Fireproof explosion-proof combination structure at power cable joint of electric power system and application method

A technology of cable joints and power systems, which is applied in the direction of cable joints, etc., can solve the problems of poor durability and low manufacturing cost, and achieve the effect of solving the effects of poor durability and reliability of fire protection performance, low manufacturing cost, and improving economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to facilitate the understanding of the technical content of the present invention, the technical solutions thereof will be further described below in conjunction with the accompanying drawings.

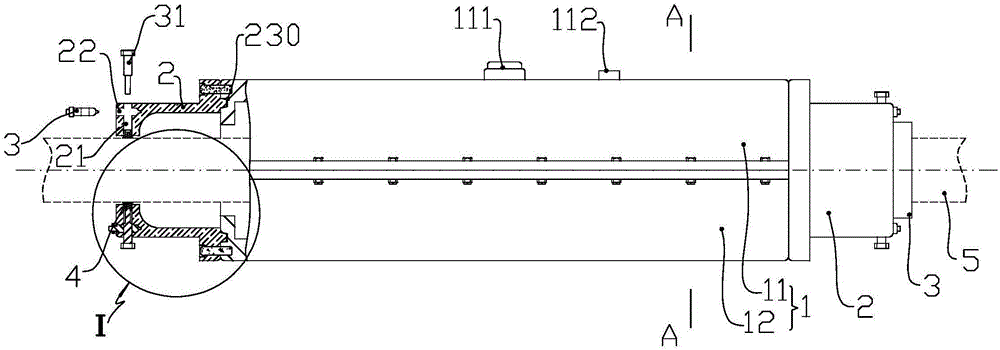

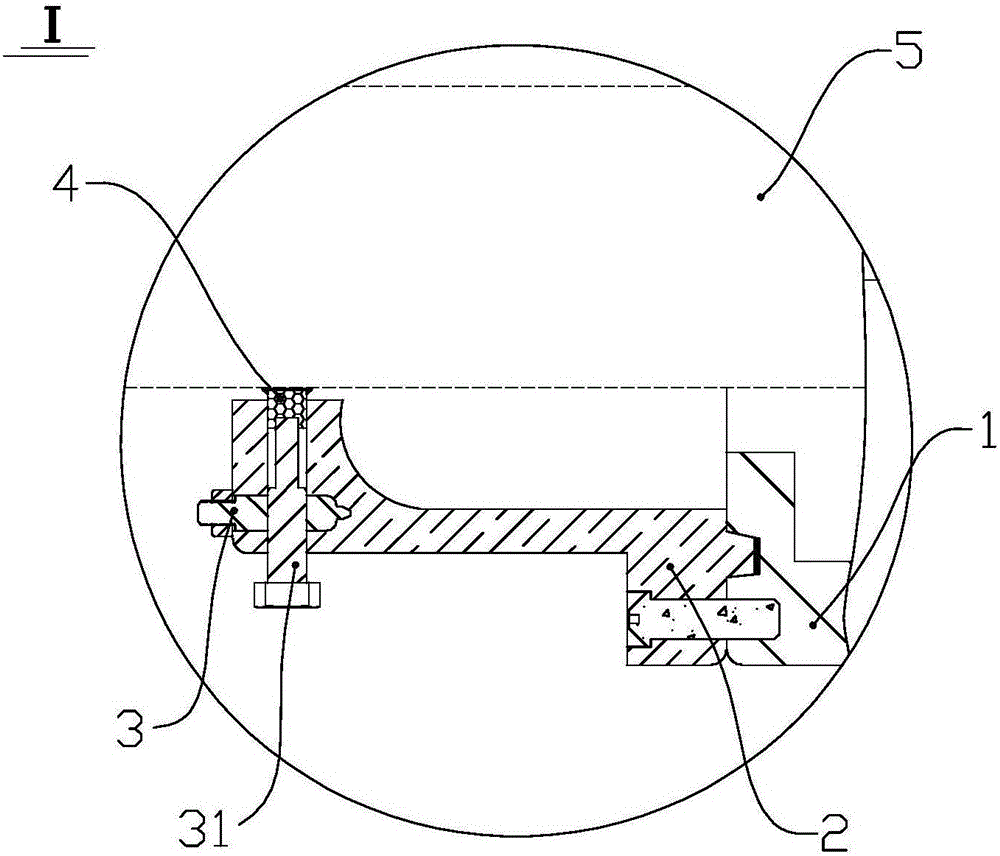

[0055] Such as figure 1 The shown fireproof and explosion-proof structure at the intermediate joint of a cable includes an outer box body 1 formed by fastening the upper half outer box 11 and the lower half outer box 12, an assembly end cover 2 connected to the left and right ports of the outer box body 1, and The insert plate 3 and the seal 4 are arranged on the assembly end cover 2 .

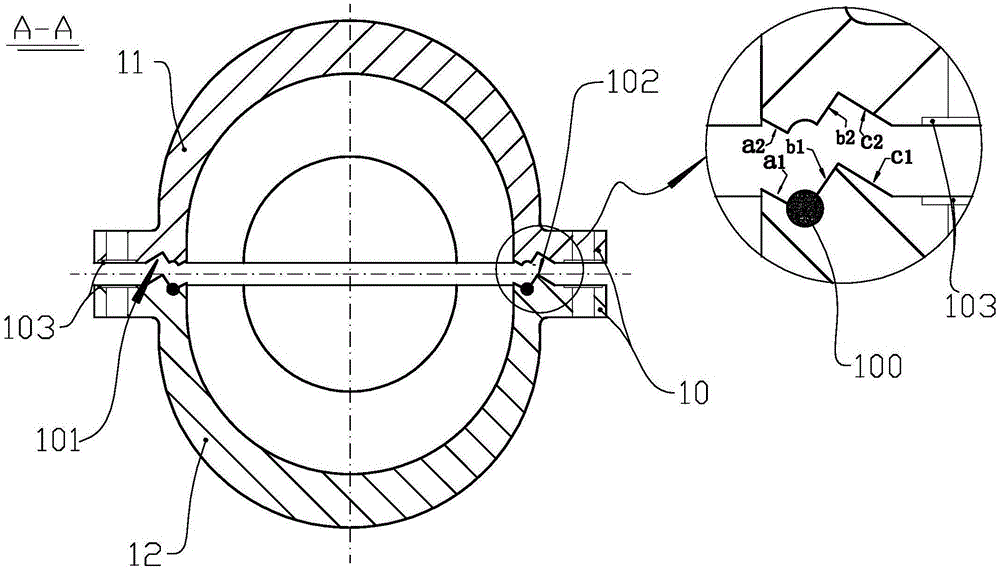

[0056] Such as figure 1 , image 3 As shown, corresponding mold grooves are provided on the upper half outer box 11 and the lower half outer box 12, and axially extending flanges 10 are respectively arranged on both sides of the transverse ports of the mold grooves. The groove here is as image 3 The settings shown are semicircular. On the lower end surface of the flange 10 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com