Patents

Literature

35results about How to "Solve moisture resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fireproof moistureproof exterior wall thermal insulation material and coating

ActiveCN105969138AImprove insulation performanceImprove flame retardant performanceFireproof paintsPolyurea/polyurethane coatingsFire retardantExternal wall insulation

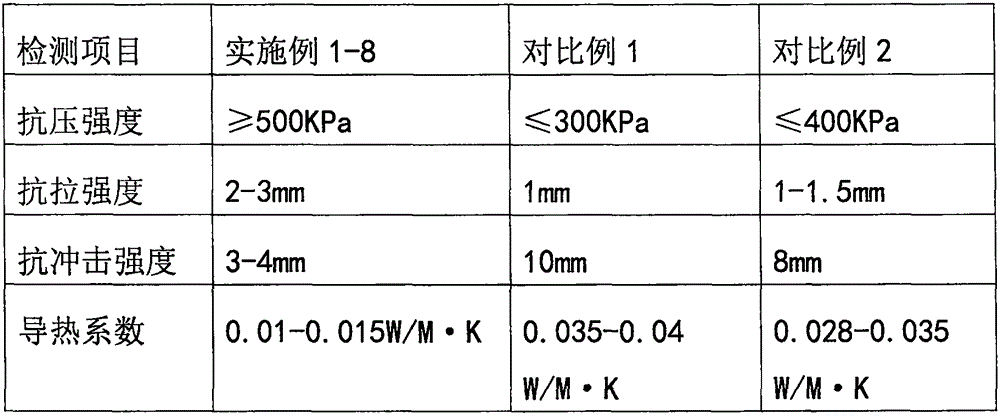

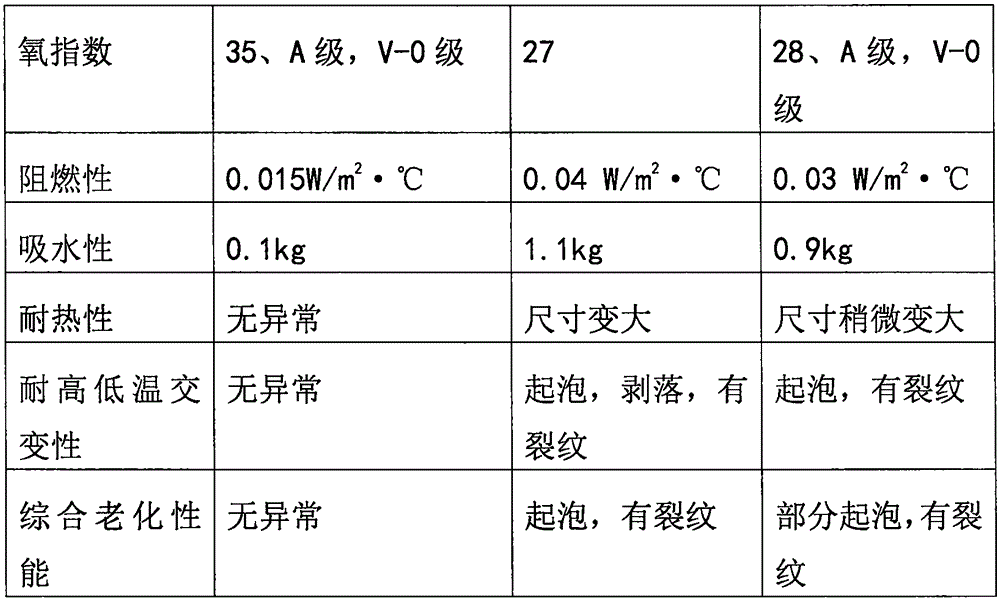

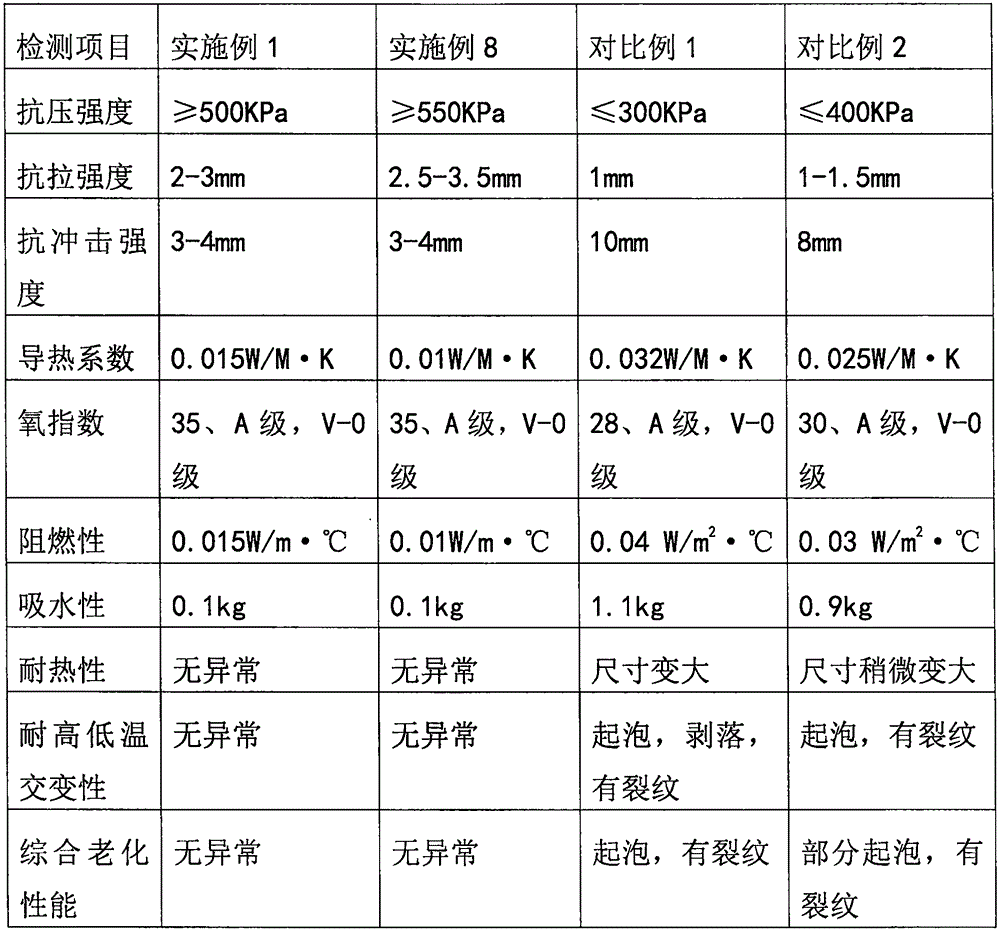

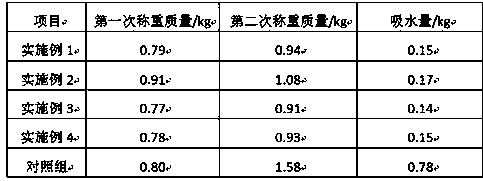

The invention provides a fireproof moistureproof exterior wall thermal insulation material. The fireproof moistureproof exterior wall thermal insulation material comprises an ingredient A and an ingredient B. The ingredient A comprises, by weight, 30-60 parts of styrene acrylic foam resin, 10-30 parts of a thermal insulation material, 1-3 parts of a catalyst, 1-3 parts of tertiary amine, 1-4 parts of a foam stabilizer and 20-40 parts of a fire retardant. The ingredient B comprises, by weight, 30-60 parts of isocyanate. The fireproof moistureproof exterior wall thermal insulation material solves the problems of poor flame retardation and water resistance of the existing exterior wall thermal insulation material and has ideal fireproof and moistureproof effects.

Owner:江苏百代节能建材有限公司

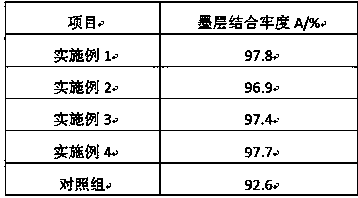

Corrugated paper printing process for fruit packaging boxes

InactiveCN110792000ASolve the problem of airtightnessSolve moisture resistanceMechanical working/deformationCoated paper substratePolymer scienceCarton

The invention relates to the technical field of carton printing, in particular to a corrugated paper printing process for fruit packaging boxes. The corrugated paper printing process comprises seven steps of corrugated paper pretreatment, flexographic plate making, corrugated paper surface treatment, corrugated paper PE lamination, outer layer PE lamination surface treatment, flexographic plate printing and polishing and calendaring treatment. The adhesive force between PE lamination and corrugated paper is enhanced through corona treatment, and then a water-based ink and the PE lamination areeffectively combined through low-temperature plasma treatment, so that the combination fastness of an ink layer is improved, and the sealing performance and the moisture resistance of the corrugatedpaper are better through PE lamination; compared with solvent-based ink, the water-based ink does not generate harmful gas, is higher in safety performance, and is cheaper than UV ink, the toughness of a film formed by the water-based ink adapts to that of PE lamination, the brittle fracture phenomenon is avoided, and the defect that the film formed by the UV ink is prone to brittle fracture is overcome.

Owner:邵帅

Method for manufacturing anti-flaming waterproof ventilated cushion

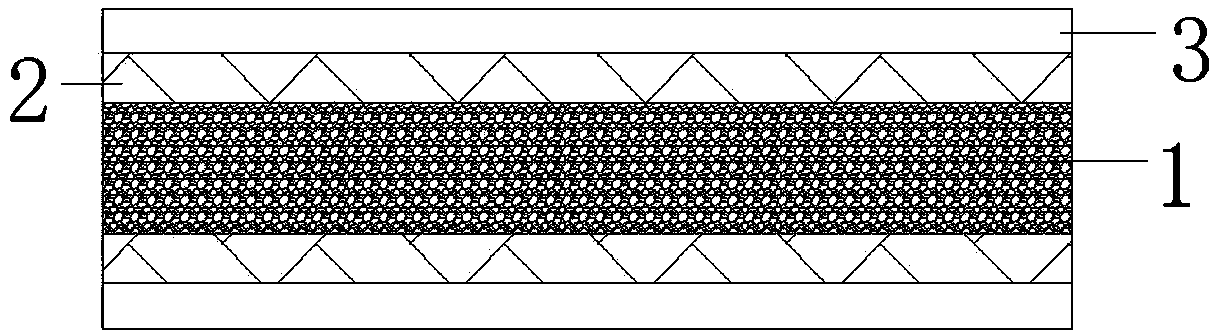

ActiveCN103009759AEasy dischargeGood char formationLamination ancillary operationsRoof covering using flexible materialsTectorial membraneElastomer

The invention provides a method for manufacturing an anti-flaming waterproof ventilated cushion, and relates to the technical field of manufacturing a composite material with functions of flame retardance, water prevention and ventilation. The method comprises the following steps of: firstly, carrying out mixing granulation on polypropylene H2800, metallocene polyethylene, Exxon Mobil elastomer PP6002, nano calcium carbonate, a coupling agent, a dispersing agent, a lubricating agent and chlorinated paraffin, so as to form a sheet material; secondly, heating and stretching the sheet material to manufacture a copolymerization microporous membrane; thirdly, thermally pressing polypropylene non-woven fabrics on the two surfaces of the copolymerization microporous membrane through a hot roll, so as to form a three-in-one semi-finished product; and finally, soaking the three-in-one semi-finished product in mixed impregnation liquid containing a fire retardant, a hydrophilic agent, and a silane coupling agent JS-D758, and drying through using a drying cylinder, so as to form the anti-flaming waterproof ventilated cushion. The anti-flaming waterproof ventilated cushion manufactured by using the method by the invention is applicable to a metal roof, a pitched roof, and one layer of protection film outside thermal-insulating cotton and rock wool. Due to the specific ventilation property of the anti-flaming waterproof ventilated cushion manufactured by using the method provided by the invention, water inside a building structure is rapidly discharged, so that the flame retardance can be shown in the case of fire, and the loss can be reduced.

