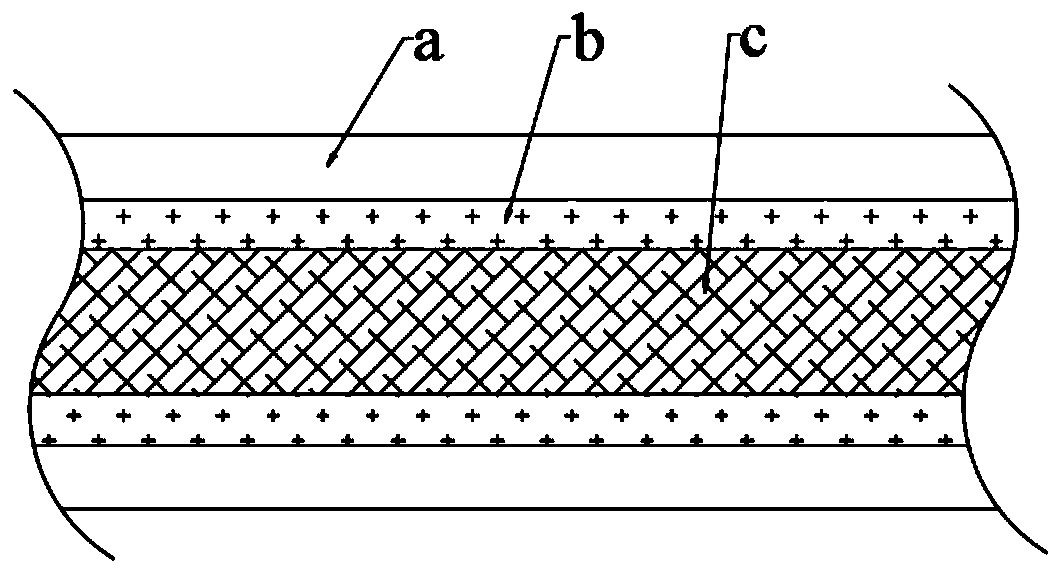

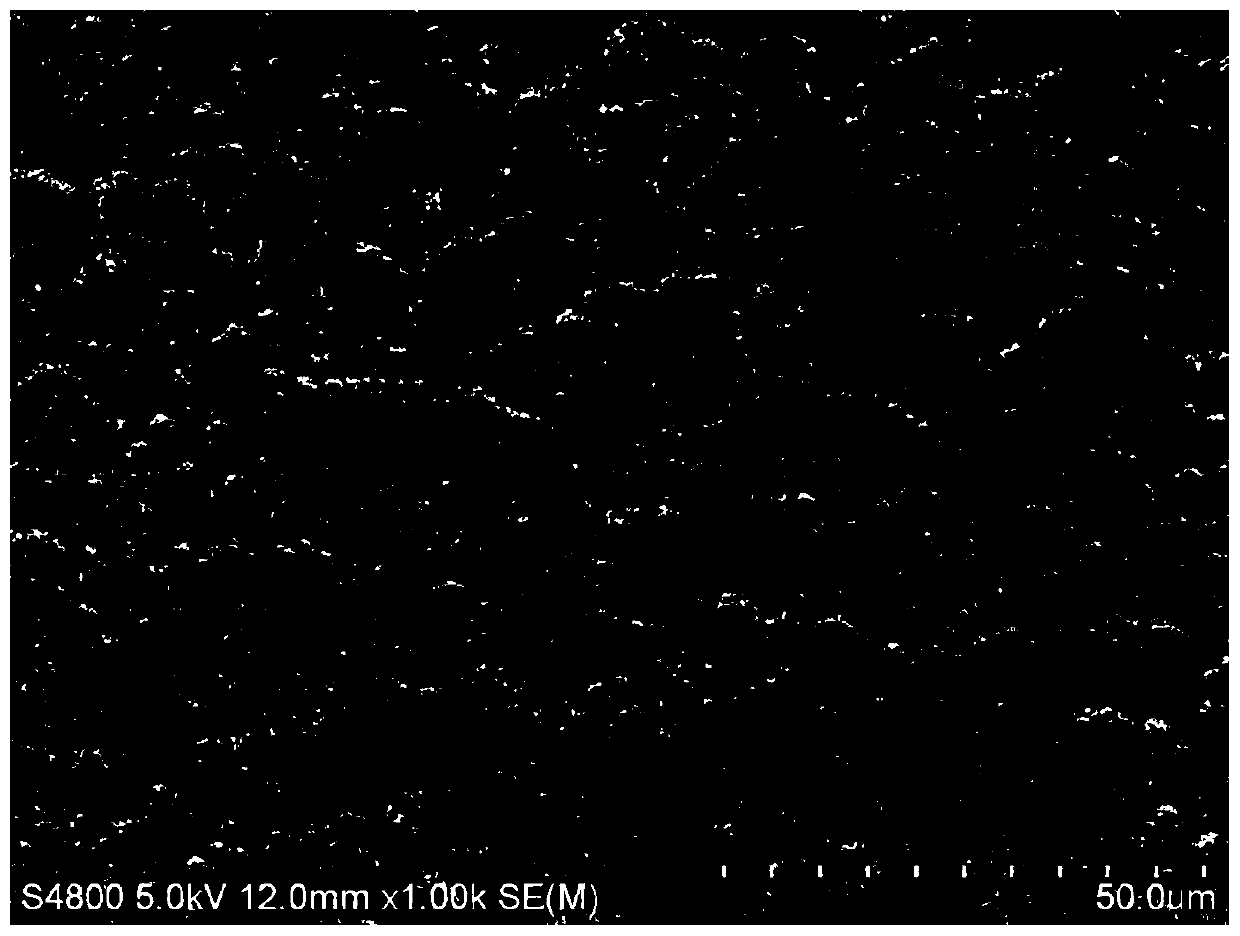

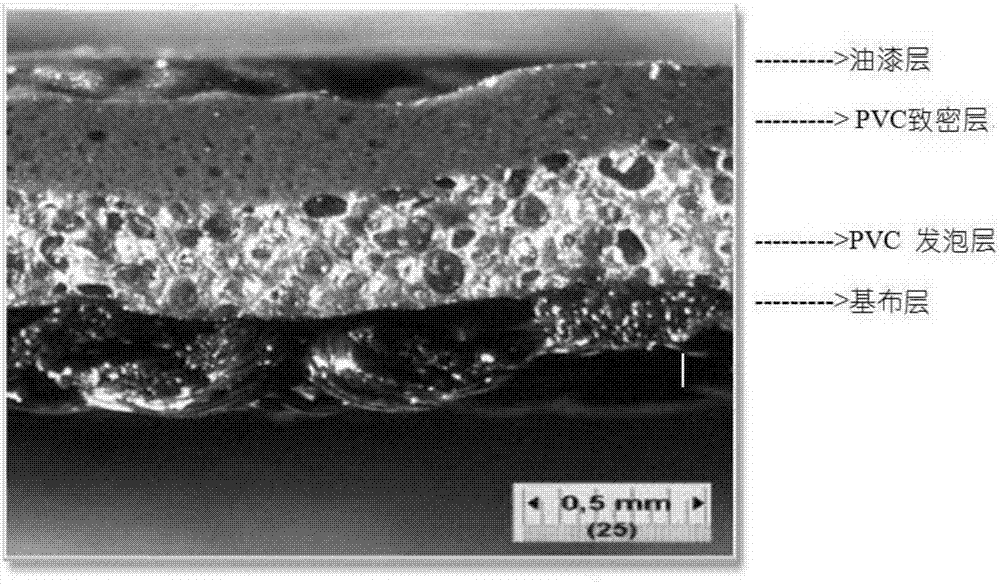

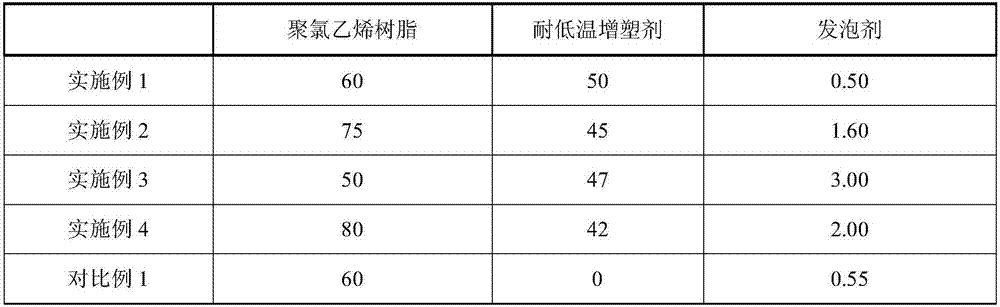

Low-temperature-deflection-resistant perforated gas-permeable polyvinyl chloride artificial leather and preparation method thereof

ActiveCN107354760AReduce volatilityLow mobilityCoatingsTextiles and paperPolyvinyl chlorideUltimate tensile strength

The invention discloses a low-temperature-deflection-resistant perforated gas-permeable polyvinyl chloride artificial leather and a preparation method thereof, wherein the artificial leather comprises a base cloth layer, a PVC foaming layer, a PVC compact layer and a paint layer. According to the present invention, the low-temperature-deflection-resistant perforated gas-permeable polyvinyl chloride artificial leather prepared by using the formula and the preparation method has characteristics of good mechanical strength, strong toughness, wear resistance and strong low-temperature-deflection resistance, further has advantages of gas permeability and comfort similar to the leather, and further has characteristics of good hand feeling and high security.

