Patents

Literature

139results about How to "Solve the problem of airtightness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

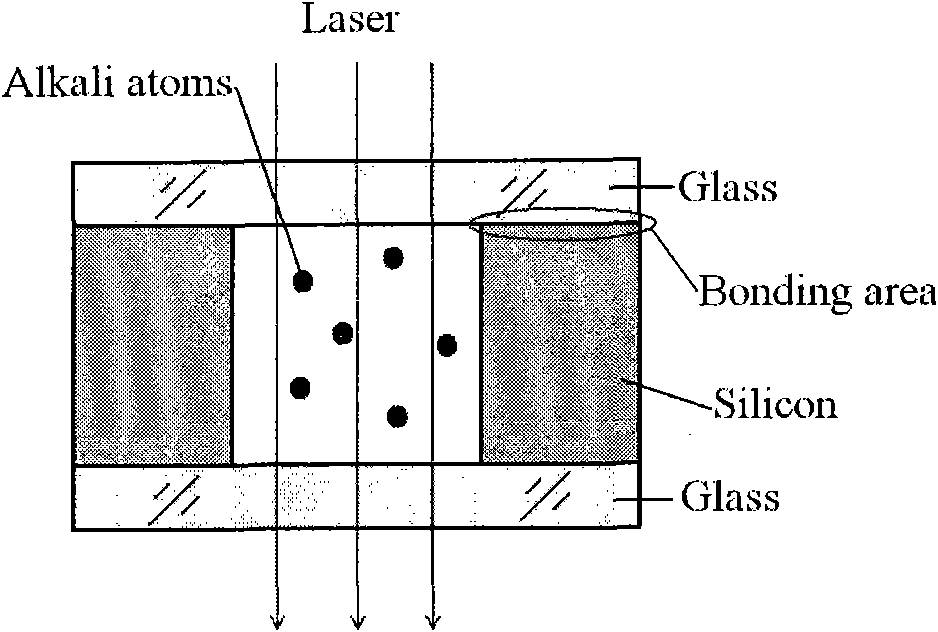

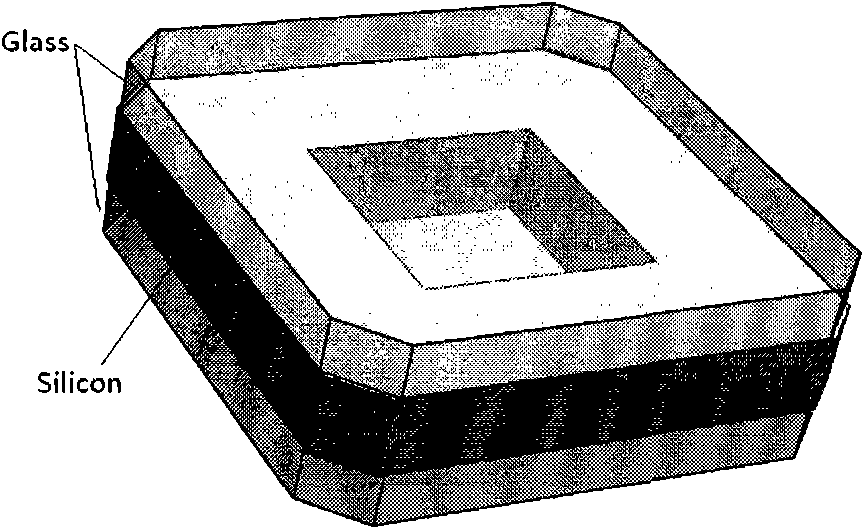

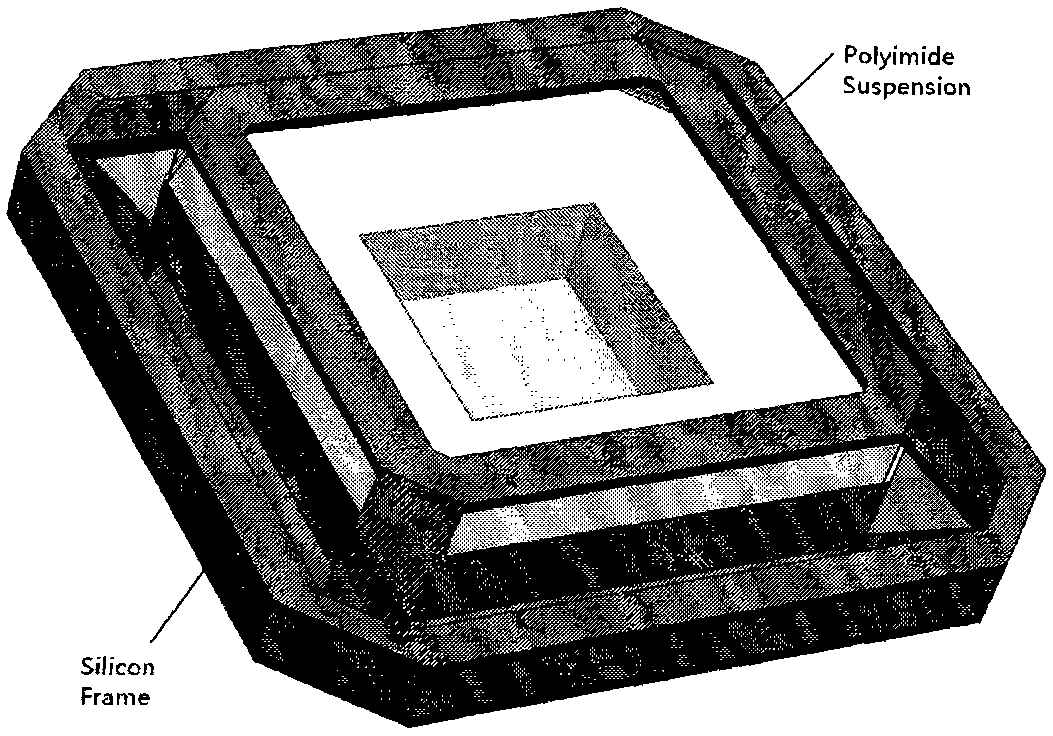

Micro electro mechanical system (MEMS) process-based micro atomic cavity device air tightness package and method

InactiveCN102205941ASimple structural designSimple processDecorative surface effectsSolid-state devicesGyroscopeEngineering

The invention relates to a micro electro mechanical system (MEMS) manufacturing process-based micro atomic cavity air tightness package structure and a method. The structure and the method are characterized in that: a micro atomic cavity which is manufactured by the MEMS process is arranged in a glass or metal seal buffer cavity through a supporting structure, and the air tightness of the micro atomic cavity is improved, so that the service life of devices such as a micro atomic clock and the like based on the micro atomic cavity is prolonged, and the stability of the devices is improved. The structure and the method have a key point that: in the glass or metal buffer cavity structure, the inside of the buffer cavity is vacuumized or filled with buffer gas of which the components and the pressure are approximate to those of gas in the micro atomic cavity, and a leading wire of the micro atomic cavity passes through the buffer cavity to realize air tightness lead. By the package structure and the method, the leakage rate of the micro atomic cavity and outside can be effectively reduced, and the technical problem of short service life of micro atomic cavity devices is solved. The air tightness package structure is particularly suitable for the micro atomic cavity devices such as micro atomic clocks, micro atom magnetometers, micro atom gyroscopes and the like with low power consumption and small volumes.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

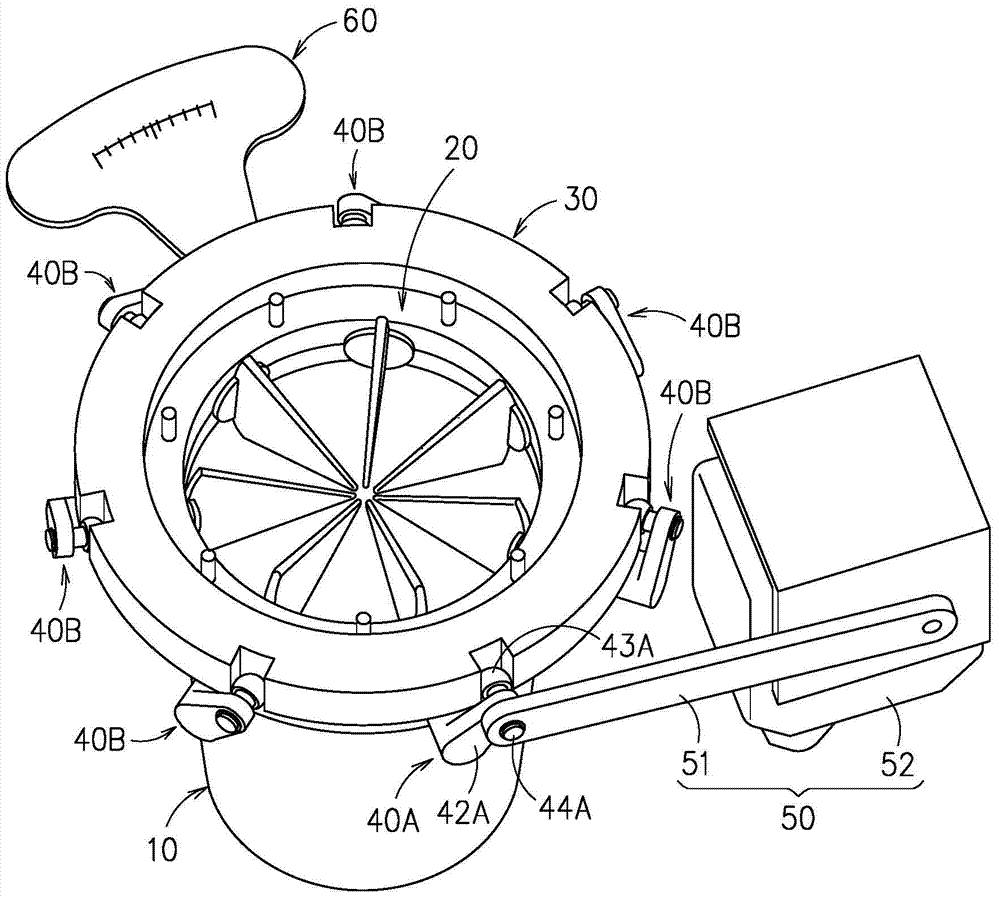

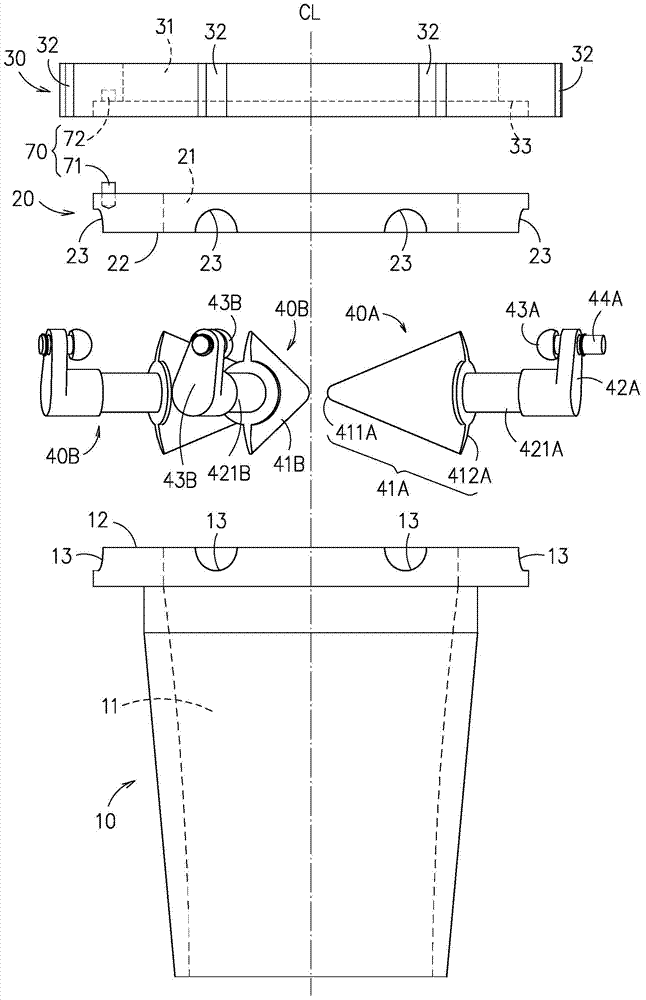

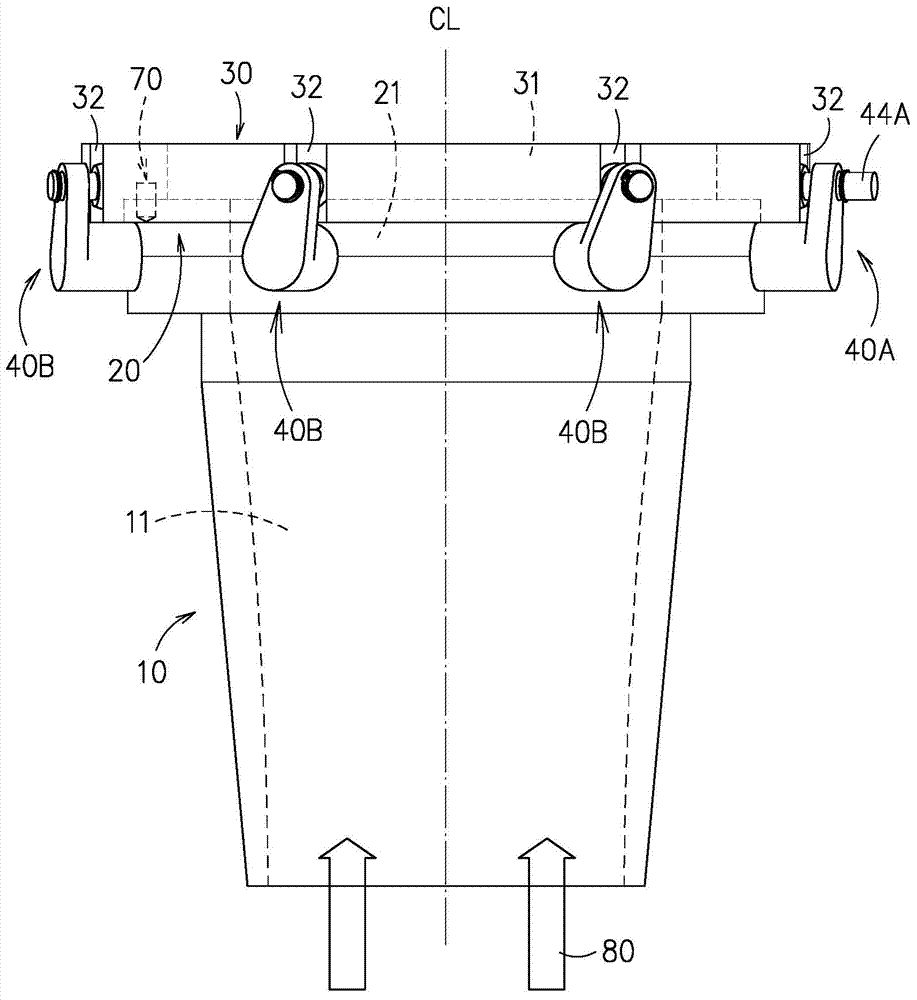

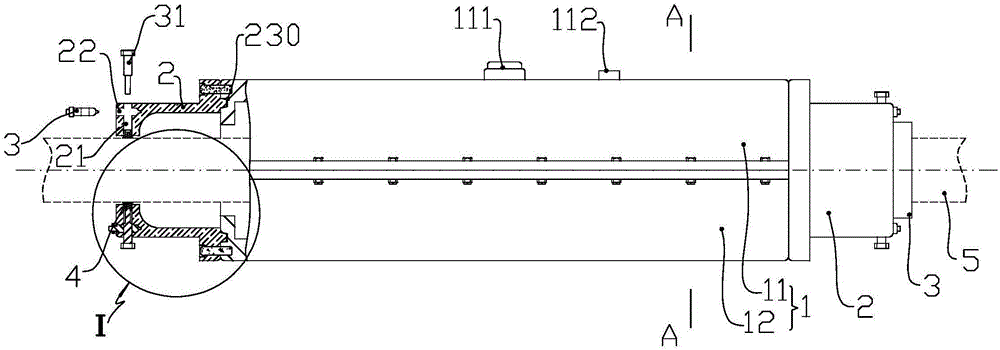

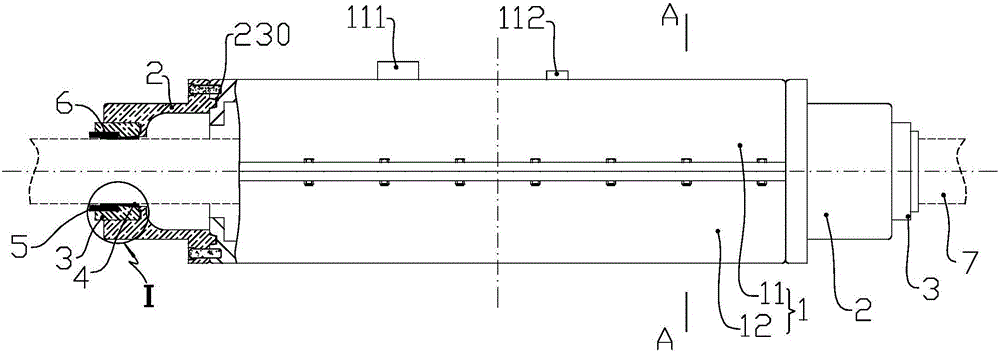

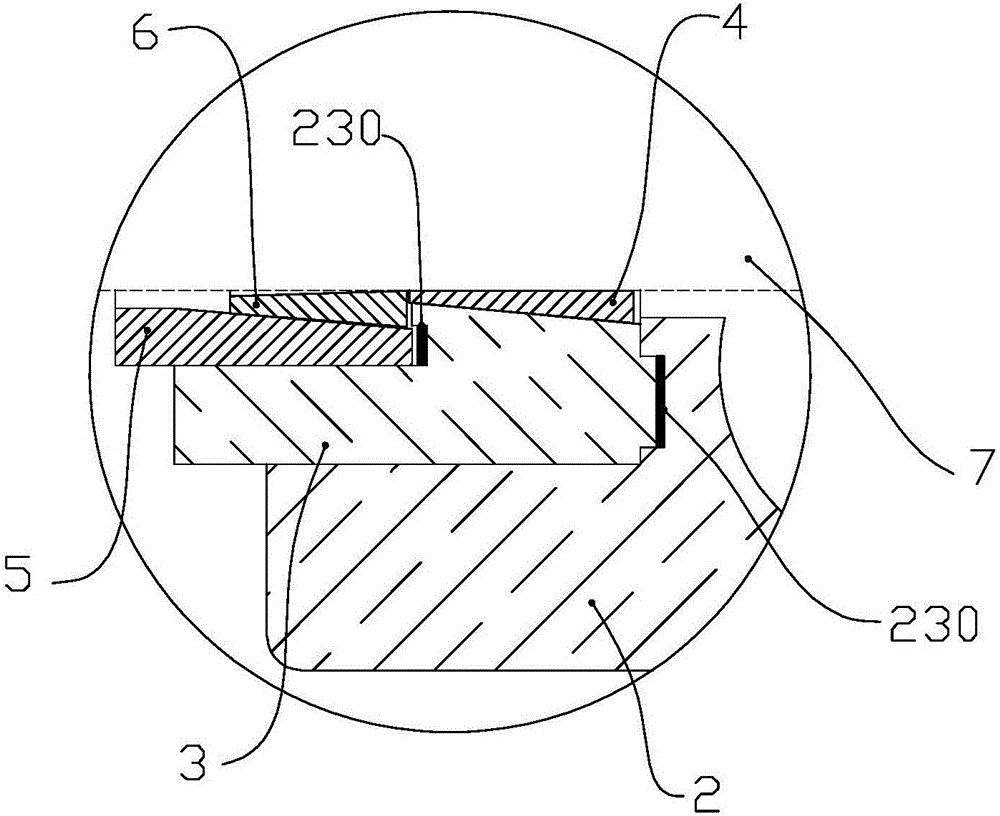

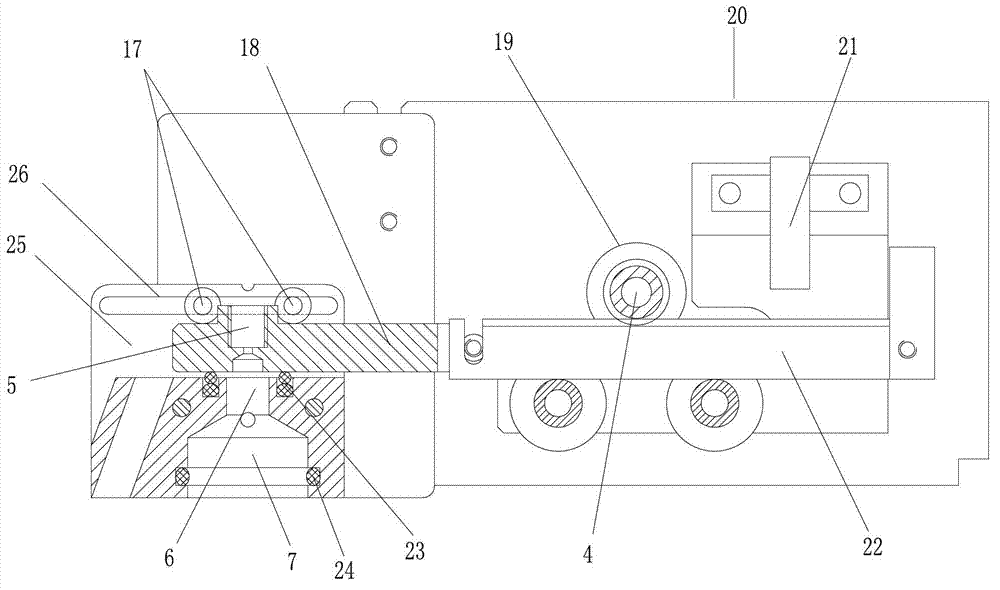

Inlet guide vane assembly

ActiveCN104712586ASolve the problem of airtightnessPrecise Fluid Flow ControlPump componentsStatorsEngineeringMechanical engineering

An inlet guide vane assembly is disclosed, which comprises: a housing, configured with a first penetration part and a plurality of first grooves; at least one fixing ring, each configured with a second penetration part and a plurality of second grooves; at least one rotary ring, each configured with a third penetration part and a plurality of sliding chutes, wherein the first, the second and the third penetration parts are arranged in communication with one another; a plurality of vane units, each vane unit is composed of a vane, a linkage and a sliding block; and at least one driving unit, for driving one vane of the plural vanes to swing, thus driving the rotary ring to rotate simultaneously, bringing along the other vanes to swing, enabling the sliding blocks to slide inside corresponding sliding chutes, and consequently flipping the vane from a first state to a second state.