Owner:NANTONG KANGDA COMPOSITE MATERIALS CO LTD

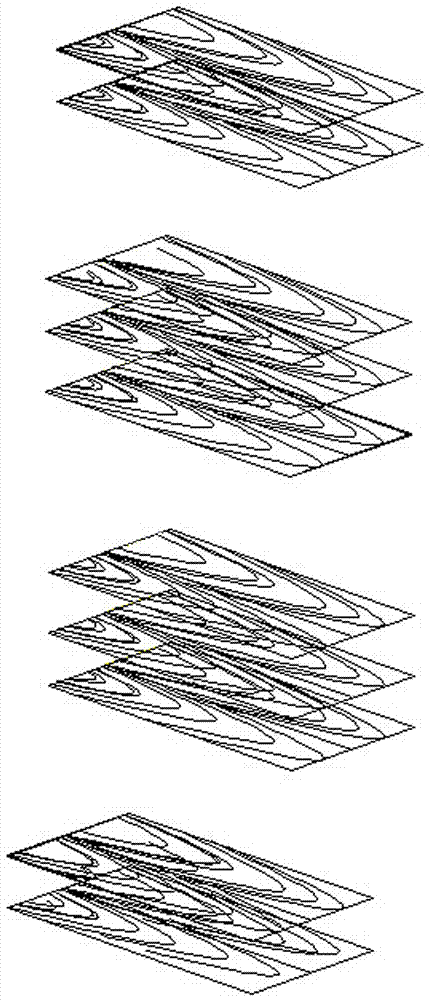

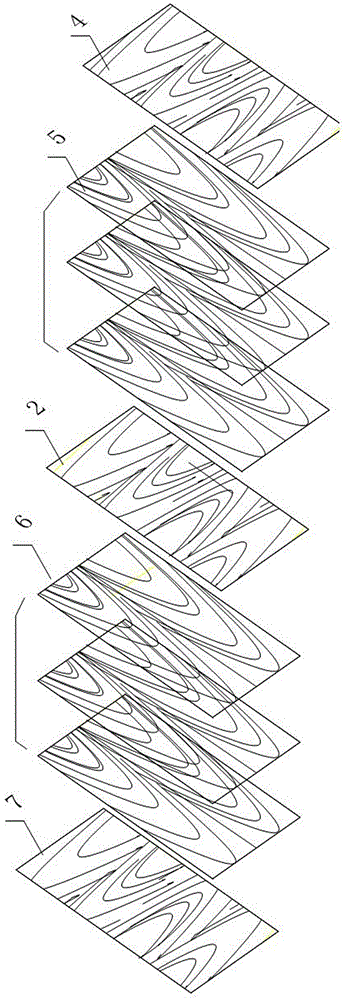

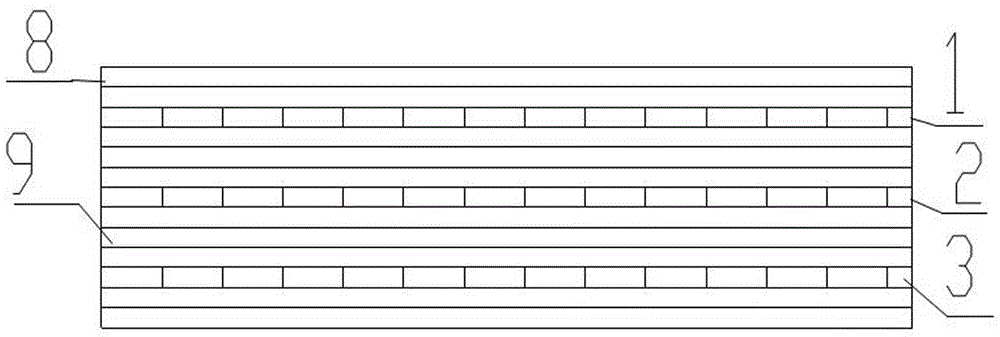

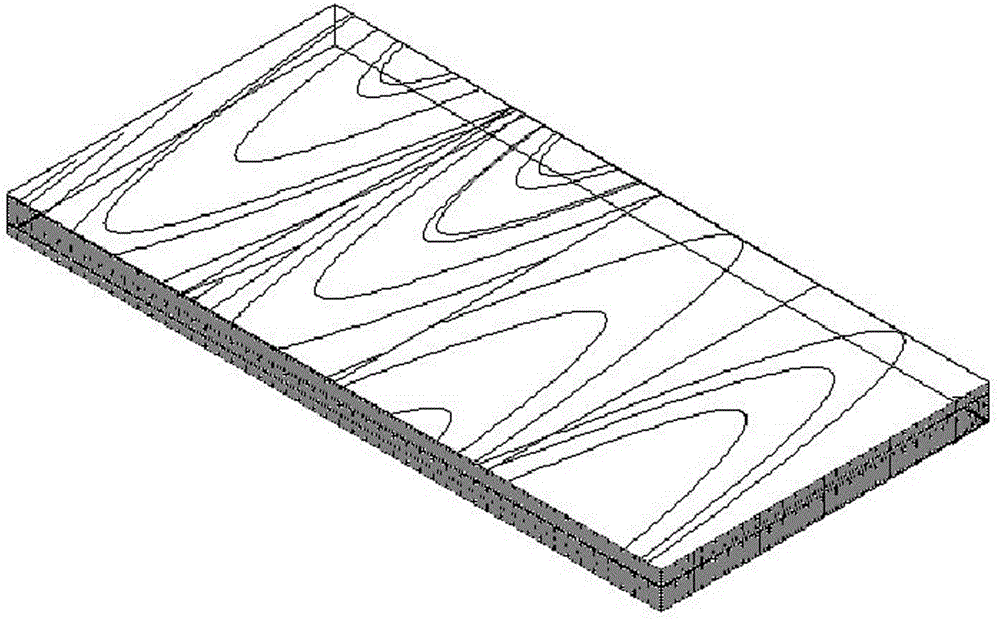

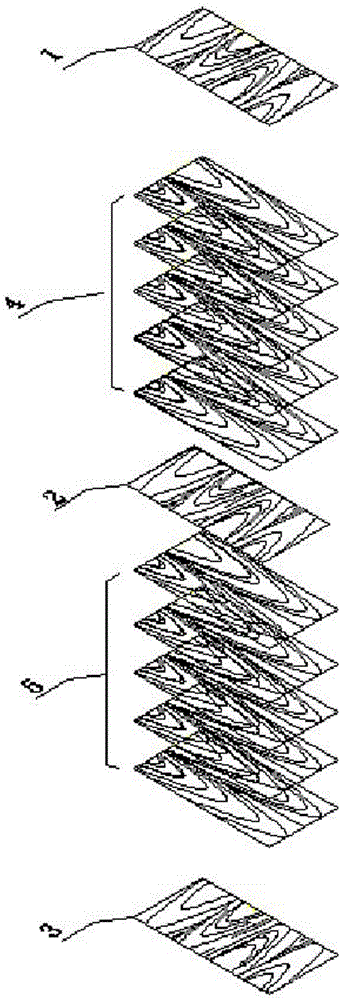

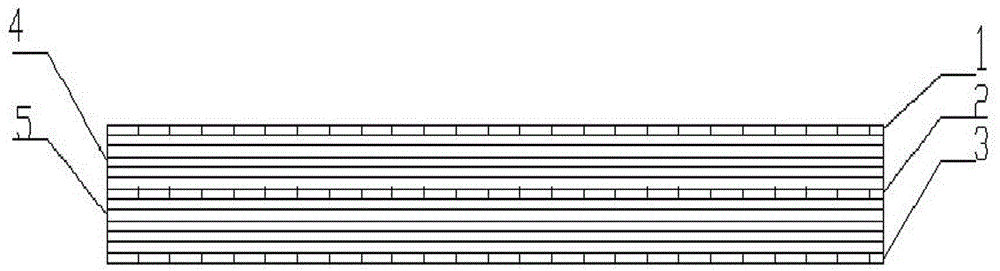

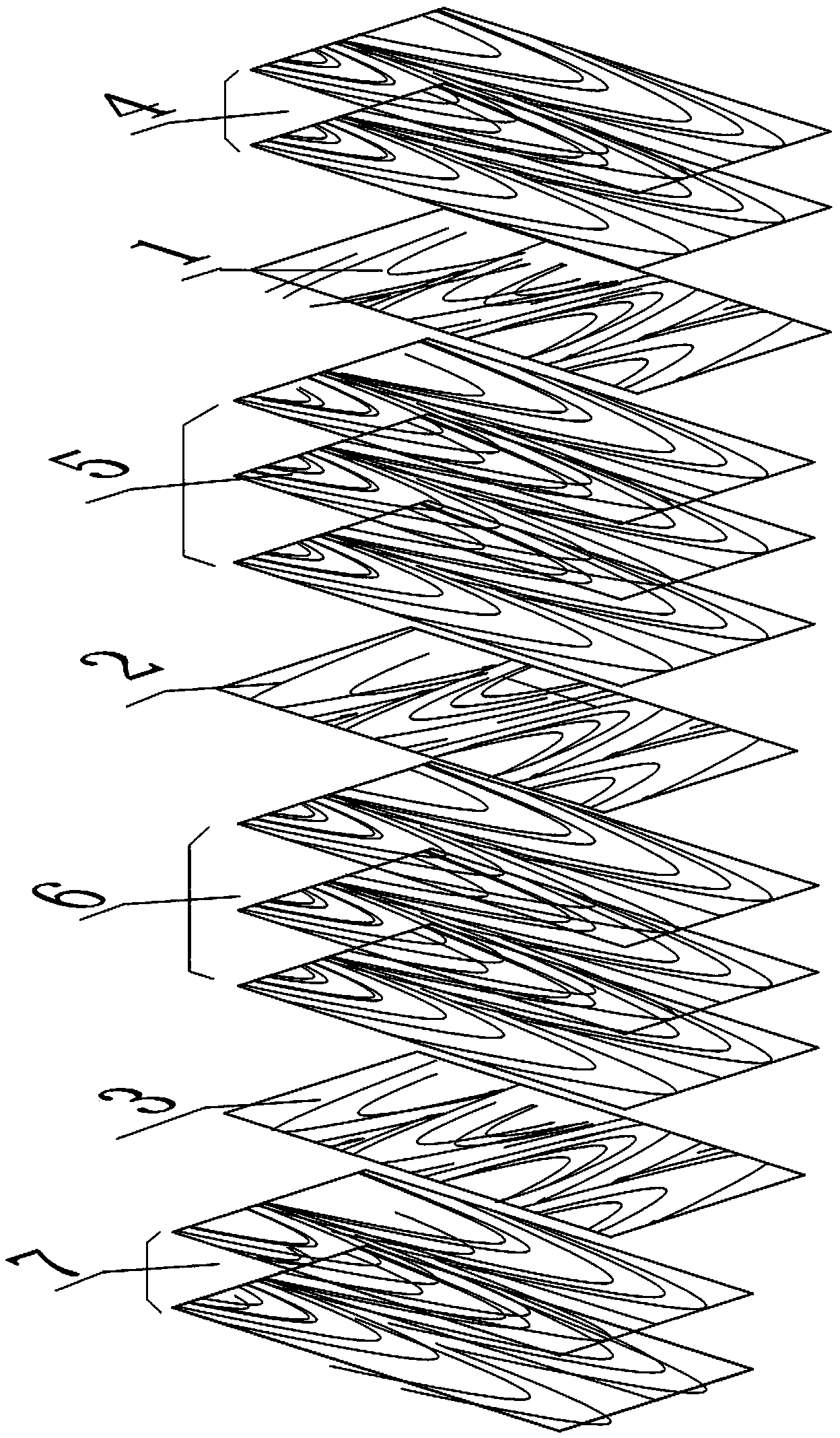

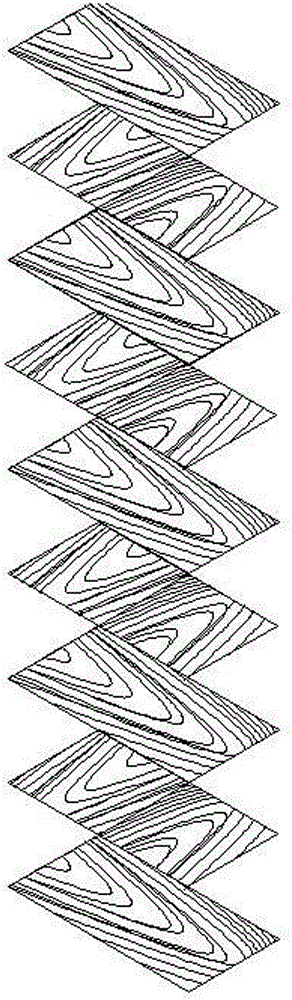

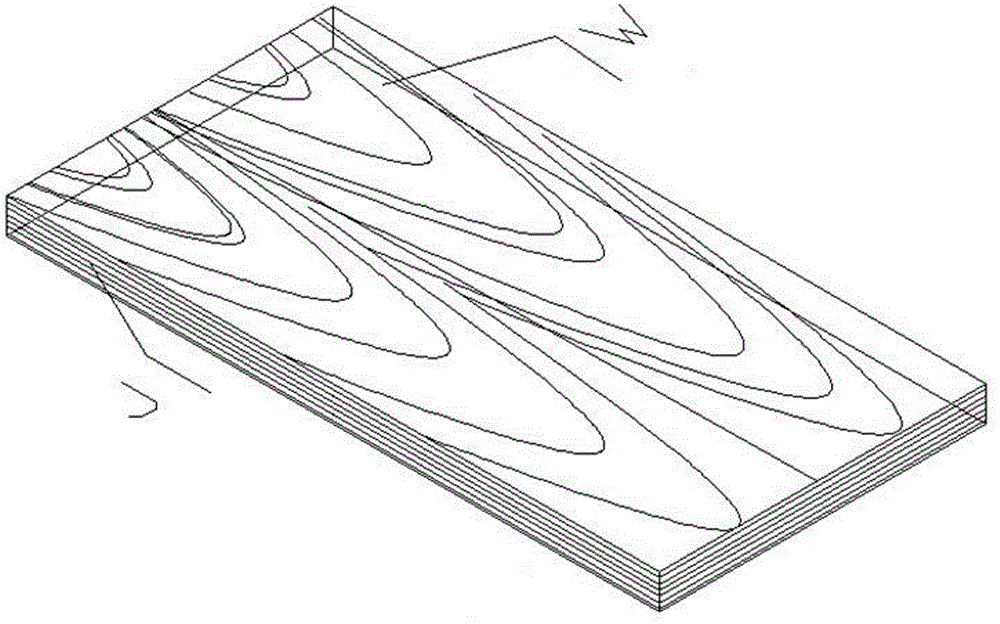

Novel solid-wood splice plate manufacturing method

InactiveCN104118019ATo overcome the problem of severe warpage, deformation and cracking, which makes it difficult to guarantee qualityImprove flatnessLaminationLamination apparatusSolid woodSander

The invention discloses a novel solid-wood splice plate manufacturing method. The method includes the following steps that softening physical treatment is conducted on raw woods; miniaturization treatment is conducted, and veneers are made; the veneers are dried through a special technology; a whole plate is formed through splicing, face plates and core materials are separated, a fully-longitudinal multi-layer plate structure is formed, and gluing is conducted; a fully-longitudinal multi-layer plate is formed through pressing of a hot press, and the wood is optimized through scientific pressure, compression ratio and compressed time; maintenance is conducted; four edges are cut off, and sanding and thickness calibrating are conducted through a sander; the longitudinal solid-wood multi-layer plate is cut into multiple layers of boards with a saw, and the boards are the same as a deformation prevention solid-wood multi-layer stacking plate in thickness; natural texture faces of the multiple layers of boards are glued, both the boards and a work table facet are put into an automatic felt-board machine, pressurization, high frequency and automatic heating are conducted, and the deformation prevention solid-wood multi-layer stacking plate is manufactured at one time, the four edges are cut off with the saw, sanding and thickness calibrating are conducted, the whole face of the spliced deformation prevention solid-wood multi-layer stacking plate is a multi-layer plate section, and the double faces are pasted with one layer or two layers of transverse signal plates. According to the novel solid-wood splice plate manufacturing method, the deformation prevention deepening treatment is further conducted based on the deformation prevention solid-wood multi-layer stacking plate; the internal stress of the wood is eliminated to the maximum degree, and wood deformation, cracking and warping are truly solved.

Owner:HARBIN SHENGSHI HUALIN TECH

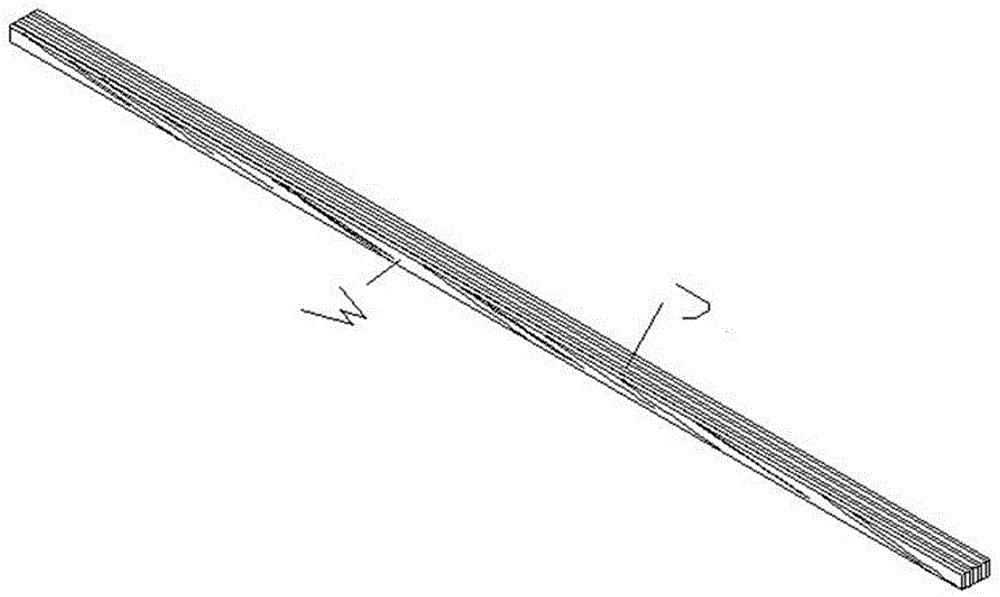

Method for manufacturing environmental-protection anti-deformation board at low carbon

InactiveCN104552496AResolves variable crackingSolve environmental problemsWood veneer joiningBattenMechanical engineering

The invention discloses a method for manufacturing an environmental-protection anti-deformation board at low carbon; timber resources are not inexhaustible resources, so the timber resources have the problems of high demand and high cost. The method comprises the following steps: S1, performing rotary cutting on logs into veneers by a rotary cutter; grading the veneers; drying the veneers until moisture content is lower than 12 percent; coating surface layers and a middle layer with glue, pressing to manufacture a composite board, and cutting into battens which are equal in specification; selecting three layers of cross grain arranged battens; putting one of the three layers of cross grain arranged battens in the middle, and putting the remaining two layers of cross grain arranged battens on the surface layers or inner layers of the surface layers; pressing the three layers of cross grain arranged battens into an anti-deformation board by a hot press; standing for more than 15 days for curing; cutting into broad battens according to fixed length, coating with the glue, and manufacturing an anti-deformation board by an automatic board jointing machine; cutting off the redundant four sides, and sanding with a sanding belt. According to the manufacturing method disclosed by the invention, valuable timber resources are replaced by fully utilizing common timber resources, and therefore the resources are saved; waste is turned into treasure, forest resources are protected strongly, and the cost is reduced.

Owner:HEILONGJIANG HUAXIN FURNITURE

Manufacturing method of environment-friendly energy-saving solid wood composite multilayer decoration board

The invention provides a manufacturing method of an environment-friendly energy-saving solid wood composite multilayer decoration board. At present, raw materials in industries of furniture, ornamentation, decoration and wood doors in China generally adopt solid wood boards, wedge joint boards, plywood, laminated wood boards, density boards, shaving boards and the like. The method comprises the following steps that firstly, raw wood is steamed and boiled for softening treatment, and is processed into veneers through rotary cutting, and drying is carried out; the wood textures of the veneers are divided into transverse texture arrangement and vertical texture arrangement, the veneers in transverse texture arrangement and vertical texture arrangement are arranged in a laminated 90-degree vertical crossing distribution mode, and in addition, the surfaces to be bonded are coated by glue; the ranged and glue coated veneers are placed into a hot pressing machine to be pressed into a multilayer plate, and resting preservation is carried out; square ranging is carried out, four edges are sawed away, grinding and thickness fixing are carried out by a grinding machine, and in addition, the glue is coated on the two sides; the glue is coated on a density board, the pressing is carried out by the hot pressing machine, and the grinding and the secondary thickness fixing are carried out by the grinding machine. The manufacturing method has the advantages that ordinary lumber resources are sufficiently used for replacing rare lumber resources, the goal of changing waste materials into valuable materials is achieved, the forest resources are powerfully protected, and the cost is reduced.

