Environmentally friendly, high-strength and anti-deformation composite door

A green, environment-friendly, anti-deformation technology, applied in the direction of door leaves, wooden veneer joints, wood processing appliances, etc., can solve the problems of curling, easy deformation of composite doors, and non-environmental protection, etc., to achieve stable quality, significant cooling, The effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

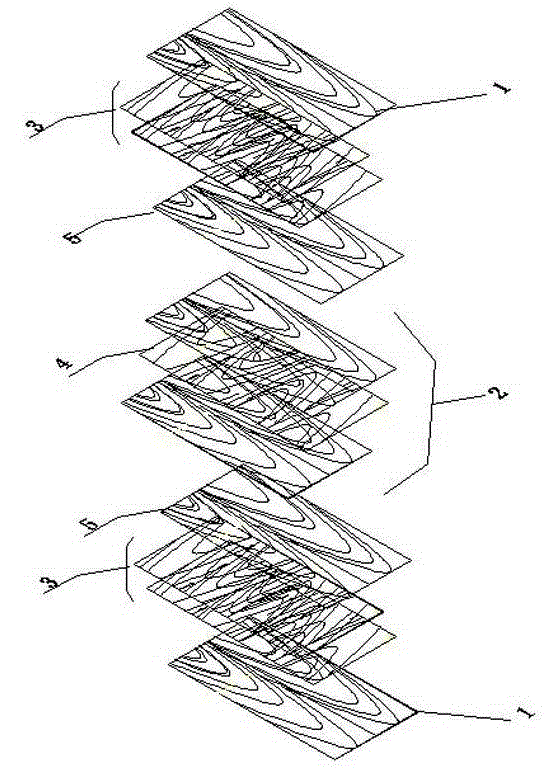

[0018] A green environment-friendly high-strength anti-deformation composite door, comprising a door panel layer 1, a door core 2, a center layer 3, a transverse grain plate 4, and a longitudinal grain plate 5, wherein the transverse grain plate 4 and the longitudinal grain plate 5 are put into In the middle of door core 2 and center layer 3, balance the horizontal and vertical tension of the door to prevent deformation of the door panel. Panel layer 1, door core 2, center layer 3, transverse grain board 4, and longitudinal grain board 5 are arranged in a multi-layer board and glued Then extrusion molding.

Embodiment 2

[0020] A green and environment-friendly high-strength anti-deformation composite door. The door core 2 is made of large boards along the grain direction as the length of the sapwood, which is sawn into fixed-width and fixed-length sapwood, and the assembled large boards are used as the core along the longitudinal direction of the grain The width of the wood, the grain is horizontally sawn into the length of the core material, and the two sapwood are distributed on both sides of the core material in the longitudinal direction of the grain direction. The grain of the core material and the sapwood are perpendicular to each other. , the frequency is controlled within the range of 6.78KHz; the time for 20mm thick plates is adjusted to 2-3 minutes, and the lateral pressure is adjusted to 8-10 tons; the time for 50mm thick plates is adjusted to 4-5 minutes, and the lateral pressure is adjusted to 12-14 tons ; After pressurization and high-frequency automatic heating, the core material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com