Owner:IND TECH RES INST

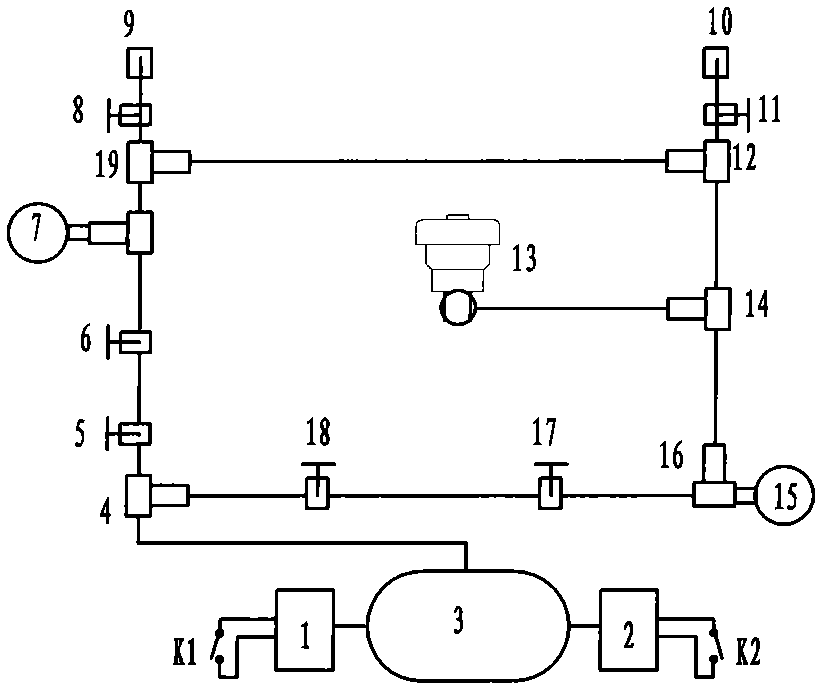

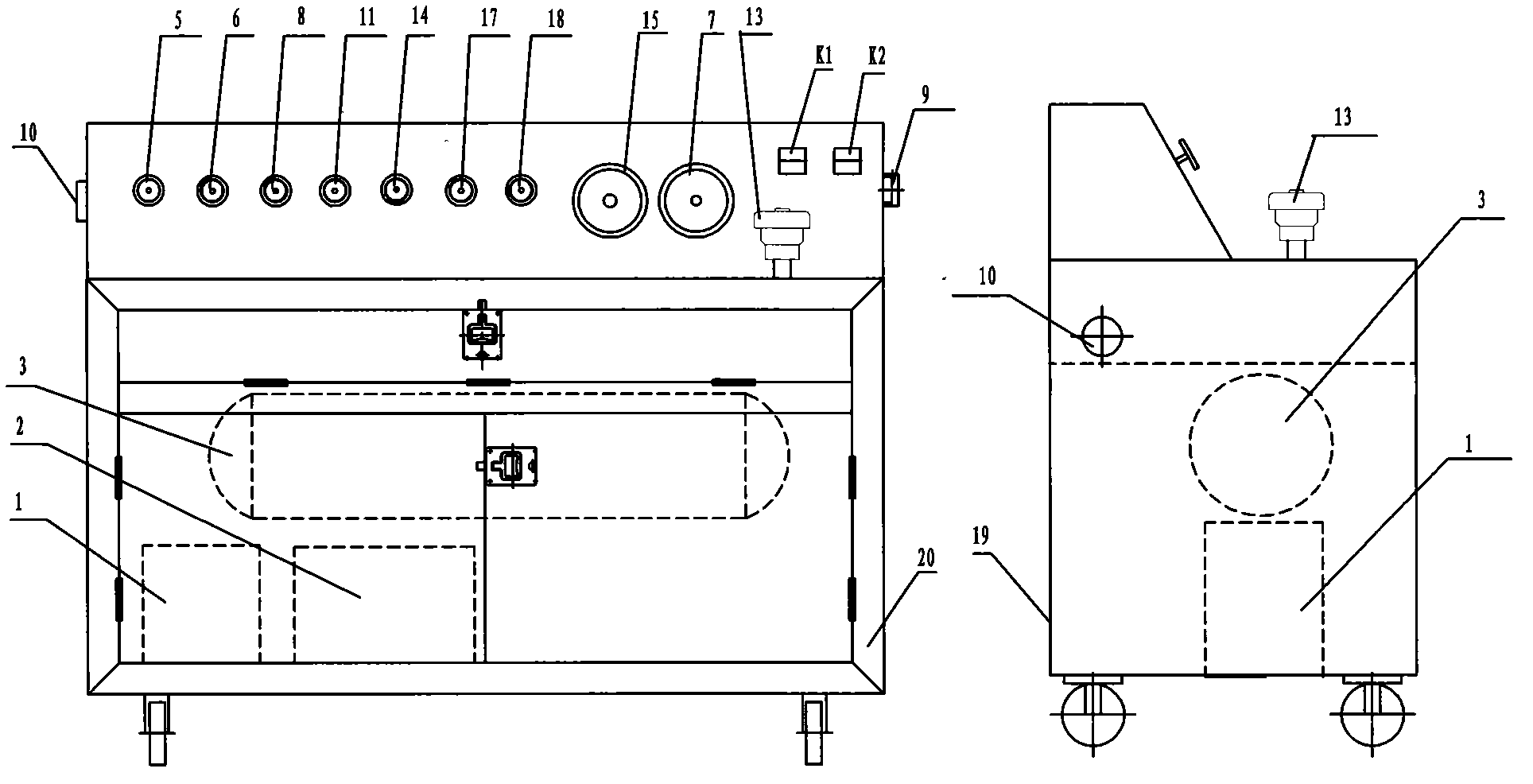

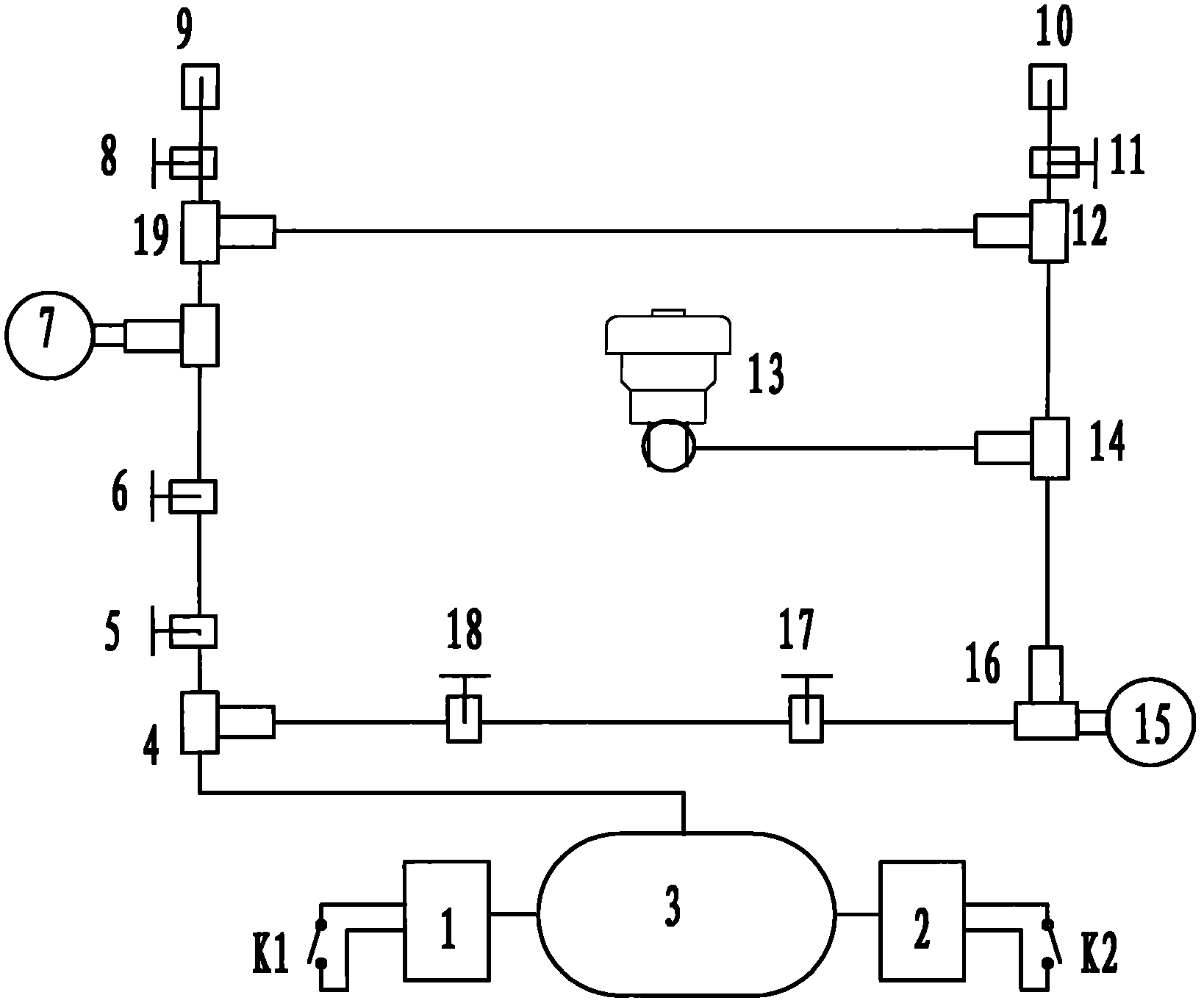

Comprehensive air pressure test bed for vehicle-mounted steel tank

ActiveCN102012302ASolve the problem of airtightnessSolve the problem of comprehensive quality performance inspectionMeasurement of fluid loss/gain rateMaterial strength using tensile/compressive forcesIn vehicleEngineering

The invention provides a comprehensive air pressure test bed for a vehicle-mounted steel tank, of which structure is composed of a test bed, a positive / negative pressure source, a tested tank positive pressure test pipeline, a loading-unloading flexible pipe positive pressure test pipeline, a breather valve positive pressure test pipeline and a breather valve negative pressure test pipeline, wherein the positive / negative pressure source, the tested tank positive pressure test pipeline, the loading-unloading flexible pipe positive pressure test pipeline, breather valve positive pressure test pipeline and the breather valve negative pressure test pipeline are installed in the test bed, the positive / negative pressure source is composed of a pressure pump and a vacuum pump connected with a buffering air tank by a pipeline; and an air source is connected with a tested tank connector by being connected in series with a first three-way pipe, a first one-way valve, a first pressure regulating valve, a pressure gauge, a second three-way pipe and a third one-way valve through the pipelines to form the tested tank positive pressure test pipeline; the comprehensive air pressure test bed for the vehicle-mounted steel tank has benefits of effectively solving a problem of detecting air tightness of the vehicle mounted tank and comprehensive quality performance of the breather valve and the unloading flexible pipe.

Owner:LIANGSHAN CIMC DONGYUE TRAILER MFG

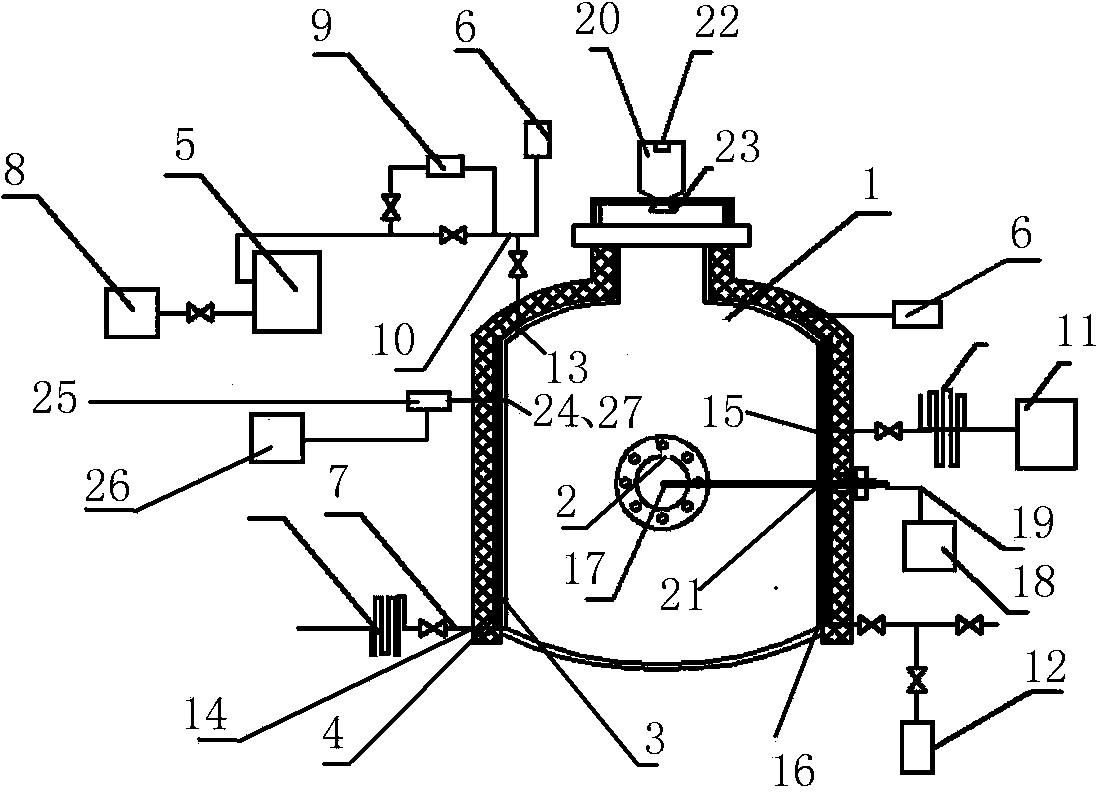

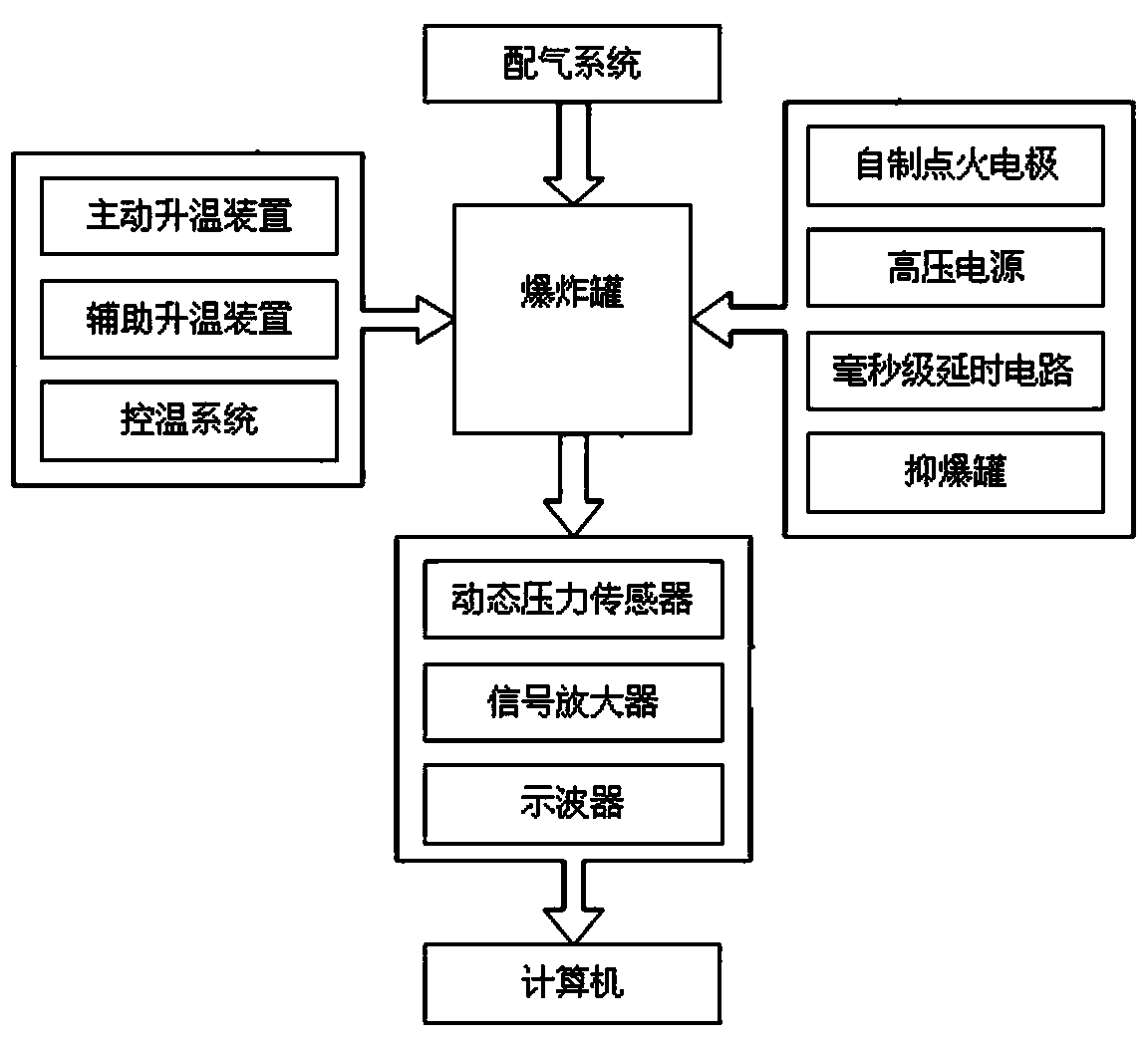

Combustible liquid vapor explosion and explosion suppression characteristic test system

InactiveCN103364531AFunctional DiversificationSimple processing capacityFuel testingIgnition delayEngineering

The invention discloses a combustible liquid vapor explosion and explosion suppression characteristic test system. The system comprises an explosion tank, a double heating temperature-control system, a gas distribution system, a double ignition delay explosion suppression system, and a data test and acquisition system. The explosion tank is provided with a window and six through holes. The explosion tank is covered by a heating sheet of the double heating temperature-control system on the explosion tank. An insulation material is covered on the heating sheet. The temperature-control system is connected with the heating sheet and an air heater. An air compressor of the gas distribution system communicates with a through hole I through the air heater, an ejector, and an ejector pipe. A gas discharge pipe communicates with a through hole II. A vacuum pump communicates with a through hole III. A static pressure sensor communicates with a through hole IV. An ignition electrode of the double ignition delay explosion suppression system is arranged in the explosion tank, and is connected with a delay circuit and a high-voltage power source through the through hole V. An explosion suppression tank is arranged on the top of the explosion tank. A gas generator is arranged in the explosion suppression tank. A nozzle is arranged on the bottom of the explosion suppression tank. A dynamic pressure sensor of the data test and acquisition system is arranged on the through hole VI, and is connected with an oscilloscope through a signal amplifier. The system provided by the invention has the advantages of simple application, multiple test functions, and high precision.

Owner:ZHONGBEI UNIV

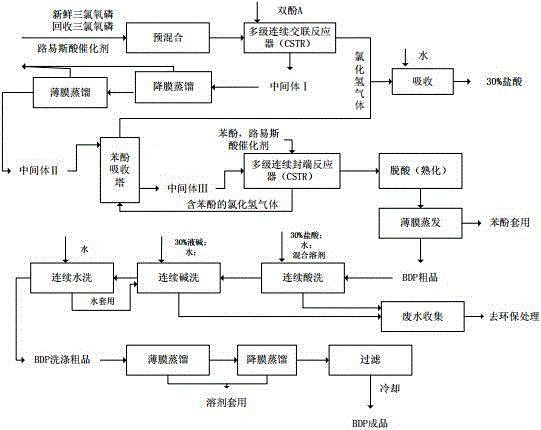

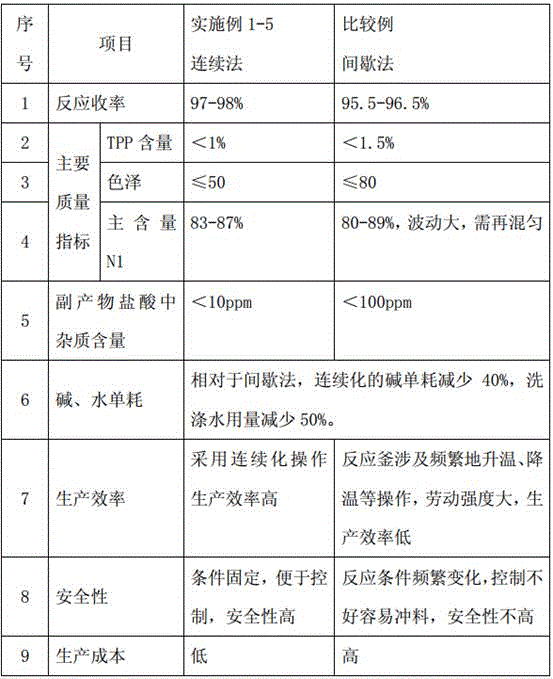

Continuous preparation method for bisphenol A-di(diphenyl phosphate)

ActiveCN106496264AReduce labor intensityMeets requirementsGroup 5/15 element organic compoundsCustomer requirementsDiphenyl phosphate

The invention discloses a continuous preparation method for bisphenol A-di(diphenyl phosphate). The continuous preparation method for the bisphenol A-di(diphenyl phosphate) comprises a multistage crosslinking reaction process, a continuous phosphorus oxychloride recycling process, a continuous multistage end capping reaction and phenol recycling process, a continuous crude product refining process, and a continuous solvent recycling and filtering process. The BDP is prepared by the continuous processes, the production cost is reduced, the labor intensity of operators is greatly reduced, the labor efficiency is improved, and the product yield is greatly improved, so the lot production quality is stable, and the production is safe and environment-friendly. The yield is improved by 1-1.5%, the color number is improved below 50, and the TPP is controlled to be 1%, and is reduced by 50% compared by an original intermittence device. The high-end customer requirement is satisfied, and the quality index fluctuation of each product is small.

Owner:ZHEJIANG WANSHENG

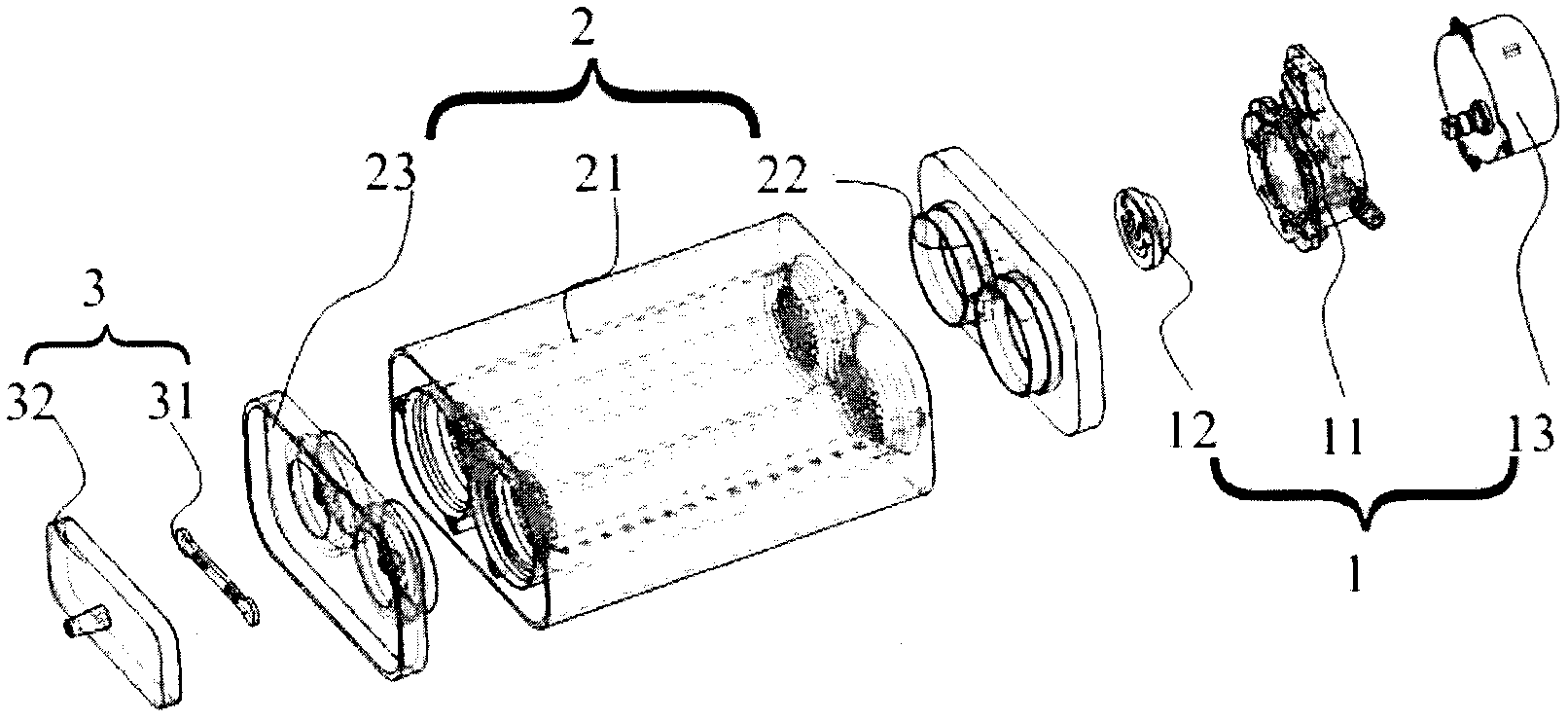

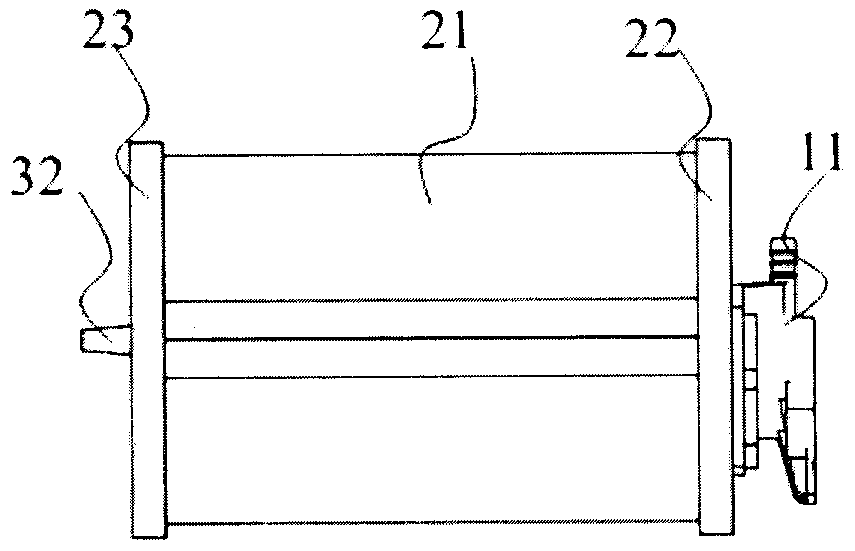

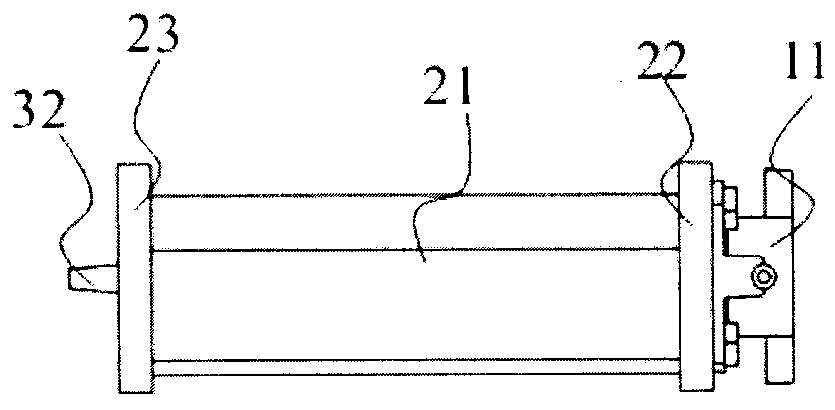

Nitrogen-oxygen separation device and corresponding oxygenerator

InactiveCN103395748ASimple structureReduce volumeDispersed particle separationOxygen preparationMolecular sieveChemical physics

The invention provides a nitrogen-oxygen separation device and a corresponding oxygenerator. The nitrogen-oxygen separation device comprises a gas intake module, a separation module and an oxygen output module; the gas intake module comprises a sealing cover, a switching rotation sliding block and a drive motor; the separation module comprises at least two molecular sieve assemblies, a molecular sieve front cover and a molecular sieve back cover; the oxygen output module comprises a sealing element and a gas outlet element. The invention also provides the oxygenerator. Due to the arrangement of the gas intake module in the nitrogen-oxygen separation device and the corresponding oxygenerator, the nitrogen-oxygen separation device has the advantages of simple structure, small size and low manufacture cost; and at the same time, due to the arrangement of the gas intake module, the nitrogen-oxygen separation device has good air tightness and high oxygen generating efficiency.