Owner:HEILONGJIANG HUAXIN FURNITURE

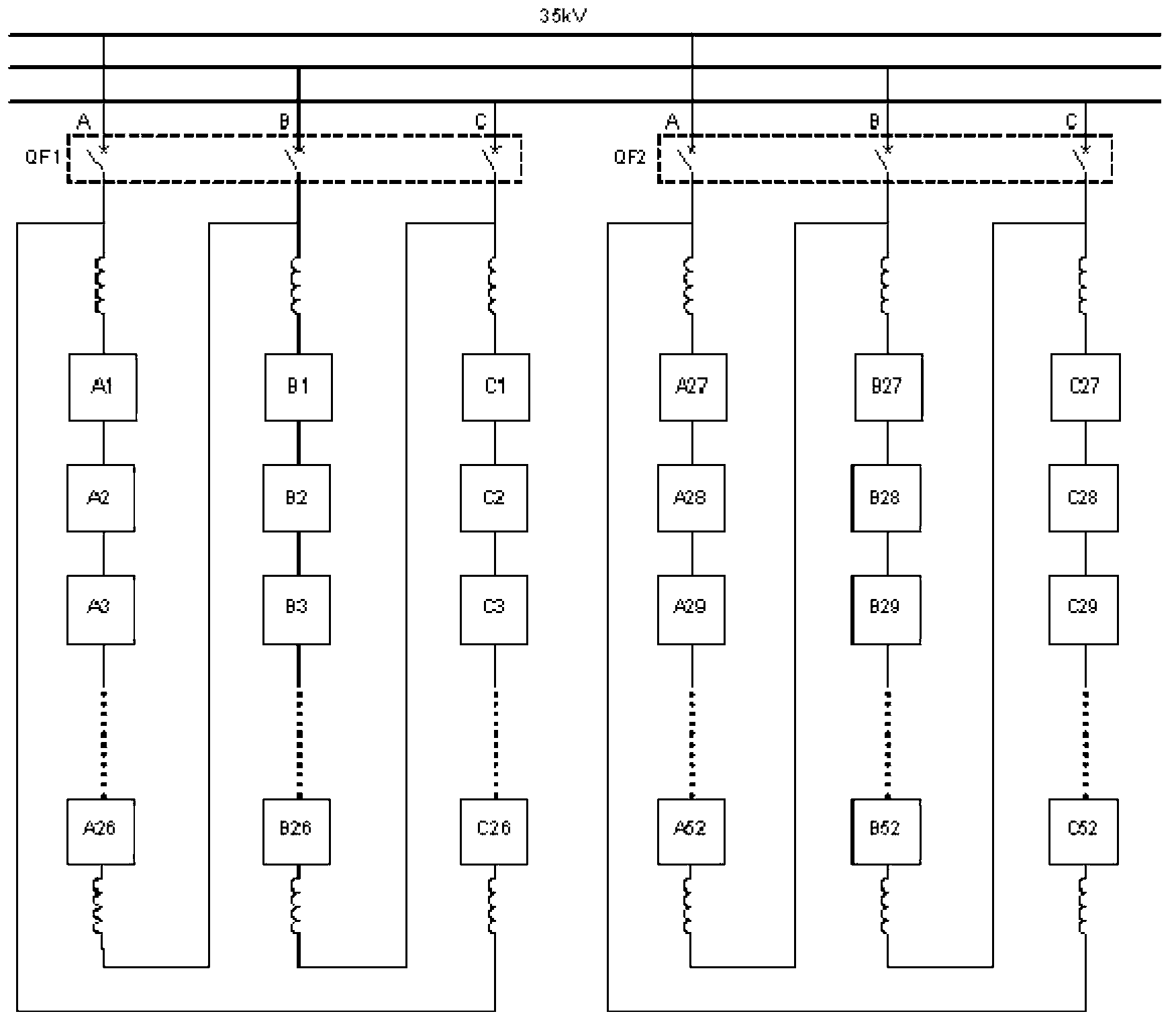

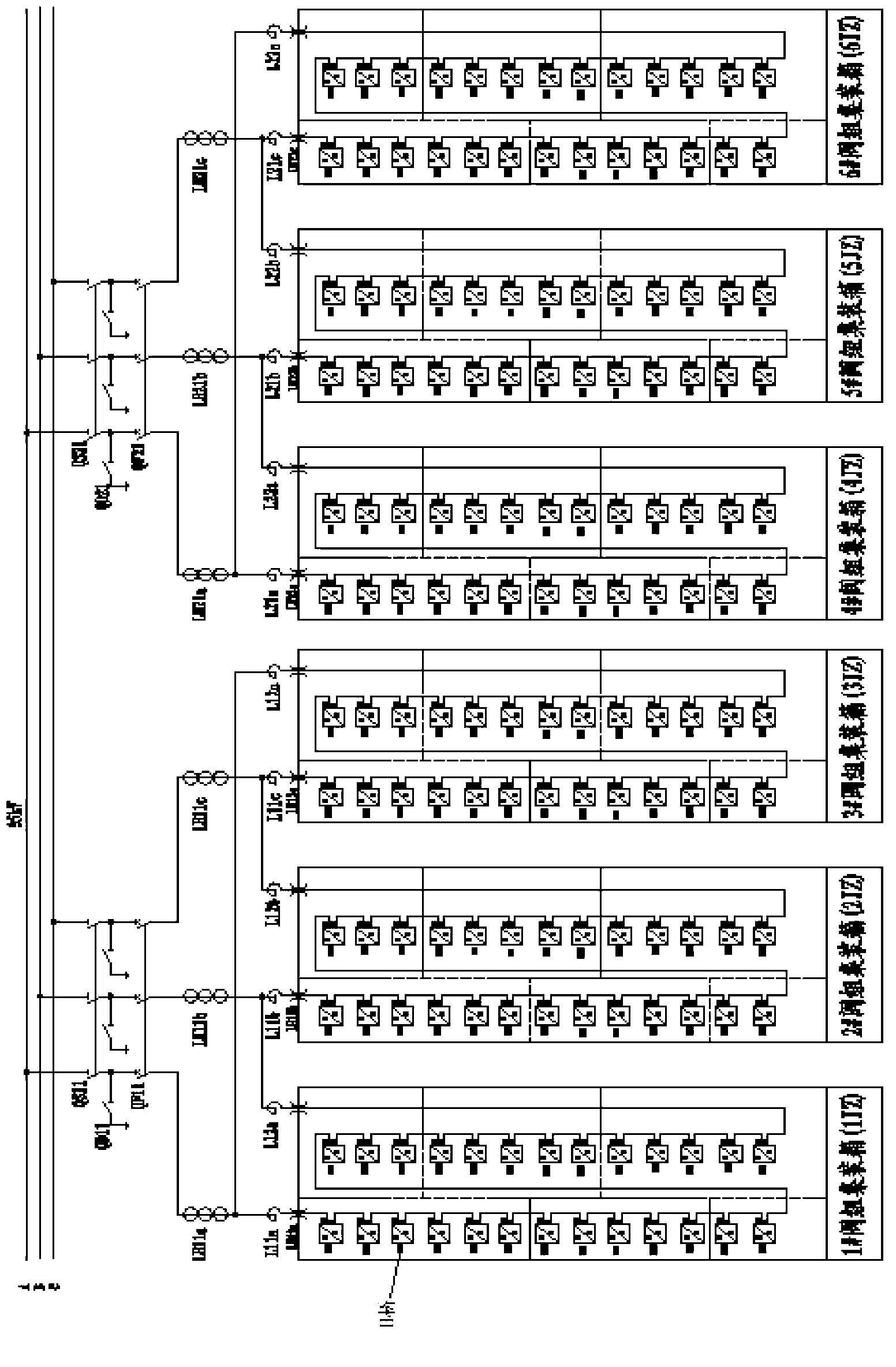

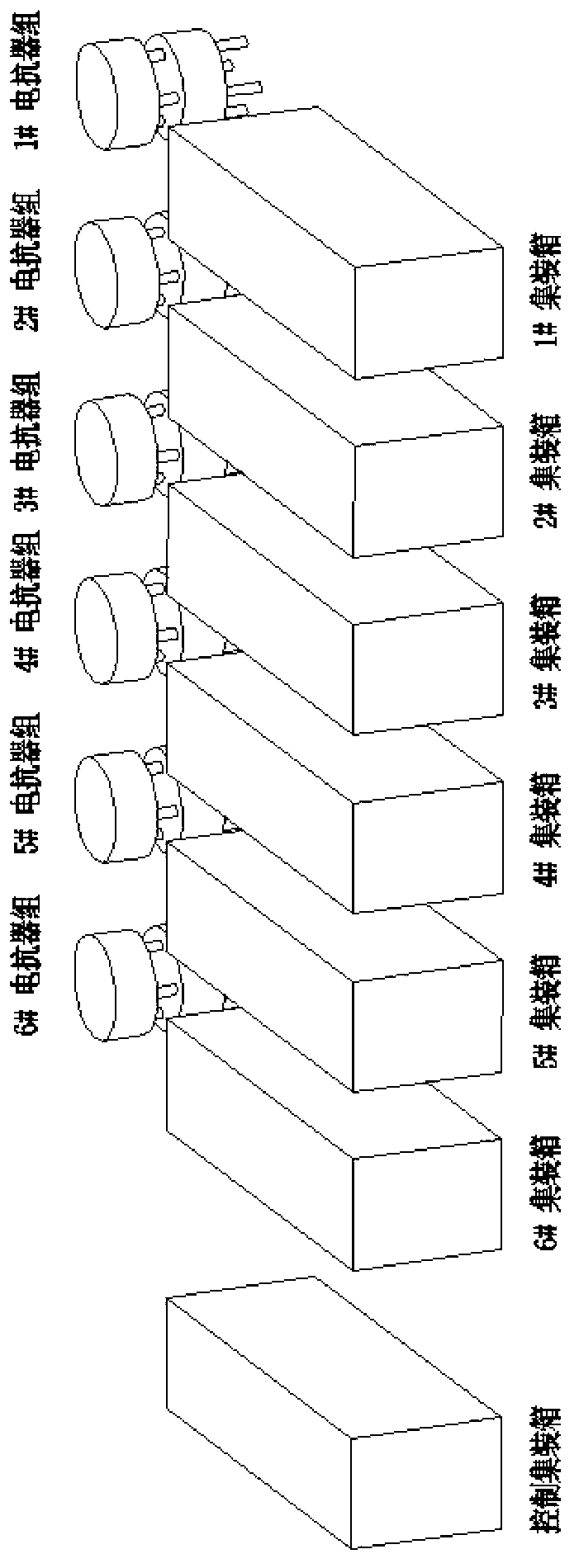

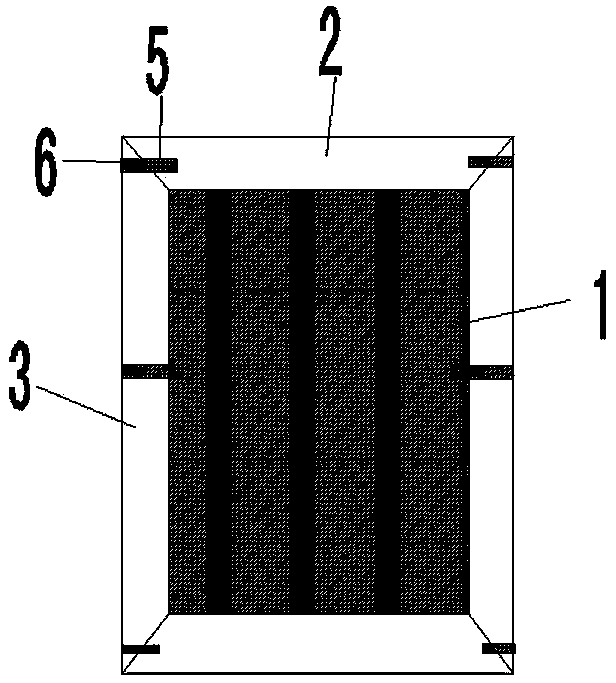

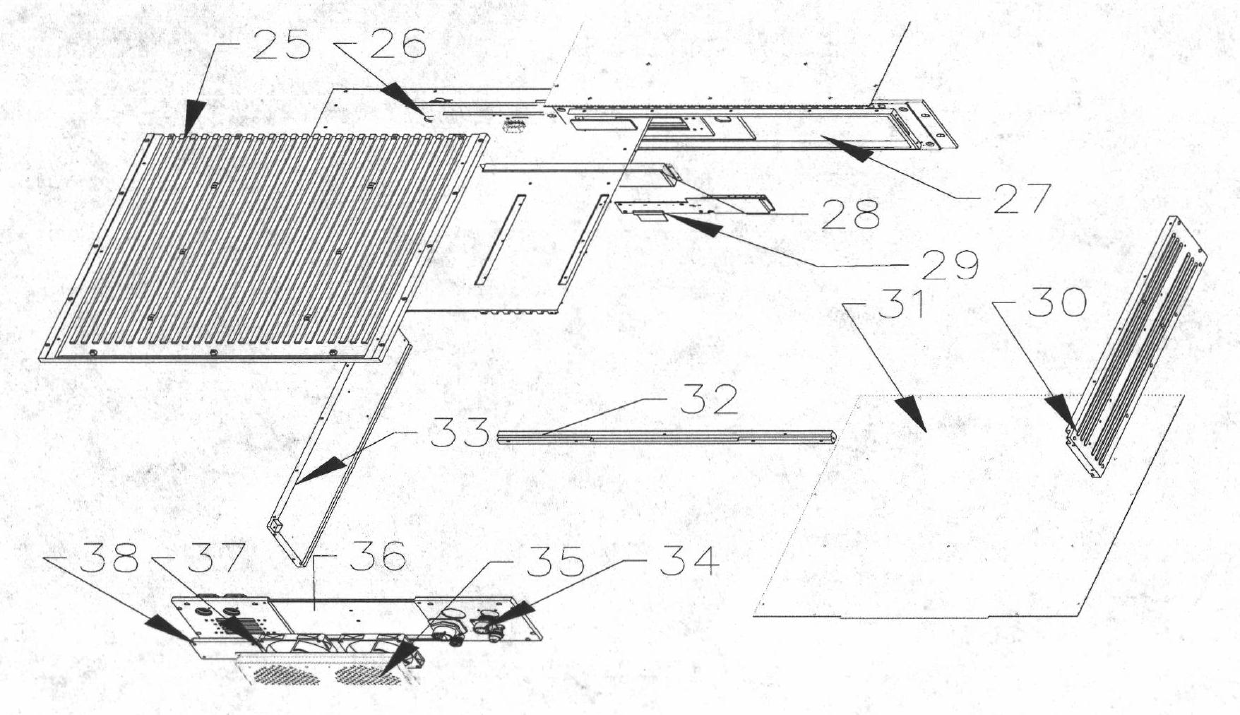

Movable high-voltage high-capacity chained STATCOM system container structure

ActiveCN102842858AGuaranteed accuracyGuaranteed reasonablenessFlexible AC transmissionSubstation/switching arrangement cooling/ventilationPower gridEngineering

A movable high-voltage high-capacity chained STATCOM system container structure comprises two chained STATCOM systems which are connected in parallel, each system comprises a three-phrase chained H bridge power unit group, and each three-phrase chained H bridge power unit group comprises a plurality of H bridge power units which are connected in series. Two ends of the each three-phrase chained H bridge power unit group are respectively provided with an electric reactor, and the each three-phrase chained H bridge power unit group is installed in a valve group container. The two electric reactors of the each three-phrase chained H bridge power unit group are placed up and down, and arranged outside the valve group container. The two systems which are connected in parallel are directly hung into a 35 kilovolt power grid respectively through a high-voltage switch QF1 and a high-voltage switch QF2. The total number of chained STATCOM system containers is seven. In the seven chained STATCOM system containers, six chained STATCOM system containers are valve group containers and one chained STATCOM system container is a controlling container. The movable high-voltage high-capacity chained STATCOM system container structure is low in manufacturing cost and good in heat dissipation, and brings convenience to mass production of STATCOM with different voltages and different capacities. In addition, the movable high-voltage high-capacity chained STATCOM system container structure is compact in structure, convenient to install, adjust, maintain, disassemble and transport, simple to place and install in the open air, convenient for power expansion and safe operation, and capable of satisfying the requirement of high-capacity installation.

Owner:GUANGDONG POWER GRID CO LTD DONGGUAN POWER SUPPLY BUREAU +1

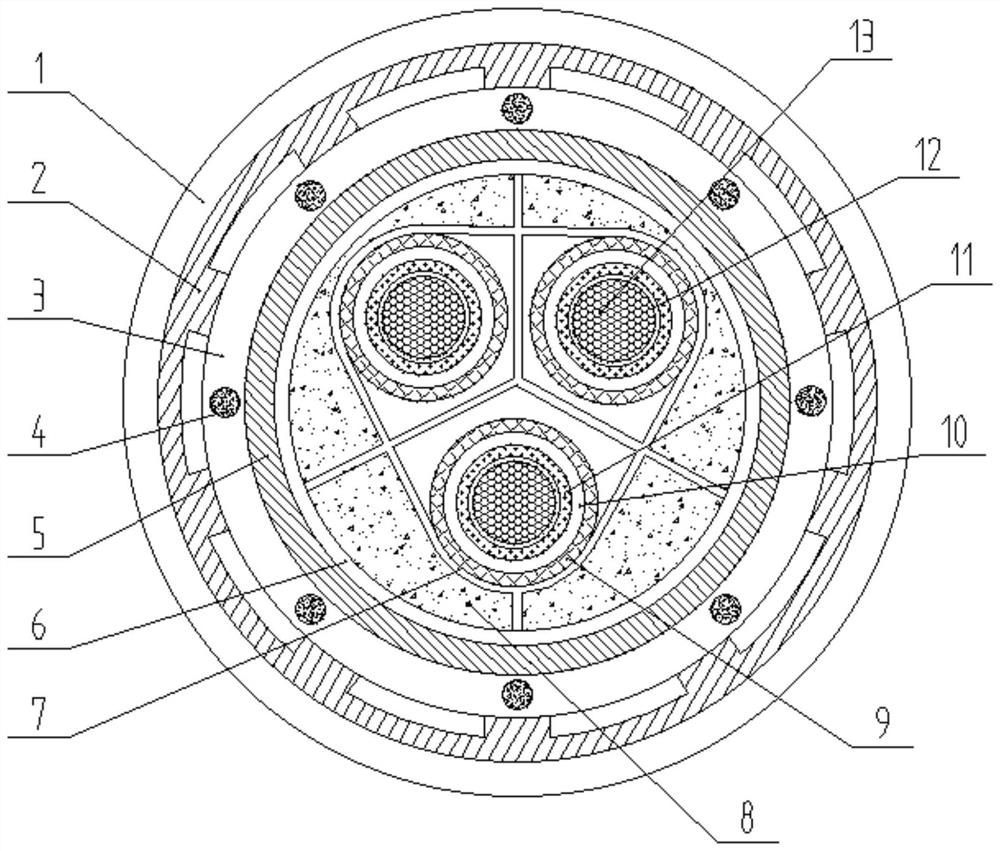

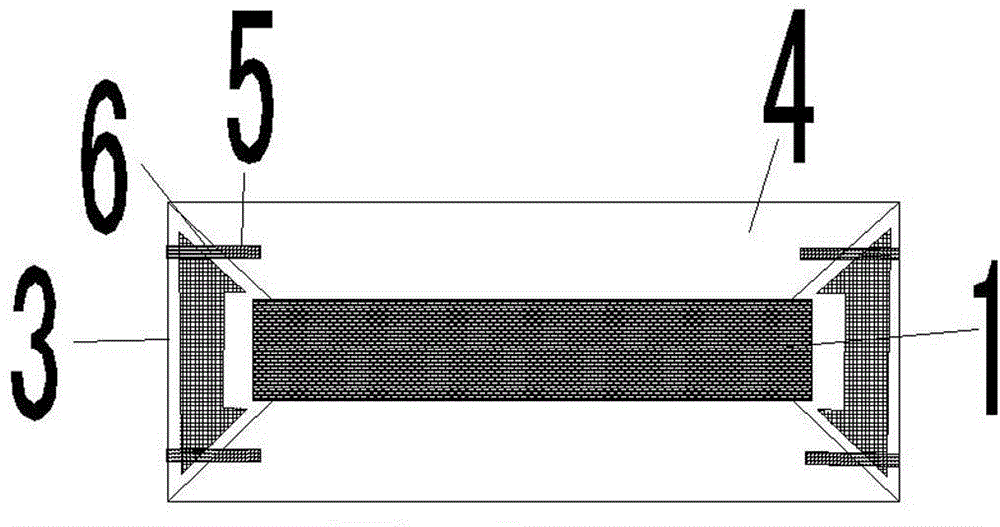

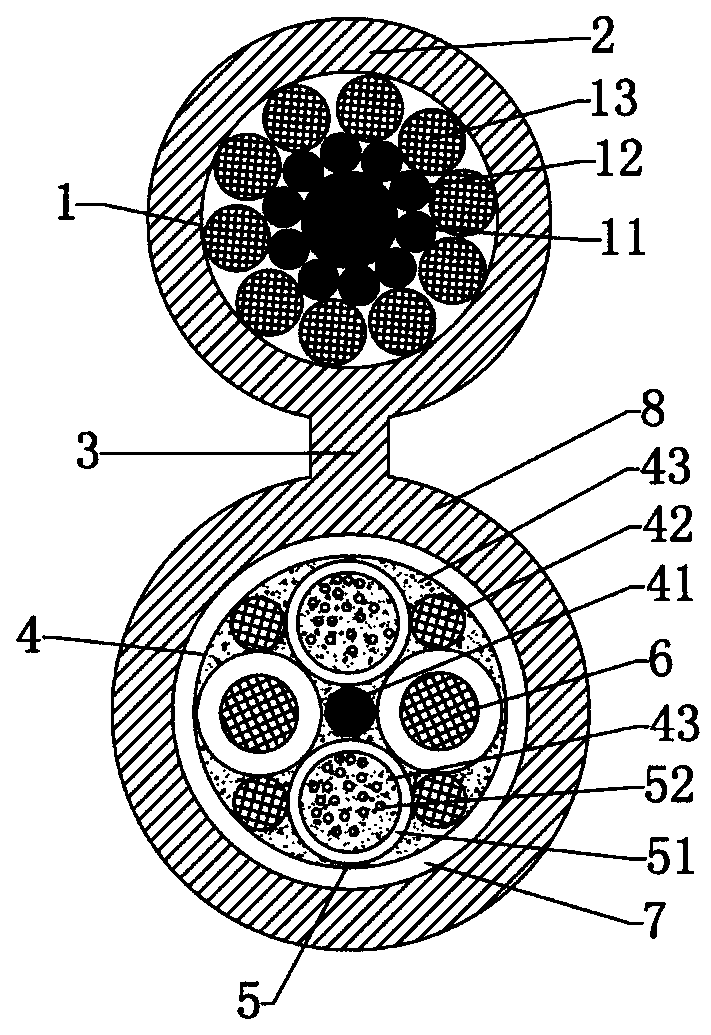

Fireproof and damp-proof subway cable

InactiveCN111653393ASolve fire resistanceSolve moisture resistanceInsulated cablesInsulated conductorsEngineeringStructural engineering

The invention relates to the technical field of wires and cables, in particular to a fireproof and damp-proof subway cable. The fireproof and damp-proof subway cable comprises a plurality of cable cores. An insulating layer, a shielding layer, a protective layer and a fireproof layer are sequentially arranged on the outer side of each cable core, the cable core is arranged in a fire insulation bracket, the fire insulation bracket is fixed on a water blocking layer, a damp-proof layer, a flame-retardant layer, an elastic isolation layer and a wear-resistant layer are sequentially coated outsidethe water blocking layer, and the fire insulation bracket divides all cable cores into independent cavities respectively. In order to overcome defects, the invention provides the fireproof and damp-proof subway cable with reliable performance, problems of poor fireproof and damp-proof performance of the existing subway cable are solved, and the cable is good in strength and not easy to damage.

