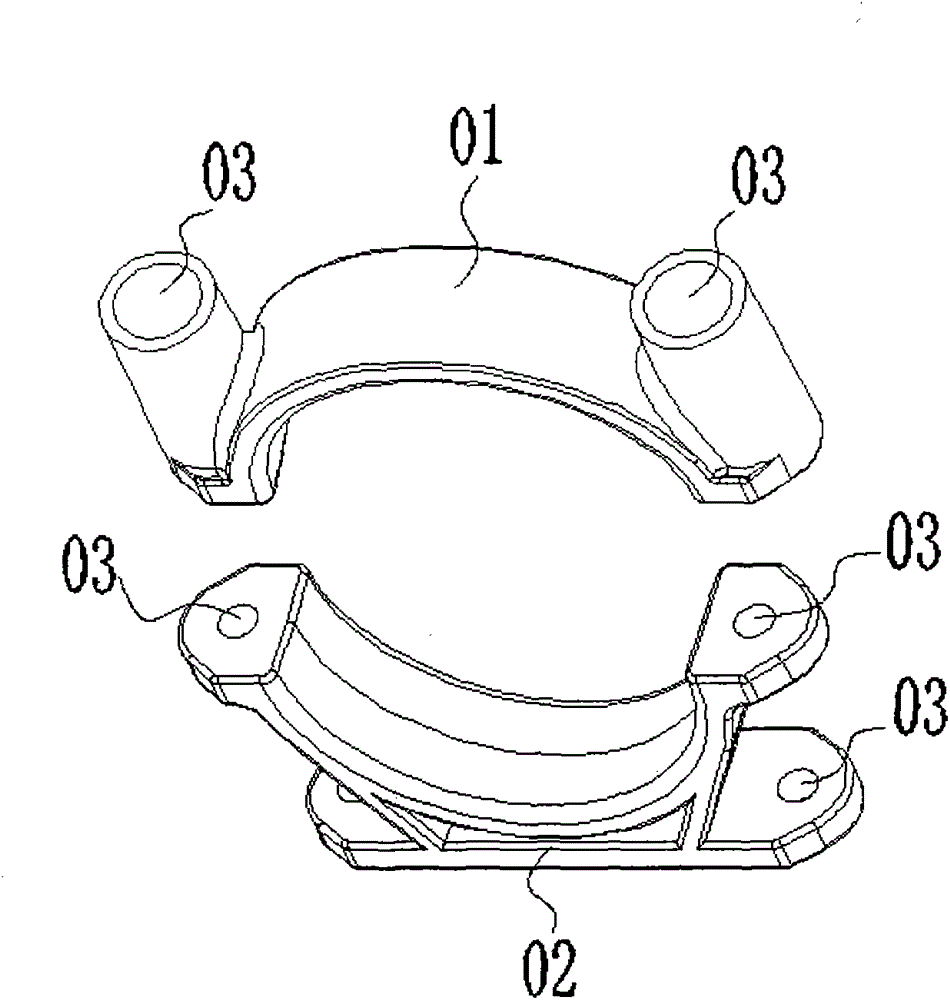

Novel cable bracket hoop and preparation method thereof

A cable support, a new type of technology, applied in the direction of pipeline support, mechanical equipment, pipes/pipe joints/pipe fittings, etc., to achieve the effect of uniform material, stable performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The composition and mass percentage of SMC composite materials are as follows:

[0023] Unsaturated polyester resin is 18%, low-shrinkage additive is 8%, flame-retardant filler is 50%, glass fiber is 20%, and other additives are 4%. The other additives are curing agents, release agents or thickeners.

[0024] The preparation process is:

[0025] (1) Put unsaturated polyester resin, low-shrinkage additives, other additives, and flame-retardant fillers into a beater to make resin paste;

[0026] (2) adding glass fibers to the resin paste, stirring at a low speed of less than 50r / min for 15 minutes to obtain a molding material;

[0027] (3) Inject the molding material into the mold, heat to 120°C, increase the pressure to 1.5 times the atmospheric pressure, and keep the temperature and air pressure for 20 minutes;

[0028] (4) Keep the air pressure, and release the mold after naturally cooling to normal temperature to obtain a molded part.

Embodiment 2

[0030] The composition and mass percentage of SMC composite materials are as follows:

[0031] Unsaturated polyester resin is 22%, low shrinkage additive is 10%, flame retardant filler is 45%, glass fiber is 20%, and other additives are 3%. The other additives are curing agents, release agents or thickeners.

[0032] The preparation process is:

[0033] (1) Put unsaturated polyester resin, low-shrinkage additives, other additives, and flame-retardant fillers into a beater to make resin paste;

[0034] (2) adding glass fibers to the resin paste, stirring at a low speed of less than 50r / min for 15 minutes to obtain a molding material;

[0035] (3) Inject the molding material into the mold, heat to 150°C, increase the pressure to 1.5 times the atmospheric pressure, and keep the temperature and air pressure for 10 minutes;

[0036] (4) Keep the air pressure, and release the mold after naturally cooling to normal temperature to obtain a molded part.

Embodiment 3

[0038] The composition and mass percentage of SMC composite materials are as follows:

[0039] Unsaturated polyester resin is 20%, low-shrinkage additive is 8%, flame-retardant filler is 50%, glass fiber is 18%, and other additives are 4%. The other additives are curing agents, release agents or thickeners.

[0040] The preparation process is:

[0041] (1) Put unsaturated polyester resin, low-shrinkage additives, other additives, and flame-retardant fillers into a beater to make resin paste;

[0042] (2) adding glass fibers to the resin paste, and stirring at a low speed of less than 60r / min for 12 minutes to obtain a molding material;

[0043] (3) Inject the molding material into the mold, heat to 100°C, increase the pressure to 2 times the atmospheric pressure, and keep the temperature and air pressure for 30 minutes;

[0044] (4) Keep the air pressure, and release the mold after naturally cooling to normal temperature to obtain a molded part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com