Owner:SHENZHEN Z AIDE TECH DEV

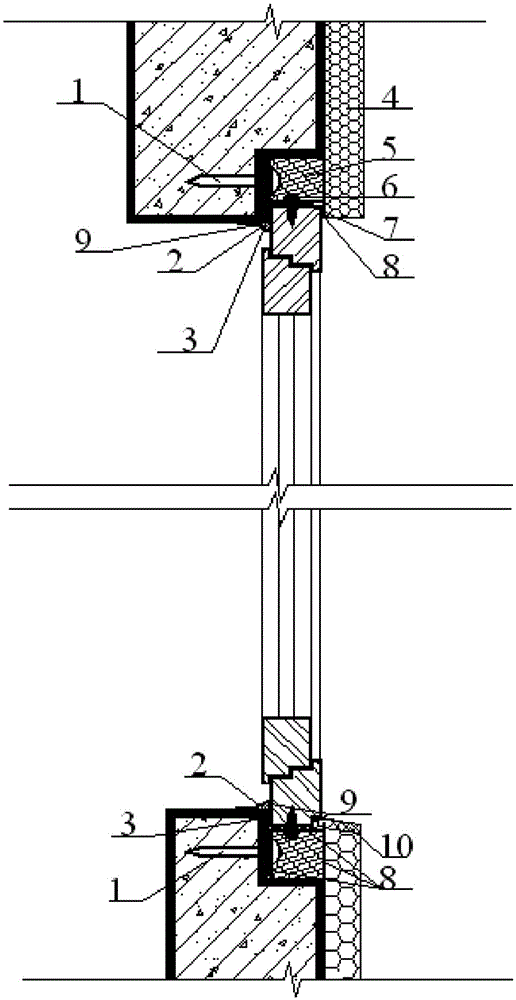

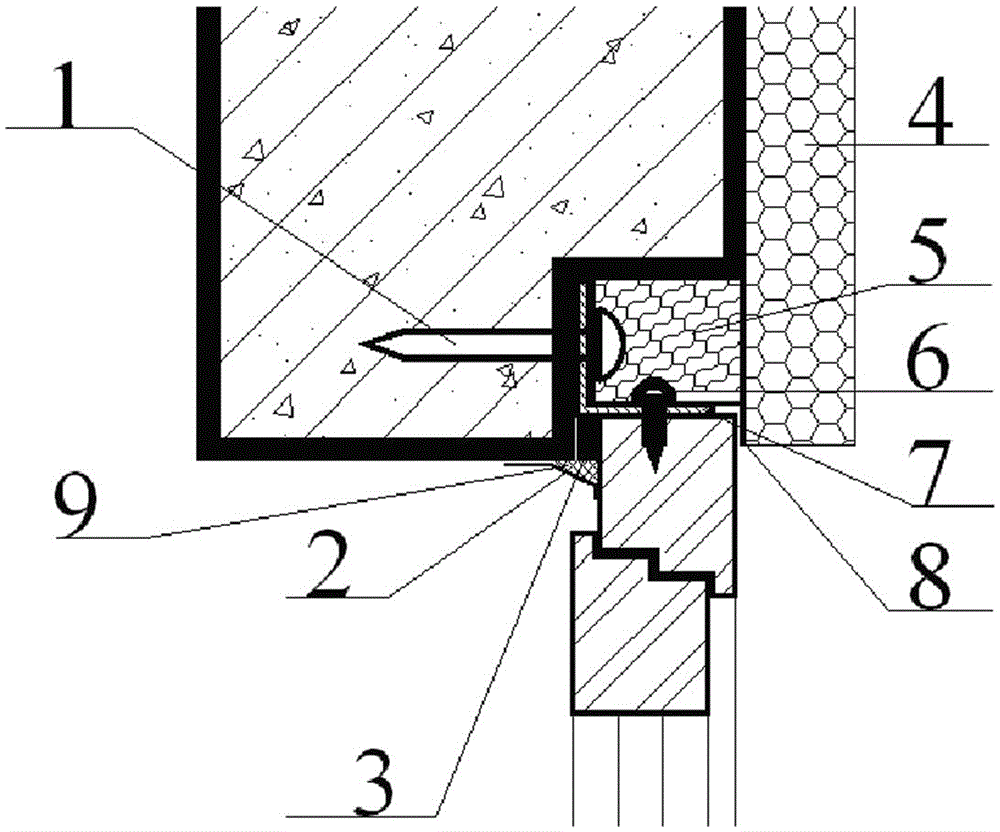

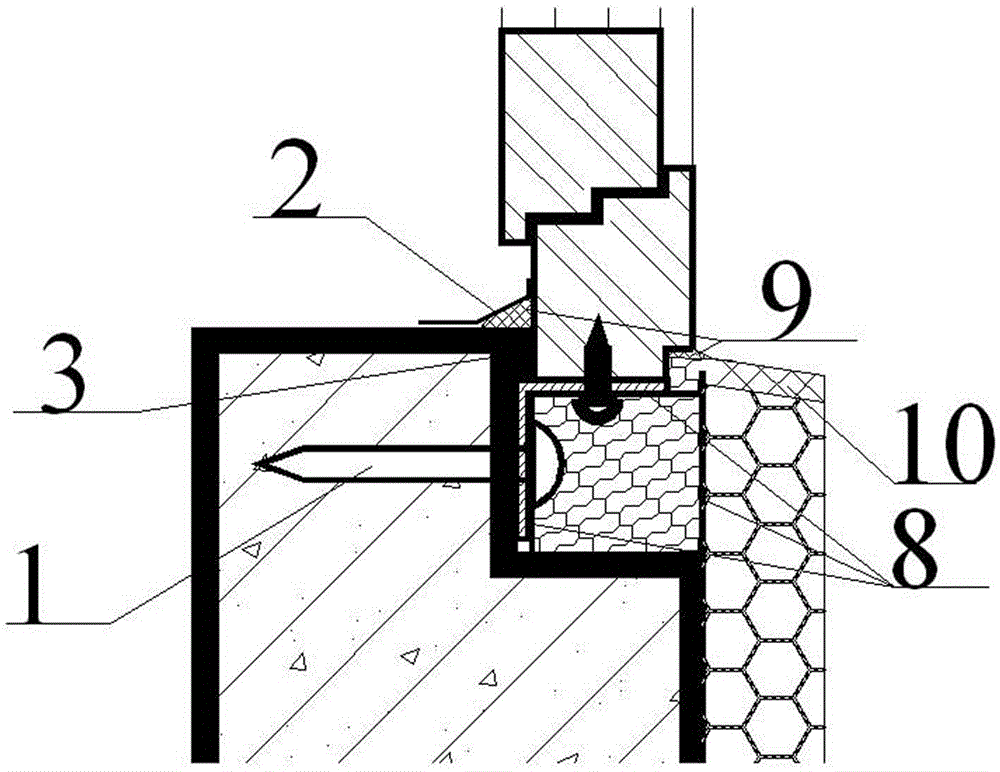

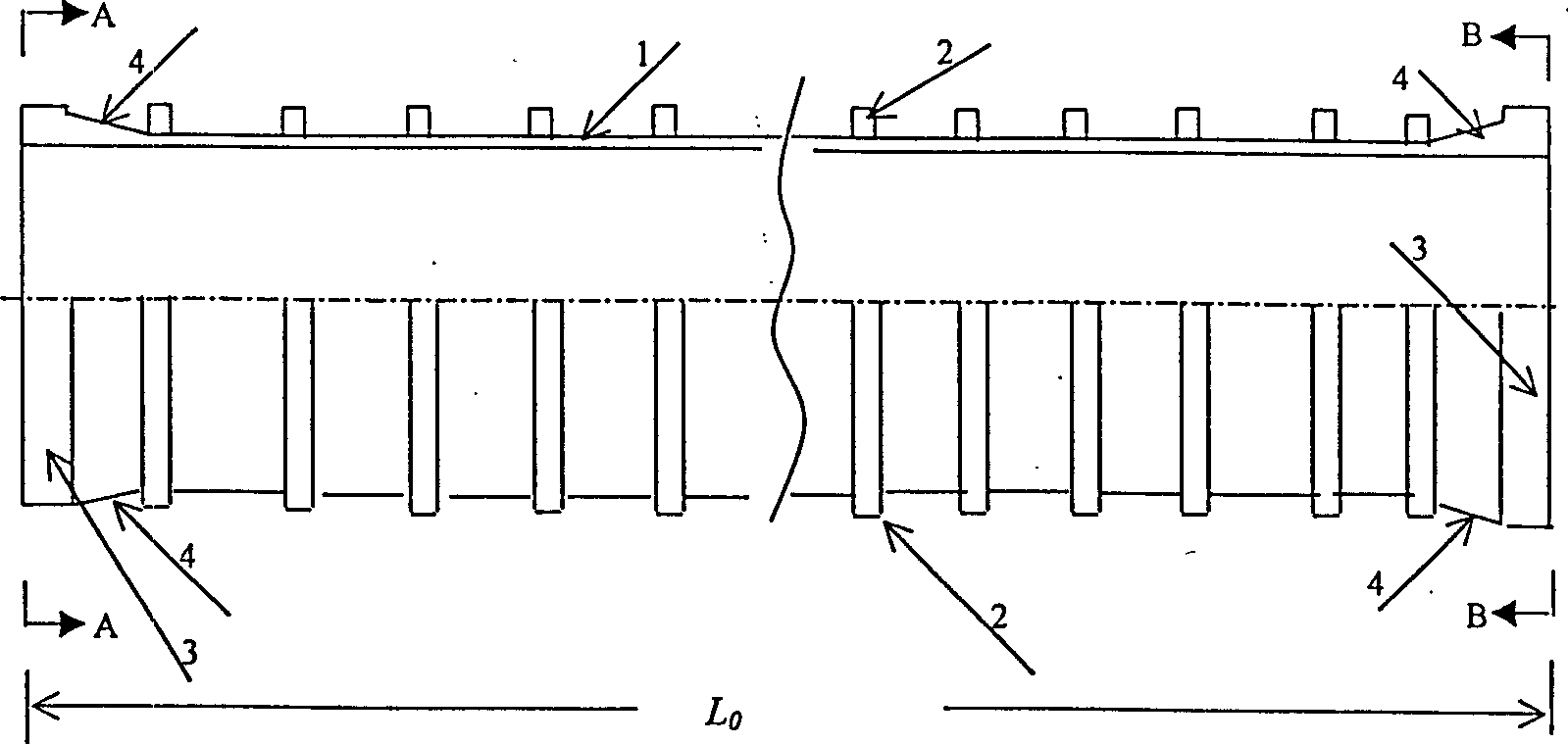

Outer window structure suitable for passive-type low-energy-consumption buildings and installation method thereof

ActiveCN105113646ASolve the problem of airtightnessGuaranteed comfortClimate change adaptationFrame fasteningSocial benefitsInsulation layer

The invention relates to an outer window structure suitable for passive-type low-energy-consumption buildings and an installation method thereof, and belongs to the technical field of building energy saving technologies. The outer window structure comprises an outer wall, an outer window and insulation materials; the window frames of the outer window are provided with fixing points, all the fixing points are connected with the outer wall through expansion bolts, screws and stainless angle steel, rock wool is filled in the outer embedding positions of the outer wall and the outer window frames, and the outer embedding positions are sealed through waterproof cloth; the contact faces of the inner sides of the window frames and the outer wall are provided with prepressing expansion seal belts; the inner sides and the outer sides of the joints of the outer wall and the window frames are each coated with a layer of sealing gum. According to the outer window structure, efficient and airtight construction of the passive-type low-energy-consumption buildings can be achieved on the condition that the outer wall is not provided with an insulation layer or the insulation layer is thin, and the obvious economical benefits and social benefits are achieved.

Owner:河北电力工程监理有限公司

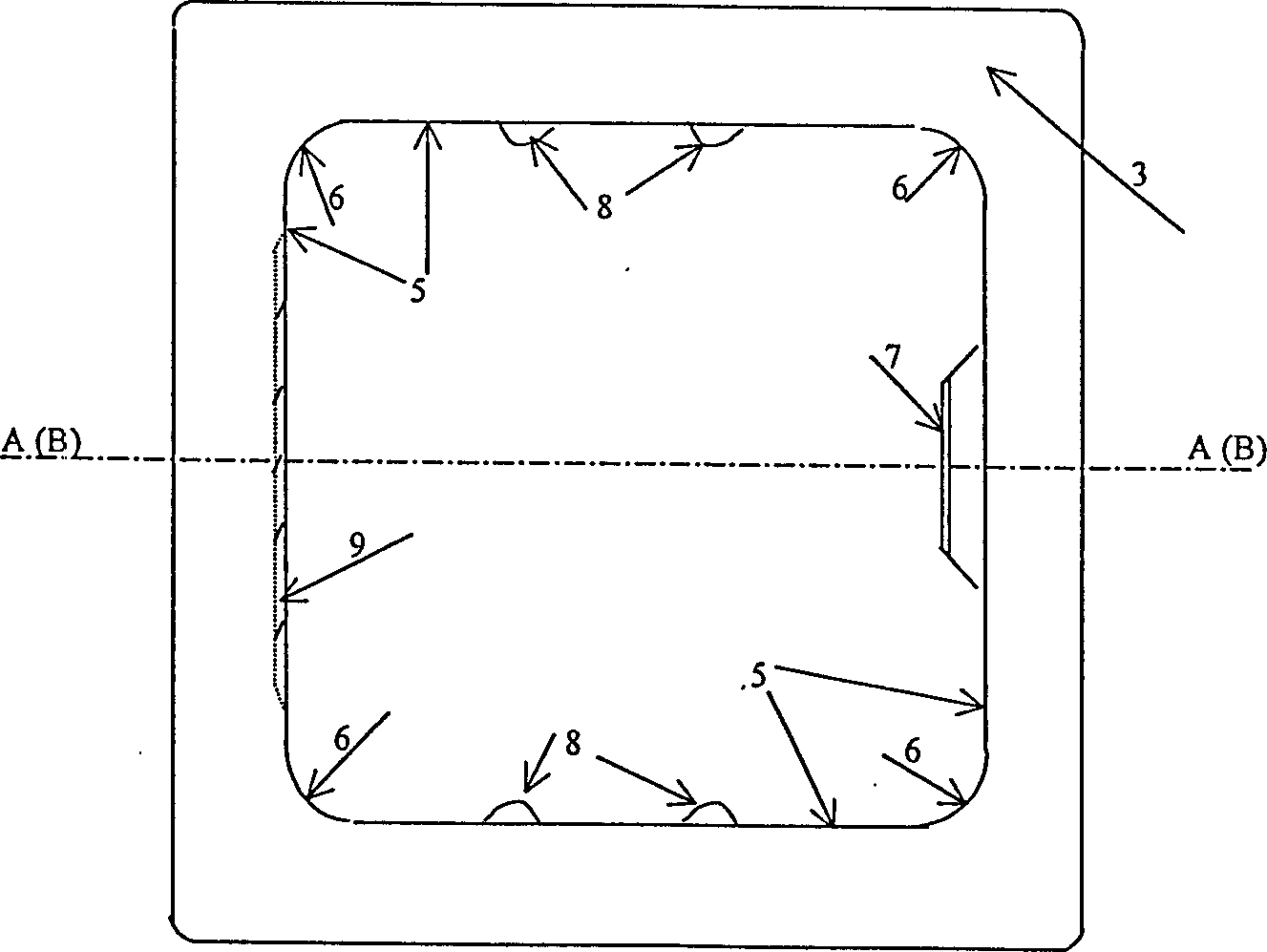

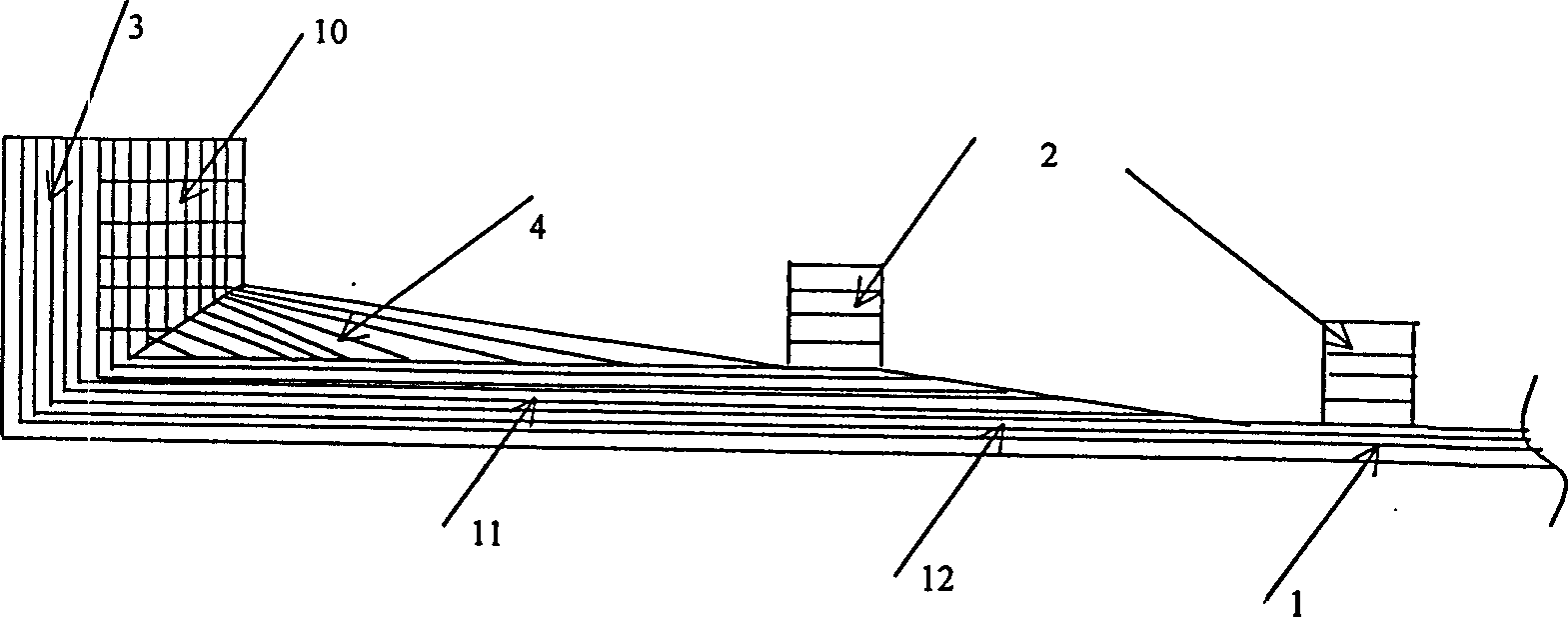

Composite material made box body structure for storage and conveying launch box

InactiveCN1419101AGuarantee safe and reliableSymmetricalSelf-propelled projectilesEngineeringAir tightness

The composite material box body structure for storage and transportion box of missile is characterized by that said box body structure possesses the shallow arched single shell plate structure with longitudinal reinforcement member and transverse reinforcing rib and correspondent symmetrical layer-spread form, its four-side base plate of said box body structure is made up by using four-side small arch degree and shallow arched shell plate and four-corner cylindrical shell plate which are smoothly connected togher, along the length direction of base plate of box body the transverse reinforcing ribs are uniformly-spaced and placed, two ends of said box body adpots the all-composite material flange flanges which are connected with box body base plates together and formed into one body, so that said box body structure possesses high specific strength.