Owner:云南龙源电缆有限公司

Low-carbon method for manufacturing environmental friendly deformation-prevention fireproof sheet material

InactiveCN103522373AImprove fire performanceSolve environmental problemsWood veneer joiningSingle plateFire retardant

The invention discloses a low-carbon method for manufacturing an environmental friendly deformation-prevention fireproof sheet material. Timber resources are not inexhaustible, so that the problems of large demand and high cost of the timber resources occur. The method includes the following steps that a raw wood is cut into veneers in a rotary mode through a rotary cutter, and the veneers are divided into grades and dried until the moisture content is lower than 12%; surface layers and a middle layer are coated by glue and then pressed to form a composite board, and the composite board is cut into laths of the same specification; three layers of laths with arrayed transverse textures are selected, one layer is placed in the middle layer, and the other two layers of the laths with the arrayed transverse textures are placed into the surface layers or inner layers of the surface layers, and a deformation-prevention sheet material is formed through a hot press in a pressing mode; the deformation-prevention sheet material is stored more than 15 days in a standing mode for conditioning, cut into wide laths according to a fixed length, coated by glue and then manufactured to be a deformation-prevention board through an automatic board jointing machine; the redundant four sides of the deformation-prevention board are cut off, and sanding is performed through a sanding belt; the deformation-prevention sheet material is soaked in a fire retardant and coated by dry oil. Common timber resources are fully used for replacing valuable timber resources, so that the resources are saved, waste is made to be profitable, forest resources are effectively protected, and cost is reduced.

Owner:HEILONGJIANG HUAXIN FURNITURE

Lily polysaccharide edible film

The invention provides lily polysaccharide edible film which is prepared by heating, moulding and film forming of lily polysaccharide molecule with molecular weight of 301-500Kda and comprising glucose, galactose, mannose, arabinose and galacturonic acid. The obtained lily polysaccharide edible film has advantages of moisture resistance, antibacterial performance, reduced moldy and high toughness, and is good substitute of traditional edible moisture-proof film.

Owner:上海汉素信生化科技发展有限公司

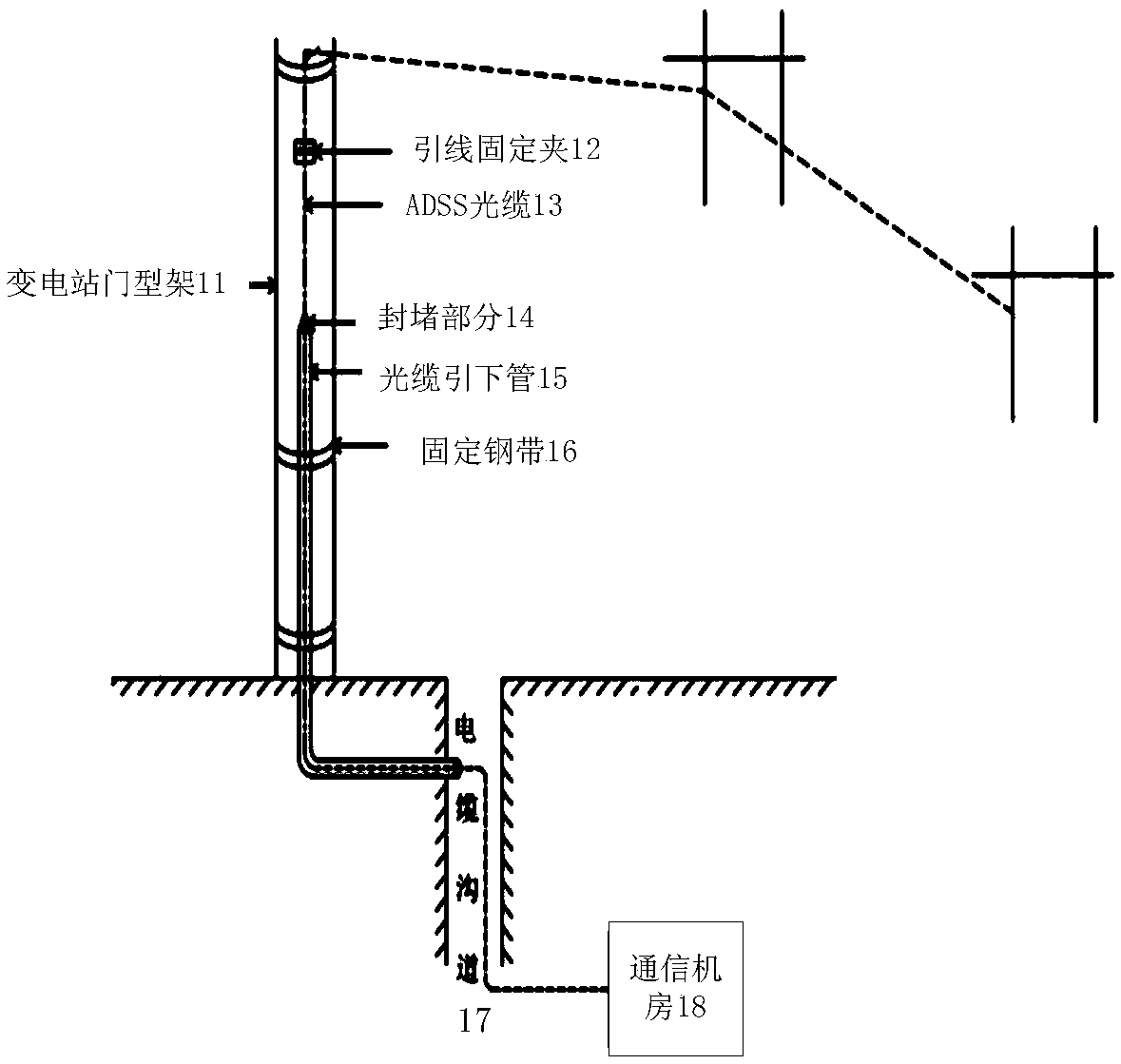

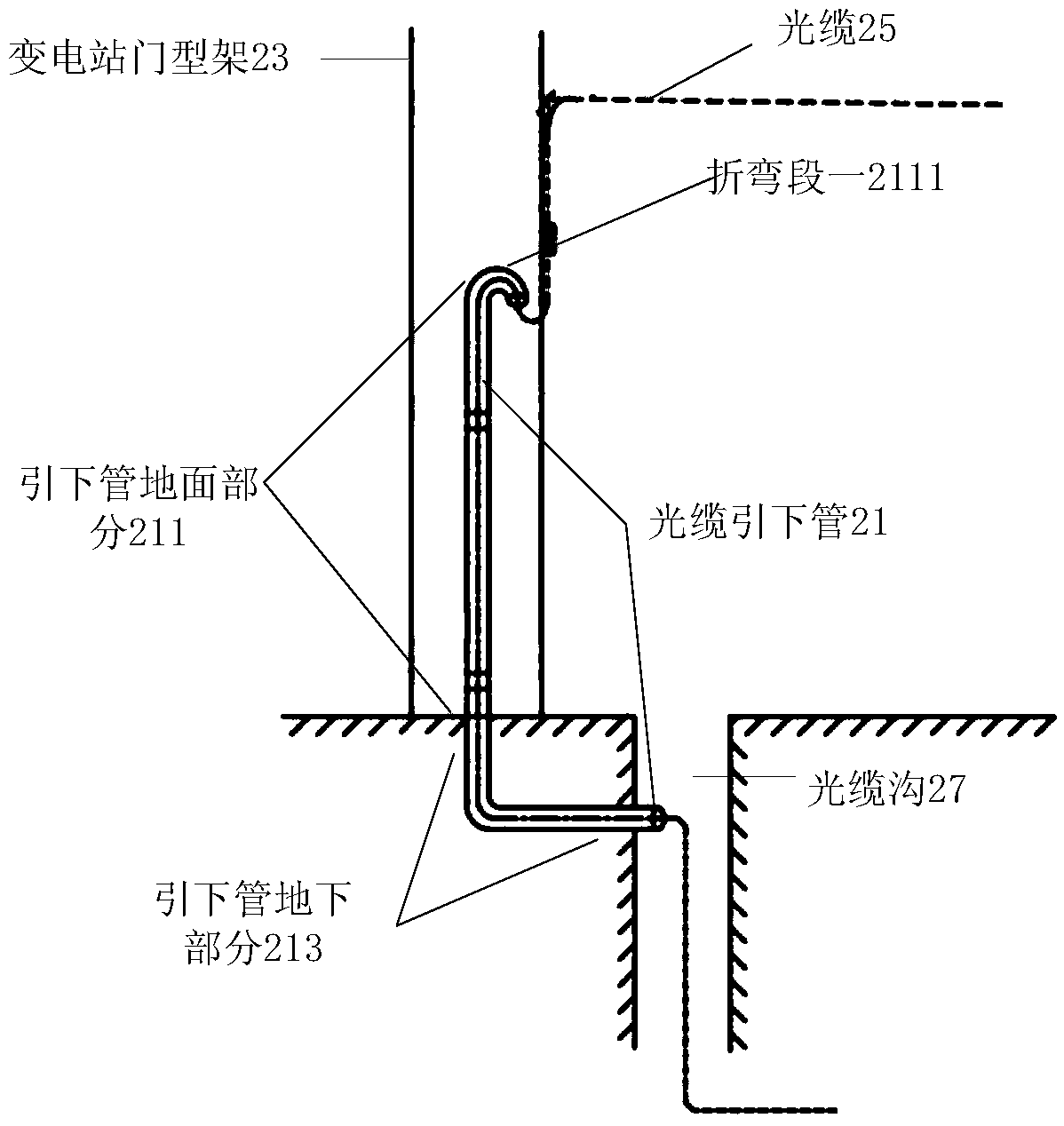

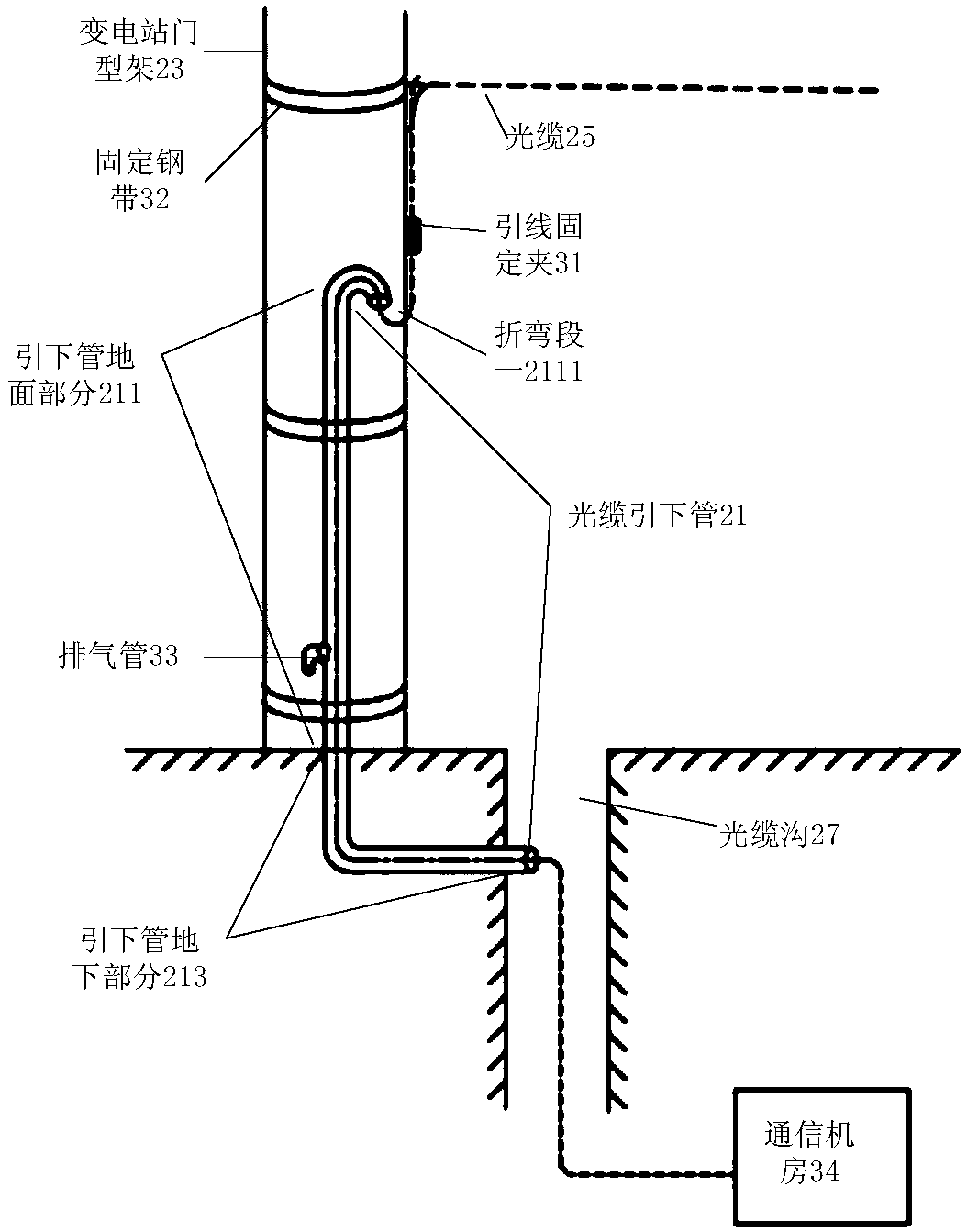

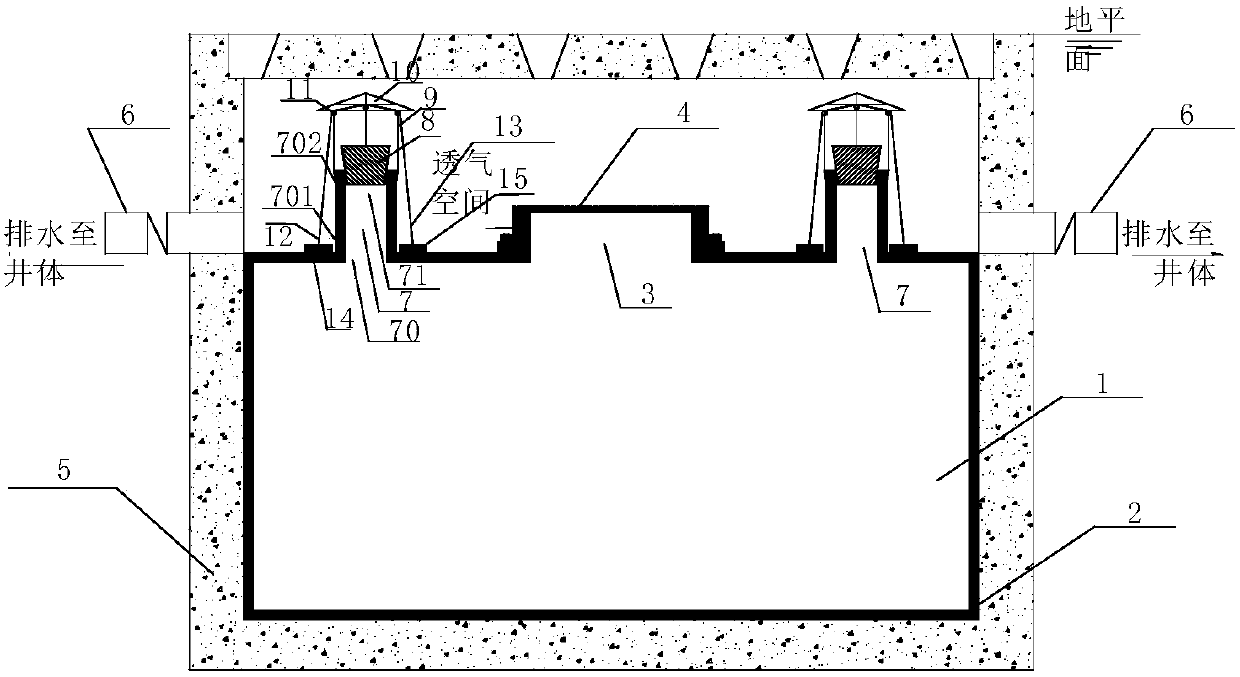

Optical cable lead-down pipe system

InactiveCN108802927AImprove reliabilitySolve moisture resistanceFibre mechanical structuresTransformerEngineering

The invention discloses an optical cable lead-down pipe system. The optical cable lead-down pipe system includes a transformer station door type framework and an optical cable lead-down pipe, whereinthe optical cable lead-down pipe is used for leading an optical cable out from an optical cable trench, and includes a ground part of the lead-down pipe and an underground part of the lead-down pipe;the top end of the ground part of the lead-down pipe includes a bended segment 1; the underground part of the lead-down pipe is laid to the optical cable trench; the transformer station door type framework is used for fixing the ground part of the lead-down pipe; and the bottom end of the transformer station door type framework is arranged at an underground preset distance location. The optical cable lead-down pipe system solves the technical problem that in the related arts, a blocking mode for the optical cable lead-down pipe is lower in the reliability.

Owner:STATE GRID CORP OF CHINA +2

Manufacturing method of environment-friendly high-strength anti-deformation aluminum core composite door

InactiveCN104552486AMake up for heavy and easily deformedMake up for crackingLayered product treatmentLaminationInter layerSingle plate

The invention discloses a manufacturing method of an environment-friendly high-strength anti-deformation aluminum core composite door, aiming at the problem that existing plates are uneven in thickness, abnormal in color, overmuch in scab, not environment-friendly and easy to deform. The manufacturing method comprises the steps of rotationally cutting scrap edge environment-friendly wood materials into 2mm-5mm veneers and drying the veneers; gluing an upper-layer panel, a lower-layer panel and a middle-layer panel, pressing the upper-layer panel, the lower-layer panel and the middle-layer panel into a composite plate, sawing the composite plate into plate strips in the same specification, and repeating a gluing process; putting core materials among three layers of transverse-grain balance tension plates, pressing to form multi-layer plates and manufacturing into wide wood strips after conditioning; putting the wide wood strips into an automatic plate splicing machine to form multi-layer plates and sanding into fixed thickness; pressing thin aluminum plates and the multi-layer plates to form an aluminum core composite plate, cutting the aluminum core composite plate into plates with specified shapes, covering wood skin, spraying priming paint, drying, sanding, correcting the color, and spraying finish paint.