Owner:BENECKE CHANGSHUN AUTO TRIMZHANGJIAGANG

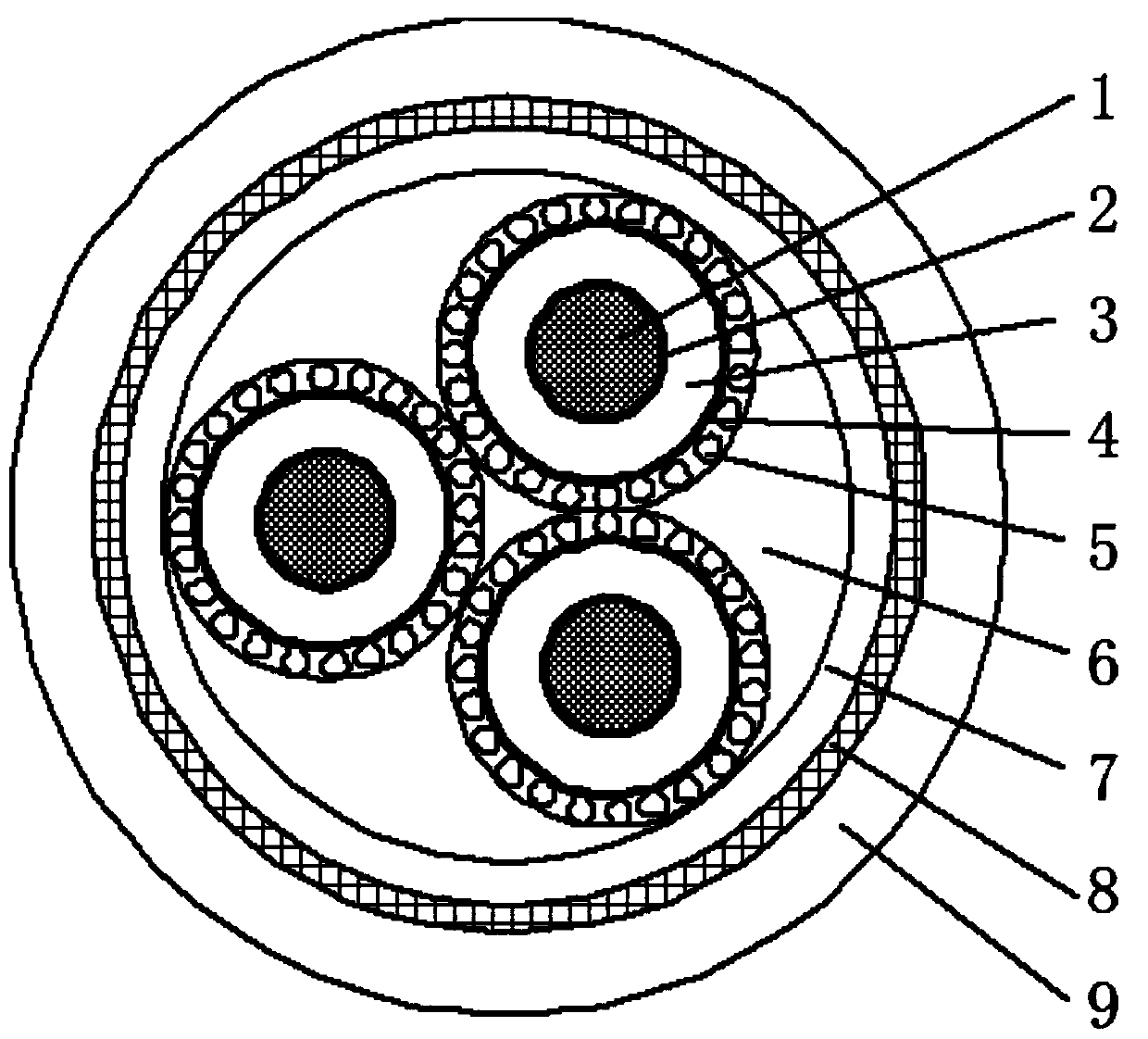

Medium-voltage variable-frequency power cable for oceanographic engineering and manufacturing method of medium-voltage variable-frequency power cable

PendingCN110120277AImprove shielding effectMagnetic field does not leakNon-insulated conductorsPower cables with screens/conductive layersCopper conductorPower cable

The invention discloses a medium-voltage variable-frequency power cable for oceanographic engineering. The cable comprises a cable body, and the cable body comprises a cable core, an inner sheath, anarmor layer and an outer sheath. An inner sheath, an armor layer and an outer sheath are sequentially sleeved and connected outside the cable core, and the cable core is formed by the twisting of three groups of insulated wire cores. Tinned circular compressed tinned copper conductors are arranged inside the insulated wire cores, and a conductor shielding layer, a crosslinked polyethylene insulating layer, an insulated shielding layer and a metal shielding layer are sequentially