Owner:SHANGHAI JIAO TONG UNIV

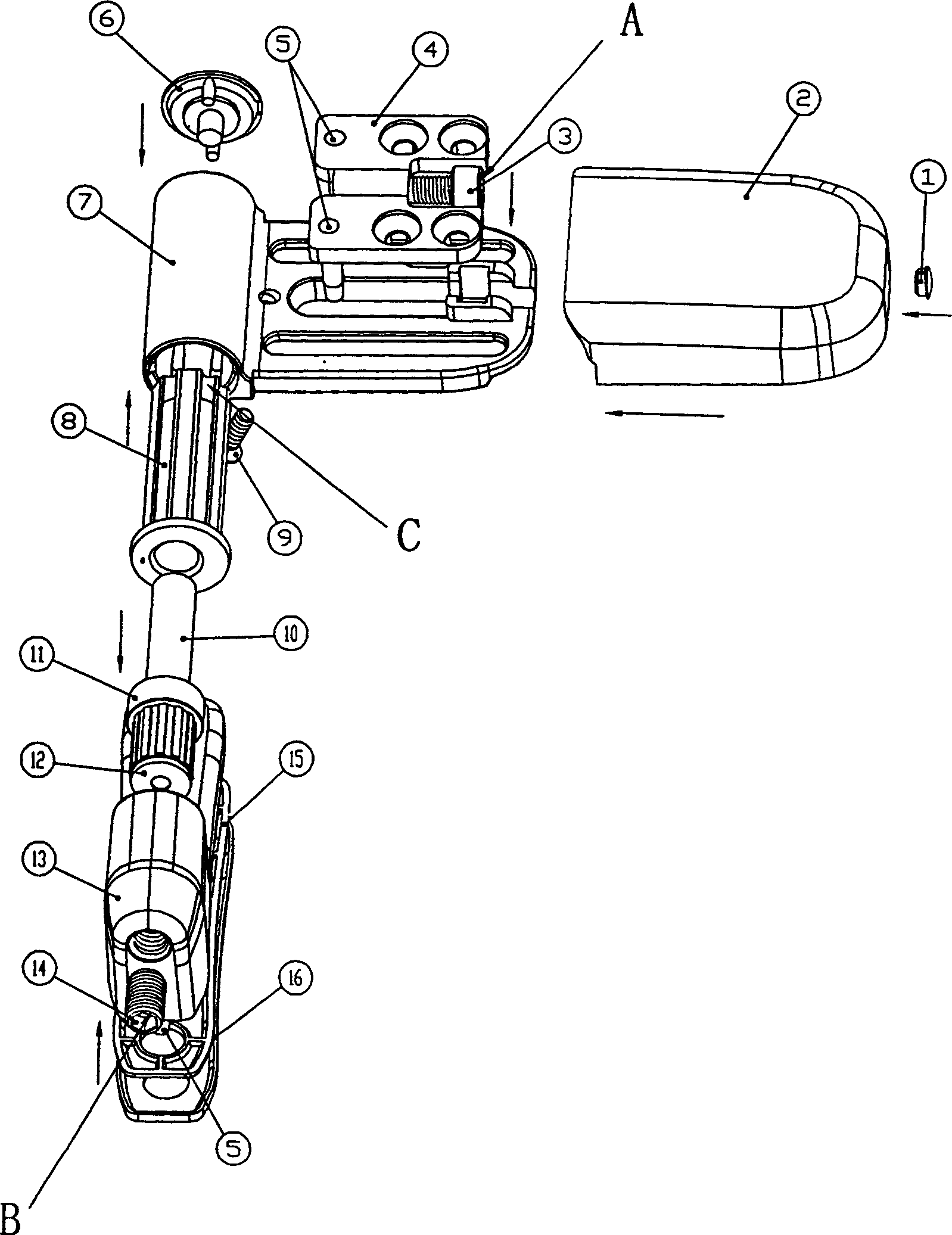

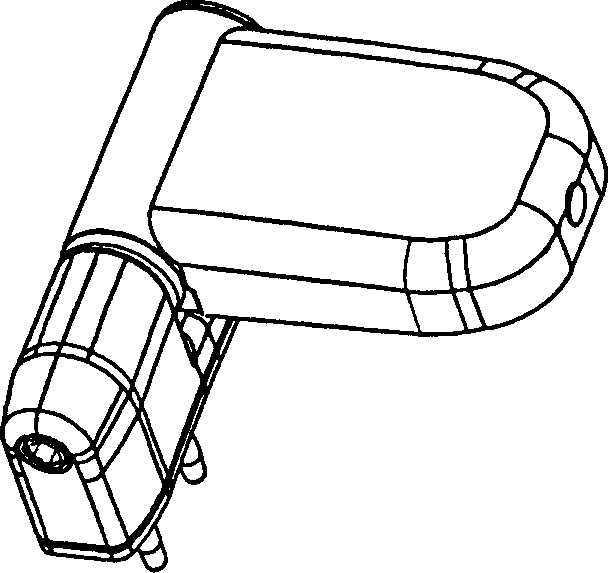

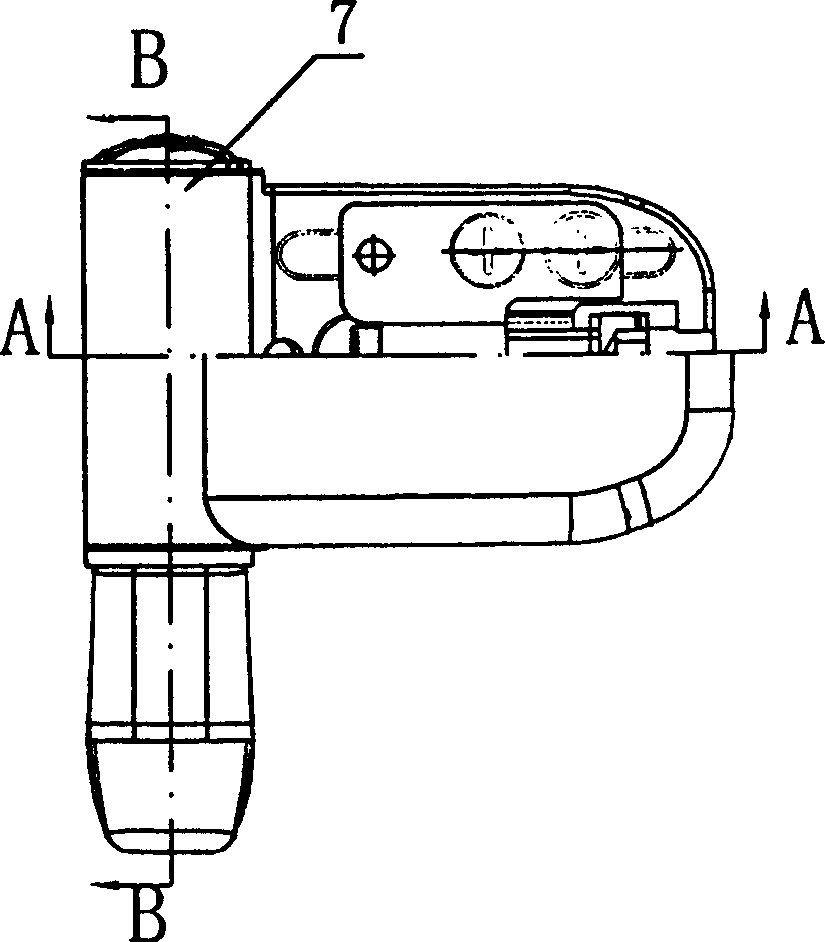

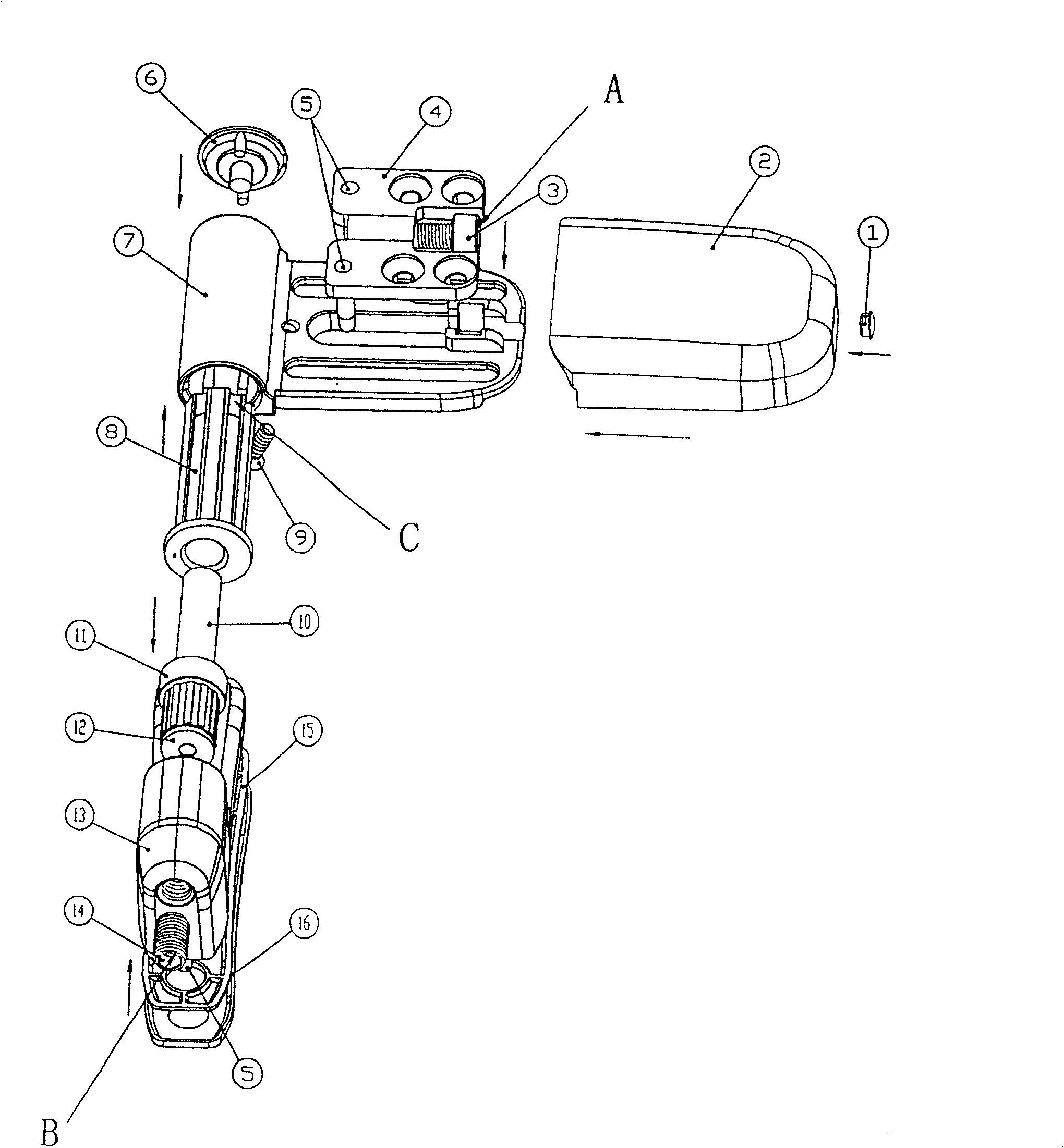

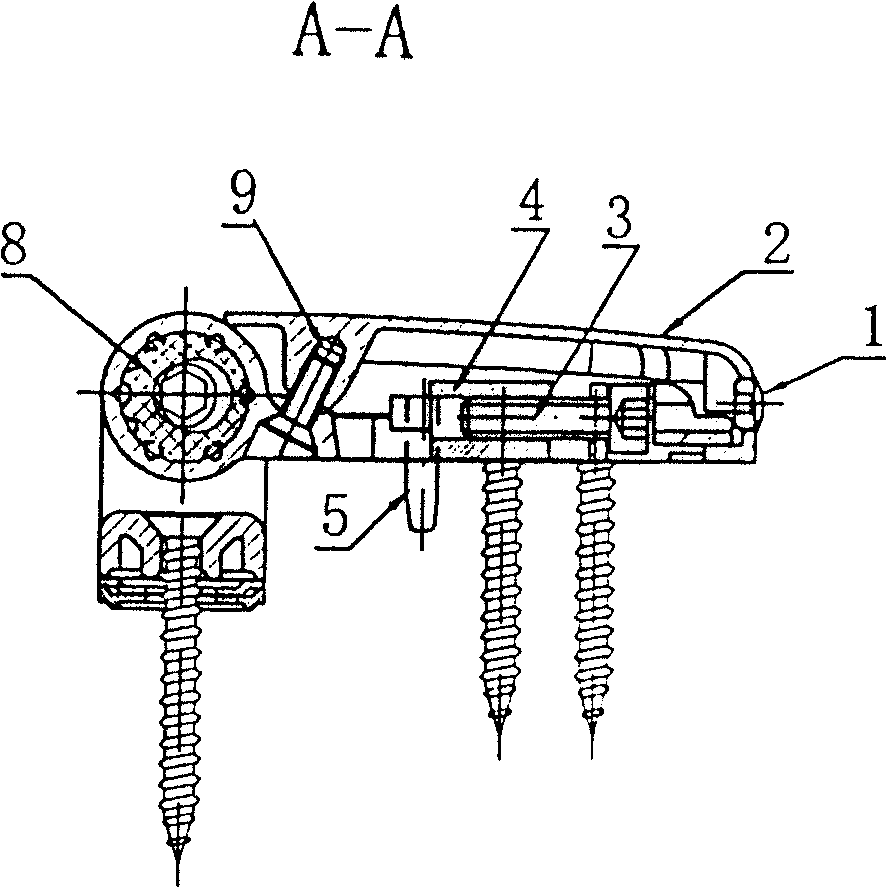

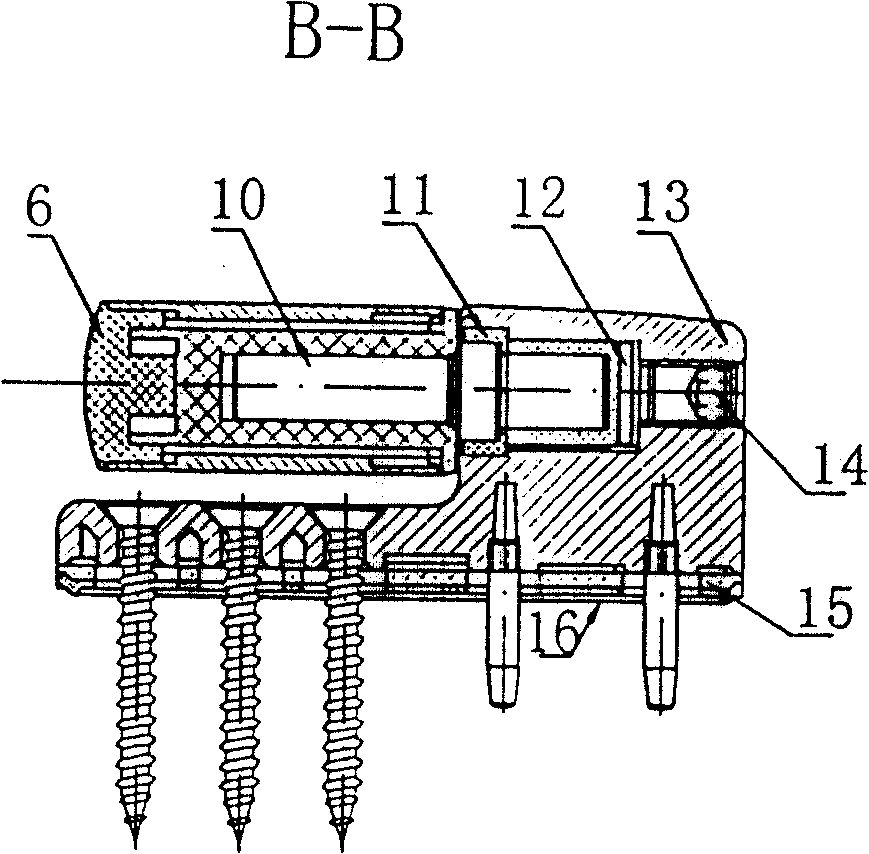

Three-dimension adjustable hinge for door and window

Involves windows and doors hinge which between the mechanical hardware the domain three dimensional may move, aims at the existing windows and doors a hinge, two approaches may the mode similar product dense be proper. The gas tightness unsatisfactory designs a kind of hinge. The design key point is x axial is equipped with the adjuster bolt in this hinge main body, gyrates the adjuster bolt in hexagon, will lead the slide displacement, will be is moved by the fixture to x axis direction. Gyrates adjusting screw which the substrate nose turns on lathe into, will be is fixed the object to move to x axis direction. Gyrates adjusting screw which the substrate nose turns on lathe into, will be is fixed the object to move to the y axis direction. Gyrates the wrap to enter main body minister of the interior in the axle sleeve the axis in hexagon, will cause by the solid object to move to the z axis direction. The kind of structure hinge reliability greatly is the enhancement, solved the windows and doors dense to be proper and the gas tight not good question. Has the prominent substantive characteristic, the product scale has the remarkable enhancement, thus lengthened the windows and doors service life.

Owner:宁波天宝恒业进出口有限公司

Fireproof explosion-proof combination structure at power cable joint of electric power system and application method

ActiveCN105977898ASolve the problem of airtightnessHigh strengthCable junctionsPower cableElectric power system

The invention discloses a fireproof explosion-proof combination structure at a power cable joint of an electric power system and an application method, belonging to the power cable connector fireproof explosion-proof combination structure. The fireproof explosion-proof combination structure at the power cable joint of the electric power system comprises an outer box body with double sealing structures on a longitudinal assembling surface, an assembling end cap which adopts an embedding sealing structure with the outer box body and a plugging board and a sealing member which seal a gap between related fitting surfaces of a cable annular surface and an assembling end cap, wherein the plugging board and the sealing member are arranged on the assembling end cap; the outer box is provided with a glue injection tube and an exhaust pipe are arranged on the outer box; the cable is fully wrapped by a power cable fireproof pack after connected to a middle connector and is arranged in the outer box; and fireproof sealing glue is injected to the outer box through the glue injection tube. In operation, air in the outer box is discharged through carbon dioxide or nitrogen and the fireproof sealing glue is injected inside the outer box and then high pressure shape forming is performed. The pressure maintaining shape forming is performed on the fireproof sealing glue by virtue of the outer box. The fireproof explosion-proof combination structure at the power cable joint realizes sealing protection on the cable connector, forms a compact filling layer on the periphery of the middle connector, solves a problem that durability and reliability of the fireproof performance are not good, and is low in manufacture cost and easy to promote.

Owner:WUHAN HANYUAN JIJI ELECTRIC POWER EQUIP

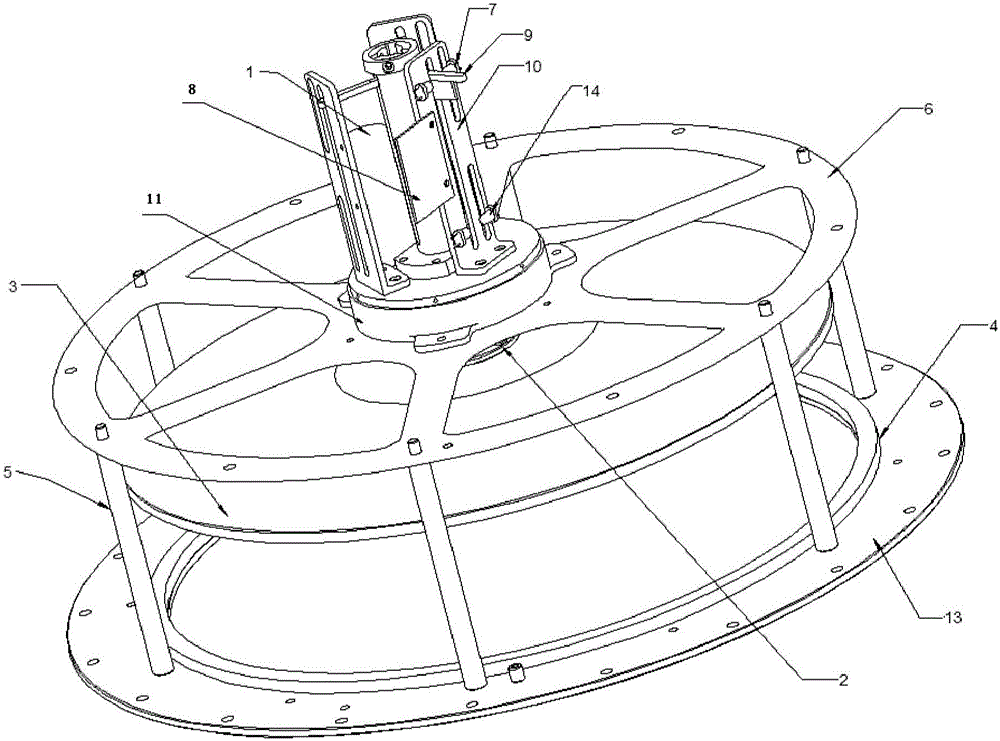

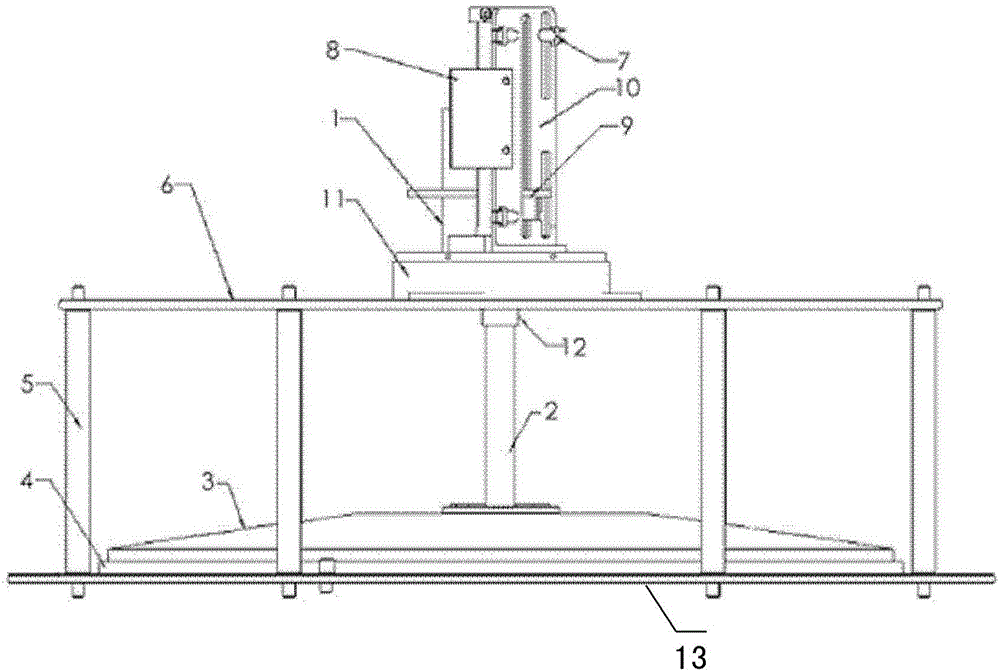

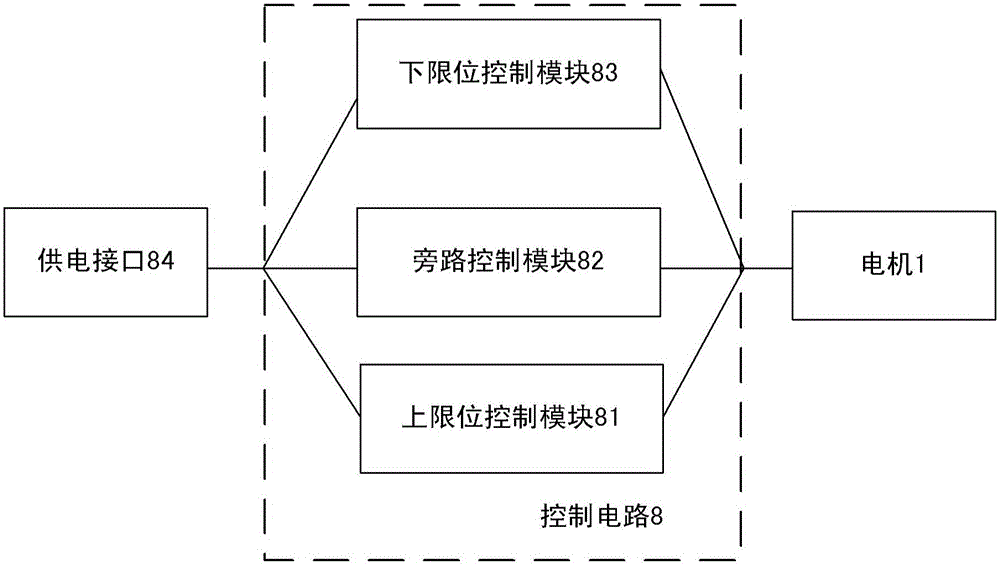

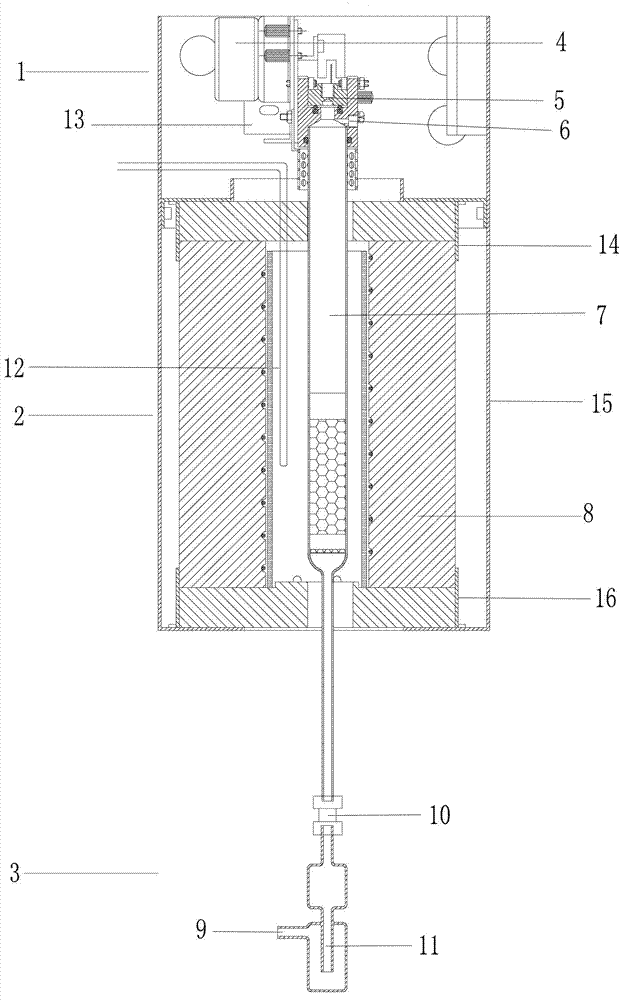

Current limiting closed exhaust valve used for aerostat and control method used for limiting same

InactiveCN105129067ASafe and reliable pneumatic shapeClose tightlyGas-bag arrangementsExhaust valveDrive wheel

The invention provides a current limiting closed exhaust valve used for an aerostat and a control method used for limiting the same. The exhaust valve comprises a motor, a screw, a valve cover, a seal ring, a column, a pedestal, an upper limiting member, a control circuit, a gear block, a support, a base, a driven wheel and a valve body, wherein the valve body covers on the seal ring and the valve port of the valve body. The control circuit is connected with the motor. The motor is connected with the valve cover and used for controlling the valve cover to move upwards and downwards along the screw. The upper limiting member is connected with the control circuit. The gear block is fixedly connected with the screw. When the motor rotates, the motor makes the gear block move upwards and downwards along the screw, the gear block contacts with the upper limiting member, the upper limiting member cuts off the control circuit, and the motor stops to make the valve cover be in a maximal opening state. When the motor rotates anticlockwise, the motor makes the gear block move downwards, the valve cover contacts with the seal ring to reach a preset compaction state, a pretightening force between the valve cover and the seal ring is kept, the current of the control circuit is limited to cut off the power supply to the motor, the valve cover can be automatically closed and in a sealed and closed state.

Owner:ACAD OF OPTO ELECTRONICS CHINESE ACAD OF SCI

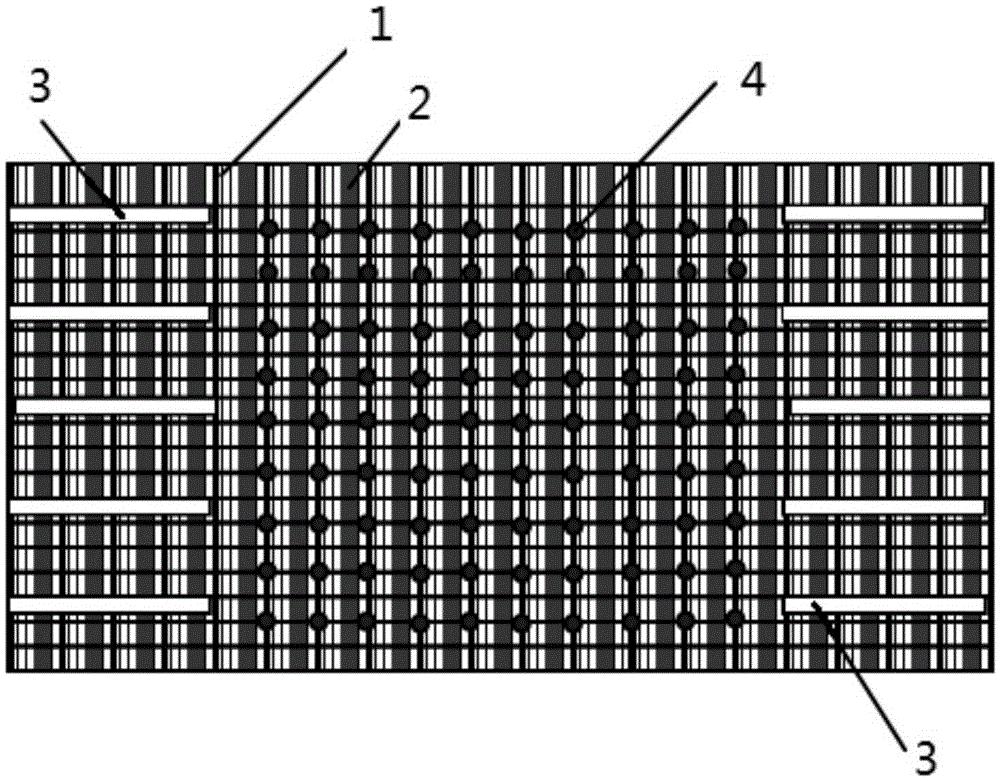

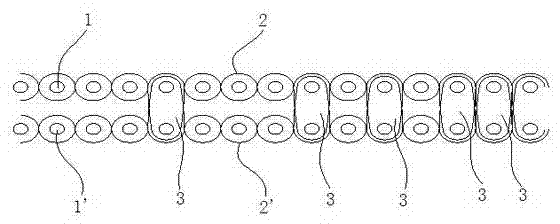

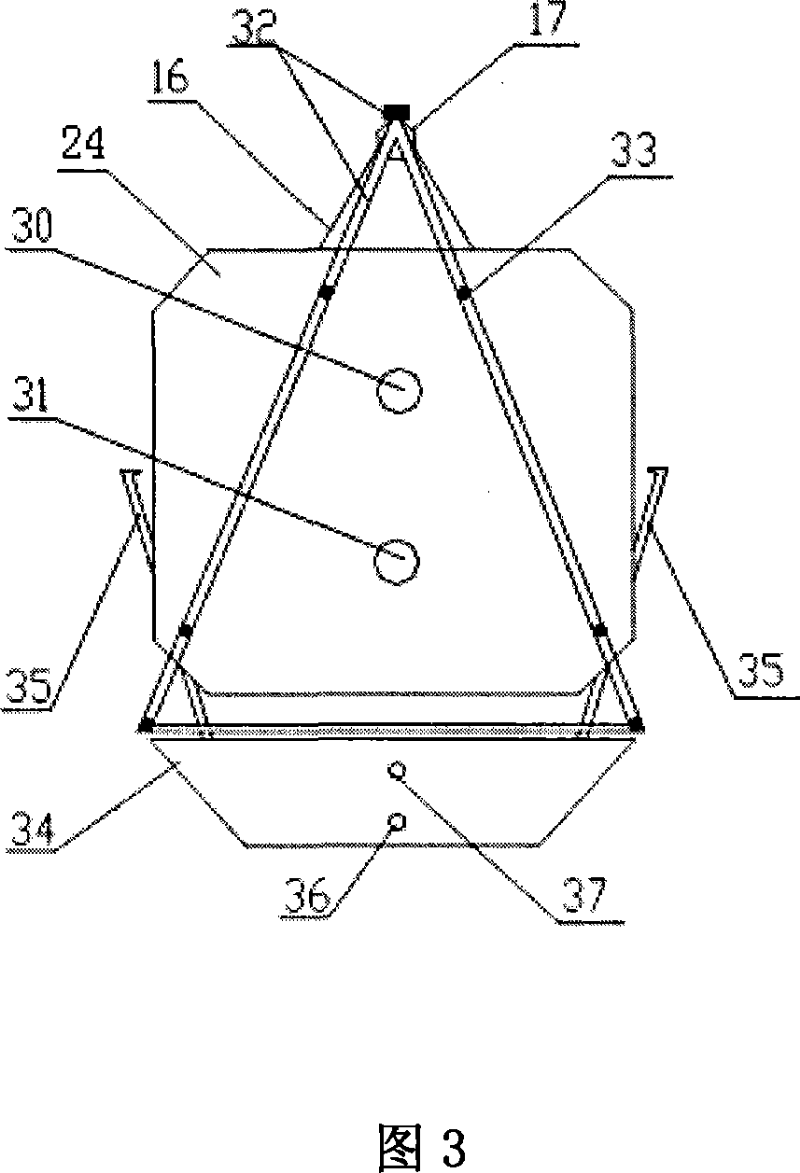

Forming method of mixed-stitch composite material of three-dimensional woven prefabrication body fabric

The invention discloses a forming method of a mixed-stitch composite material of three-dimensional woven prefabrication body fabric. The method comprises the following steps that thermoplastic resin fibers and reinforced fibers are premixed or reinforced fibers attached with thermosetting resin films and reinforced fibers are premixed, so that resin and the reinforced fibers are subjected to synchronous mixed stitch knitting; during stitch knitting, resin adhesive films are laid in the set portion of the fabric in a needling mode; after stitch knitting is finished, the set portion of an obtained three-dimensional woven prefabrication body is subjected to three-dimensional stitch laying through stitch laying resin fibers; the resin content of the set portion is increased, and the obtained three-dimensional woven prefabrication body fabric is subjected to vacuum mould pressing linkage forming. By the adoption of combined application of the above three technologies, the forming method can adapt to a traditional composite material hot press molding process, the prepared fiber composite prefabrication body fabric can be used for forming machining of the composite material directly through a hot press molding mold, the gas tightness in a vacuum infusion RTM process is achieved, and the production efficiency is effectively improved.