Owner:HEILONGJIANG HUAXIN FURNITURE

Vegetable delivery elevator and preparation method thereof

InactiveCN109504230AEfficient killingSolve moisture resistanceAntifouling/underwater paintsPaints with biocidesChemistryMagnesium

The invention discloses a vegetable delivery elevator. The elevator comprises a car, which comprises a body and an antibacterial coating arranged on the surface of the body; the antibacterial coatingis mainly prepared from the following raw materials in parts by mass: 5-15 parts of calcium carbonate, 5-15 parts of zinc oxide, 5-15 parts of magnesium oxide, 40-60 parts of a phosphoric acid solution, 0.1- 2 parts of silver powder, 10-15 parts of kieselguhr, 5-20 parts of epoxy resin and 2-5 parts of an auxiliary agent. A mode that the antibacterial coating coats the surface of the car is adopted, and the moisture-proof and antibacterial effects of the vegetable delivery elevator are effectively achieved; a disinfecting component compounded by the kieselguhr, cerium oxide and the silver powder is adopted; bacteria can be effectively killed in an environment short of light. Moreover, a reasonable formula system is adopted by the antibacterial coating, and has particularly strong adhesiveforce to a metal matrix; the antibacterial coating is uniformly attached to the surface of the car through a reasonable spraying process, so that the service time of the elevator is long.

Owner:佛山市高明区安承升降装备研究院

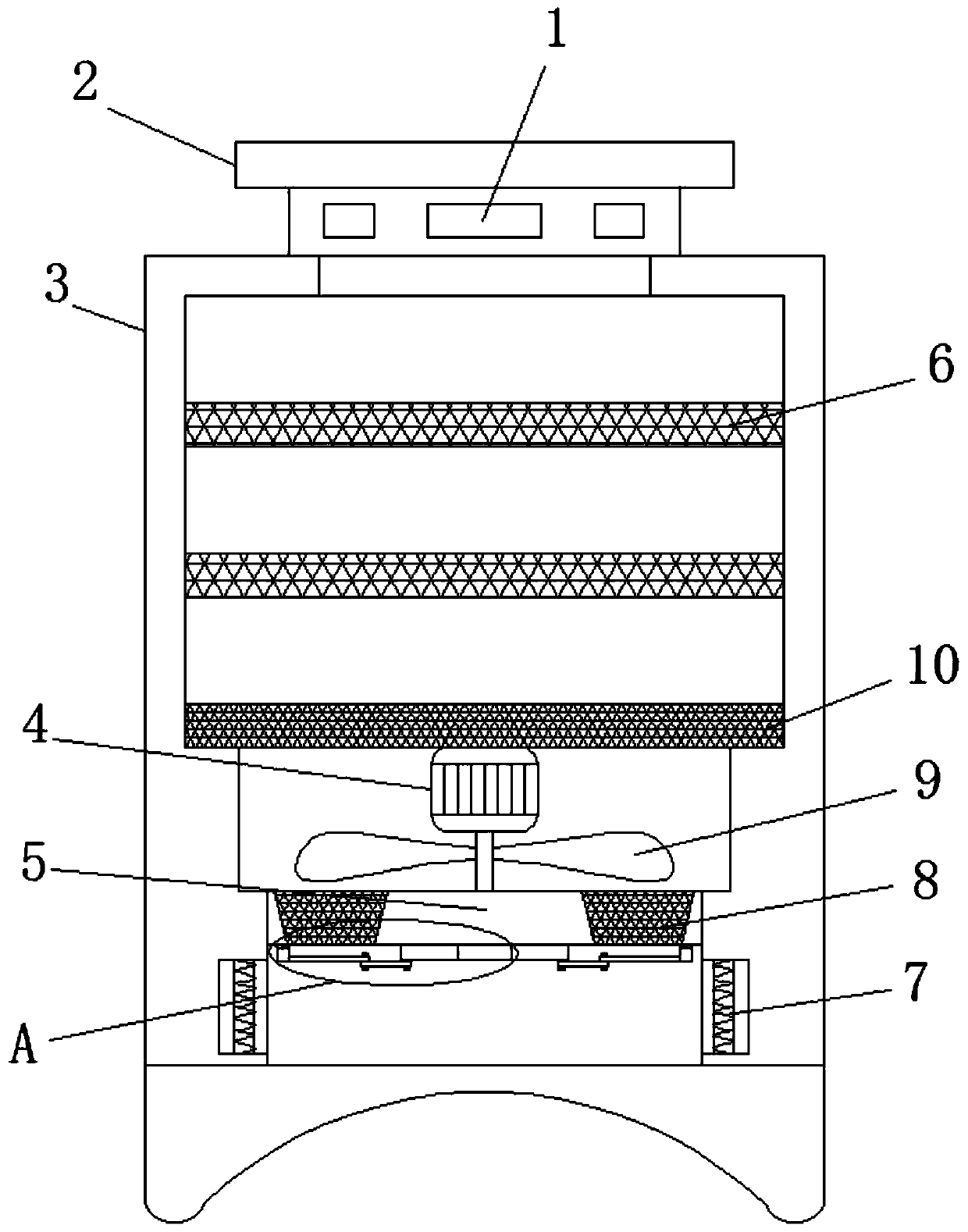

Computer waterproof and moistureproof protection equipment

ActiveCN110612005AImprove cooling effectImprove adaptabilityCasings/cabinets/drawers detailsRefrigerationRefrigerated temperature

The invention relates to the technical field of computer equipment and particularly discloses computer waterproof and moistureproof protection equipment. A protection assembly which comprises a dryingmoistureproof refrigeration cavity and a containing cooling cavity is set, the containing cooling cavity is used for accommodating computer equipment to be protected, a drying assembly and a refrigerator are arranged in the drying moistureproof refrigeration cavity, and a circulating flow channel cooling assembly is arranged outside the containing cooling cavity in a surrounding manner. Airflow refrigerated by the refrigerator is communicated to the circulating flow channel cooling assembly, the circulating flow channel cooling assembly can take away heat generated by a computer, the heat dissipation capacity of the computer can be effectively improved, meanwhile, the waterproof and moistureproof effects are guaranteed, the problem of the contradiction between waterproof and moistureproofeffects and heat dissipation is effectively solved, the adaptability of the computer in a severe environment is improved, and the reliability and safety of computer work are guaranteed.

Owner:HEILONGJIANG UNIV OF TECH

Manual fire hydrant button for optical fiber

PendingCN108766814AFix false positivesSolve the problem of failureElectric switchesCopper wireElectromagnetic interference

The invention discloses a manual fire hydrant button for an optical fiber. A first spring is arranged at the lower part of a touch panel of the button; a bottom shell is connected with a reset component through a second spring; a lug boss is arranged on the side, close to the touch panel, of the reset component; an inserted part is arranged on the side, close to the reset component, of the touch panel; when the touch panel manually moves downwards to get close to the bottom shell, the inserted part of the touch panel justly falls into the middle of two optical fiber clamping racks, the lug boss of the reset component enters into the inserted part of the touch panel, and then an optical path between the two optical fiber clamping racks is cut, a reset tool is used for running through a reset hole and pressing the reset component, so that the lug boss of the reset component is separated from the inserted part of the touch panel, and the touch panel moves upwards to reset under the effectof the first spring at the lower part of the touch panel. The function of manual fire hydrant button is realized in a pure optical manner so as to solve the problems such as anti-electromagnetic interference, moisture prevention and the corrosion, rust and verdigris prevention of copper wires, and the reliability performance is improved.

Owner:深圳晶点光科有限公司

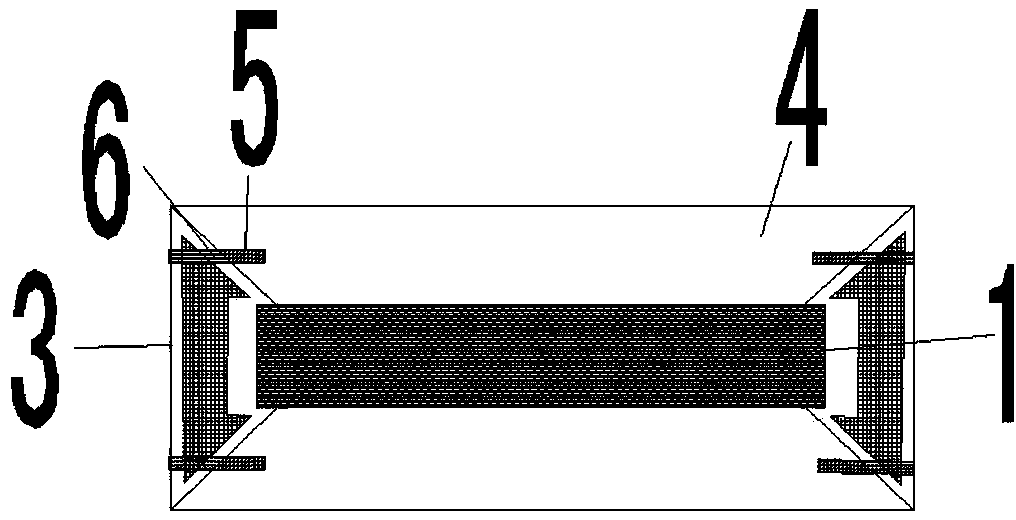

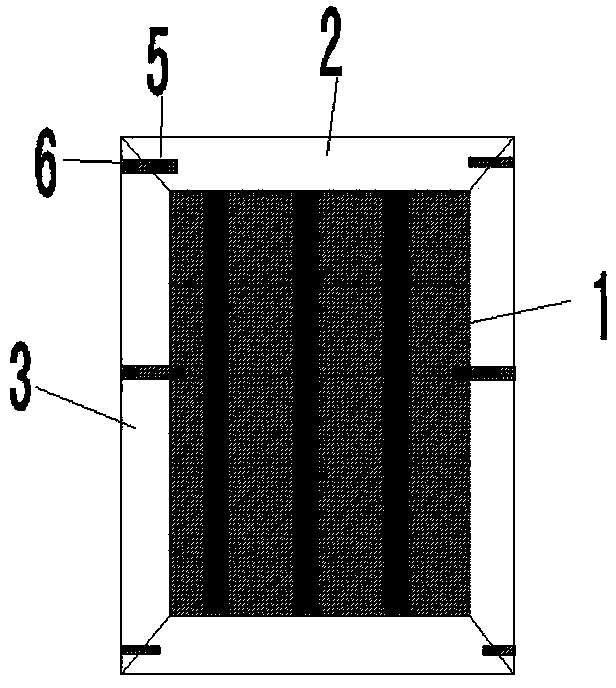

Anti-deformation aluminum-clad heat insulation door

InactiveCN104563783AResolves variable crackingSolve environmental problemsDoor leavesBolt connectionBlind hole

The invention discloses an anti-deformation aluminum-clad heat insulation door, which consists of components such as a door core 1, an aluminum-clad wood door transverse frame 2, an aluminum-clad wood door vertical frame 3 and a surface layer 4, wherein the door core 1, the aluminum-clad wood door transverse frame 2, the aluminum-clad wood door vertical frame 3 and a door surface 4 are formed by connecting screw nuts, screw bolts, through holes 6 and blind holes 5, the through holes 6 and the blind holes 5 are dug in the aluminum-clad wood door transverse frame 2, the aluminum-clad wood door vertical frame 3, the door core 1 and the door surface 1, the blind holes 5 are formed in the door core 1 and the door surface 4, the aluminum-clad wood door transverse frame 2 and the aluminum-clad wood door vertical frame 3 are provided with the through holes 6 with corresponding the positions and the sizes to those of the blind holes, the aluminum-clad wood door transverse frame 2 and the aluminum-clad wood door vertical frame 3 are connected by fixing screw bolts arranged in the blind holes 5 and the through holes 6, and the screw nuts are arranged in the blind holes formed in the door core 1 and the door surface 4.

Owner:HEILONGJIANG HUAXIN FURNITURE

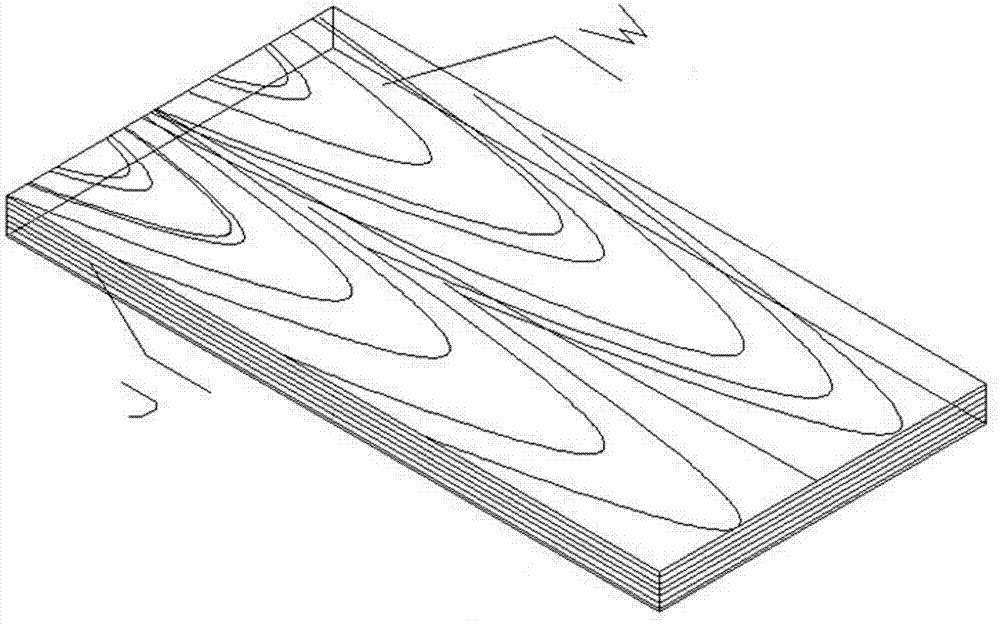

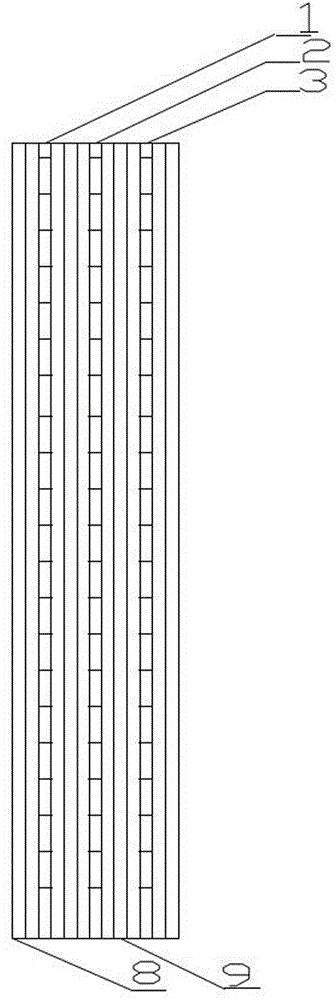

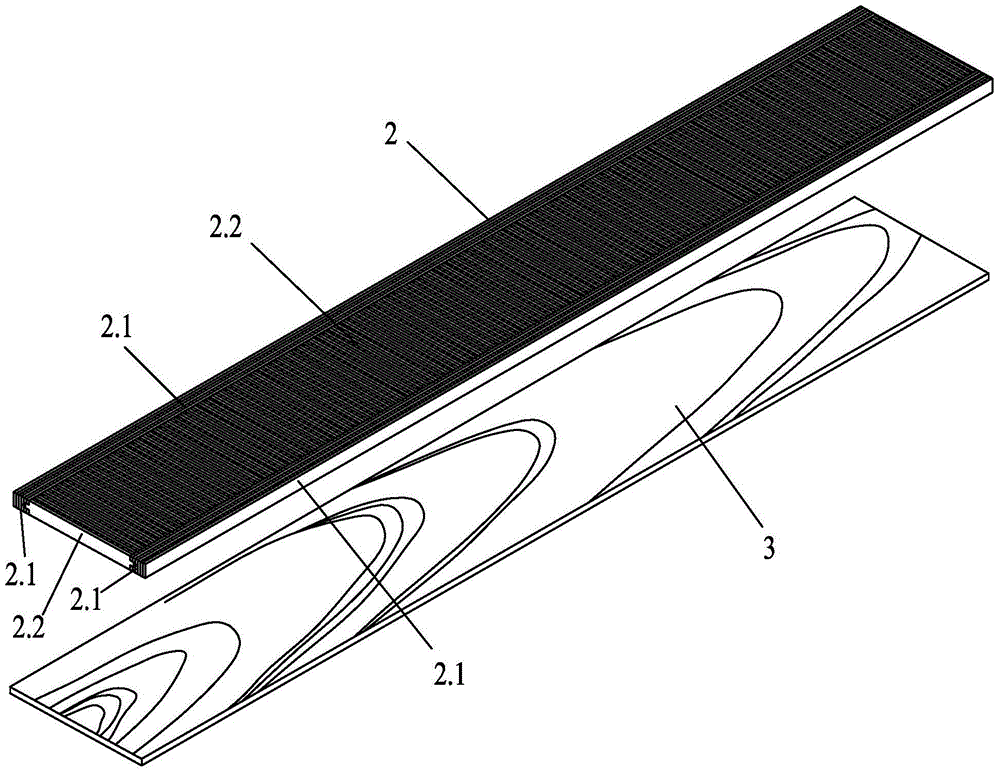

Deformation-preventing solid-wood floor-heating-resistant floor base material, manufacturing method of deformation-preventing solid-wood floor-heating-resistant floor base material and floor manufactured with deformation-preventing solid-wood floor-heating-resistant floor base material

InactiveCN104594607AReduce moistureBalance moistureWood working apparatusFlooringSolid woodHigh pressure

The invention discloses a deformation-preventing solid-wood floor-heating-resistant floor base material, a manufacturing method of the deformation-preventing solid-wood floor-heating-resistant floor base material and a floor manufactured with the deformation-preventing solid-wood floor-heating-resistant floor base material, and belongs to the field of solid-wood composite floors. The deformation-preventing solid-wood floor-heating-resistant floor base material, the manufacturing method and the floor aim at solving the problems that a current solid-wood floor is high in cost, is deformed, warped and cracked, is not environmentally friendly, is not resistant to moisture and can not be used on a floor-heating ground. A base plate is pasted to the bottom of a middle layer of the base material; edge strips are arranged on the two lateral sides of a core, the edge strips and the core are composed of veneers in a spliced mode, wood grains of the edge strips are perpendicular to wood grains of the core, and the wood grains of the edge strips and the wood grains of the core are perpendicular to wood grains of the base plate. The floor is composed of the base material and a famous-and-precious-wood face plate in a spliced mode. The method includes the steps that raw wood is boiled to be softened and cut into the veneers and the base plate, and drying is carried out; edge strip blank plates and a core blank plate are formed in a spliced mode, high-temperature and high-pressure pressing processing is carried out, conditioning, edge cutting, sanding and thickness fixing are carried out, the materials are spliced together to be pressed and sanded, and the base material is obtained. According to the deformation-preventing solid-wood floor-heating-resistant floor base material, the manufacturing method and the floor, energy emitted by a floor heating tube can be stored through a cavity groove of the core, and resources are saved; meanwhile, the internal stress of the wood is eliminated, and the floor can be prevented from being deformed. The deformation-preventing solid-wood floor-heating-resistant floor base material, the manufacturing method and the floor are particularly suitable for floor heating pavement.

