Color printing method for polypropylene film composite corrugated paper box

A corrugated box and polypropylene film technology, applied in the printing field, can solve the problems that the pattern of corrugated boxes cannot achieve the design effect, cannot obtain composite packaging boxes, and the thickness tolerance of corrugated cardboard is large, so as to improve the utilization rate and the accuracy of trimming , Improve the printing grade and work efficiency, and improve the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

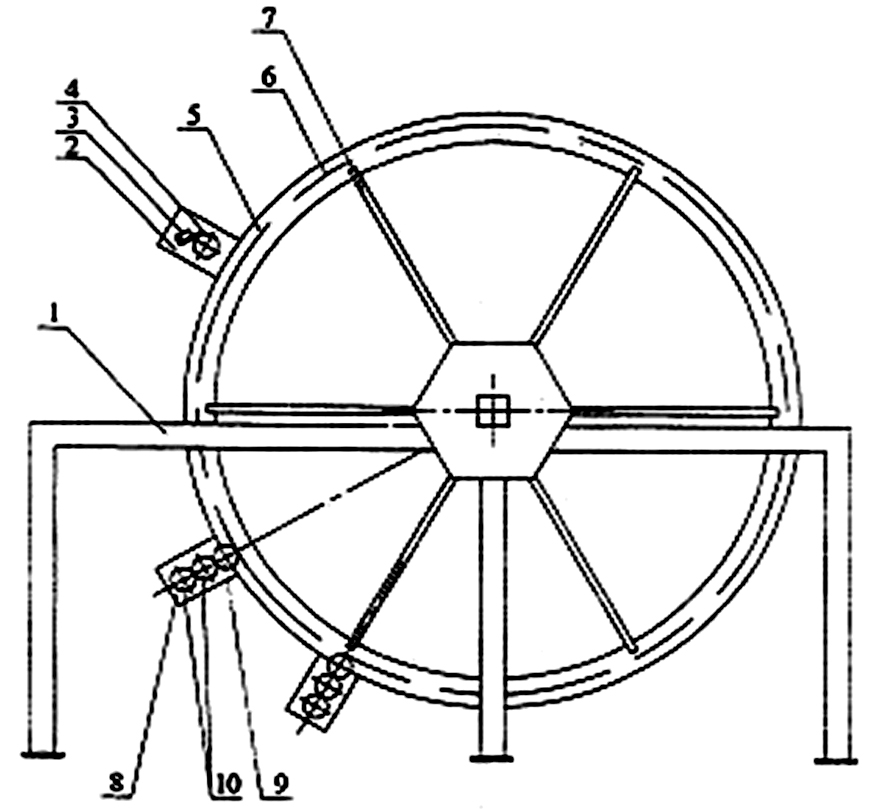

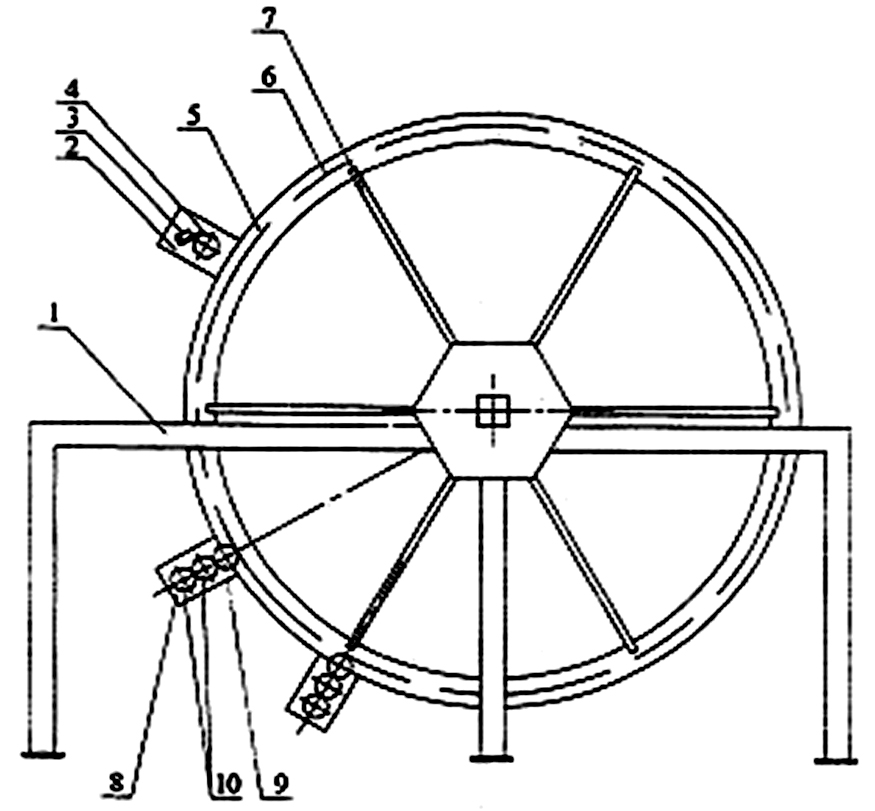

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

[0030] The color printing method of a kind of polypropylene film composite corrugated box of the present invention, its steps are as follows:

[0031] In the first step, the power of the power supply drives the power of the drive shaft to be transmitted to the ring-shaped composite cylinder, the glue anilox roller and the flexible printing roller of the flexible composite printing device;

[0032] In the second step, when the corrugated cardboard is first compounded, it is closely attached to the ring compound roller, and the glue contact is completed by using the tension of the paper;

[0033] The third step is to rotate the ring-shaped composite roller to drive the initial multi-layer corrugated cardboard to pass through multiple sets of flexible printing rollers;

[0034] The fourth step is to transfer the ink color adjusted by the ink adjusting roller to the print...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com