Owner:SHANDONG ZHONGHENG CARBON FIBER TECH DEV CO LTD

Three-dimension adjustable hinge for door and window

Involves windows and doors hinge which between the mechanical hardware the domain three dimensional may move, aims at the existing windows and doors a hinge, two approaches may the mode similar product dense be proper. The gas tightness unsatisfactory designs a kind of hinge. The design key point is x axial is equipped with the adjuster bolt in this hinge main body, gyrates the adjuster bolt in hexagon, will lead the slide displacement, will be is moved by the fixture to x axis direction. Gyrates adjusting screw which the substrate nose turns on lathe into, will be is fixed the object to move to x axis direction. Gyrates adjusting screw which the substrate nose turns on lathe into, will be is fixed the object to move to the y axis direction. Gyrates the wrap to enter main body minister of the interior in the axle sleeve the axis in hexagon, will cause by the solid object to move to the z axis direction. The kind of structure hinge reliability greatly is the enhancement, solved the windows and doors dense to be proper and the gas tight not good question. Has the prominent substantive characteristic, the product scale has the remarkable enhancement, thus lengthened the windows and doors service life.

Owner:宁波天宝恒业进出口有限公司

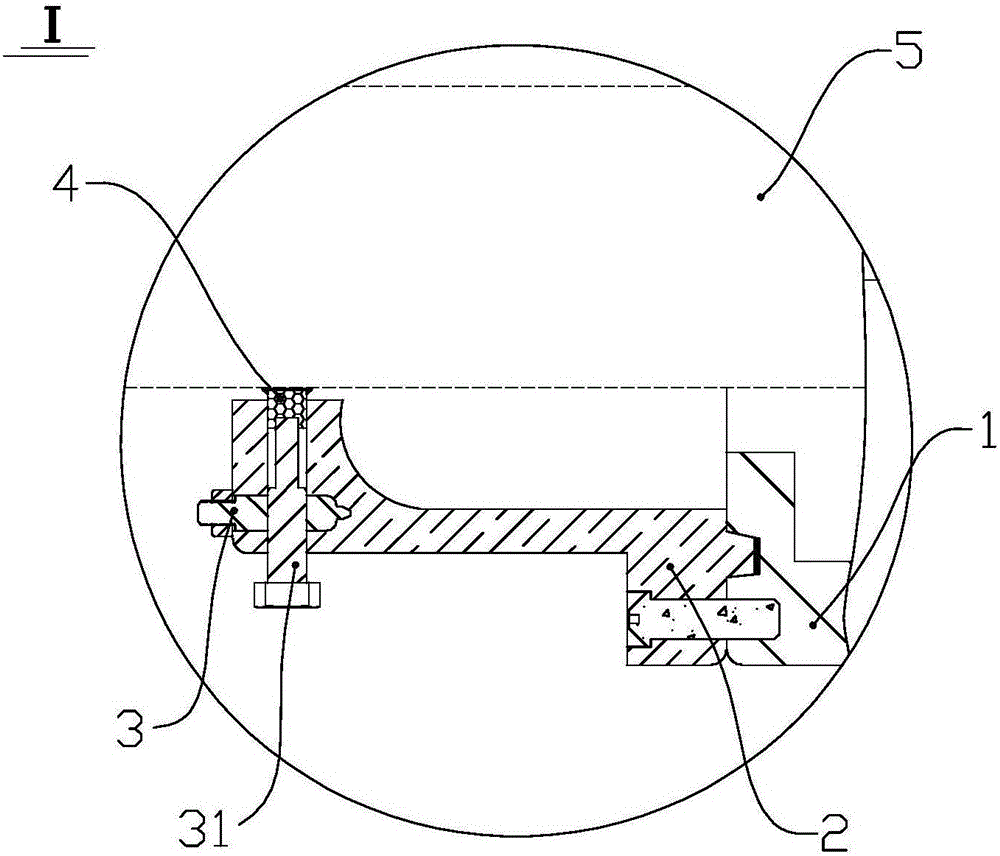

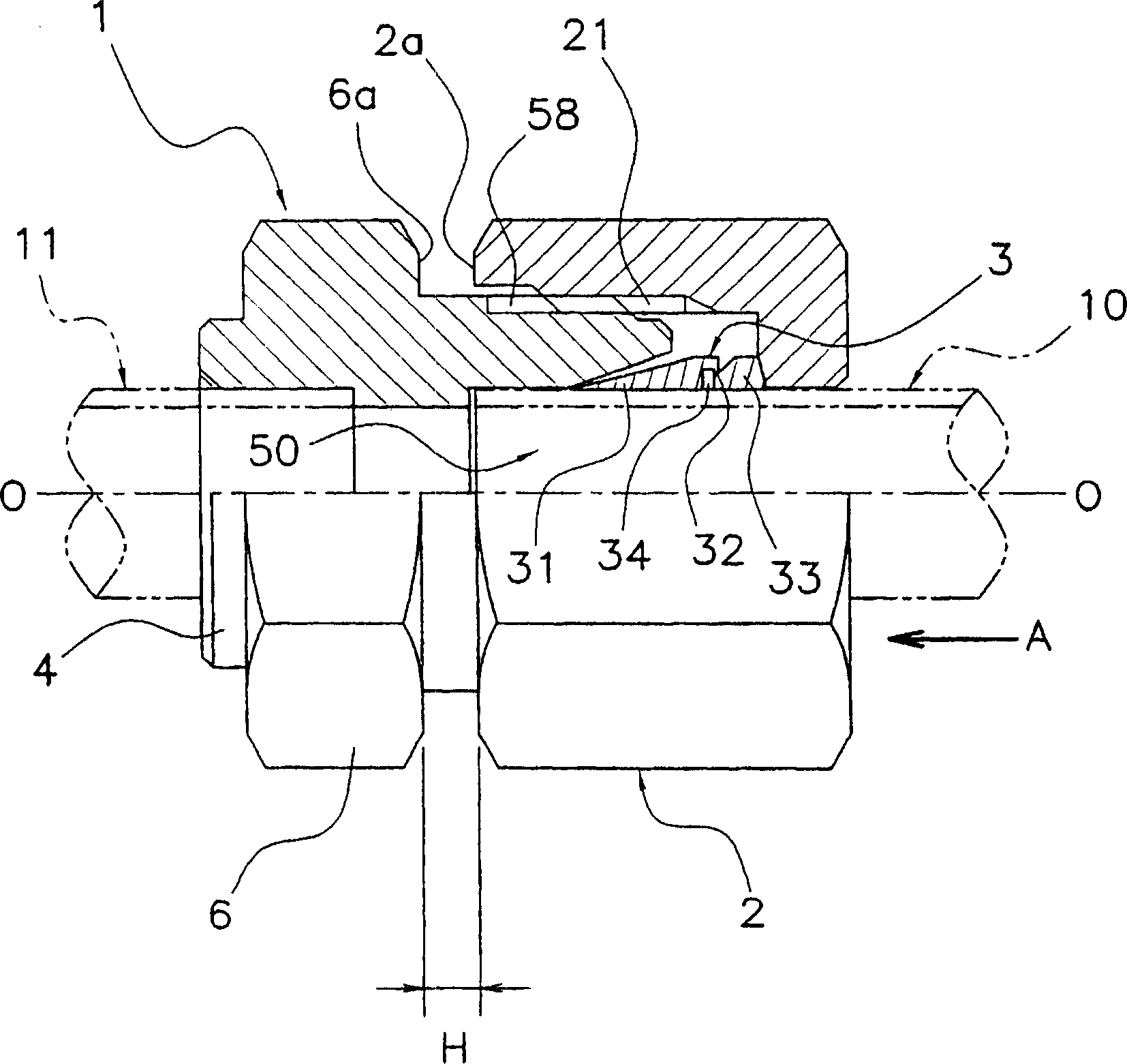

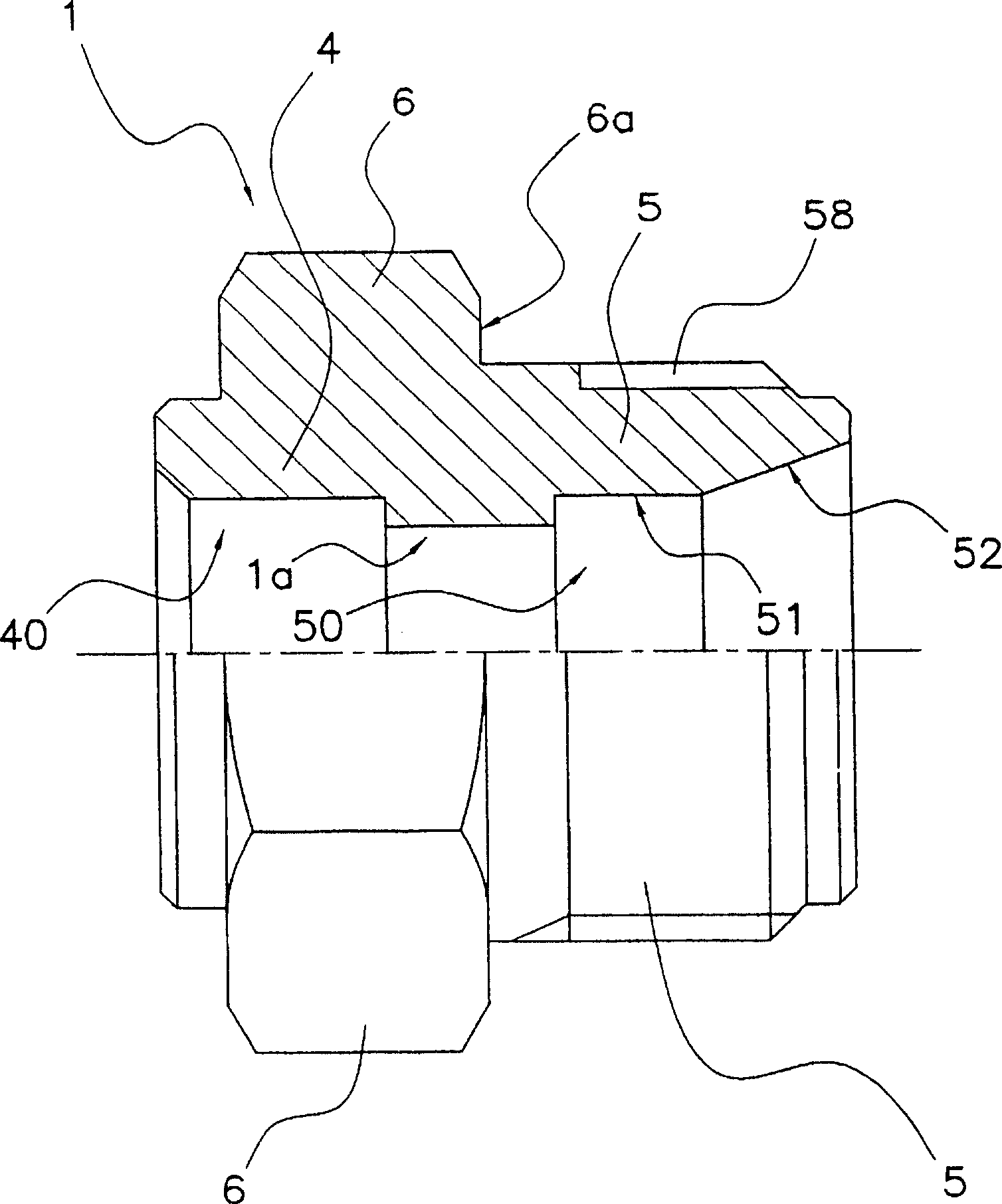

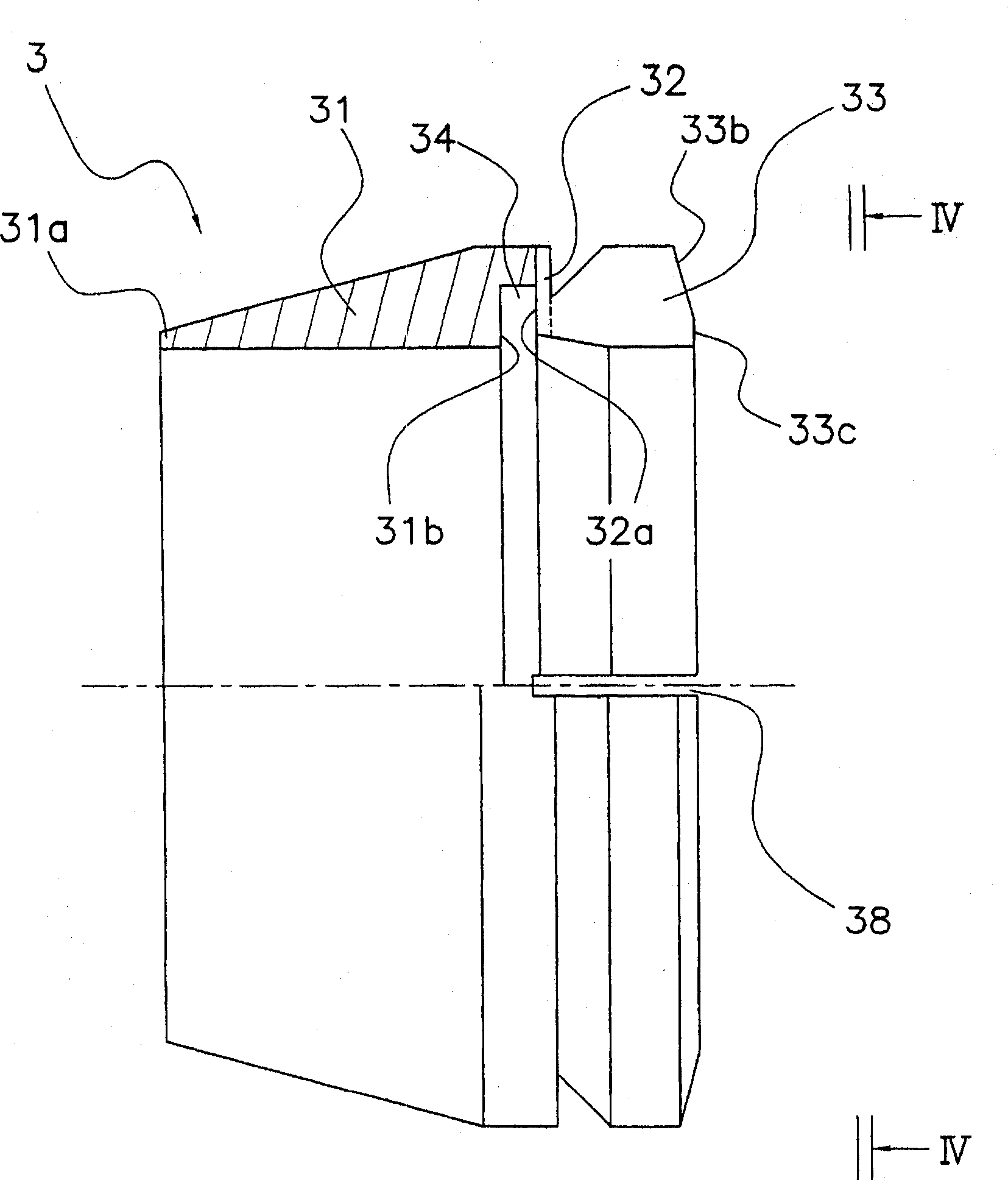

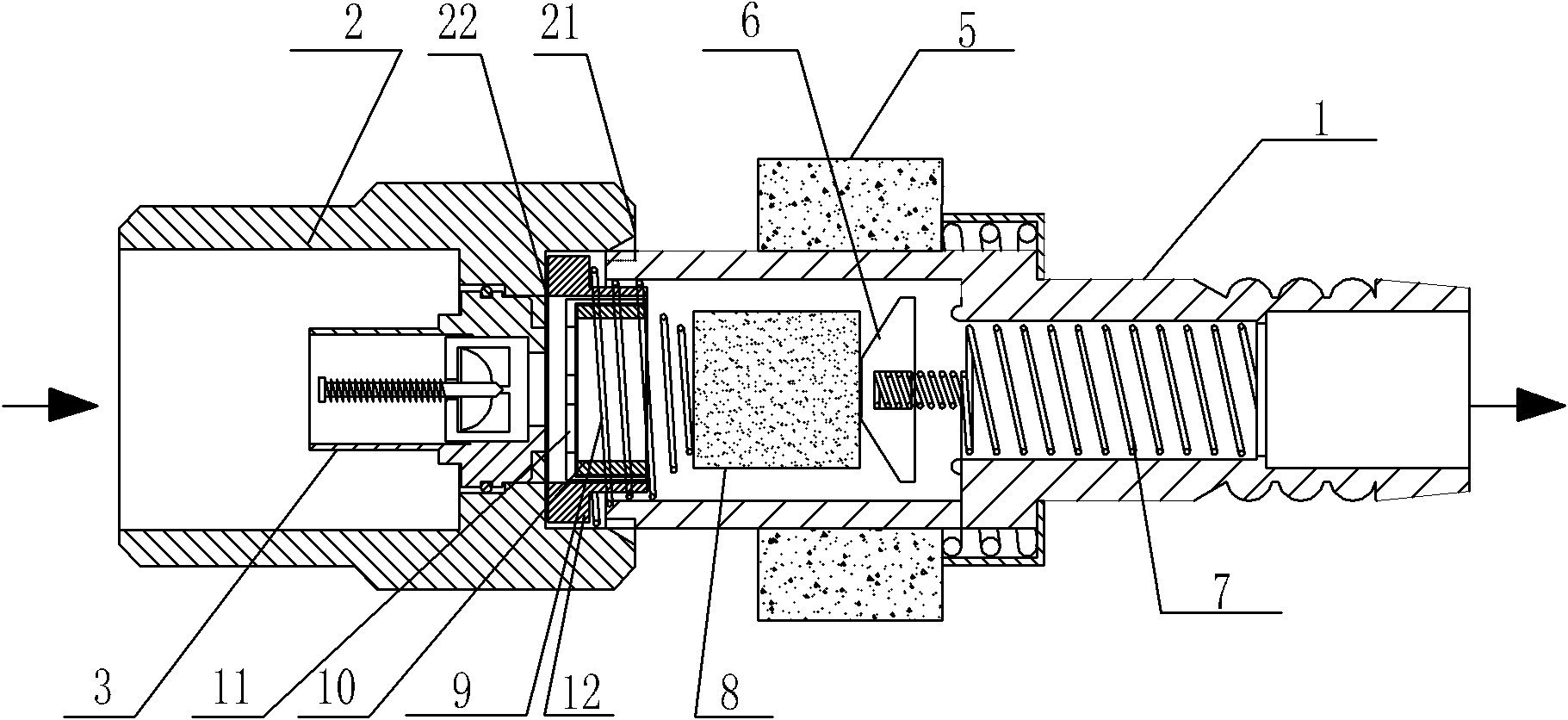

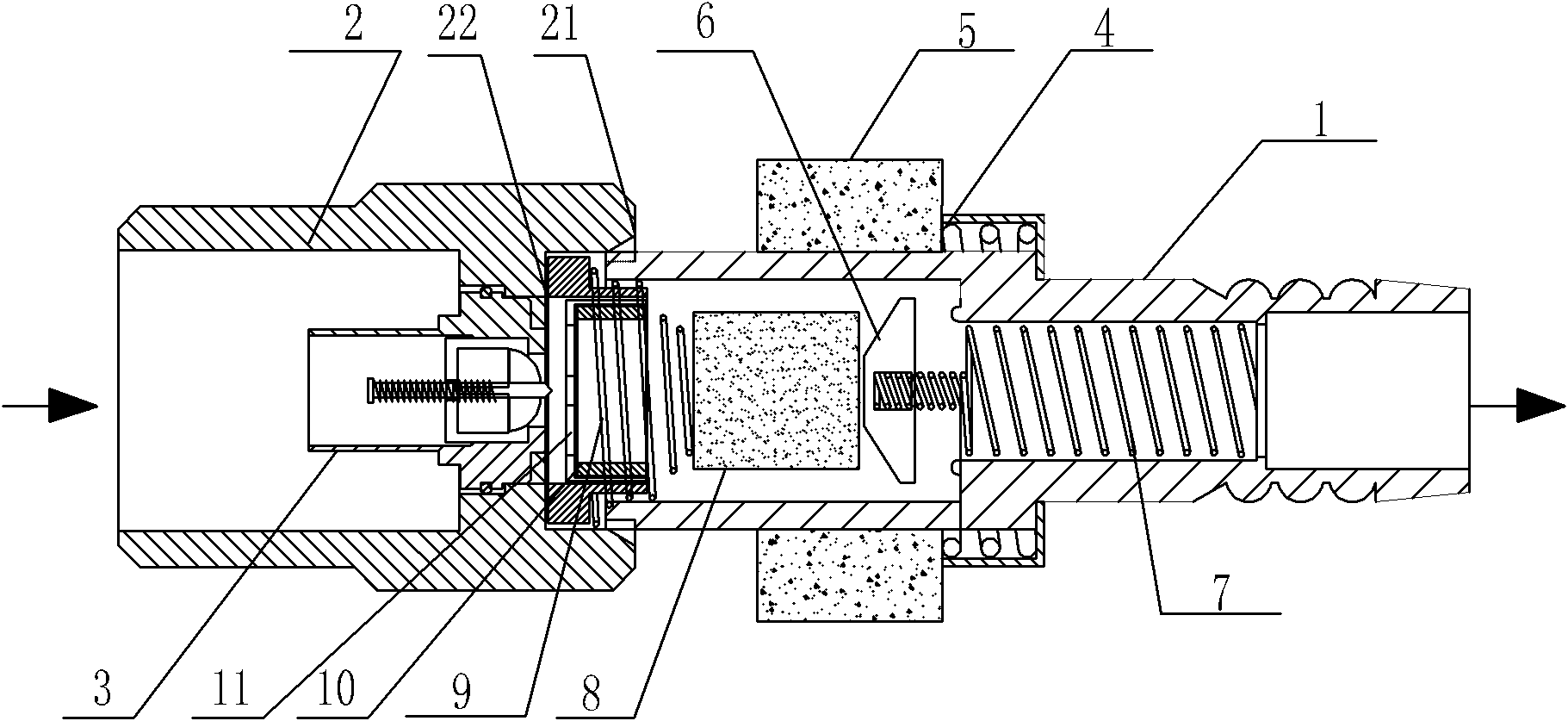

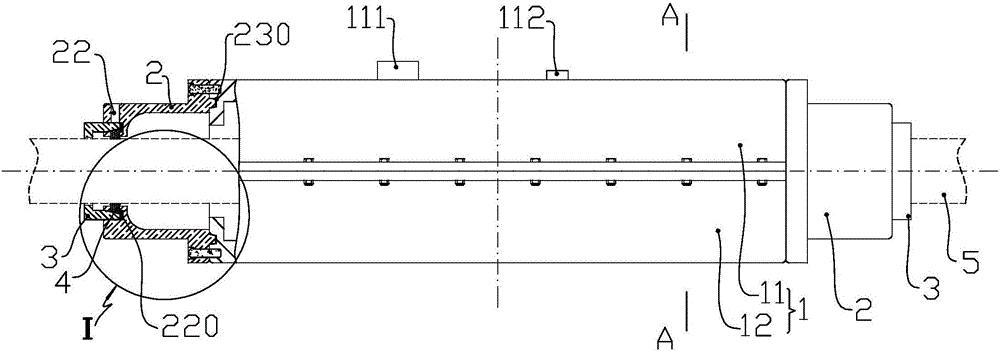

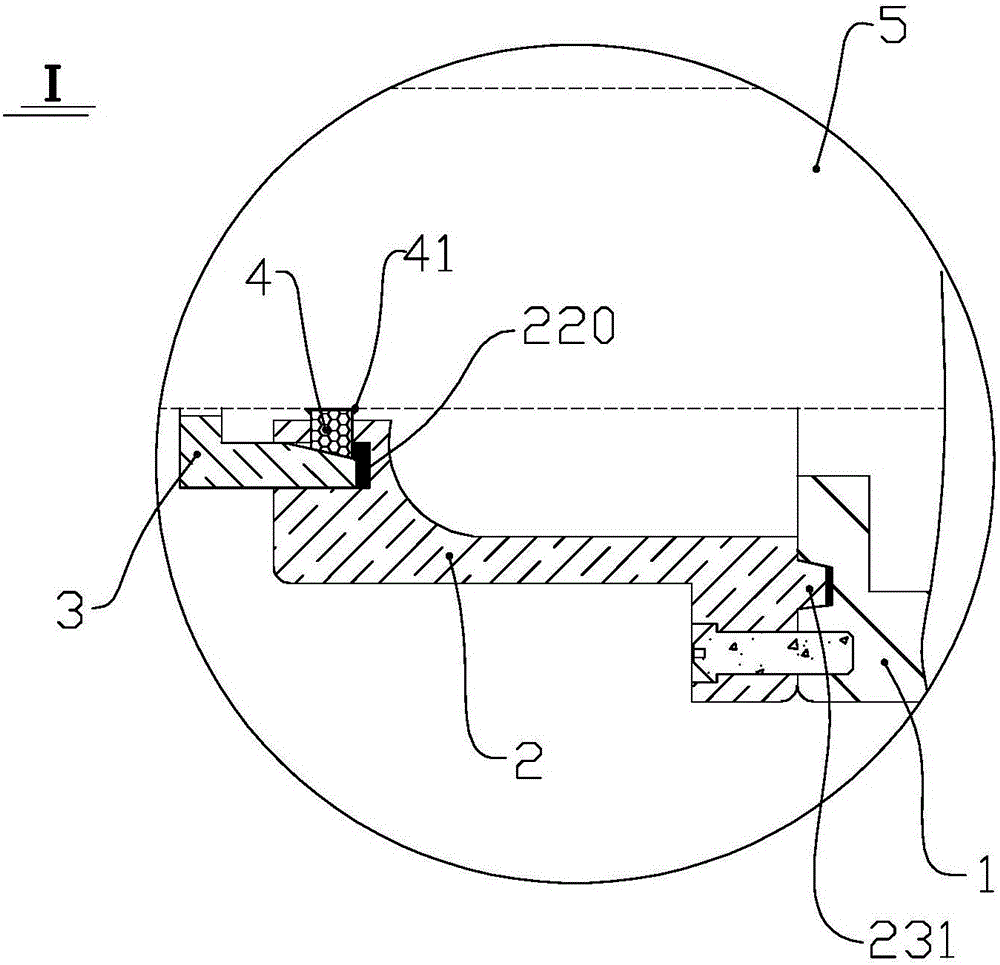

Pipe joint

InactiveCN1823240AAvoid bad phenomenaSolve the problem of airtightnessJoints with sealing surfacesAir tightnessBiomedical engineering

It is an object of the present invention to resolve problems resulting from removing a nut, pulling a pipe and a sleeve out from a joint main body, and then using these items to rejoin the pipe, that is, to resolve the problems of not being able to ensure airtightness or pressure resistance. The joint according to the present invention comprises a joint main body (1) having a joining hole (50) and an external threaded part (58), as well as a sleeve (3) and a nut (2). The nut (2) is screwed onto the external threaded part (58) in a state in which the pipe (10) and sleeve (3) are inserted through the joining hole (50), and is used to join the pipe (10) to the joining hole (50) via the sleeve (3). The sleeve (3) is tightly fitted to the pipe (10) and the joint main body (1) by the screwing of the nut (2), and is cut off through a linking part (32) that links a sleeve main body (31) and a separating part (33). The sleeve (3) can no longer join the pipe (10) to the joining hole (50) after the nut (2) is removed and the pipe (10) and the sleeve (3) are pulled out from the joining hole (50).