Owner:张福贵

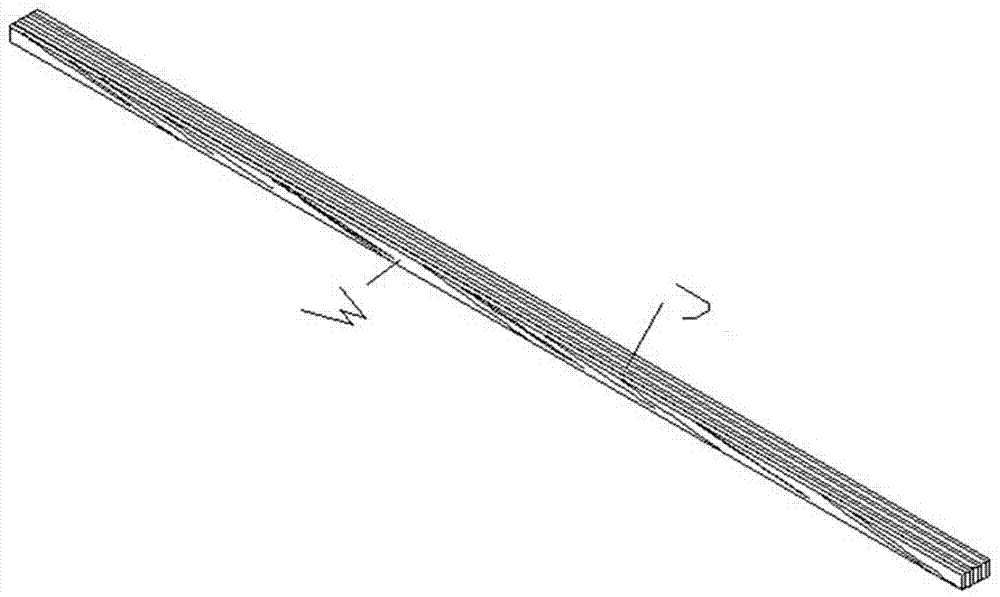

Manufacturing method for novel solid wood composite plate special for door pocket

InactiveCN105313197ATo overcome the problem of severe warpage, deformation and cracking, which makes it difficult to guarantee qualityImprove flatnessLaminationLamination apparatusSolid woodSander

The invention discloses a manufacturing method for a novel solid wood composite plate special for a door pocket. The manufacturing method comprises the following steps: performing softening physical treatment on raw wood; performing miniaturizing treatment on the raw wood to make the raw wood into thin wood plates; drying the thin wood plates with a special process; splicing the thin wood plates into an integrated plate, forming panels and core materials, arranging the panels and the core materials into all-longitudinal multi-layer plate structures, and printing glue; pressing the all-longitudinal multi-layer plate structures into an all-longitudinal multi-layer plate by using a hot press, and optimizing the wood material by adopting scientific pressure, compression ratio and compression time; enabling the all-longitudinal multi-layer plate to experience a unique curing period so that the solid wood multi-layer plate is more stable and non-deformable; cutting the four edges of the solid wood multi-layer plate, sanding the solid wood multi-layer plate by using a sanding machine, and fixing the thickness; sawing the longitudinal solid wood multi-layer plate into multi-layer plate strips, wherein the widths of the multi-layer plate strips are determined as required and are consistent with the thickness of an anti-deformation solid wood multi-layer laminated plate; coating the natural texture surfaces of the multi-layer plate strips with the glue, enabling the multi-layer plate strips coated with the glue to be perpendicular to a work surface, and placing the multi-layer plate strips coated with the glue into an automatic plate splicing machine (namely, the multi-layer plate strips are used vertically); pressurizing, performing high-frequency treatment, heating automatically, and performing one-time forming to form an anti-deformation solid wood multi-layer laminated plate; sawing the four edges, sanding, and fixing the thickness, wherein the overall surface of the spliced anti-deformation solid wood multi-layer laminated plate is the cross section of the multi-layer plate; adhering density plates to the two surfaces of the anti-deformation solid wood multi-layer laminated plate. According to the technology, anti-deformation deepening treatment is further performed on the basis of the anti-deformation solid wood multi-layer laminated plate, so that the internal stress of the wood material is eliminated to the greatest extent, and the difficult problems of deformation, crack and warpage of the wood material are really solved.

Owner:HARBIN SHENGSHI HUALIN TECH

High-intensity deformation-resistant aluminum-clad sound isolation door

InactiveCN104563814AResolves variable crackingSolve environmental problemsNoise insulation doors/windowsEngineeringHigh intensity

The invention discloses a high-intensity deformation-resistant aluminum-clad sound isolation door, which comprises components including a door core 1, an aluminum-clad wood door transverse frame 2, an aluminum-clad wood door vertical frame 3, a door surface 4, a sound isolation layer 5 and the like, wherein the door core 1, the aluminum-clad wood door transverse frame 2, the aluminum-clad wood door vertical frame 3 and the door surface 4 are connected through screw nuts, screw bolts, through holes 6 and blind holes 5 formed in the aluminum-clad wood transverse frame 2, the aluminum-clad wood door vertical frame 3, the door core 1 and the door surface 4 for forming the door, the blind holes 5 are formed in the door core 1 and the door surface 4, the aluminum-clad wood door transverse frame 2 and the aluminum-clad wood door vertical frame 3 are provided with the through holes 6 with the positions and dimensions corresponding to those of the blind holes, and the aluminum-clad wood door transverse frame 2 and the aluminum-clad wood door vertical frame 3 are connected through fixing screw bolts arranged in the blind holes 5 and the through holes 6, and the screw nuts are arranged in the blind holes formed in the door core 1 and the door surface 4.

Owner:HEILONGJIANG HUAXIN FURNITURE

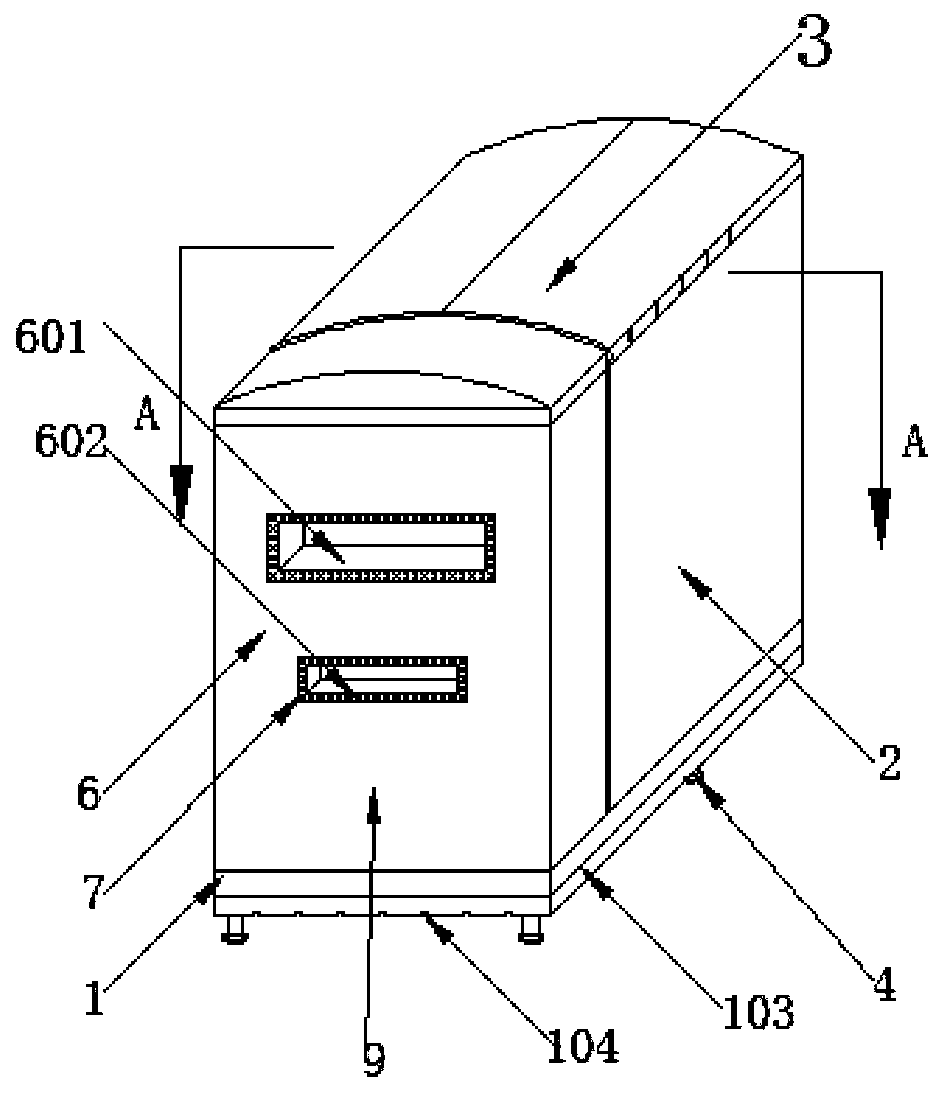

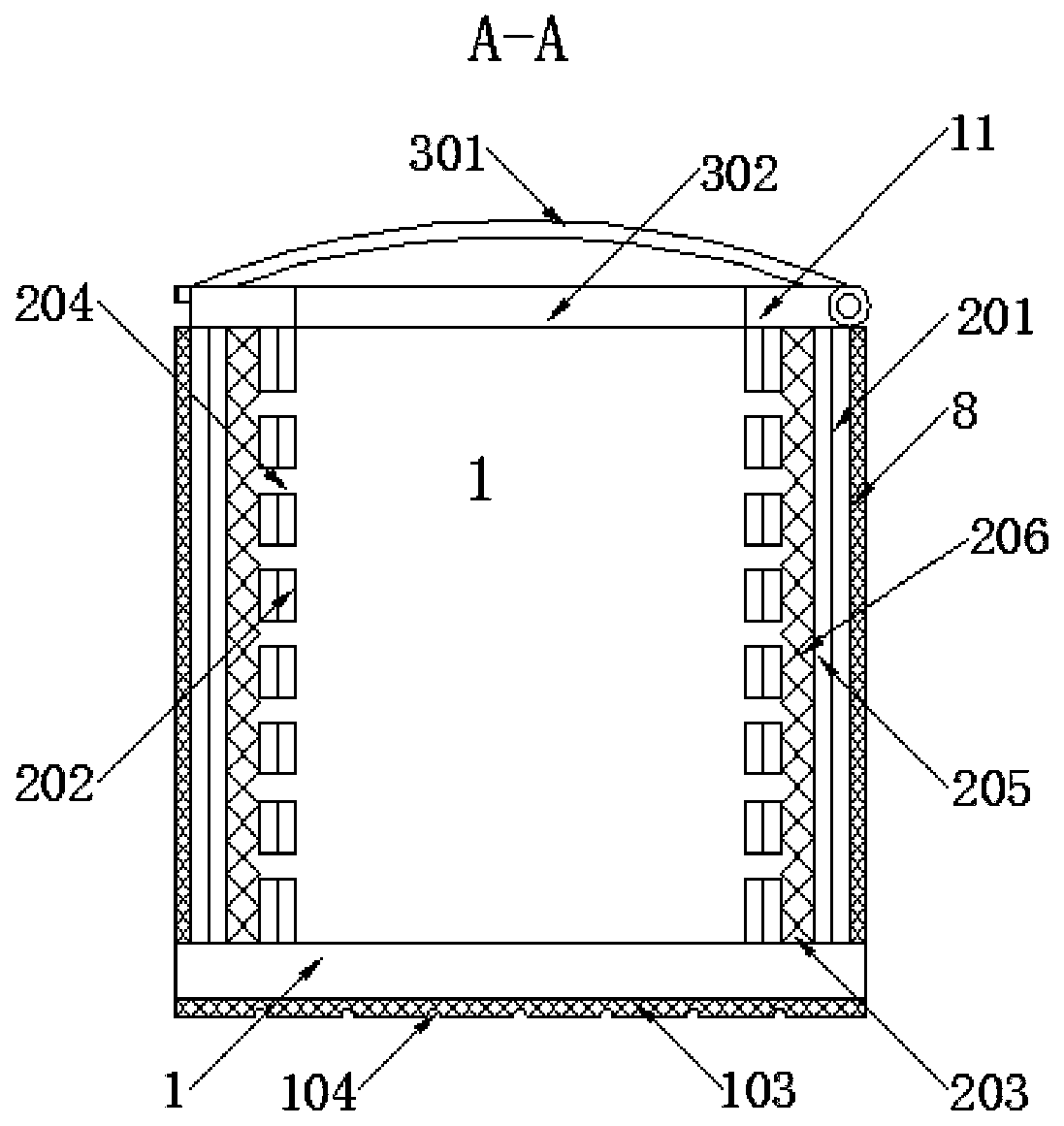

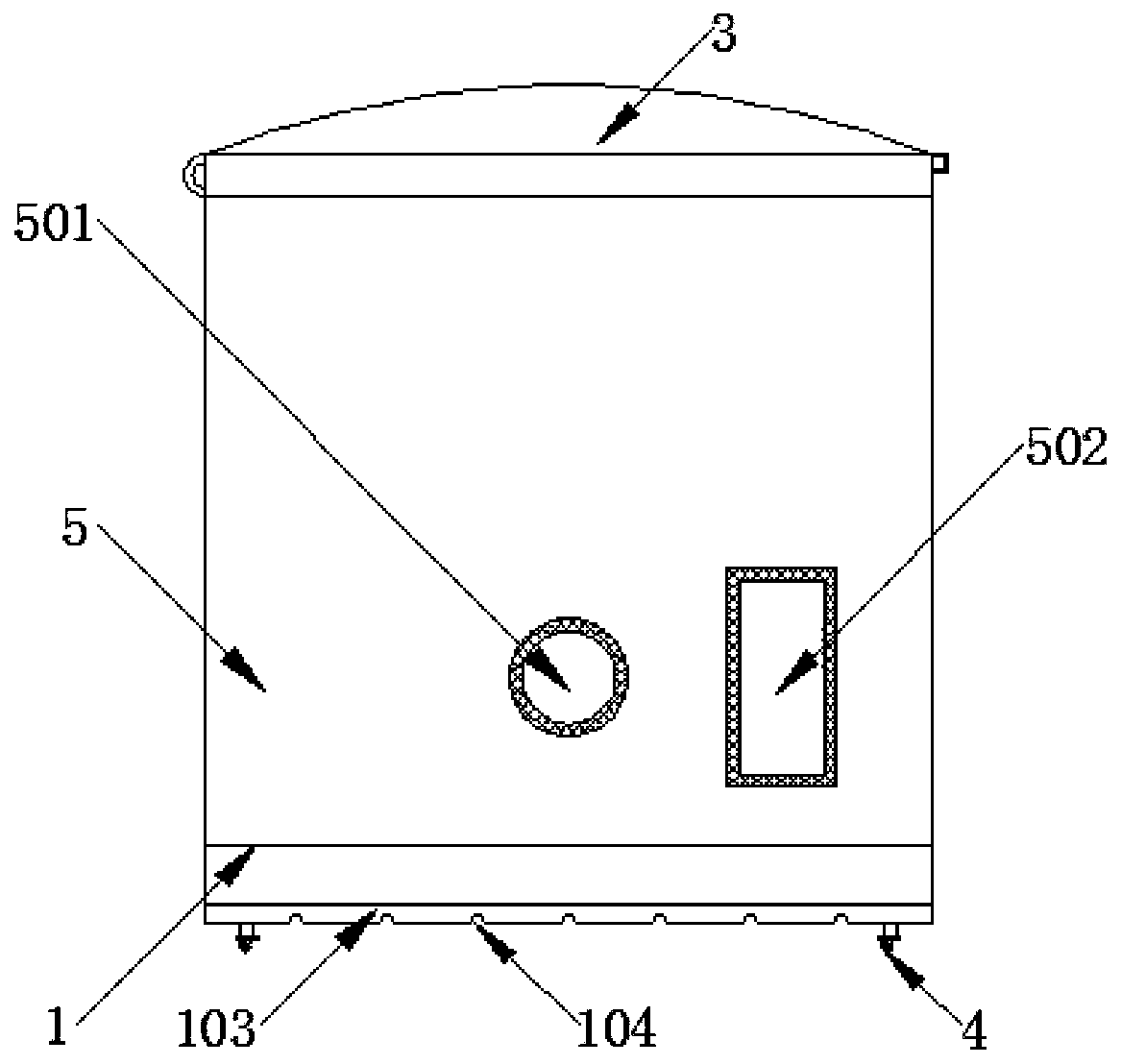

Control cabinet with double-layer cabinet cover

InactiveCN107613706ASolve the waterproof problemSolve moisture resistanceCasings/cabinets/drawers detailsHermetically-sealed casingsWater flowEngineering

The present invention discloses a control cabinet with a double-layer cabinet cover. The control cabinet comprises a control cabinet body used for integrating electronic components. The control cabinet further comprises a waterproof cabinet cover and an overhaul access hole both arranged in the control cabinet body. A sealing cover plate matched with the overhaul access hole is arranged on the overhaul access hole. An anti-pressure cabinet cover is tightly arranged at the periphery of the waterproof cabinet cover. The anti-pressure cabinet cover and the waterproof cabinet cover are covered above the control cabinet body to form a hollow interlayer. Drainage holes communicated with the bottom of the hollow interlayer are respectively arranged on the two side surfaces of the anti-pressure cabinet cover. The drainage holes are connected with an external drainage pipe. According to the invention, a double-cover structure composed of an inner cabinet cover and an outer cabinet cover is adopted. The outer cabinet cover is an anti-pressure layer and plays the self-weight anti-floating and supporting role. The inner cabinet cover is a waterproof layer, and plays the waterproof and moisture-proof effects. The sealing cover plate solves the problem in the prior art that water flows into the cabinet body of the control cabinet so as to reduce the space in the cabinet body. Therefore, thesealing effect is ensured. According to the technical scheme of the invention, the supporting strength of the control cabinet is improved. The sealing performance and the waterproof and moisture-proofeffects of the cabinet body of the control cabinet are greatly improved. The control cabinet is simple in implementation and relatively low in cost.

Owner:WUHAN SHENGYU DRAINING SYST

Waterproof stain-resistant wooden packaging box material and preparation method thereof

InactiveCN112077964AEfficient hydrophobic and anti-fouling effectFree from pollutionPressure wood treatmentWood treatment detailsPolymer scienceToluene diisocyanate

The invention discloses a preparation method of a waterproof stain-resistant wood packaging box material, which comprises the following steps: steaming a wood material at high temperature, cooling toroom temperature, vacuumizing, maintaining the pressure, and recovering to normal pressure to obtain a pretreated wood material; the preparation method comprises the following steps: mixing epoxy silane, ethyl methacrylate, methacrylic acid, acrylamide, glycidyl acrylate, diethylenetriamine and adipic acid, adding nano silicon dioxide and a surfactant in a stirring state, and continuously stirringto obtain an initial solution; toluene diisocynate, ammonium fluorocarboxylate, a surfactant and water are mixed, the pretreated wood material is immersed in the mixture, the initial solution, epichlorohydrin and peroxide are slowly dropwise added in sequence in a stirring state, and ultrasonic oscillation is performed to obtain an impregnated wood material; and the impregnated wood material is naturally cooled to normal temperature, pressurizing and maintaining pressure are carried out, then the material is cooled to normal pressure, the surface impregnation liquid is drained, and dried to constant weight, and heat treatment is carried out to obtain the waterproof stain-resistant wood packaging box material.