arranged on the outer layer of each copper conductor. The conductors adopt a 2-type wire compression tinned copper conductor structure. Because the filling coefficient reaches 97% or above, the molded line conductor structure has a small conductor outer diameter under the requirements of the same nominal cross section and direct current resistance, and the weights of the insulating layer and the outer sheath are reduced, thereby achieving the purposes of reducing the outer diameter of a cable finished product and reducing the overall weight of the cable. The split-phase shielding of the cable is changed into sparse winding of tin-plated copper wires and wrapping shielding of copper strips from traditional wrapping shielding of the copper strips, so that the shielding effect is improved.

Owner:安徽新特华宇新材料科技有限公司

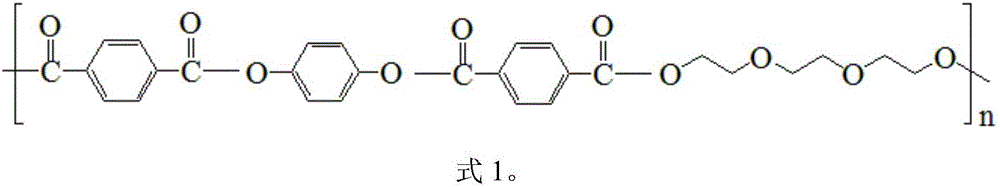

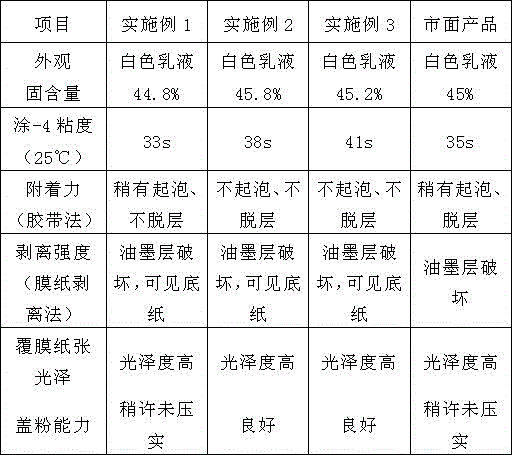

Aqueous dry lamination adhesive and preparation method thereof

ActiveCN105482745AFully bondedImprove adhesionEster polymer adhesivesRosin adhesivesSodium bicarbonateIsooctyl acrylate