Owner:IHARA SCIENCE CORPORATION +1

Preparation method for low-resistance injector

ActiveCN104014056AAvoid it happening againAvoid pollutionInfusion syringesPush and pullLow-resistance syringe

The invention discloses a preparation method for a low-resistance injector. The preparation method for the low-resistance injector comprises a core bar and a jacket. The core bar and the jacket are formed by polymethyl methacrylate through the extrusion pipe processing technology. The inner circular surface of the jacket is ground and pressed through the vacuum grinding and pressing technology, so that the accuracy error of the circular degree of the inner circle is not larger than 5 micrometers, the outer circular surface of the core bar is ground and pressed through the heat outer circle grinding and pressing technology, so that the accuracy error of the circular degree of the outer circle is not larger than 5 micrometers, and then the outer circular surface of the core bar is coated with a teflon film with the thickness not larger than 5 micrometers through the fast teflon steam film coating method. According to the preparation method for the low-resistance injector, chippings which pollute medicine liquid are avoided, the initial push-and-pull resistance of the low-resistance injector produced through the preparation method does not exceed 0.5 N, the sliding push-and-pull resistance of the low-resistance injector does not exceed 0.3 N, and the clinical application requirements can be met.

Owner:蔡朝林

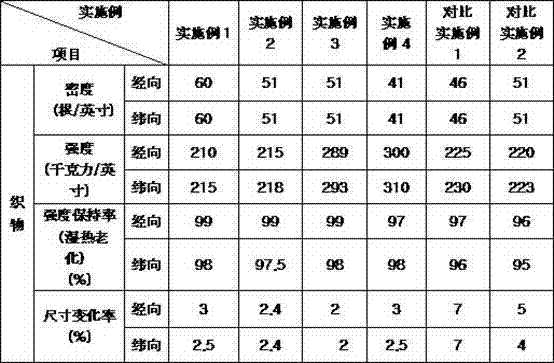

Fabric for airbag, fully moulded airbag as well as manufacturing method thereof

ActiveCN103541224ALow costGood technical effectFibre typesPedestrian/occupant safety arrangementPolyamidePolyester

The invention relates to a fabric for an airbag, wherein the warps and wefts of the fabric consist of polyamide or polyester fibers. The fabric is characterized in that the dry and wet hot shrinking percentages of the polyamide or polyester fibers are below 5%, and the size rate of change of the fabric for the airbag after hot water and hot wind treatment as well as coating of 35-115g / m<2> silica gel resin on the surface of the fabric is less than 3%. The invention further relates to a fully moulded airbag comprising the fabric for the airbag as well as a manufacturing method thereof. On the basis of lowering the cost, the invention solves the problems of size stability, smoothness, air impermeability, high strength, ageing resistance and the like of existing fully moulded airbags.

Owner:KOLON NANJING SPECIAL TEXTILE

Fire and explosion protection structure installed on cable intermediate head, and use method thereof

InactiveCN106058788AReduce security risksLow manufacturing costCable junctionsApparatus for joining/termination cablesCarbon dioxideSizing

The invention discloses a fire and explosion protection structure installed on a cable intermediate head, and a use method thereof, and belongs to the technical field of the fire and explosion protection of a cable head. The fire and explosion protection structure comprises an outer box body, an assembling end cover, a disposable sealing end cover and an inner sealing ring, wherein the longitudinal assembling surface of the outer box body is provided with a double-channel sealing structure; the assembling end cover and the outer box body adopt an embedded sealing structure; the disposable sealing end cover and the inner sealing ring are arranged on the assembling end cover and are used for sealing a gap between a cable ring surface and the relevant cooperation surface of the assembling end cover; the outer box body is provided with a sealant injection pipe and a vent pipe; and the cable is completely covered with a cable fire protection wrapping tape after the cable is connected by the intermediate head, and is arranged in the outer box body, and fire protection sealant is injected into the outer box body through a sealant injection pipe. On an aspect of operation, firstly, carbon dioxide or nitrogen is used for discharging air in the outer box body, and then, the fire protection sealant is injected into the outer box body to carry out high-pressure sizing. The fire and explosion protection structure carries out pressure maintaining sizing on the fire protection sealant through the outer box body to realize the sealing protection of the cable head, a compact filling layer can be formed on the periphery of the intermediate head, the defect of poor fire protection performance durability and reliability is eliminated, and the fire and explosion protection structure is low in cost and is favorable for popularization.

Owner:九江电力勘察设计院有限公司 +1

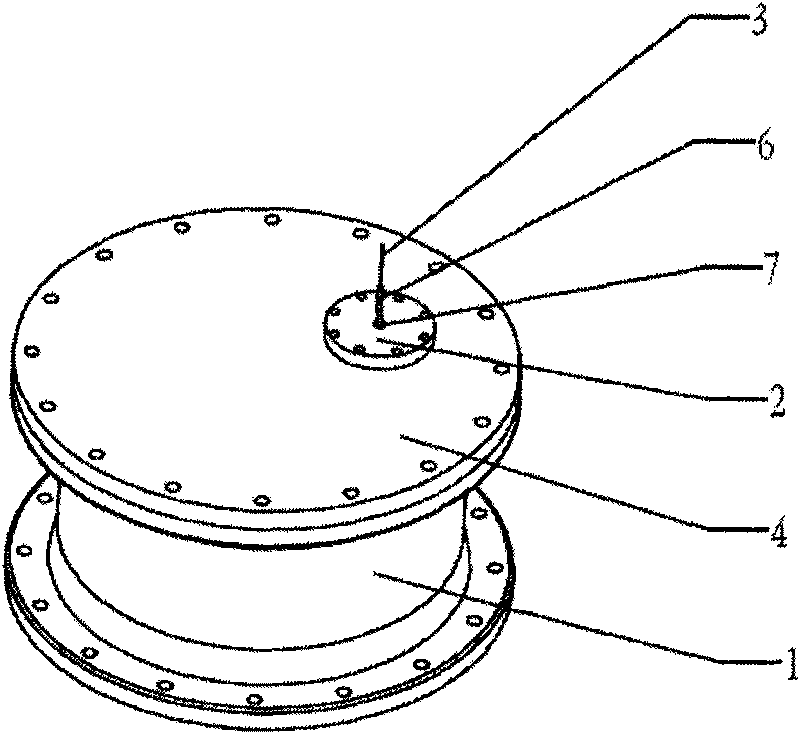

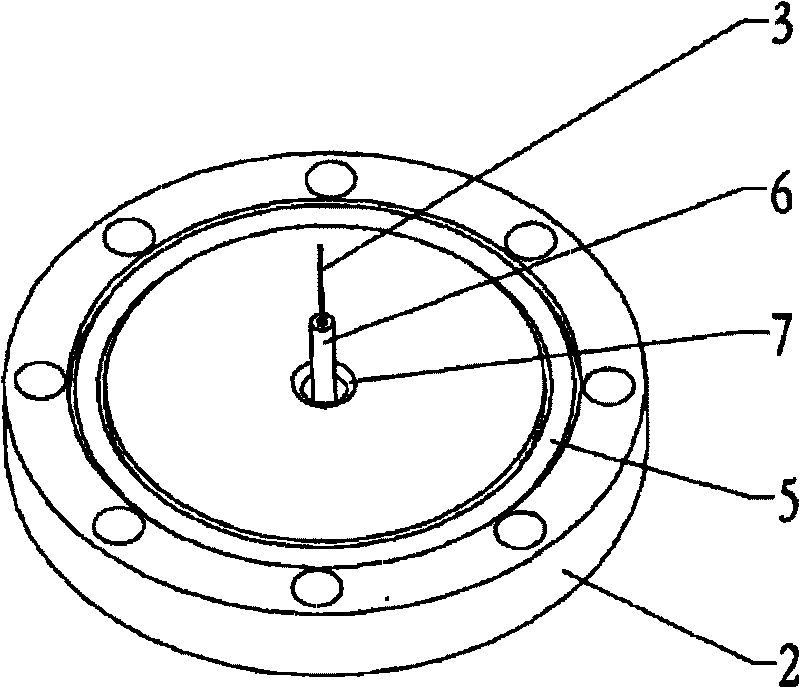

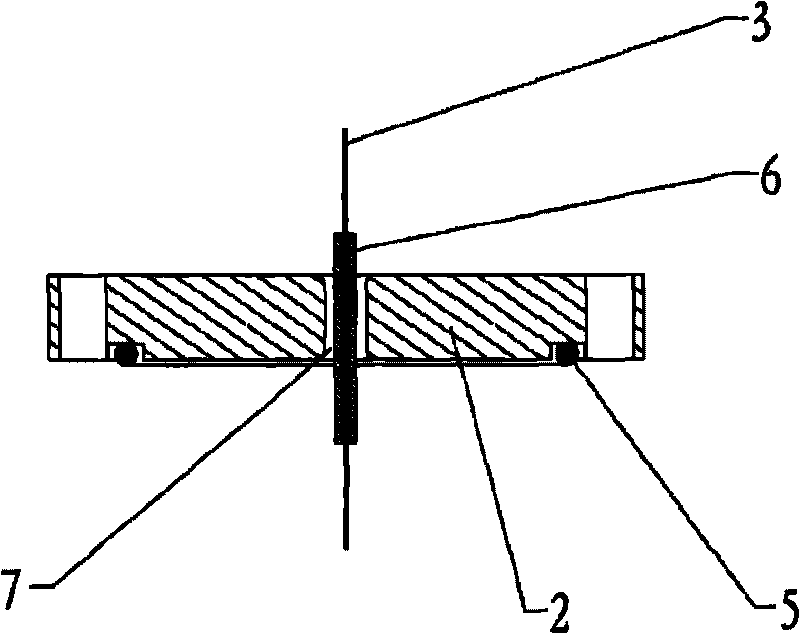

Optical fiber airtightly leading out method for GIS cavity

ActiveCN101710201ASolve the problem of airtightnessReduce fusion jointsFibre mechanical structuresOptical fiber cableElectrical and Electronics engineering

The invention discloses an optical fiber airtightly leading out method for a GIS cavity, and provides a scheme for leading out a tail fiber of an optical element in GIS application. In the scheme, the tail fiber of the optical element in the GIS cavity is subjected to metal packaging, and a metal packaging structure comprises a metal optical fiber, a metal pipe and the like; the metal pipe passes through optical fiber through holes on a mounting flange and an optical fiber leading out flange positioned on the GIS cavity in turn, and the optical fiber through holes are sealed and cured by epoxy resin glue; and the tail fiber leading out parts of the metal optical fiber and the metal pipe are provided with protective devices additionally. In the method, the metal optical fiber packaging technology is applied to the optical element in the GIS cavity of a power system for the first time, the airtightness problem generated when the optical fiber of the GIS cavity is led out is effectively solved, stress applied to the optical fiber is reduced, the balance of the stress of the optical fiber is ensured, the pressive strength and the insulating property of the GIS system are ensured, and the reliability of the GIS system is improved.

Owner:NARI TECH CO LTD

Vulcanization type hydrogenation catalyst starting method

ActiveCN109926100ASuppress overflowGuarantee vulcanization qualityCatalyst activation/preparationRefining to eliminate hetero atomsVulcanizationHydrogenation reaction

The invention discloses a vulcanization type hydrogenation catalyst starting method, which comprises: loading a vulcanization type hydrogenation catalyst composition into a reactor; carrying out nitrogen gas tightness; gradually introducing hydrogen gas after the nitrogen gas tightness is qualified; carrying out hydrogen gas low-pressure gas tightness; increasing the temperature and the pressure after the low-pressure gas tightness is qualified; carrying out high-pressure gas tightness; and after the high-pressure gas tightness is qualified, adjusting the pressure to a reaction pressure untilvulcanization is completed, adjusting the temperature to a reaction temperature, feeding raw material oil, and starting a hydrogenation reaction. With the starting method of the present invention, thevulcanization quality of the catalyst can be ensured, the gas tightness problem of the device can be solved, and the advantages of no environment pollution, economy and environmental protection can be achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

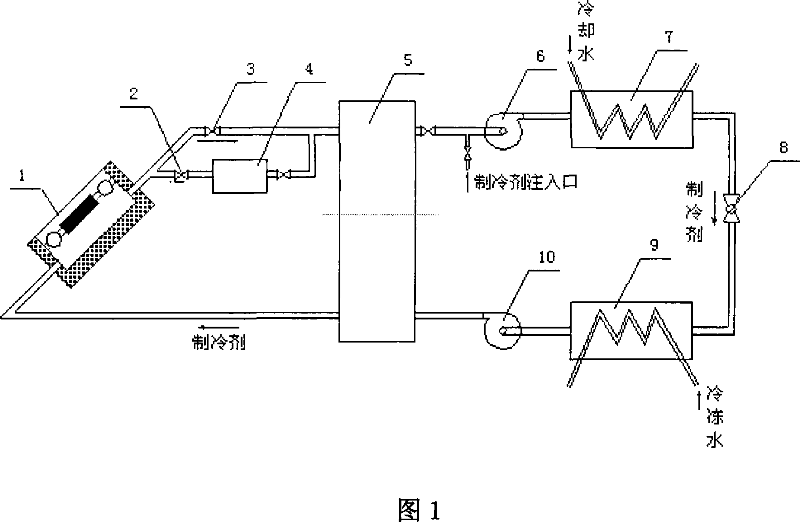

Absorber used in solar refrigeration equipment

InactiveCN101038112AEnables continuous cooling processPrevent leakageAbsorbers/adsorbersEngineeringRefrigeration

The present invention provides a rotary absorber for solving the fault existing in heat exchanging and energy lost of existing solar solid absorber. The rotary absorber includes a rotary wheel, a cooling device and a rotary device. The rotary absorber is characterized in that the rotary wheel includes a rotary wheel housing connected to the rotary device, a wheel body and front, rear block plates fixed on the two end surfaces of the wheel body. The wheel body includes a rotary shaft and a wheel hub which is disposed with radiate wedge-shaped absorb beds on the circumferential direction. A wedge-shaped mass transfer passage is disposed between each two adjacent wedge-shaped absorb beds, the radiate end circle of the wedge-shaped absorb bed is fixed on the inner wall of the rotary wheel housing; the two end surfaces of the wheel body and the rotary wheel housing form a round concave, the inner side of the front and rear cover plates are respectively disposed with round platforms having the same diameter with the round concave. The round platforms are disposed with V shape clapboard and bearing seat, and are embedded into the round concave of the rotary wheel housing to divide the two end surface of the wheel body into upper and lower two regions.

Owner:CHANGAN UNIV

Push-type multifunctional overflow-preventing fuel gas safety valve

ActiveCN101963253AEasy to operateReturn quicklyOperating means/releasing devices for valvesEqualizing valvesMagnetic coreInternal cavity

The invention discloses a push-type multifunctional overflow-preventing fuel gas safety valve. The valve comprises a valve casing and a valve joint, wherein the valve casing is made of a non-magnetized material; a magnetic core controller is arranged outside the valve casing; a magnetic core is arranged in a valve cavity; the valve joint is connected to the gas inlet end of the valve casing; the internal cavity of the valve joint is provided with an ultra-flow protective valve for controlling the on-off state of gas flow at the gas inlet end of the valve cavity; the ultra-flow protective valve is provided with a sealing piece for controlling the on-off state of the gas flow; and the sealing piece is provided with a head part which protrudes outward. The push-type multifunctional overflow-preventing fuel gas safety valve is characterized in that: a return magnetic ring is also arranged in the valve cavity and can be controlled by the magnetic pole of the magnetic core controller to move and push the head part of the sealing piece which is in a closed state, so that the ultra-flow protective valve is opened. The push-type multifunctional overflow-preventing fuel gas safety valve has the advantages of capability of causing the return magnetic ring to act by the manual magnetic core controller so as to remove the overflow protection state of the ultra-flow protective valve, fast and accurate return, safe use and high durability.