Owner:柳州唐辰木业有限公司

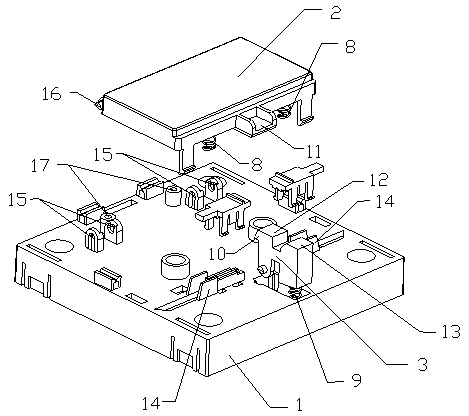

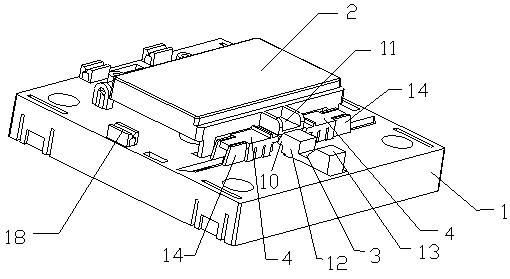

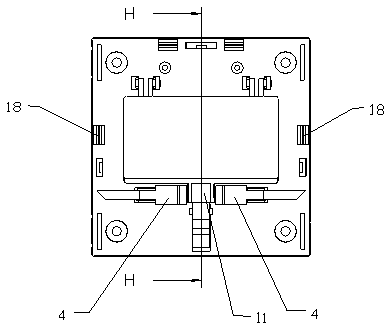

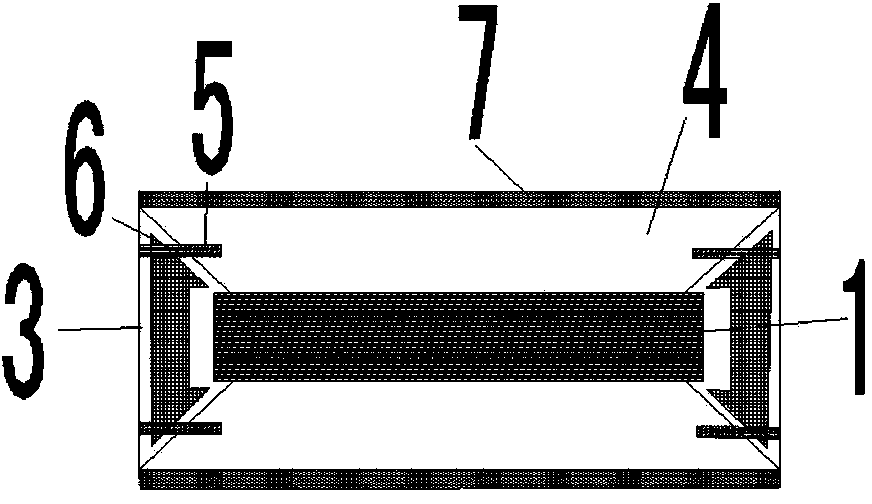

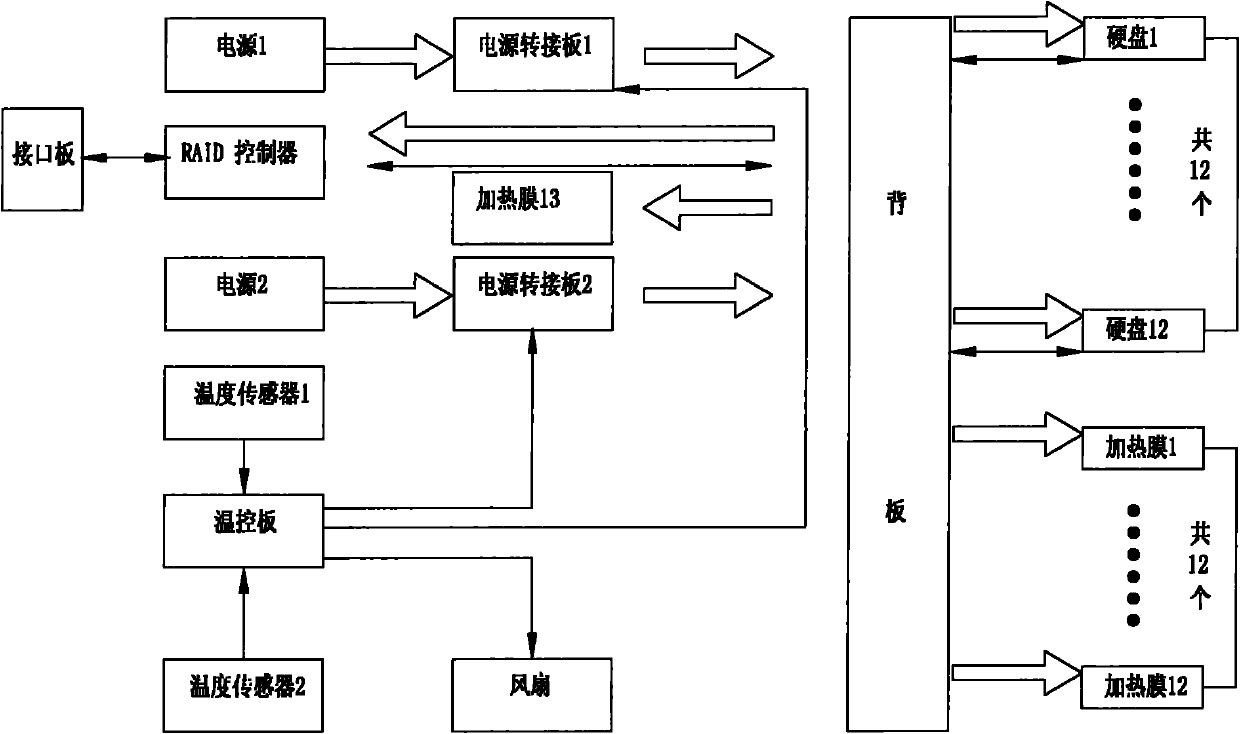

Reinforced magnetic disc array

InactiveCN101477825BSolve the anti-vibration and shockSolving Electromagnetic Compatibility IssuesCarrier constructional parts dispositionUndesired vibrations/sounds insulation/absorptionRAIDTemperature control

The invention discloses a ruggedized redundant array of independent disks (RAID) and belongs to the technical field of RAID. An RAID controller, a redundancy power supply and a hard-disk pack are arranged inside a chassis, wherein, the RAID controller is connected with an interface board and controls a plurality of hard disks which are connected; a backplate is arranged in the chassis, socket connectors are arranged on the baseplate, and the RAID controller is oppositely connected with the socket connectors on the baseplate through the socket connectors; the overall shock absorption of the hard disk is performed by means of hard disk silica shock absorption, and the hard disk is oppositely inserted with the socket connectors on the baseplate through socket connectors, socket connectors are connected with the baseplate through adopting a flexible printing circuit board (PCB); the redundancy power supply is fixed through adopting a locking device and connected with a pinboard of the power supply, and the pinboard of the power supply and the baseplate are connected through the flexible PCB; and a temperature-control plate is arranged in the chassis and matched with the pinboard of the power supply. The ruggedized RAID solves the deficiencies in the storage device of the RAID, and has the advantages of anti-vibrating and impact, electromagnetic compatibility, and moisture proofing, mould proofing, salt spraying proofing and the like.

Owner:SHANDONG CHAOYUE DATA CONTROL ELECTRONICS CO LTD

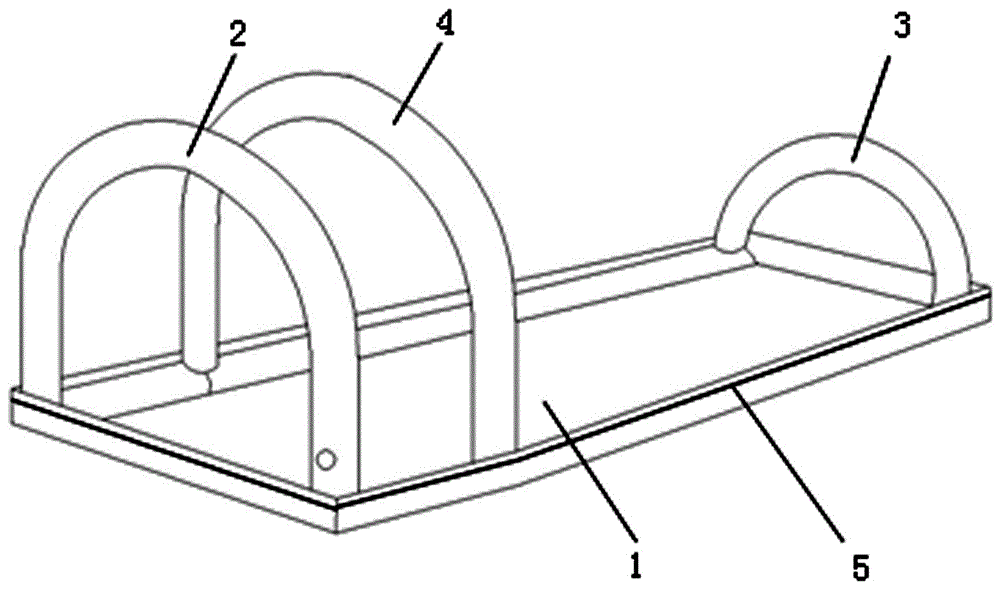

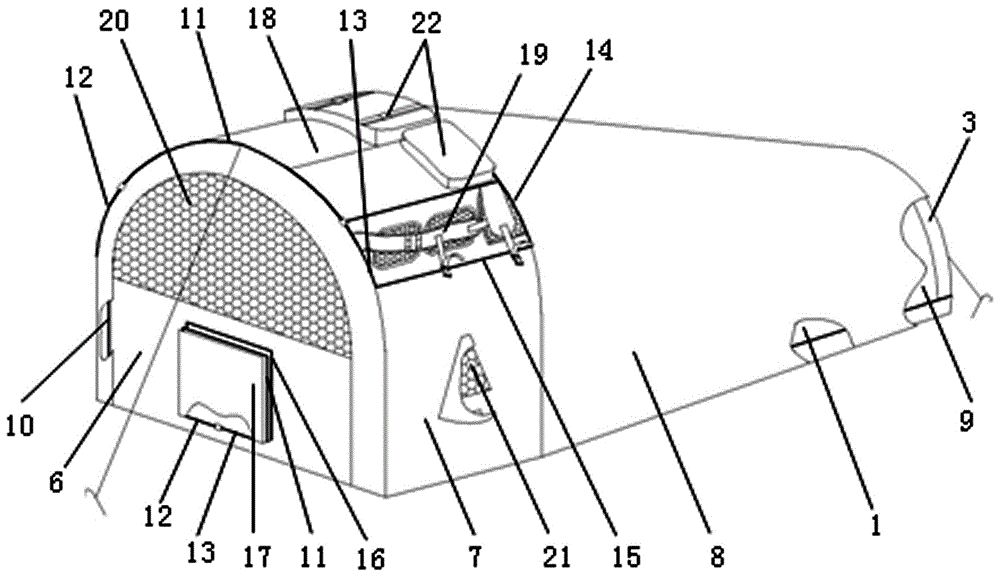

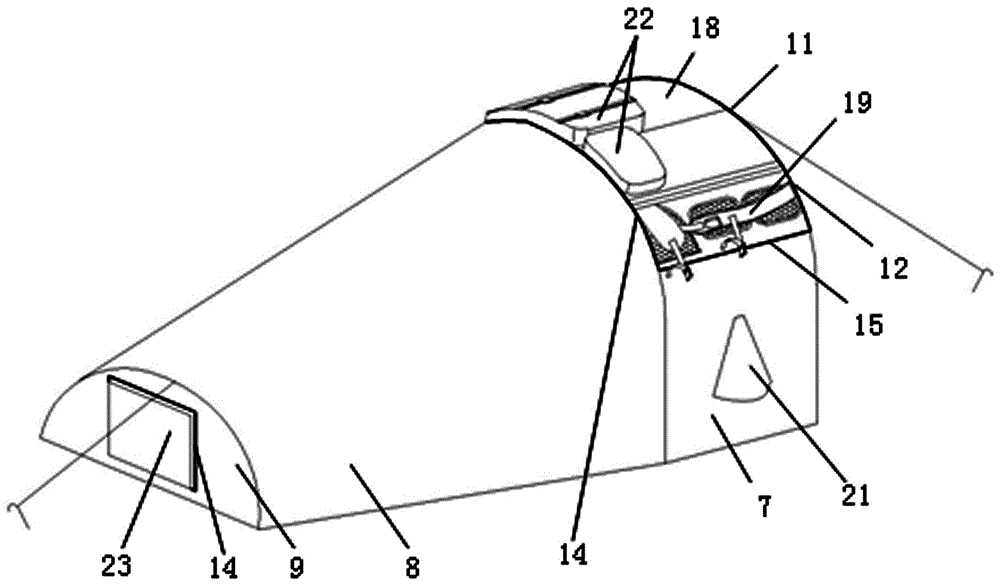

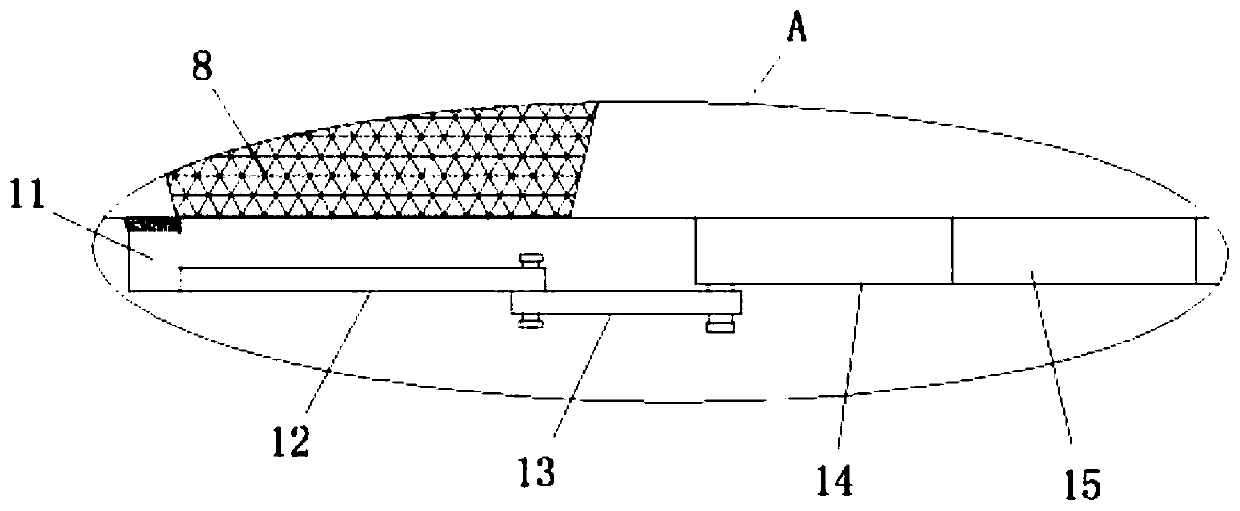

Backpack and tent integrated camping tool

ActiveCN106377050AOptimizing the Portfolio StructureReduce weightTravelling sacksTents/canopiesEngineeringColumn structure

The invention discloses a backpack and tent integrated camping tool which adopts the structural design of integration of a backpack, a tent and an inflatable bottom pad. A tent body of the tent is connected with the inflatable bottom pad through zippers and is erected by arch-shaped air columns on the inflatable bottom pad; and the zippers arranged on the tent body of the tent are connected in a buckling manner to form the backpack. The combined structure of the backpack and tent integrated camping tool is optimized, so that the weight of the backpack and tent integrated camping tool is further reduced, the carrying volume of the camping tool is decreased, and the use comfortableness is improved; meanwhile, a ground mat of the tent and supports of the tent are of an integrated inflatable bottom pad and inflatable arch-shaped column structure, so that the tent is easy and convenient to erect, and the firmness and the stability of the whole structure of the tent are also improved; and by the design of the inflatable bottom pad, the problems of rainwater prevention, dampness prevention, cold prevention and outdoor camping comfortableness during the use of the tent are well solved.

