Vulcanization type hydrogenation catalyst starting method

A hydrogenation catalyst and sulfidation type technology, which is applied in the directions of physical/chemical process catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of insufficient vulcanizing agent, affecting the vulcanization effect of catalysts, etc., and achieve uniform and thorough vulcanization. Avoid flying temperature and ensure the effect of vulcanization quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Preparation of hydrogenation catalyst A

[0031]Take 100g of an industrially produced catalyst in an oxidation state, mix 18g of DMDS with 10ml of hydrazine hydrate, and then spray the catalyst. Put the sample in a blast drying oven for the first low-temperature heat treatment. The conditions for the first low-temperature heat treatment are: 3°C / min The temperature was raised to 80 °C at a constant rate for 3 hours. Get tetrakis hydroxymethyl phosphorus sulfate aqueous solution (75wt%) 50g spray the sample of low-temperature heat treatment for the first time, after spraying, sample is put into blast drying box and carry out low-temperature heat treatment for the second time, the low-temperature heat treatment condition for the second time is the same as the first time Once the same, the hydrogenation treatment catalyst A is obtained.

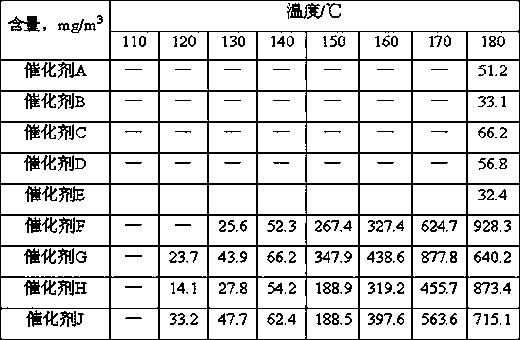

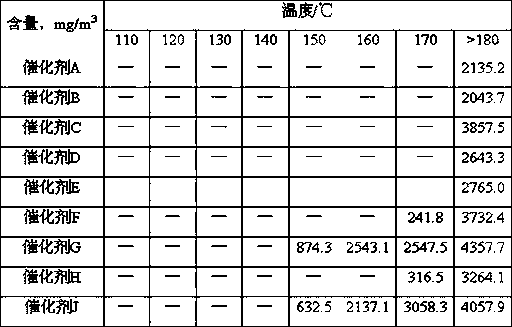

[0032] (2) Catalyst start-up method and evaluation

[0033] Put the sulfurized hydrogenation catalyst into the reactor, and carry ...

Embodiment 2

[0035] (1) Preparation of hydrogenation catalyst B

[0036] Take 100g of an industrially produced catalyst in an oxidation state, take 18g of DMDS and 10ml of hydrazine hydrate mixture, and 50g of tetrakis hydroxymethyl phosphorus sulfate aqueous solution (solution concentration: 75wt%). Low-temperature heat treatment was carried out in a drying oven, and the low-temperature heat treatment conditions were as follows: the temperature was raised to 80° C. at a rate of 3° C. / min, and the temperature was kept constant for 3 hours. That is, the hydrotreating catalyst B is obtained.

[0037] (2) Catalyst start-up method and evaluation

[0038] The catalyst start-up method and evaluation are the same as step (2) of Example 1, and the contents of hydrogen sulfide and sulfide are shown in Table 1 and Table 2. The evaluation results are shown in Table 3.

Embodiment 3

[0040] (1) Preparation of hydrogenation catalyst C

[0041] Take 100g of industrially produced oxidized catalyst, mix 13g of carbon disulfide and 12ml of hydrazine hydrate, add 65ml of tetrahydroxyethylphosphorus sulfate aqueous solution, and stir for 20min containing 36g of tetrahydroxyethylphosphorus sulfate to form a homogeneous solution. Put into blast drying box and carry out low-temperature heat treatment, treatment condition is: be heated up to 80 ℃ with the rate of 3 ℃ / min, keep constant temperature for 3 hours. That is, hydrotreating catalyst C is obtained.

[0042] (2) Catalyst start-up method and evaluation

[0043] Put the sulfurized hydrogenation catalyst into the reactor, and carry out nitrogen airtightness; after the nitrogen airtightness is qualified, gradually introduce hydrogen, and carry out hydrogen low-pressure airtightness, the airtight pressure is 2.0MPa, and after the airtightness is qualified, the heating furnace is ignited and heated until the reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com