Owner:广州凯亨阀门有限公司

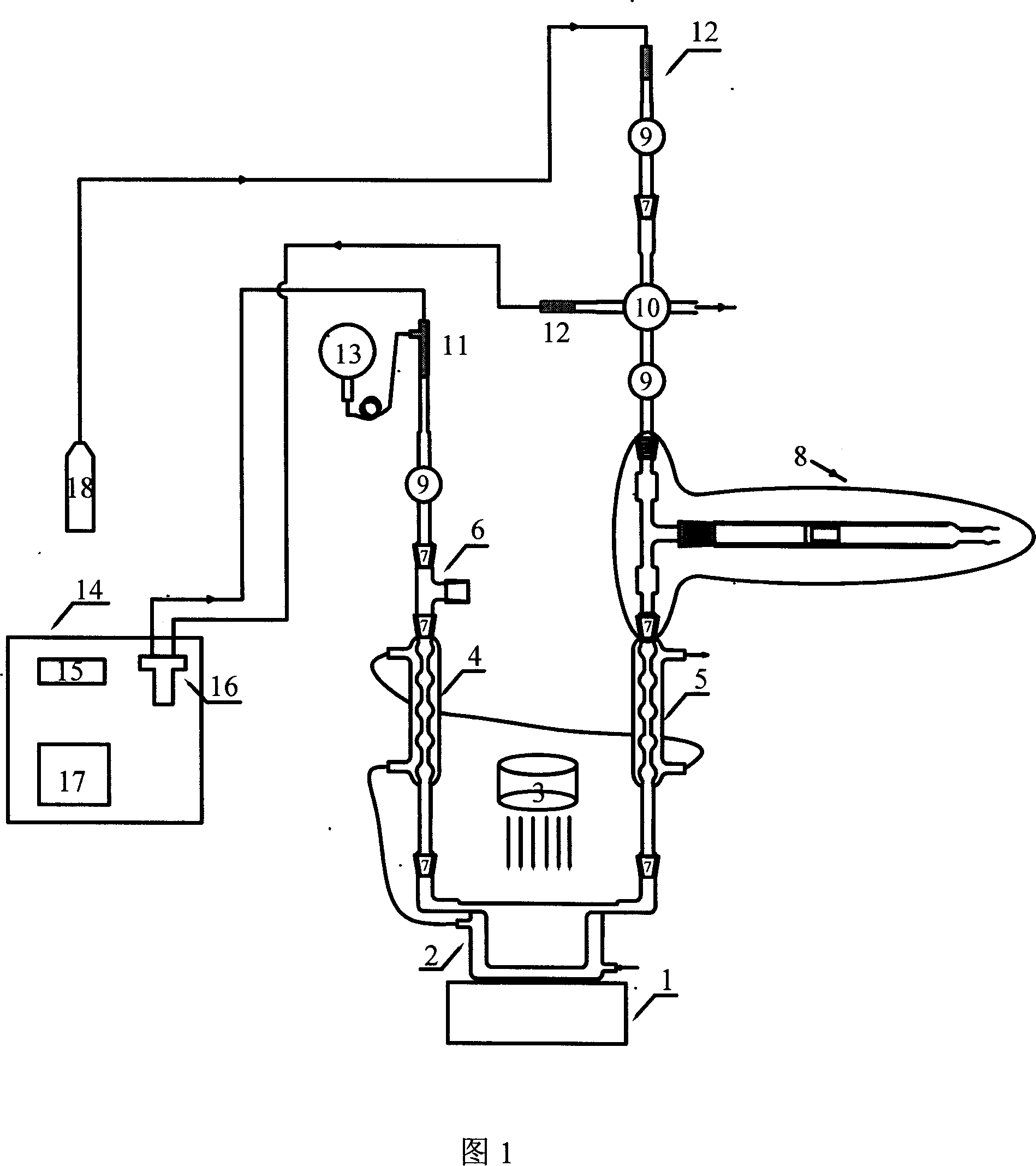

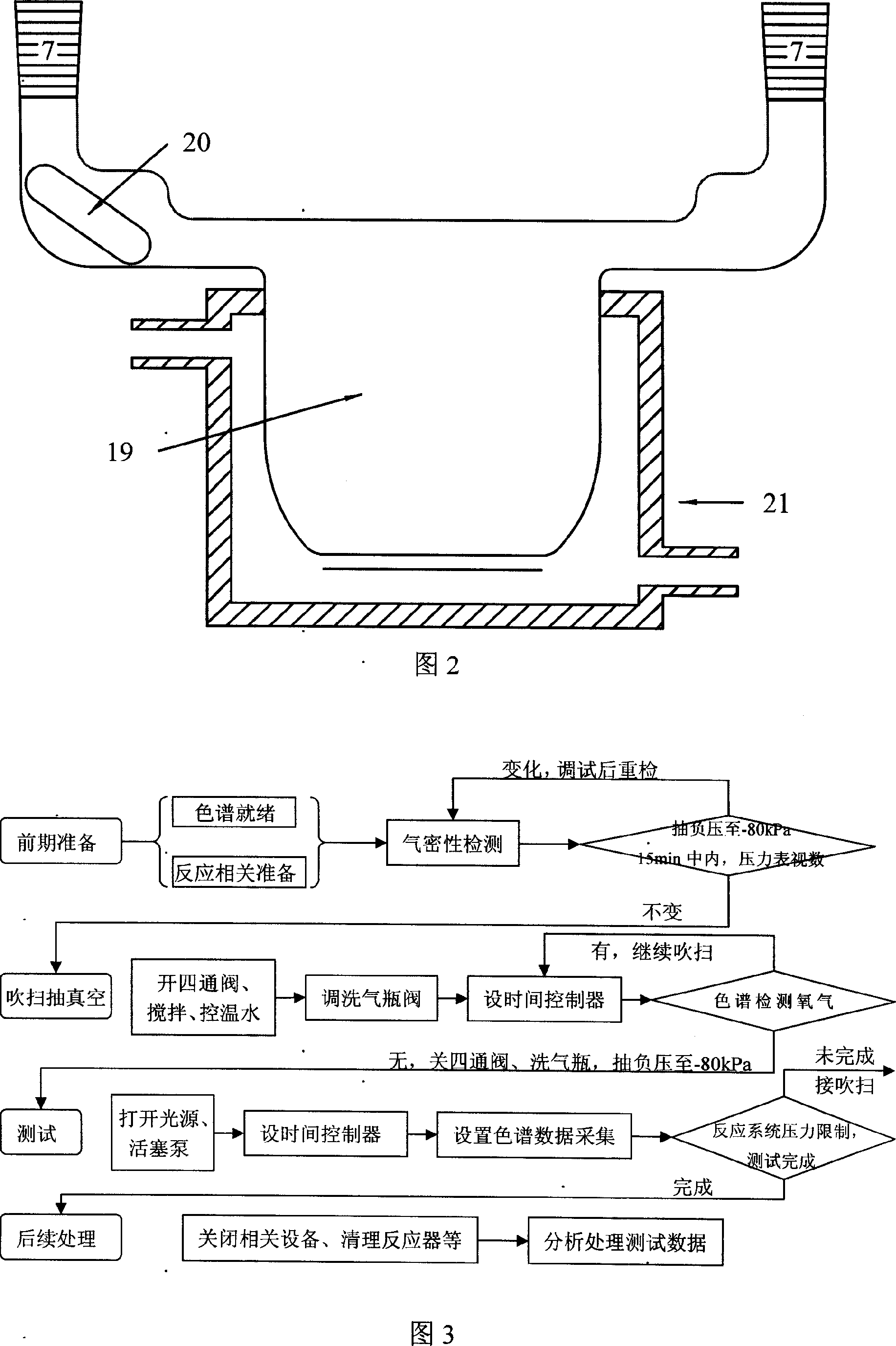

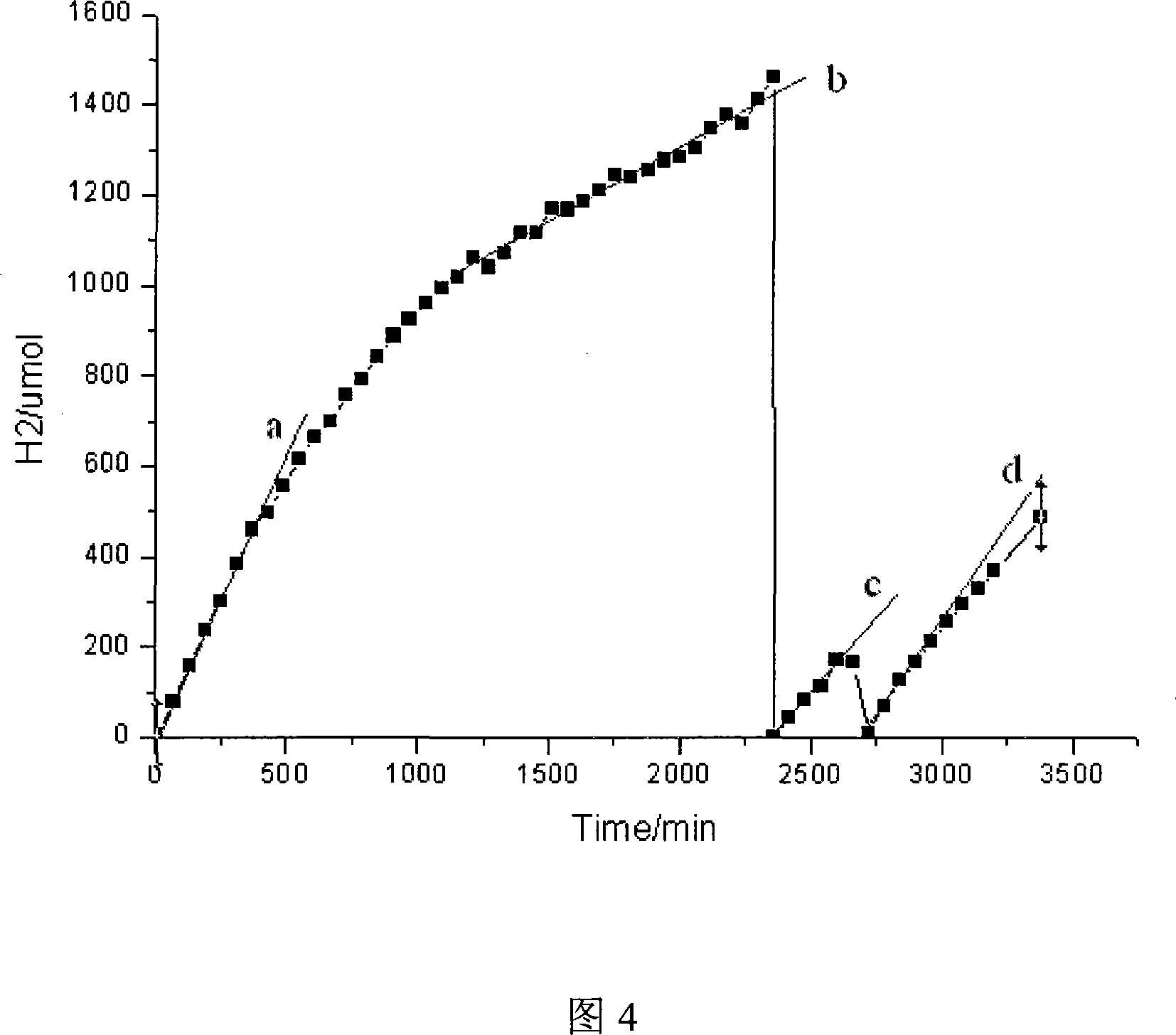

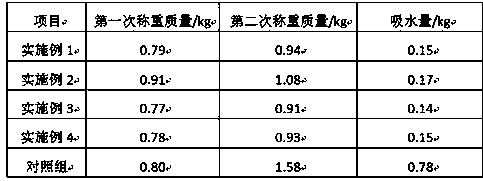

Light-catalyzed reaction negative-pressure loop circuit automatically testing system

InactiveCN101082617AUniform gas concentrationSolve the problem of airtightnessMaterial analysisMagnetic tension forcePhotocatalytic reaction

The invention discloses a self-testing system of negative pressure loop of optical catalyzed reaction, which comprises the following parts: reacting part with magnetic stirrer, reactor, xenon lamp source, circulating part with magnetic glass piston pump, spherical glass condenser, gas-phased chromatogram, reactor, blowing vacuum extracting part with ten-shaped four-way vacuum piston, scrubbing bottle, precise vacuum pressure list and vacuum pump, sampling detecting part with gas phased chromatogram, automatic six-way sampling valve, gas-carrier bottle and gas driving bottle, temperature control part with thermostatic circulating pump, reactor temperature control jacket and spherical glass condenser. The invention can estimate the catalytic property of catalyst precisely and in time, which is fit for other optical catalyzed reacting tests in relative to gas participation or generation.

Owner:XI AN JIAOTONG UNIV

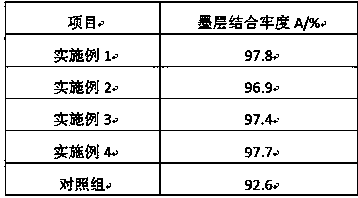

Corrugated paper printing process for fruit packaging boxes

InactiveCN110792000ASolve the problem of airtightnessSolve moisture resistanceMechanical working/deformationCoated paper substratePolymer scienceCarton

The invention relates to the technical field of carton printing, in particular to a corrugated paper printing process for fruit packaging boxes. The corrugated paper printing process comprises seven steps of corrugated paper pretreatment, flexographic plate making, corrugated paper surface treatment, corrugated paper PE lamination, outer layer PE lamination surface treatment, flexographic plate printing and polishing and calendaring treatment. The adhesive force between PE lamination and corrugated paper is enhanced through corona treatment, and then a water-based ink and the PE lamination areeffectively combined through low-temperature plasma treatment, so that the combination fastness of an ink layer is improved, and the sealing performance and the moisture resistance of the corrugatedpaper are better through PE lamination; compared with solvent-based ink, the water-based ink does not generate harmful gas, is higher in safety performance, and is cheaper than UV ink, the toughness of a film formed by the water-based ink adapts to that of PE lamination, the brittle fracture phenomenon is avoided, and the defect that the film formed by the UV ink is prone to brittle fracture is overcome.

Owner:邵帅

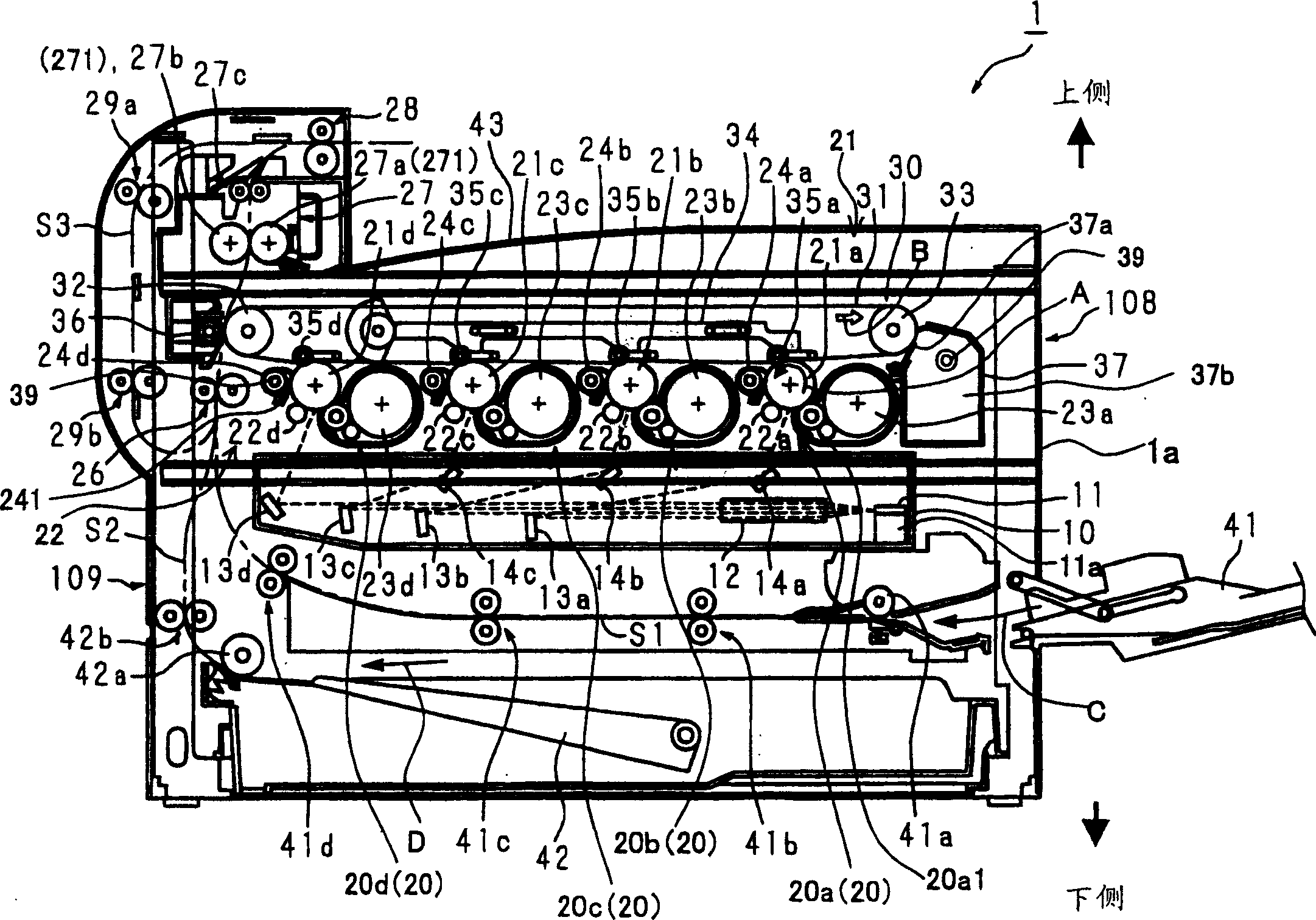

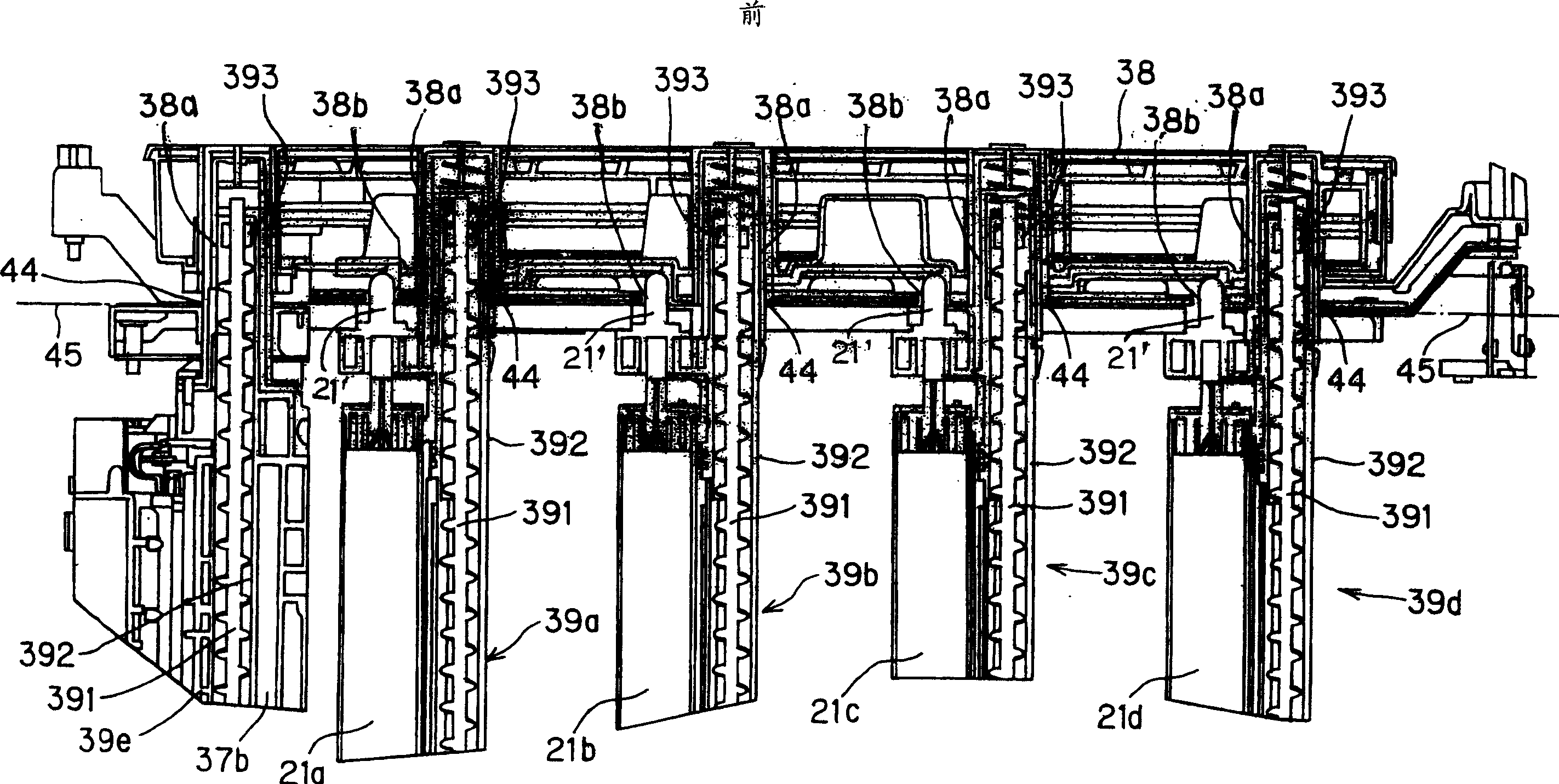

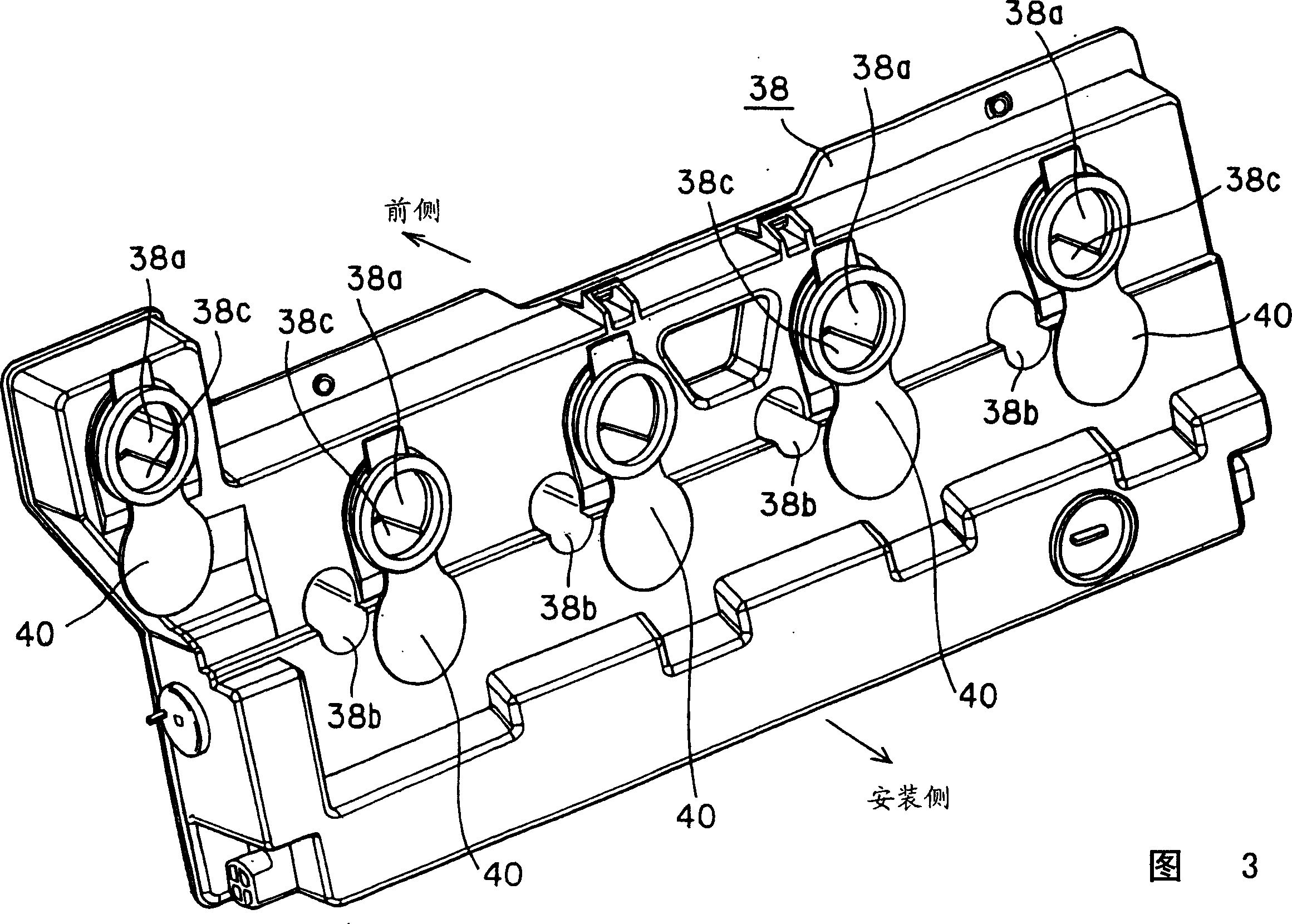

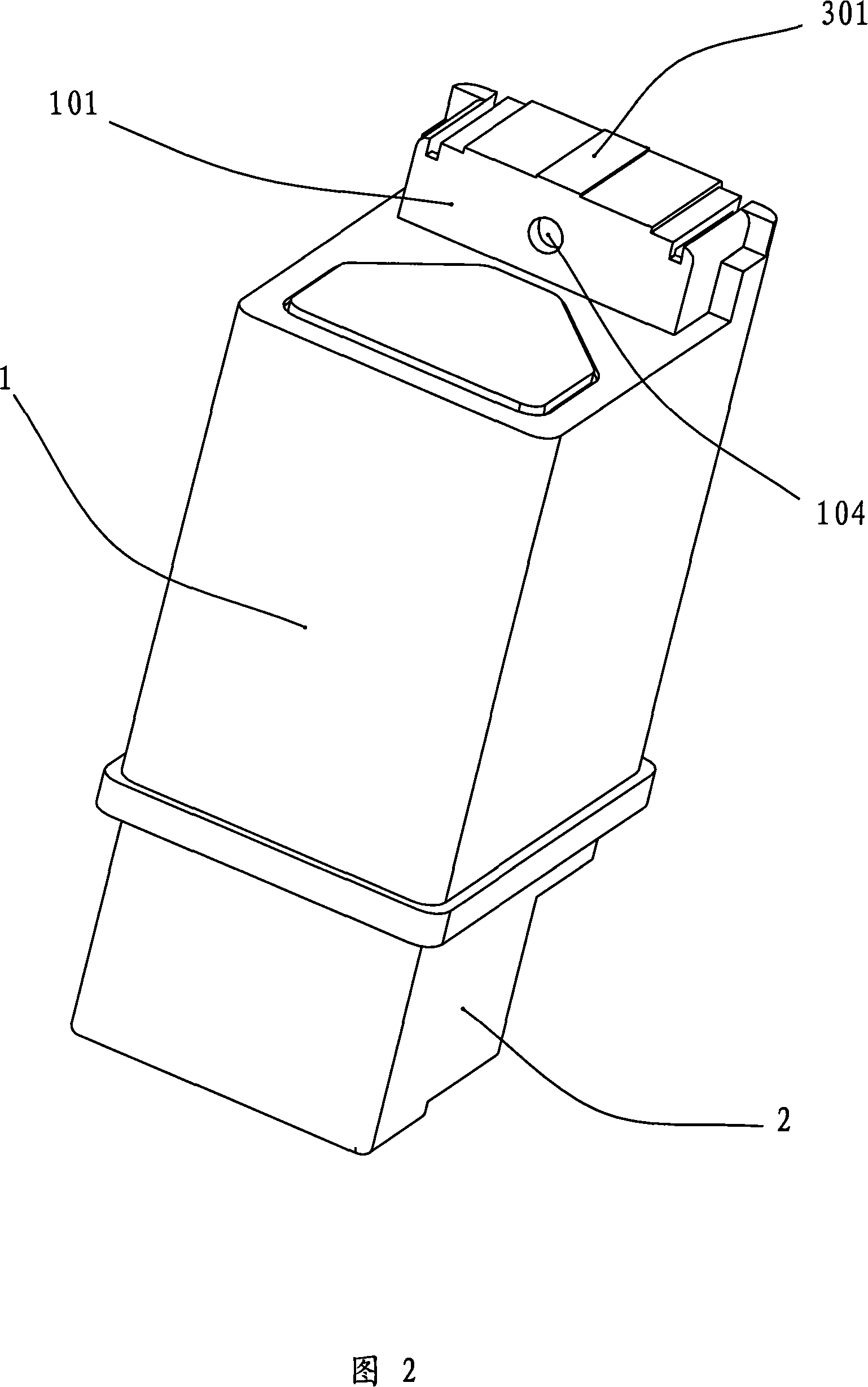

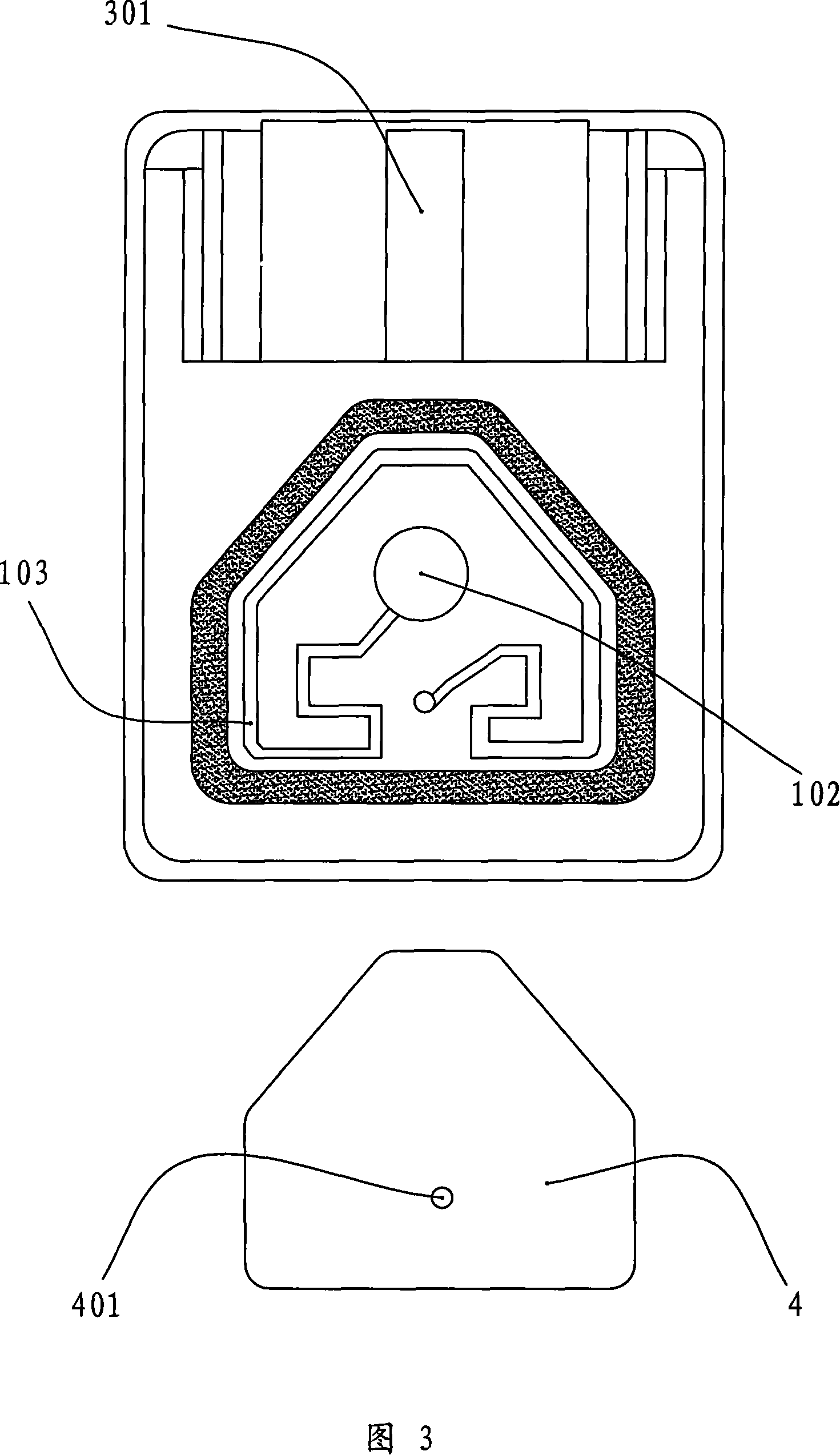

Waste developer collecting container for image forming apparatus

InactiveCN1763660APrevent leakageAvoid tightnessSealingElectrography/magnetographyColor imageRecording media

The present invention provides a waste toner collecting container which is used in a color image forming apparatus. The container can be removed from the image forming apparatus and stores waste toner which have not been transferred to recording paper and have been collected. The collecting container is constructed such that an air sealing member is disposed at the coupling between the waste toner collecting container and a conveying member for conveying the collected waste toner into the waste toner collecting container. The air sealing member can prevent the waste toner from seeping out at the coupling when the waste toner is conveyed and to seal the collecting port so that no waste toner will spill out from the waste toner collecting container which has been removed for replacement after the waste toner collected and conveyed therein has reached the predetermined amount.