The invention discloses an aqueous dry lamination adhesive and a preparation method thereof. Raw materials of the aqueous dry lamination adhesive comprise styrene, butyl acrylate, isooctyl acrylate, acrylonitrile, N-methylolacrylamide, hydroxyethyl acrylate, acrylic acid, rosin, potassium persulfate, sodium dodecylbenzene sulfonate, isooctyl phenol polyoxyethylene ether, sodium bicarbonate, deionized water, ammonia water, a wetting agent and antifoaming agent. Aqueous latex with a core-shell structure is prepared through a segmented polymerization technology, so functional groups make a substrate and a plastic film be fully bonded, and polymer molecular chains are self-crosslinked, thereby the adhesion and the peeling strength of the substrate are improved, the adhesive has excellent initial adhesion, pressure sensitivity and covering ability, the excellent leveling property and the dynamic wetability of the adhesive make a laminated product have brilliant gloss, and the adhesive can be widely used in paper plastic lamination.

Owner:常德市雄鹰科技有限责任公司

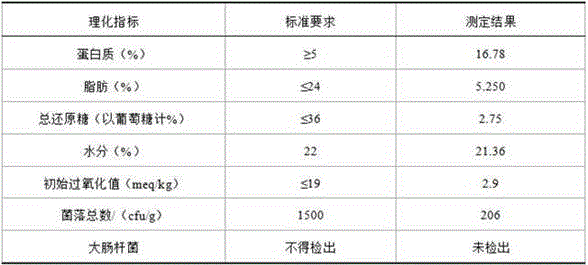

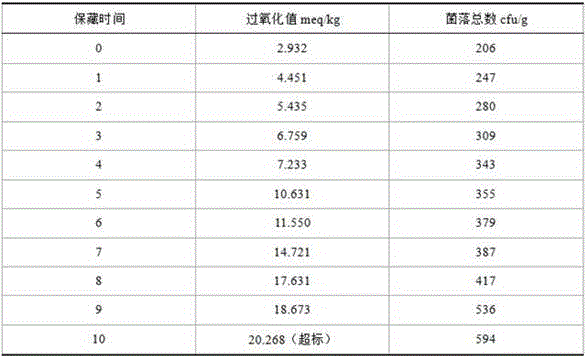

Tea flavor minced fillet mooncake and preparation method thereof

InactiveCN106259799ASolve wasteSolve processabilityDough treatmentBakery productsMaltitolAlpha-amylase

The invention discloses a tea flavor minced fillet mooncake and a preparation method thereof. A mooncake wrapper is prepared by taking low gluten flour as the basic material and adding composite maltitol syrup, plant oil, skim milk powder, alkaline water and sodium dehydroacetate. Mooncake stuffing is prepared by taking minced fillet as the basic material and adding maltitol, glutinous rice powder, plant oil, purified water, composite tea powder, baijiu, salt, instant dry yeast, sodium dehydroacetate and alpha-amylase. The tea flavor minced fillet mooncake is prepared through the procedures of minced fillet preprocessing, wrapper and stuffing making, forming, baking, cooling, packaging and the like. The prepared finished product is golden in color, free of fishy smell, fresh in tea aroma and soft in taste, has the advantages of being high in protein and low in fat and calorie, has the health-care effects of clearing away heat and toxin, refreshing people and arousing the brain, helping digestion and promoting appetite, preventing ageing and cardiovascular diseases, enhancing memory and the like, and can be preserved at normal temperature.

Owner:武夷学院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com