Owner:QINHUANGDAO AOSENER GARMENT

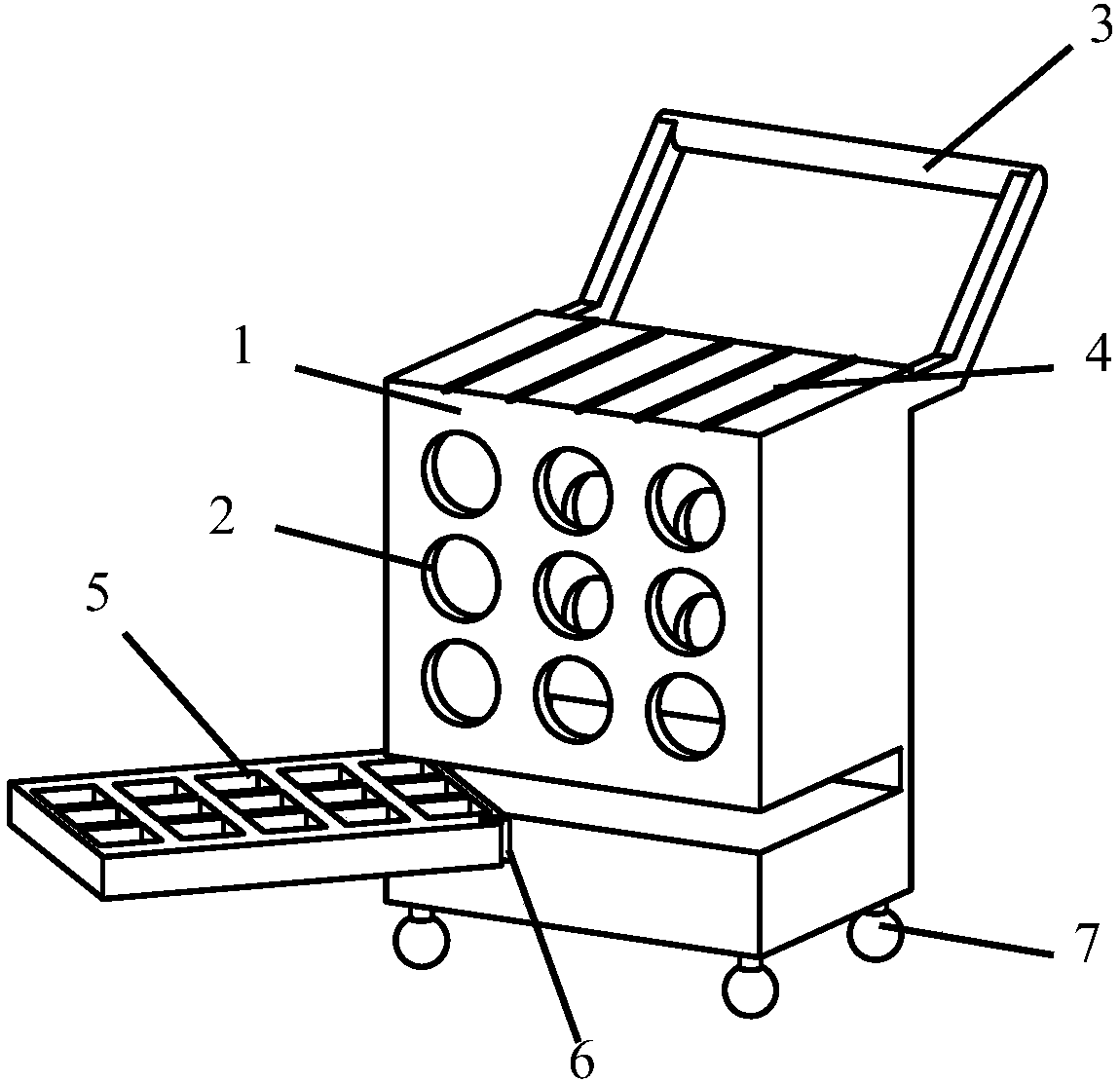

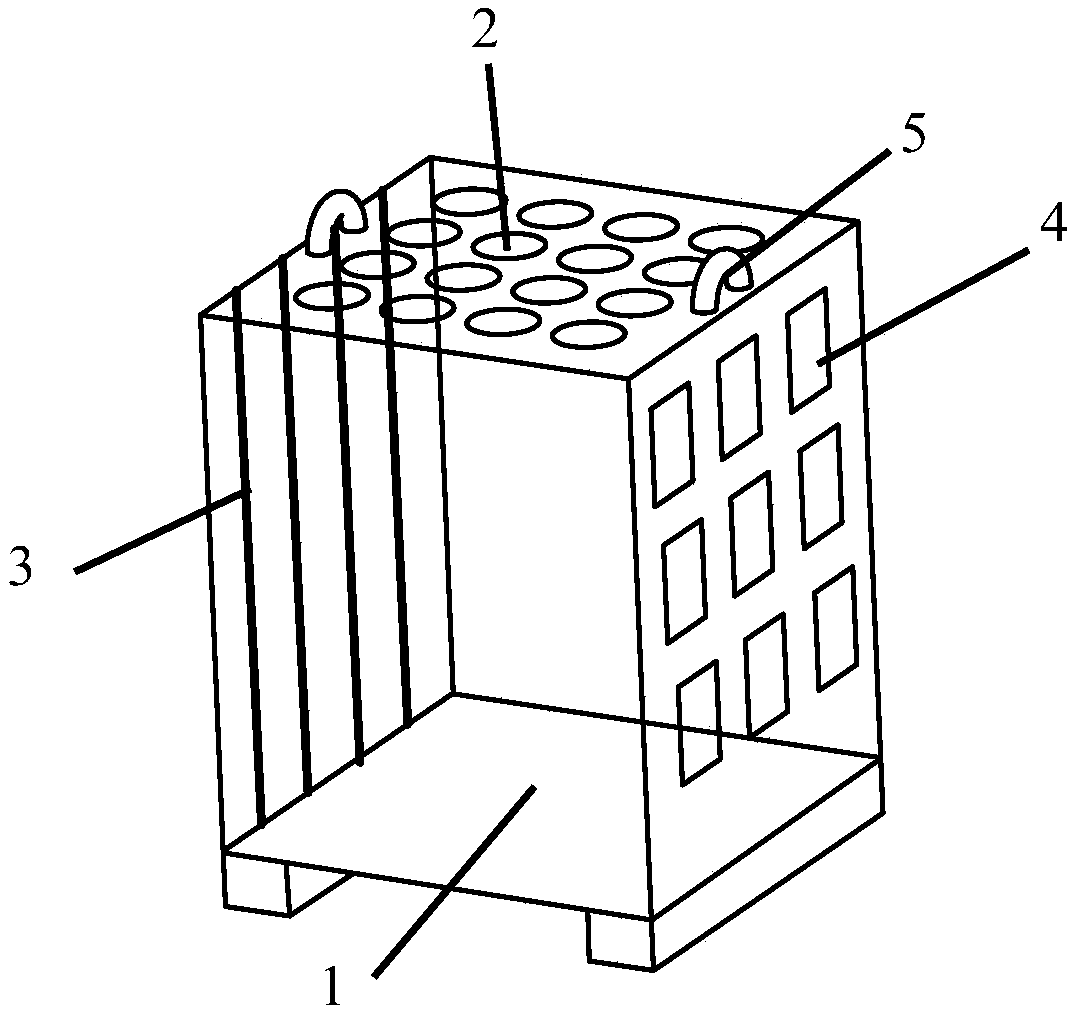

Movable drying storage cabinet for shaft parts

InactiveCN109926998ASolve Drying ProblemsSolve moisture resistanceDrying solid materialsWork tools storageAgricultural engineeringMoisture

The invention provides a movable drying storage cabinet for shaft parts. The movable drying storage cabinet comprises a cabinet body, storage holes, a push rod, heating wires, a rotary plate, a rotaryplate limiting hole and universal wheels, the cabinet body is a hollow cuboid, the heating wires are arranged on the upper surface of the cabinet body, the storage holes are formed in the front surface of the cabinet body, the push rod is arranged on the rear surface of the cabinet body, the rotary plate limiting hole is formed in the right rear corner of the rotary plate, and the universal wheels are arranged on the lower surface of the cabinet body. The movable drying storage cabinet for the shaft parts can effectively solve the problem of drying and moisture-proof storage of the metal shaft parts.

Owner:绍兴市齐翔贸易有限公司

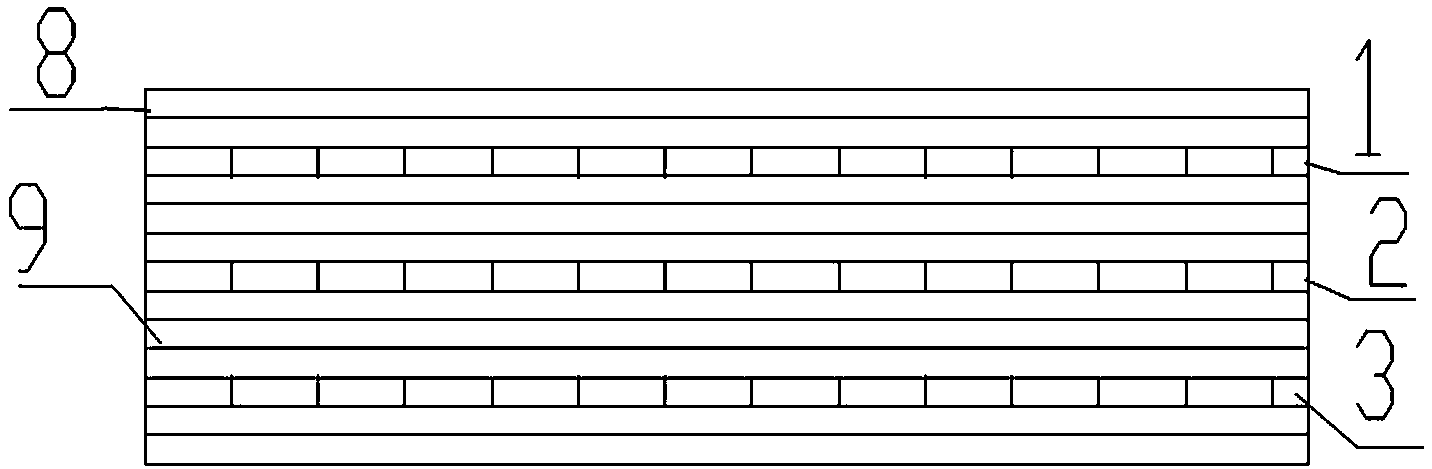

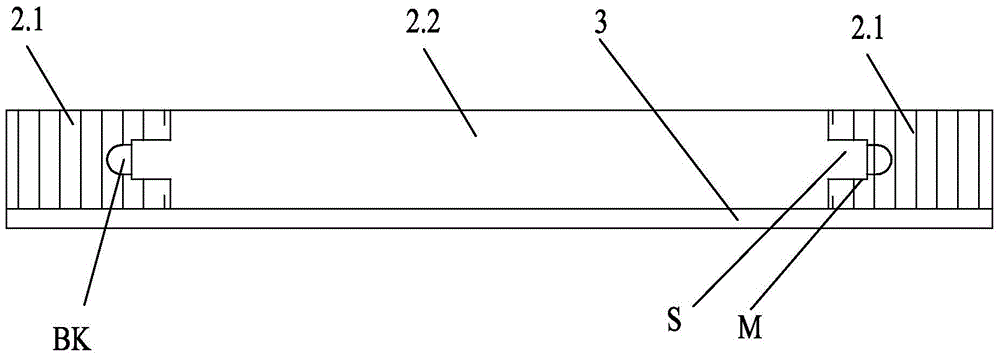

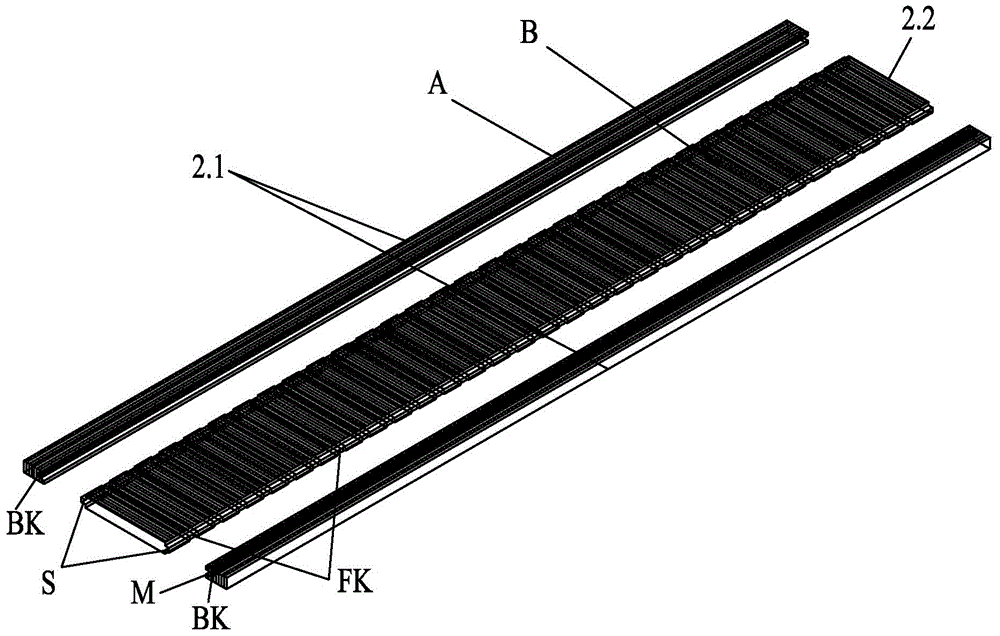

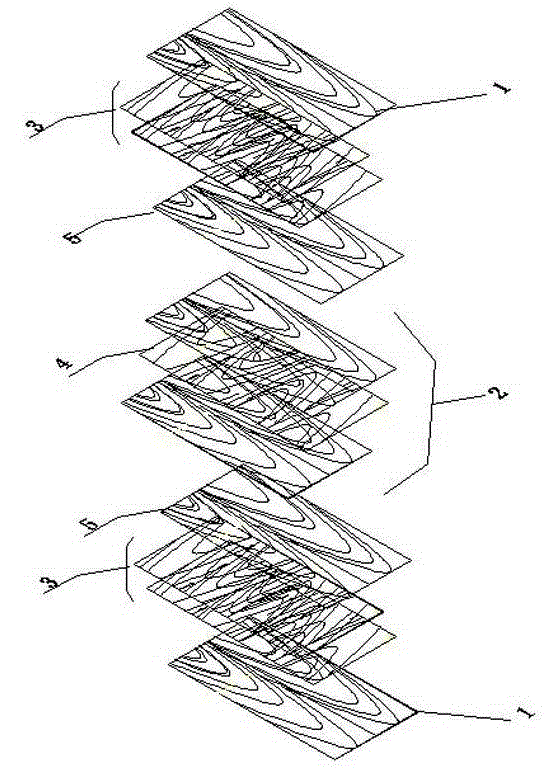

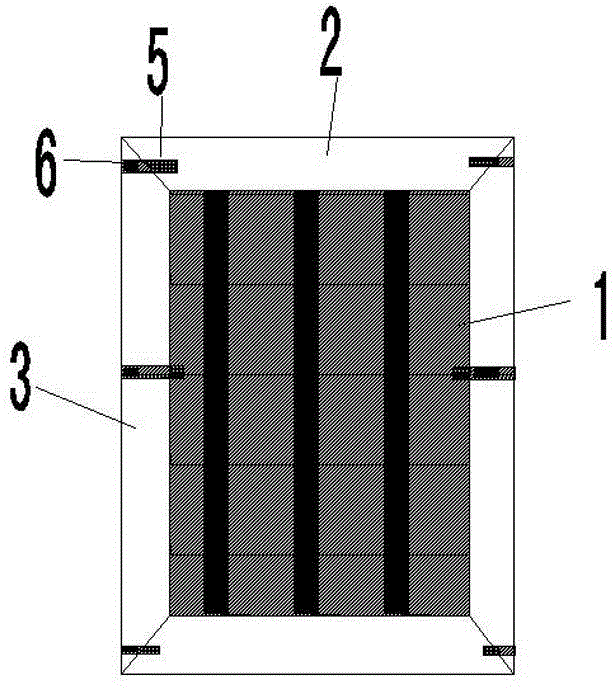

Environmentally friendly, high-strength and anti-deformation composite door

InactiveCN105370164AResolves variable crackingSolve environmental problemsWood veneer joiningWood layered productsCentral layerIndustrial engineering

The invention discloses an environmentally friendly, high-strength and anti-deformation composite door. The composite door is formed by extruding after sticking (with glue) following materials: door panel layers 1, a door core 2, central layers 3, horizontal texture plates 4, and longitudinal texture plates 5. The door core 2 is formed by sawing a big plate into fixed-width and fixed-length edge materials by taking the texture direction as the length direction of the edge materials, the longitudinal direction of the texture direction of the spliced big plate is used as the width direction of core materials, the horizontal direction of the texture direction is sawn as the length direction of the core materials, two edge materials are distributed in the longitudinal direction of the texture direction of two sides of the core materials, the core materials are vertical to the texture direction of the edge materials, the core materials and the edge materials are put in a high-frequency plate splicing machine after adjacent edges are glued, and an environmentally friendly energy-saving anti-deformation multi-layer plate core material is formed through pressurizing and high-frequency automatic heating in one step. The core material can be sawn into needed length and needed width and can be polished into needed thickness.

Owner:HARBIN SHENGSHI HUALIN TECH

High-intensity deformation-resistant aluminum core dismounting and mounting door plate

InactiveCN104563785AResolves variable crackingSolve environmental problemsWing framesDoor leavesHigh intensityBolt connection

Owner:HEILONGJIANG HUAXIN FURNITURE

Optical cable applicable to severe environments

InactiveCN110221394ASolve the problem of moisture corrosion and crackingSolve side pressureFibre mechanical structuresLow smoke zero halogenElectricity

The invention discloses an optical cable applicable to severe environments. According to the optical cable, an aluminium-clad steel stranded wire is used as a self-supporting suspension wire of the optical cable so as to effectively solve a problem that a self-supporting suspension wire is partially affected with damp to be rusted and broken; a stainless steel band armored structure is adopted tolongitudinally wrap a cable core part so as to effectively solve problems of side pressure resistance, damp resistance and rat biting resistance of the optical cable; by extruding a low-smoke zero-halogen polyolefin material on an outer surface of the aluminium-clad steel stranded wire and the anchored cable core, problems of solarization ageing and fire and flame retardance of the optical cable are effectively solved; when an optical cable main body is an optical unit, transmission of an optical signal can be implemented; when the optical cable main body is a feeder line unit, transmission ofpower can be implemented; and when the optical cable main body is an optic-electric hybrid unit, simultaneous transmission of the optical and electric signals can be implemented; and the optical cable is applicable to various severe environments.

Owner:武汉瑞联光通信技术有限公司

Instrument general cabinet

InactiveCN107231771ASimple structureSolve moisture resistanceCasings with display/control unitsCasings/cabinets/drawers detailsEngineeringInstrumentation

Owner:池州市创新电工机械有限公司

Accessory storage device for research of animation cooperative task undertaking machine

InactiveCN110226841AStructural solutionSolve moisture resistanceDispersed particle filtrationTransportation and packagingAnimationComputer science

The invention relates to the field of storage devices and particularly discloses an accessory storage device for research of an animation collaborative task undertaking machine. In the prior art, an existing storage device is simple in structure, and the moisture-proof effect is not realized. According to the technical scheme of the invention, the storage device comprises a storage box. The storage box is of a hollow cuboid structure. A box door is hinged to one side of the storage box. Partition plates of the same structure are connected to the inner wall of the storage box at equal intervals. A transverse plate and a bottom plate are connected to the inner wall of the storage box. The transverse plate is located below the partition plates. The bottom plate is located below the transverseplate. A rotating motor is installed in the middle of the bottom end of the transverse plate through screws. The storage box is novel in structure, and accessories can be placed in a layered and classified mode through the storage box. The disorder of accessories is prevented. The accessories in the storage box can be effectively ventilated. The accessories in the storage box can be prevented from being wet and rusted. The normal service life of the accessories is guaranteed. The resource waste is avoided, and the storage box is suitable for popularization.

Owner:兰州翼途动漫文化传播有限公司

Shaft part drying and storing cabinet capable of being hoisted

InactiveCN109931752ASolve Drying ProblemsSolve moisture resistanceDrying solid materials without heatDrying chambers/containersDamp proofingDrying Agents

The invention provides a shaft part drying and storing cabinet capable of being hoisted. The shaft part drying and storing cabinet comprises a cabinet body, storage holes, an electric heating wire, drying agent storage grids and anchorage points, wherein the cabinet body is in the shape of a hollow cuboid; the electric heating wire is arranged on the left side surface of the cabinet body; the drying agent storage grids are arranged on the right side surface of the cabinet body; the storage holes are formed in the upper surface of the cabinet body; and the anchorage points are symmetrically arranged on the upper surface of the cabinet body. The shaft part drying and storing cabinet capable of being hoisted provided by the invention can effectively solve the metal shaft part drying, damp-proofing and warehousing problem.

Owner:张琴珍

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com