Owner:SHARP KK

A hole sealing method for a powder metallurgy chromium alloy fuel cell connector

ActiveCN105562698BSolve the problem of airtightnessImprove air tightnessFuel cell detailsPorosityCarbon potential

A hole sealing method for a powder metallurgy chromium alloy fuel battery connecting part is characterized in that the powder metallurgy chromium alloy connecting part to be subject to hole sealing is put into a heat treatment furnace under the sintering state, oxidation-carbonization heat treatment under the carburizing atmosphere at 800 DEG C to 1050 DEG C is carried out, the carbon potential Cp ranges from 0.3% to 1.5%, the heat preservation time ranges from 1 h to 8 h, then cooling in the air is carried out, and finally, through sand blasting, chromium carbon / oxygen compounds on the surface of the connecting part are removed; the content of chromium in the powder metallurgy chromium alloy connecting part ranges from 75% to 100%, the porosity ranges from 5% to 20%, oil does not exist, and treatment like machining or sand blasting does not exist. The method is simple in technology and convenient to operate; the problem of gas tightness of the powder metallurgy chromium alloy connecting part is solved well, through heat treatment and sand blasting, a continuous compact compound layer is formed on the porous surface of the powder metallurgy chromium alloy connecting part, and the performance of a base body is not changed; and the gas tightness of the connecting part can be effectively improved, and the hole sealing method for the chromium alloy has the wide application prospect.

Owner:NBTM NEW MATERIALS GRP

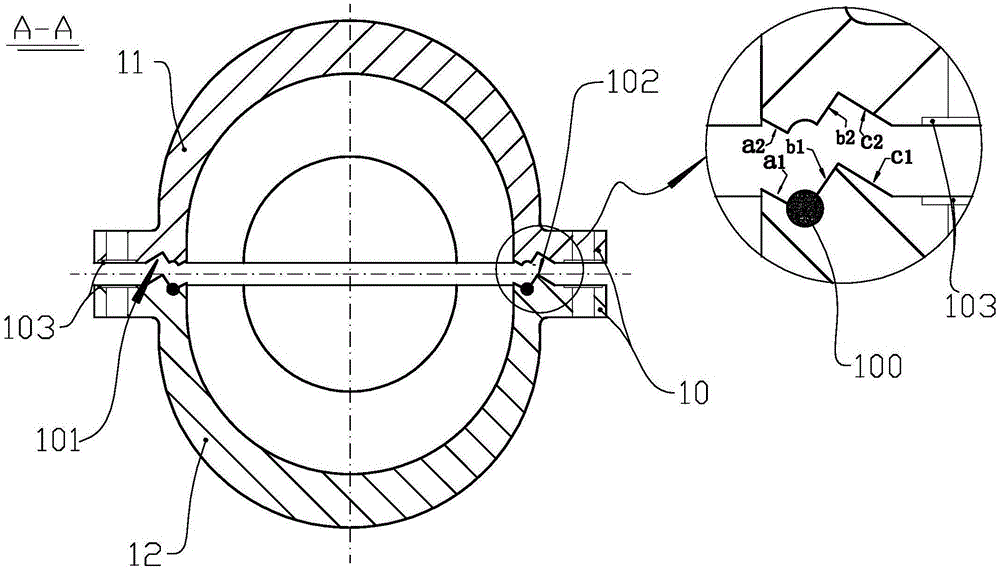

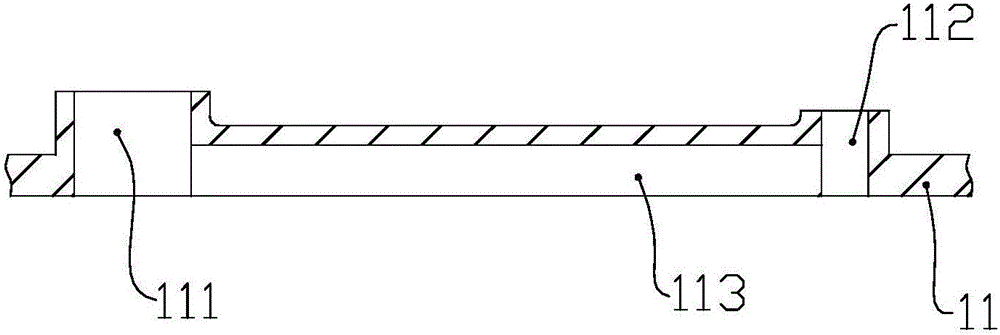

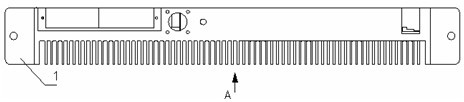

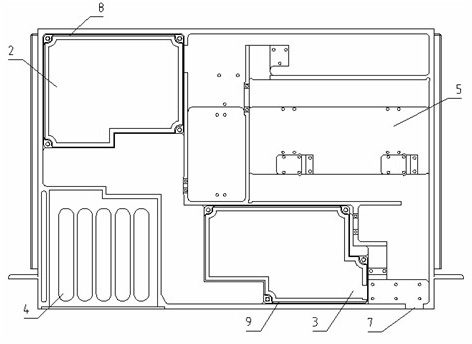

Shell structure of T/R assembly of phased array radar

InactiveCN102368092AGuaranteed reliabilitySolve the problem of airtightnessWave based measurement systemsRadarElectromagnetic interference

The invention, which belongs to the radar structure design, relates to a structure of a T / R assembly of phased array radar solid state transmitter. The invention comprises a T / R assembly shell, an excitation source module with a sealed aluminum box, a receiving module with a sealed aluminum box, a first shielding washer, a second shielding washer, a sealing washer, and a shell cover; and a structure of a ''double peak'' sealing strip is formed by the first shielding washer, the second shielding washer, and the sealing washer. Therefore, problems on air tightness and strong electromagnetic interferences of the T / R assembly in the shell are solved; an adaptation capability of a radar environment is enhanced; and reliability during the using process of the radar can be effectively ensured.

Owner:WUHAN BINHU ELECTRONICS

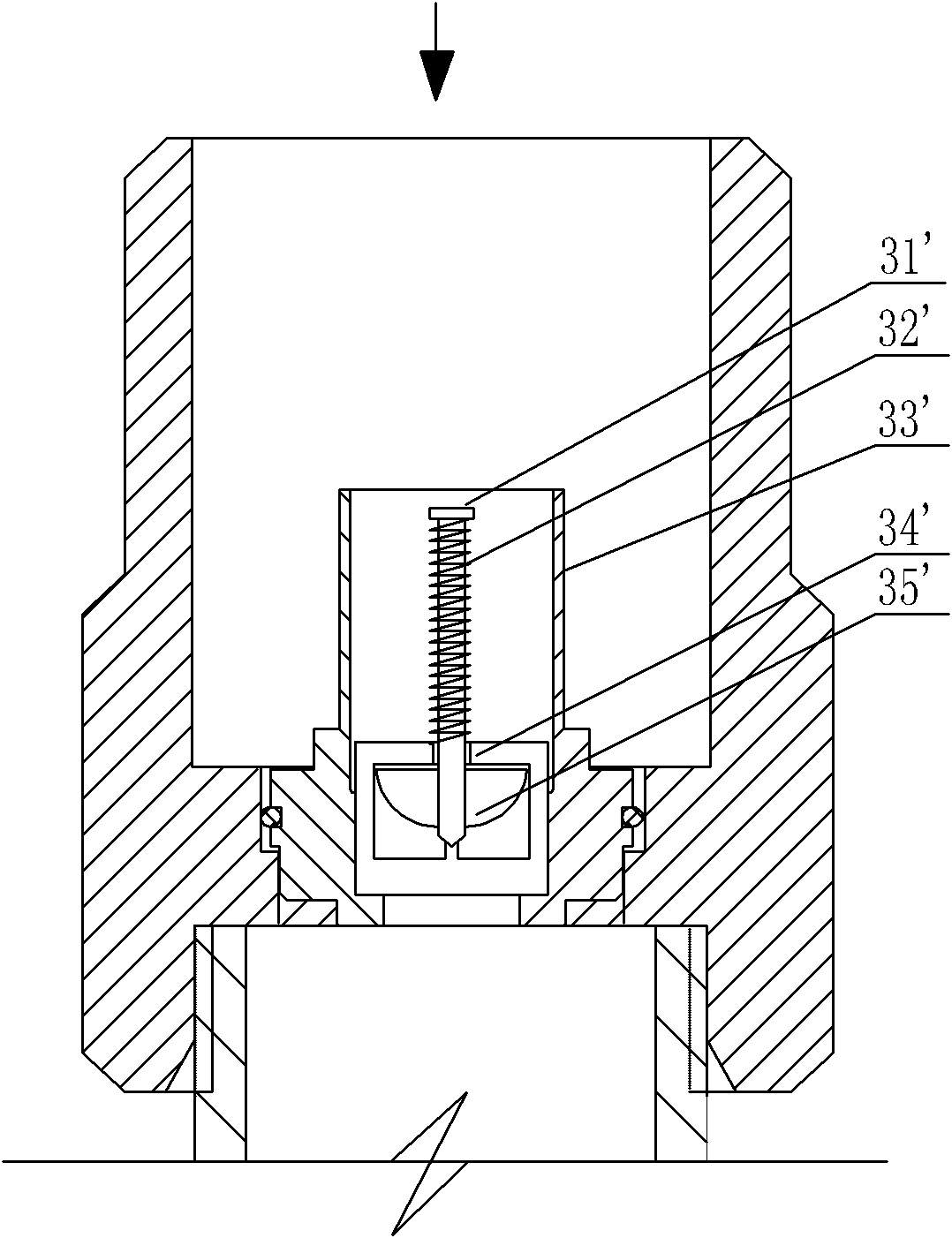

Dry-type oxidation reactor

InactiveCN102778530ASolve the problem of airtightnessBurn fullyChemical analysis using combustionTotal organic carbonAir tightness

The invention discloses a dry-type oxidation reactor for detecting total organic carbon. The dry-type oxidation reactor comprises a sample feeding unit and a burning unit. An air inlet in the sample feeding unit is arranged nearby a burning pipe in the burning unit, an air-tight component is arranged on the periphery of an inlet of the burning pipe and butts against the bottom of a sliding block in the sample feeding unit. Under the effect of a photoelectric sensor, a driving device drives the sliding block to generate two limiting positions, at one limiting position, an injection hole penetrating through the sliding block is arranged at the inlet of the burning pipe and connected with the inlet, and at the other limiting position, other bottoms of the sliding block seal the inlet of the burning pipe. The dry-type oxidation reactor solves the problem of poor air-tightness of a traditional oxidation reactor.

Owner:UNIVERSTAR SCI & TECH SHENZHEN

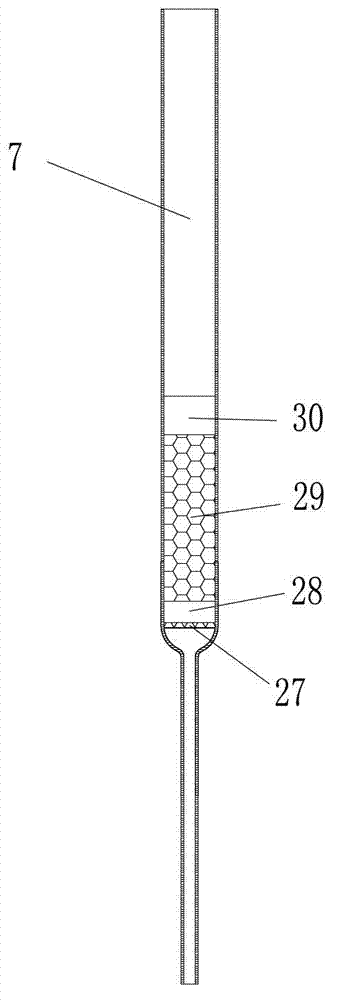

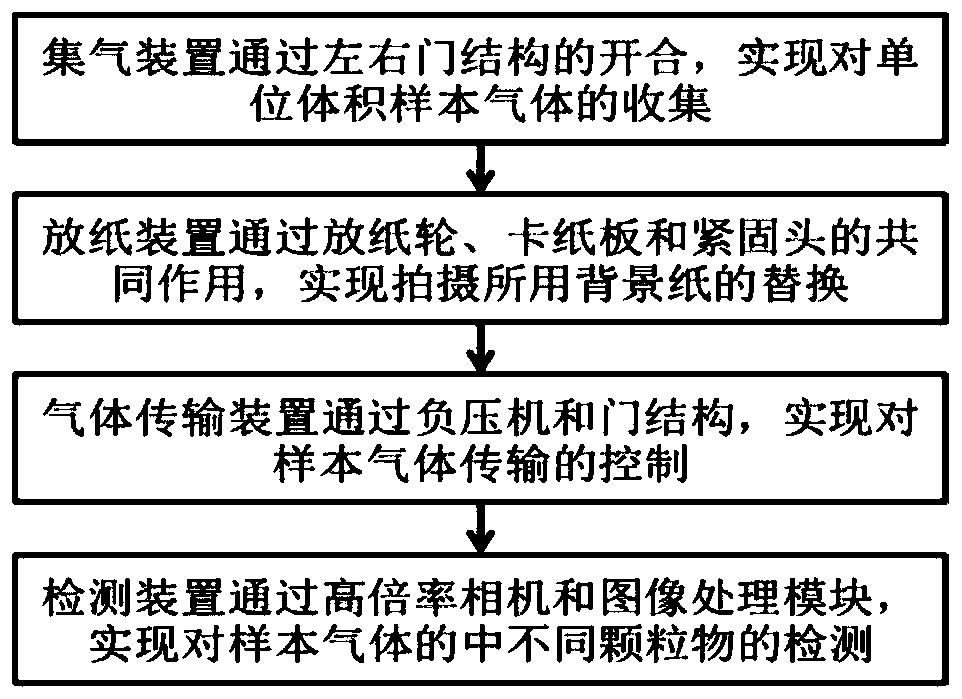

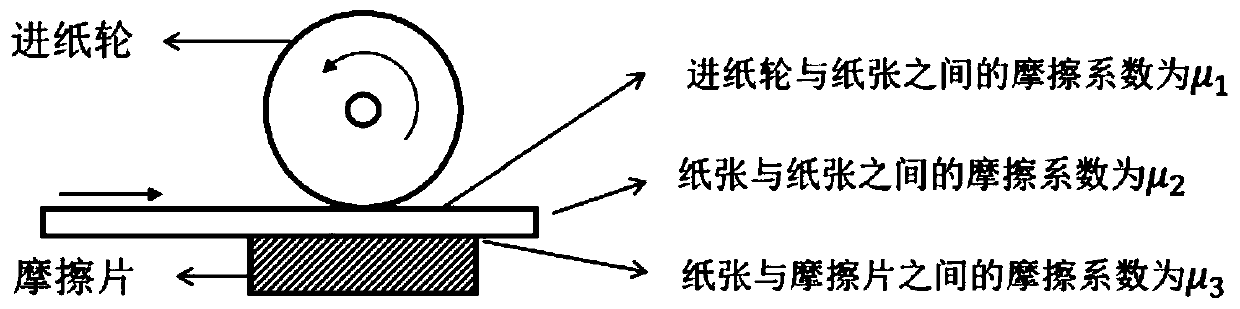

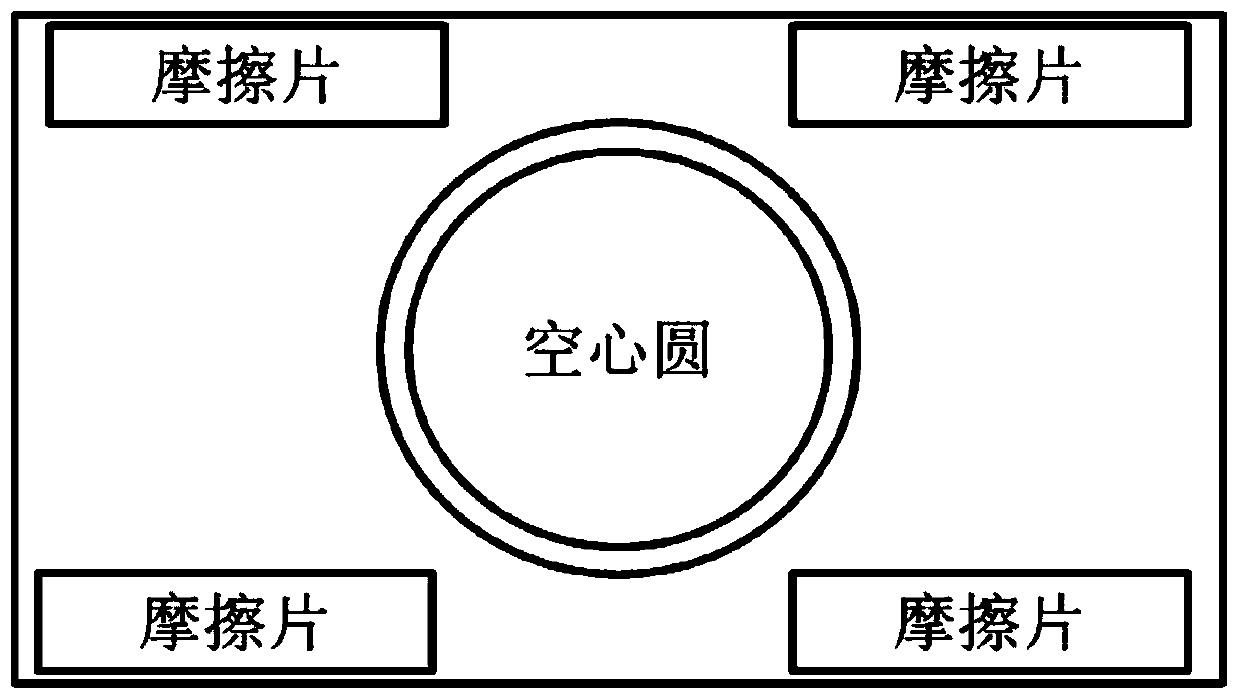

Flying dust concentration detection device and flying dust detection method

PendingCN111307681ASolve the problem of airtightnessParticle suspension analysisMeteorologyAtmospheric sciences

The invention relates to a flying dust concentration detection device and flying dust detection method based on deep learning, belongs to the technical field of air quality detectors, and solves the problems of flying dust concentration detection cost, long recognition time and poor measurement effect in the prior art. The invention comprises an air collection device, an air transmission device,n a paper feeding device and a measuring device. The method comprises the following steps: the air collection device acquires real-time sample air collected in a detection field environment; the air transmission device is used for internally transmitting the sample air through a negative pressure machine; the paper feeding device automatically replaces background paper used for shooting after shooting is completed, and the measuring device detects an object through an artificial neural network after shooting sample gas. The sizes of the flying dust particles can be effectively detected, thedifferent particles are recognized and detected by means of a deep learning algorithm of target detection, and the concentrations of the different particles in the flying dust can be accurately detected in real time.

Owner:山东诺蓝信息科技有限公司

Fireproof and explosion-proof structure at intermediate of cable and installation and application method thereof

InactiveCN106025999AReliable fire and explosion protectionReduce security risksCable junctionsApparatus for joining/termination cablesNitrogenEngineering

The invention discloses a fireproof and explosion-proof structure at the intermediate joint of a cable and an installation and application method thereof, and belongs to the technical field of cable joint fire and explosion prevention. The fireproof and explosion-proof structure comprises an outer box body, an assembling end cover, a sealing end cover and a sealing ring, wherein the longitudinal assembling surface of the outer box body is provided with a dual-sealing structure; the assembling end cover adopts an embedded sealing structure with the outer box body; the sealing end cover and the sealing ring are arranged on the assembling end cover for sealing a gap between a cable ring surface and a related matching surface of the assembling end cover; the outer box body is provided with a glue injecting pipe and an exhaust pipe; the cable is completely wrapped by a cable fireproof wrapping tape after being connected by the intermediate joint, and the cable is placed in the outer box body; and a fireproof sealing glue is injected into the outer box body through the glue injecting pipe. Operationally, firstly air inside the outer box body is exhausted out by using carbon dioxide or nitrogen, and then the fireproof sealing glue is injected inwards for carrying out high pressure shaping. The outer box body is used for carrying out pressure maintaining shaping on the fireproof sealing glue to realize sealing protection for the joint of the cable, and a compact filling layer can be formed on the periphery of the intermediate joint, so that the defect that the enduring stability of fireproof performance is poor is solved, the manufacturing cost is low, and the structure is beneficial for popularization.

Owner:国网江西省电力有限公司九江供电分公司 +2

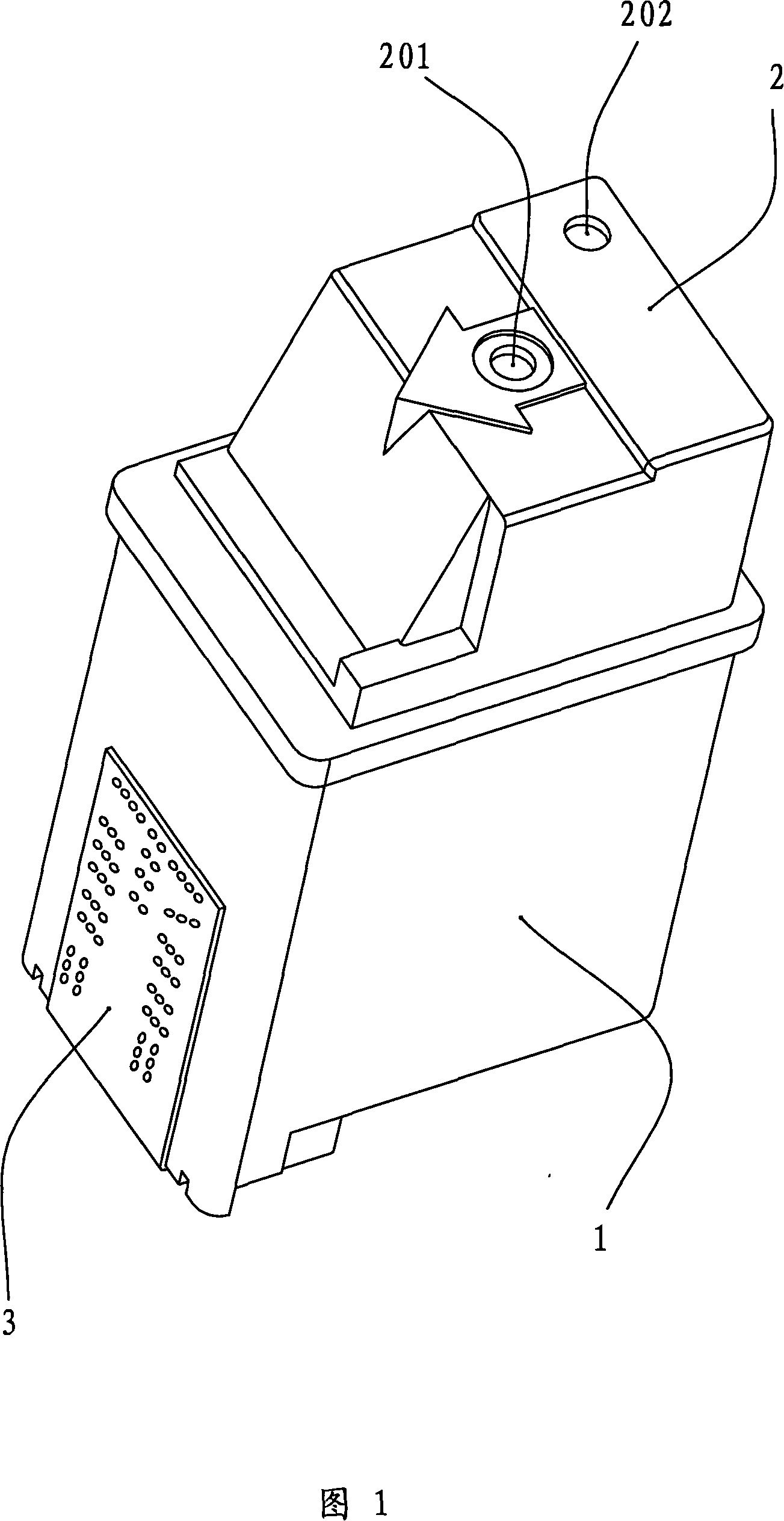

Regeneration method for printer cartridge

InactiveCN101152794ARestoration of sealing propertiesPrevent air leakageHollow article cleaningCleaning using liquidsPass rateEngineering

The present invention provides a regeneration method of an ink jet printer ink box, which aims at a waste ink box which takes a spring and an airbag as a subpressure regulator structure. A splicing does is smeared around a cover of the ink box and then is solidified by illuminating; or the splicing does is smeared around the air holes at the bottom of the ink box and is plastered with the relative film and then solidified by illuminating. A pylome is opened on the box cover and the box body through which the cleaning liquid is injected and an ink storage and an ink supply road are cleaned in the way. So that the closure performance of the air holes of the regenerated ink box cover and the closing film are improved; the damage to the subpressure regulator structure is avoided; the original subpressure regulator structure is effectively used and the using cost of the ink box is reduced. The passing rate of the recycling ink box products is over 65 percent.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD OF ZHUHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com